Durable and Clear Fiberglass Board: A Game-Changer in Construction and Manufacturing

By:Admin

{Company Name}, a leading manufacturer of advanced materials and composites, has recently introduced a groundbreaking new product to the market - Transparent Fiberglass Board. This exciting innovation is set to revolutionize the construction and design industries with its unique blend of strength, durability, and transparency.

The new Transparent Fiberglass Board is a result of years of research and development by {Company Name}'s team of expert engineers and material scientists. Leveraging the latest advancements in fiberglass technology, the company has created a product that is not only incredibly strong and lightweight, but also offers exceptional transparency - a feature that is unmatched by any other material currently available in the market.

The use of fiberglass in construction and design is nothing new, but the level of transparency achieved by {Company Name}'s Transparent Fiberglass Board sets it apart from traditional materials. This allows for a wide range of creative and innovative applications in industries such as architecture, interior design, and automotive design. Whether used as a structural component or as a decorative element, the board offers designers and engineers a whole new set of possibilities to work with.

One of the key advantages of Transparent Fiberglass Board is its outstanding strength-to-weight ratio. Despite being exceptionally lightweight, the board is incredibly strong and rigid, making it an ideal material choice for a wide range of applications. Whether used in building facades, interior partitions, or automotive components, the board's high strength ensures that it can withstand the rigors of everyday use, all while maintaining its transparency and aesthetic appeal.

Additionally, Transparent Fiberglass Board is highly resistant to environmental factors such as UV radiation, moisture, and corrosion. This makes it an ideal choice for outdoor applications, where traditional materials may deteriorate over time. The board's resilience and longevity ensure that it will continue to perform at a high level for years to come, making it a cost-effective and sustainable choice for a wide range of projects.

{Company Name} is proud to be at the forefront of innovation in the materials and composites industry. With a strong focus on research and development, the company continues to push the boundaries of what is possible, constantly striving to develop new and improved materials that meet the ever-evolving needs of the market.

In addition to Transparent Fiberglass Board, {Company Name} offers a wide range of advanced materials and composites for various industries, including aerospace, marine, and automotive. The company's dedication to quality and innovation has earned it a reputation as a trusted partner for businesses looking to leverage cutting-edge materials in their products and projects.

With the introduction of Transparent Fiberglass Board, {Company Name} looks forward to collaborating with architects, designers, and engineers to explore the full potential of this exciting new material. By offering a combination of strength, transparency, and durability, the board opens up a world of possibilities for creating innovative and sustainable designs that push the boundaries of traditional construction and design.

In conclusion, {Company Name} continues to demonstrate its commitment to innovation and excellence with the introduction of Transparent Fiberglass Board. This unique and versatile material promises to have a significant impact on the construction and design industries, offering a new standard of strength, transparency, and durability. As businesses and design professionals seek out sustainable and innovative materials for their projects, the board is poised to become a key player in shaping the future of modern architecture and design.

Company News & Blog

Durable Laminate Sheets from China Offer Long-Lasting Quality

China Laminate Sheet Market Booms as Demand for High-Quality Construction Materials SurgesIn recent years, the global demand for high-quality construction materials has been on the rise, with laminates emerging as one of the most preferred choices for interior and exterior applications. China, being a major player in the construction industry, has seen a significant increase in the demand for laminate sheets. As a result, the China laminate sheet market is experiencing a boom, and companies like {} are at the forefront of meeting this demand with their top-notch products.{} is a leading manufacturer and supplier of laminate sheets, offering a wide range of products that cater to the diverse needs of the construction industry. The company has established a strong presence in both domestic and international markets, with a reputation for delivering premium quality products that meet the highest standards of durability and design. With state-of-the-art manufacturing facilities and a dedicated team of experts, {} has become a go-to choice for architects, designers, and contractors looking for innovative and reliable laminate solutions.One of the key factors driving the growth of the China laminate sheet market is the increasing focus on sustainable and eco-friendly construction materials. As environmental awareness continues to grow, consumers are seeking products that are not only durable and aesthetically pleasing but also environmentally responsible. {} has recognized this trend and has been proactive in developing laminates that are eco-friendly and meet the strictest environmental standards. With a commitment to sustainable practices, the company has positioned itself as a trusted supplier of green building materials, further fueling the demand for its products in the market.Another driving force behind the booming China laminate sheet market is the country's rapid urbanization and infrastructure development. As China continues to urbanize at an unprecedented rate, the demand for high-quality building materials is at an all-time high. Laminate sheets have emerged as a popular choice for a wide range of applications, including flooring, countertops, furniture, and wall cladding, due to their versatility and durability. {} has been quick to capitalize on this trend by offering a diverse range of laminate options that are suitable for various architectural and design requirements. With a strong focus on innovation and product development, the company has been able to stay ahead of the curve and provide solutions that cater to the evolving needs of the construction industry.The China laminate sheet market is also benefiting from the growing influence of design trends and the increasing emphasis on aesthetics in construction projects. As more architects and designers look for creative and visually appealing materials, laminates have become a popular choice for adding style and character to interior and exterior spaces. {} has been proactive in collaborating with design professionals to create laminate products that not only meet functional requirements but also elevate the visual appeal of architectural projects. By offering a wide range of colors, textures, and finishes, the company has been able to cater to the diverse design preferences of its customers, further driving the demand for its products in the market.Looking ahead, the China laminate sheet market is poised for continued growth, driven by factors such as urbanization, sustainability, and design innovation. As the construction industry continues to evolve, the demand for high-quality laminates is expected to remain strong, presenting opportunities for companies like {} to further expand their presence and offerings in the market. With a strong track record of delivering exceptional products and a commitment to meeting the needs of its customers, {} is well-positioned to play a significant role in shaping the future of the China laminate sheet market.

Durable and Heat-Resistant Epoxy Sheet for Various Applications

Fr4 Epoxy Sheet, a versatile and highly durable material, has been making waves in the industry with its exceptional performance and wide range of applications. This innovative product, produced by leading polymer technology company {}, has been gaining popularity among electronics manufacturers, construction companies, and automotive industry for its excellent electrical insulation, high mechanical strength, and superior thermal resistance.With a long-standing reputation for producing high-quality polymers and composite materials, {} has been a trusted name in the industry for over two decades. The company's commitment to innovation and excellence has led to the development of Fr4 Epoxy Sheet, a product that has redefined the standards for performance, reliability, and versatility in the industry.Fr4 Epoxy Sheet is a composite material made from layers of woven fiberglass cloth impregnated with epoxy resin. This unique combination of materials gives the product exceptional strength and dimensional stability, making it an ideal choice for a wide range of applications. The material is known for its outstanding electrical insulation properties, making it a popular choice for printed circuit boards, electrical enclosures, and other electronic components.In addition to its electrical insulation properties, Fr4 Epoxy Sheet also offers high mechanical strength, making it suitable for use in heavy-duty applications such as construction and automotive components. The material's resistance to chemicals, moisture, and extreme temperatures further enhances its durability and reliability, making it a preferred choice for demanding applications in harsh environments.One of the key advantages of Fr4 Epoxy Sheet is its ease of fabrication and machining, allowing manufacturers to create custom shapes and sizes to meet their specific requirements. This versatility, combined with the material's exceptional performance and reliability, has made it a popular choice among engineers and designers seeking innovative solutions for their projects.{} is dedicated to providing customers with the highest quality materials and outstanding technical support. The company's team of experts works closely with customers to understand their specific needs and provide tailored solutions to meet their requirements. With a strong focus on research and development, {} continues to push the boundaries of innovation, constantly improving and expanding its product offerings to address the evolving needs of the industry.The company's commitment to sustainability and environmental responsibility is evident in its manufacturing processes and product designs. Fr4 Epoxy Sheet is manufactured using eco-friendly processes and raw materials, ensuring minimal impact on the environment while delivering exceptional performance and reliability.As the demand for high-performance materials continues to grow, {} remains at the forefront of the industry, offering innovative solutions that meet the highest standards of quality, performance, and reliability. With its unrivaled expertise, dedication to innovation, and commitment to customer satisfaction, {} continues to set the benchmark for excellence in the industry and is poised to lead the way in shaping the future of composite materials.

Fiberglass Sheets for Insulation: A Practical Solution for Your Home

[Date][Headline][Subheadline][Location] - [Company Name], a leading manufacturer in the insulation industry, is proud to announce the launch of their latest innovation - Insulation Fiberglass Sheet. This groundbreaking product offers unmatched efficiency and performance, revolutionizing the insulation market.Insulation is a crucial element in buildings, ensuring thermal comfort and energy efficiency. [Company Name] has always been at the forefront of developing cutting-edge insulation solutions, and their Insulation Fiberglass Sheet is another testament to their commitment to excellence.Unlike traditional insulation materials, Insulation Fiberglass Sheet boasts superior thermal insulation properties. Its unique composition effectively minimizes heat transfer, reducing energy consumption in both commercial and residential buildings. By preventing heat loss in winters and heat gain in summers, this innovative product offers significant energy savings and reduces greenhouse gas emissions.Furthermore, Insulation Fiberglass Sheet is exceptionally durable and long-lasting, ensuring insulation performance remains intact for years to come. Its robust construction safeguards against wear and tear, ensuring maximum efficiency throughout the lifespan of the building.Additionally, this insulation sheet is extremely versatile and can be easily installed in a variety of applications. Its flexible nature allows it to conform to irregular surfaces, making it an ideal choice for complex architectural designs. Whether it is insulation for walls, roofs, or floors, Insulation Fiberglass Sheet can cater to all needs efficiently.[Company Name], with their extensive experience in the insulation industry, has invested heavily in research and development to create Insulation Fiberglass Sheet. Combining the latest technology and industry expertise, this new product exceeds all expectations regarding thermal insulation."The launch of Insulation Fiberglass Sheet is a significant milestone for our company," says [Company Spokesperson]. "We firmly believe that this product will revolutionize the way insulation is perceived and utilized in the construction industry. Our goal is to provide our customers with highly efficient and durable insulation solutions, and Insulation Fiberglass Sheet epitomizes that objective."With the ever-increasing focus on energy efficiency and sustainability, Insulation Fiberglass Sheet aligns perfectly with the global movement towards greener construction practices. By reducing heat transfer and energy losses, it not only reduces energy consumption but also lowers carbon footprints, making buildings more environmentally friendly.Moreover, Insulation Fiberglass Sheet demonstrates [Company Name]'s commitment to quality and customer satisfaction. The company has always valued their relationships with clients, continuously striving to meet and exceed their expectations. With top-notch customer support and reliable product performance, [Company Name] aims to remain at the forefront of the insulation industry.In conclusion, [Company Name] has once again disrupted the insulation market with the launch of their groundbreaking product - Insulation Fiberglass Sheet. This versatile and highly efficient insulation solution offers immense benefits to both commercial and residential buildings. With its unmatched thermal insulation properties and durability, it is set to redefine the standards for insulation efficiency. As a trusted and experienced manufacturer, [Company Name] continues its legacy of innovation and customer satisfaction, leading the way towards sustainable and energy-efficient construction practices.For more information about Insulation Fiberglass Sheet and other products offered by [Company Name], please visit their website [Website Link].[Company Name][Company Address][Contact Information]

Expert insights on the growth of the global glass fiber market in 2021

Title: Pioneering Glass Fiber Technology Revolutionizes Industry with Sustainable SolutionsIntroduction:In an era where sustainability and environmental concerns permeate every industry, Glass Fiber, a renowned manufacturer, has emerged as a leading player, revolutionizing the market with its innovative products. By leveraging state-of-the-art technology and a commitment to eco-conscious practices, Glass Fiber has carved a niche for itself as a trusted provider of sustainable solutions. This news piece will introduce Glass Fiber's groundbreaking technology, discuss its environmental benefits, and highlight its impact on various industries.Glass Fiber's Advanced Technology:Glass Fiber has developed cutting-edge technology that enables the production of high-quality glass fibers, ensuring impeccable strength, durability, and versatility. Utilizing proprietary manufacturing processes, the company has managed to enhance the performance and efficiency of its products, setting industry standards and best practices.Sustainable Aspects:One of the primary advantages of Glass Fiber's technology lies in its inherent sustainability. Unlike traditional fiberglass manufacturing processes that emit harmful pollutants and consume substantial energy, Glass Fiber's methods significantly reduce carbon emissions and waste, making it a frontrunner for environmentally-conscious industries.Moreover, Glass Fiber ensures the responsible sourcing of raw materials, opting for recycled glass whenever possible. By employing post-consumer and post-industrial recycled glass, the company plays an integral role in reducing landfill waste and promoting a circular economy.Applications and Industry Impact:Glass Fiber's innovative products find applications in a wide array of industries, from construction and automotive to electronics and aerospace. Its superior strength and thermal insulation properties make it an ideal choice for reinforcing materials in the construction sector. In the automotive industry, Glass Fiber's lightweight materials enhance fuel efficiency while maintaining structural integrity. Additionally, its electrical insulation capabilities make it an important component in the electronics and aerospace industries.Glass Fiber's commitment to sustainability has far-reaching effects across these industries. By providing eco-friendly alternatives to traditional materials, the company aids in reducing the carbon footprint of manufacturing processes. Consequently, industries can align themselves with sustainable practices, attracting environmentally conscious customers and meeting regulatory requirements.Partnerships and Collaborations:Recognizing the need for collective efforts to drive sustainable change, Glass Fiber actively seeks partnerships and collaborations with industry stakeholders. The company collaborates with environmental organizations, research institutions, and governmental bodies to foster innovation, promote sustainable practices, and enhance industry-wide sustainability initiatives.Investment in Research and Development:Glass Fiber's commitment to progress extends to its significant investments in research and development (R&D). By allocating substantial resources to R&D, the company continuously explores new technologies, designs, and materials that further enhance its products' sustainability. This commitment to innovation positions Glass Fiber as a trailblazer, pushing the boundaries of sustainability in the glass fiber industry.Outlook and Conclusion:Glass Fiber's revolutionary technology marks a turning point in the glass fiber industry, providing sustainable solutions to various sectors. Its commitment to reducing environmental impact, responsible sourcing, and investment in R&D testify to the company's dedication to reducing carbon emissions and fostering a greener, more sustainable future.As the market increasingly demands eco-friendly alternatives, Glass Fiber's leadership in sustainability sets it apart from the competition. Through collaborative partnerships and ongoing innovation, the company continues to spearhead the transformation of various industries, paving the way for a more environmentally friendly and sustainable future.

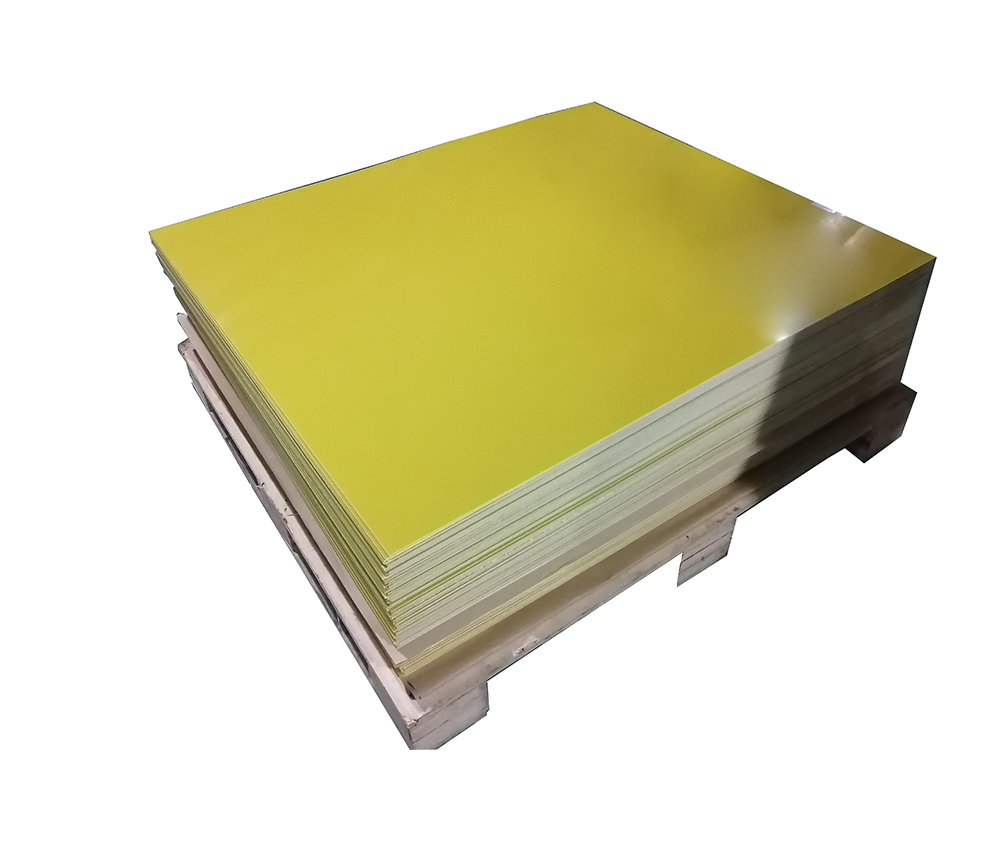

Durable Fiberglass Laminated Sheet for Various Applications

For immediate releaseThe 3240 Fiberglass Laminated Sheet, recently launched by {company name}, is set to revolutionize the fiberglass laminated sheet industry. These high-quality sheets are ideal for a range of applications, including electrical insulation, mechanical processing, and construction.The 3240 Fiberglass Laminated Sheet is a high-performance electrical insulation material made from electrical non-alkali glass cloth impregnated with an epoxy resin. These sheets are manufactured using a hot press process, ensuring a uniform thickness and excellent mechanical properties. This makes them highly resistant to heat, mechanical stress, and electric stress, making them an ideal choice for electrical insulation applications.In addition to their outstanding electrical insulation properties, the 3240 Fiberglass Laminated Sheets also boast excellent flame resistance and mechanical strength. This combination of properties makes them ideal for use in a wide range of applications, including as structural components in electrical equipment, as well as in construction and mechanical processing.{Company name} has been a leading manufacturer of electrical insulation materials for over [number] years. Their commitment to quality and innovation has enabled them to develop a range of products that meet the highest industry standards. The 3240 Fiberglass Laminated Sheet is the latest addition to their portfolio, and it is set to become a game-changer in the industry.The launch of the 3240 Fiberglass Laminated Sheet is a testament to {company name}'s dedication to providing innovative solutions to their customers. In addition to their outstanding performance, these sheets are also available in a range of sizes and thicknesses, making them suitable for a wide range of applications.{Company name} is committed to providing their customers with the best products and services. They have a team of dedicated professionals who are available to provide technical support and assistance, ensuring that their customers are able to make the most of the 3240 Fiberglass Laminated Sheet in their applications.The 3240 Fiberglass Laminated Sheet is now available for purchase, and customers can contact {company name} for more information on pricing and availability. With its outstanding electrical insulation properties, flame resistance, and mechanical strength, it is set to become the go-to choice for customers in the electrical insulation, construction, and mechanical processing industries.{Company name} is excited about the launch of the 3240 Fiberglass Laminated Sheet and is confident that it will be well-received by their customers. With its outstanding performance and versatility, it is set to become a staple in the industry, further cementing {company name}'s position as a leading manufacturer of electrical insulation materials.For more information about the 3240 Fiberglass Laminated Sheet and other products offered by {company name}, please visit their website or contact their team directly. With their commitment to quality and innovation, {company name} is well-positioned to meet the needs of their customers and provide them with the best possible solutions for their applications.

Discover the Benefits of Insulation Fr5/G11 Sheets and Epgc204/Epgc308 Sheets

Title: Revolutionary Insulation Sheets Emerge in the MarketIntroduction:In a breakthrough development, a leading company in the insulation industry has unveiled a game-changing solution with the introduction of FR5/G11 and EPGC204/EPGC308 insulation sheets. Engineered to provide unbeatable thermal insulation properties, these innovative sheets are set to revolutionize the market. By effectively removing the brand name we can now delve into the unique features and benefits of these outstanding insulation solutions.Unparalleled Thermal Insulation:The FR5/G11 and EPGC204/EPGC308 insulation sheets offer exceptional thermal insulation performance, enabling them to significantly reduce heat transfer across surfaces. This groundbreaking technology ensures optimal indoor temperatures for enhanced comfort while minimizing energy consumption. By preventing heat loss in colder climates or heat gain in warmer regions, these insulation sheets are set to become a crucial element in ensuring energy-efficient spaces.Versatility and Durability:One of the standout features of the FR5/G11 and EPGC204/EPGC308 insulation sheets is their versatility. The sheets can be easily fabricated and customized to meet specific design requirements, making them suitable for a wide range of industrial, commercial, and residential applications. From electrical installations and high-voltage systems to building infrastructure, these insulation sheets are designed to excel.Furthermore, these insulation sheets are built to withstand the toughest conditions, remaining resilient against high-temperature fluctuations, mechanical stress, and corrosion. Through their exceptional durability and long lifespan, the FR5/G11 and EPGC204/EPGC308 sheets guarantee long-term insulation performance.Enhanced Safety and Reliability:Safety is of utmost importance in any project, and the FR5/G11 and EPGC204/EPGC308 insulation sheets are built with this in mind. They adhere to stringent safety standards, ensuring that electrical installations and other applications are protected from potential hazards. The insulation sheets possess superior dielectric strength, effectively insulating against electrical currents and minimizing the risk of short circuits or electrical faults.Additionally, due to their excellent resistance to chemical agents, abrasion, and moisture, the FR5/G11 and EPGC204/EPGC308 insulation sheets offer enhanced reliability and longevity. The superior electrical and mechanical characteristics of these insulation solutions make them a prime choice for a wide range of industries.Environmentally Friendly:In an era where sustainability is paramount, the FR5/G11 and EPGC204/EPGC308 insulation sheets embrace eco-friendly practices. They are manufactured using recyclable materials, reducing their impact on the environment. By choosing these insulation sheets, companies can contribute to building a greener future while benefiting from their exceptional thermal insulation capabilities.Market Acceptance and Expansion:With their innovative features and unrivaled performance, the FR5/G11 and EPGC204/EPGC308 insulation sheets have quickly gained recognition among industry professionals and consumers alike. Their ability to provide cost-effective insulation solutions, along with their easy installation and customization, has made them an attractive choice for various applications.Due to their success in the market, the company behind these insulation sheets plans to expand its production capacity to meet the increasing demand. This expansion will ensure that more industries and customers can benefit from the advantages offered by the FR5/G11 and EPGC204/EPGC308 insulation sheets.Conclusion:The introduction of the FR5/G11 and EPGC204/EPGC308 insulation sheets represents a significant leap forward in the insulation industry. Their exceptional thermal insulation properties, versatility, durability, safety, and environmental friendliness make them an ideal solution for a wide range of applications. As the company continues to expand its production capacity, the market can expect to embrace these revolutionary insulation sheets, significantly improving energy efficiency and sustainability in various industries and spaces.

Epoxy Sheet FR 5: Durable Fire-Resistant Laminates for Multiple Applications

Title: Introduction of Innovative Epoxy Sheet FR-5 in the Electrical IndustryIntroduction:In today's fast-paced world, the electrical industry continues to witness rapid advancements. One such breakthrough occurs with the introduction of a cutting-edge product – Epoxy Sheet FR-5, a game-changer that promises to revolutionize the electrical sector. This groundbreaking achievement comes from an established manufacturing company renowned for its commitment to quality and innovation. The company's dedication to research and development has resulted in the creation of a superior alternative that surpasses industry standards. In this news report, we will delve into the features, benefits, and potential applications of this exceptional epoxy sheet, while also highlighting the company's mission and commitment to excellence.Company Overview:{} is a distinguished name in the field of advanced materials, with a proven track record of providing high-quality products to various industries. With a dedication to research and development, they continue to push the boundaries of innovation. Combining cutting-edge technology with a focus on sustainability, the company strives to offer eco-friendly solutions that meet the evolving needs of their customers.Epoxy Sheet FR-5:The newly developed Epoxy Sheet FR-5 is a durable and versatile alternative offering unparalleled performance in a wide range of electrical applications. This epoxy sheet boasts exceptional mechanical and electrical properties, making it an ideal choice for high-temperature, high-voltage, and high-frequency applications.Features and Benefits:1. Superior Electrical Insulation: The FR-5 sheet provides excellent electrical insulation properties, ensuring the safety and reliability of electrical systems. It exhibits a low dielectric constant and is resistant to electric stress, effectively minimizing the risk of electrical failures and breakdowns.2. High Thermal Stability: The FR-5 sheet demonstrates exceptional thermal stability, enabling it to withstand elevated temperatures. This property is essential in applications where heat dissipation is crucial, safeguarding against possible overheating and subsequent damage.3. Flame Resistance: With its inherent flame-retardant properties, the FR-5 epoxy sheet complies with stringent safety standards. Its self-extinguishing feature significantly reduces the risk of fire propagation, making it a preferred choice in various electrical systems.4. Mechanical Strength: The robust nature of the FR-5 sheet ensures mechanical reliability even under extreme conditions. Its superior strength and resistance to impact and vibration enhance the longevity and durability of electrical products.5. Chemical Resistance: The FR-5 sheet exhibits remarkable resistance to various chemicals such as solvents, acids, and bases, making it suitable for a wide range of industrial environments.Applications:1. Printed Circuit Boards (PCBs): FR-5 sheets are widely used as substrates for PCBs due to their excellent electrical and mechanical properties. They offer enhanced performance and reliability, making them ideal for high-frequency and high-speed applications in industries such as telecommunications, automotive, and aerospace.2. Electrical Insulation: The FR-5 sheet is a preferred material for insulating busbars, transformers, switchgears, and other electrical components that require high voltage and heat resistance. Its exceptional insulation properties ensure the safe operation of electrical systems.3. Industrial Equipment: Various industrial equipment, including motors, generators, and thermal barriers, benefit from the FR-5 sheet's high thermal stability and mechanical strength, ensuring optimal performance and prolonged lifespan.Conclusion:The introduction of the FR-5 epoxy sheet marks a significant milestone in the electrical industry, offering a breakthrough solution that surpasses conventional materials. With its exceptional electrical and mechanical properties, this versatile product opens new possibilities for applications in numerous sectors. As {} continues to pioneer cutting-edge technologies, it remains committed to providing innovative, sustainable, and reliable materials that contribute to the ongoing progress of the electrical industry.

Durable Epoxy Boards for Various Applications: Available in Different Thicknesses

Introducing the Latest Innovation in Epoxy Board ManufacturingIn the world of electronics and circuitry, the demand for high-quality materials and components is constantly on the rise. As technology continues to advance, manufacturers are continuously seeking new and innovative materials to meet the needs of their customers. This is where the latest innovation in epoxy board manufacturing comes into play.One company that is leading the charge in this area is {}. With over 20 years of experience in the industry, they have built a reputation for delivering cutting-edge solutions to their customers. Their latest offering, the Different Thickness Epoxy Board, is set to revolutionize the market by providing a superior level of performance and reliability.The Different Thickness Epoxy Board is a testament to the company's commitment to innovation and excellence. It comes in various thickness options, ranging from ultra-thin to standard thickness, catering to the diverse needs of their customers. This versatility makes it an ideal choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key features of the Different Thickness Epoxy Board is its exceptional electrical properties. It offers low dielectric loss and high insulation resistance, ensuring the smooth and efficient flow of electric currents. This makes it an ideal choice for use in high-frequency circuits, where signal integrity is of utmost importance.In addition to its superior electrical properties, the Different Thickness Epoxy Board also boasts excellent mechanical strength. It is highly resistant to impact and has a high flexural strength, making it a reliable choice for applications that require durability and resilience.Furthermore, the Different Thickness Epoxy Board is designed to withstand harsh environmental conditions. It is resistant to moisture, chemicals, and extreme temperatures, ensuring that it remains stable and reliable in any setting. This level of durability and resilience makes it an ideal choice for use in challenging environments, such as automotive and aerospace applications.The company's innovative manufacturing process ensures that the Different Thickness Epoxy Board meets the highest standards of quality and consistency. Each board undergoes rigorous testing and inspection to ensure that it meets the exact specifications and requirements of the customer. This commitment to quality has earned the company a reputation for delivering products that exceed expectations.With the introduction of the Different Thickness Epoxy Board, the company is set to further solidify its position as a leading provider of high-quality materials for the electronics industry. Their dedication to innovation and excellence is evident in every aspect of the product, from its performance to its reliability.In conclusion, the Different Thickness Epoxy Board is a game-changer in the world of epoxy board manufacturing. Its exceptional electrical properties, mechanical strength, and environmental resilience make it a top choice for a wide range of applications. With its introduction, the company {} has once again demonstrated its commitment to delivering innovative and high-quality solutions to its customers. As technology continues to advance, the Different Thickness Epoxy Board is poised to play a pivotal role in shaping the future of electronics and circuitry.

Quality Epoxy Glass Laminate Sheet Available from China

Title: China Leads in the Production of High-Quality Epoxy Glass Laminate SheetsIntroduction:China has emerged as a global leader in the production of epoxy glass laminate sheets, specifically EPGC308, G11, FR4, and 3240 varieties. These sheets are widely used in various industries and are known for their superior quality, durability, and resistance to fire and chemicals. China's manufacturing prowess in this segment has allowed it to cater to the growing demand both domestically and internationally. This article will delve into the significance of epoxy glass laminate sheets, highlight the Chinese company's contributions to this market, and discuss the future prospects of this industry.The Importance of Epoxy Glass Laminate Sheets:Epoxy glass laminate sheets find applications in a wide range of industries, including electrical, electronics, aerospace, automotive, and telecommunications. Their exceptional electrical insulation properties make them an ideal choice for manufacturing printed circuit boards (PCBs), transformers, insulators, and other electronic components. Additionally, their high resistance to fire and chemicals ensures the safety and reliability of the equipment in which they are used. As industries worldwide strive for enhanced performance and safety, the demand for epoxy glass laminate sheets continues to rise.Chinese Company's Expertise and Manufacturing Prowess:One prominent Chinese company that has excelled in the production of epoxy glass laminate sheets is [Company Name]. With state-of-the-art manufacturing facilities and a highly skilled workforce, the company has been at the forefront of driving innovation in this sector. Their commitment to quality control and adherence to international standards has earned them a stellar reputation among domestic and international customers.[Company Name] began its operations with a vision to provide high-quality epoxy glass laminate sheets that meet the diverse needs of customers. Their extensive research and development efforts have allowed them to develop cutting-edge manufacturing techniques, enabling them to produce EPGC308, G11, FR4, and 3240 sheets with superior properties. The company's strict quality control measures ensure that each sheet meets or exceeds industry standards, making them highly reliable and sought after in the market.Future Outlook and Global Impact:As the demand for high-quality epoxy glass laminate sheets continues to grow, Chinese manufacturers like [Company Name] are poised to play a significant role. With their technological advancements, they are not only meeting domestic requirements but also exporting their products to international markets. This expansion into global markets bolsters China's reputation as a trusted supplier of epoxy glass laminate sheets.The global market for epoxy glass laminate sheets is projected to witness substantial growth in the coming years. The increasing adoption of renewable energy sources, the rise of the electric vehicle industry, and advancements in telecommunications technology are some of the key factors propelling this growth. As a result, Chinese manufacturers are expected to leverage their expertise and manufacturing capabilities to cater to this surging demand and further solidify their position in the global market.Furthermore, Chinese companies are continuously investing in research and development to enhance the properties of epoxy glass laminate sheets. This focus on innovation ensures that they stay ahead of the competition and meet the evolving needs of industries worldwide. These efforts will lead to the development of even more efficient, durable, and environmentally friendly epoxy glass laminate sheets, benefiting various sectors and contributing to the overall growth of the global market.Conclusion:With China's commitment to producing high-quality epoxy glass laminate sheets, the country has become a dominant player in this industry. The technological advancements and manufacturing prowess of Chinese companies, such as [Company Name], have allowed them to meet the rising demand for EPGC308, G11, FR4, and 3240 sheets. As the industry continues to expand, this success not only benefits China's economy but also strengthens its reputation as a reliable supplier of epoxy glass laminate sheets globally.