Investigation Reveals Health Issue with Laminate Flooring

Lumber Liquidators, one of the largest national hardwood flooring retailers in the United States, has been found guilty of selling laminate flooring that violates health and safety regulations. An investigation conducted by non-profit organization, Environmental Health News Center for Environmental Health (CEH), has found that the company's products contain high levels of formaldehyde, a chemical that has been linked to cancer and other negative health effects.Formaldehyde is a naturally occurring chemical commonly found in the environment. However, it is also used in many industrial processes, including the manufacturing of composite woods such as laminate flooring. The issue with formaldehyde lies in its toxic properties, which can cause respiratory problems, headaches, and, in some cases, cancer.The CEH investigation found that Lumber Liquidators' laminate flooring contained levels of formaldehyde that far exceeded the limits set by the California Air Resources Board (CARB). The organization tested 31 samples of Lumber Liquidators' flooring products purchased from the company's stores in California, Florida, Texas, Illinois, and New York. Of those samples, 29 exceeded the CARB limits for formaldehyde emissions.The findings of the investigation have prompted the California Air Resources Board to take action against Lumber Liquidators. The CARB has issued a citation to the company for violating the state's health and safety regulations. Lumber Liquidators has been ordered to pay a fine of $2.5 million and to stop selling the offending products in California.Lumber Liquidators has responded to the citation by issuing a statement saying that the company was taking the matter seriously and was cooperating with the authorities to resolve the issue. The company also announced that it was launching an independent review of its product testing and quality control procedures to ensure that all of its products are safe and compliant with regulations.The incident is not the first time that Lumber Liquidators has come under scrutiny for its products. In 2015, the CBS News program 60 Minutes aired an investigation that found that the company was selling Chinese-made laminate flooring that contained dangerous levels of formaldehyde. The program's findings resulted in Lumber Liquidators pulling the offending products from its shelves and paying a settlement of $50 million.The latest incident comes at a time when there is growing concern about the safety of products made in China. The US government has been warning consumers about the dangers of Chinese-made goods, particularly electronics and food products, for several years. The COVID-19 pandemic has further heightened the concerns about Chinese manufacturing practices, with many people worried about the safety of medical supplies and other essential items that China produces.The incident has also raised questions about the effectiveness of government regulations and oversight. The CARB, which is responsible for regulating formaldehyde emissions from composite wood products in California, has been criticized for not doing enough to protect consumers from the risks associated with the chemical. The state agency has reportedly been underfunded and understaffed, making it difficult for it to enforce its regulations effectively.The Lumber Liquidators incident highlights the need for government agencies to be more proactive in protecting consumers from dangerous products. It also underscores the importance of companies taking responsibility for the safety and quality of their products. With consumers increasingly concerned about the safety of the products they buy, companies that fail to take their responsibilities seriously risk damaging their reputations and losing business.In conclusion, the Lumber Liquidators incident is a stark reminder of the importance of product safety and regulation. Companies that fail to meet regulatory standards and take responsibility for the safety of their products put consumers at risk and damage their own reputations. Government agencies must ensure that their regulations are effective, while companies must prioritize product safety and quality control to maintain consumer confidence.

Read More

Discover the Benefits and Applications of Insulation Sheets for Effective Temperature Control

[Company Name] Introduces Innovative Insulation Sheet for Enhanced Energy Efficiency[date]In today's rapidly evolving world, energy conservation and environmental sustainability have become paramount concerns. As people increasingly recognize the importance of reducing carbon footprints and conserving energy, industries have responded by developing innovative solutions to enhance energy efficiency. In this regard, [Company Name], a leading provider of cutting-edge insulation products, has recently introduced an exceptional insulation sheet that promises to revolutionize the market.Derived from years of extensive research and development, [Company Name]'s newly launched insulation sheet is designed to address the growing demand for energy-efficient solutions across various sectors. By leveraging advanced materials and cutting-edge technologies, the company strives to provide its customers with a product that not only meets their insulation needs but surpasses expectations.At the core of [Company Name]'s insulation sheet is its exceptional design, incorporating state-of-the-art materials that enable improved thermal performance and energy conservation. Crafted with precision and attention to detail, the insulation sheet offers an unparalleled level of insulation. Its innovative composition allows for enhanced heat resistance, preventing unnecessary energy loss and minimizing energy consumption.The insulation sheet, which is available in various sizes and thicknesses, is incredibly versatile and can be adapted to meet a wide range of insulation requirements. Whether it is residential, commercial, or industrial applications, the sheet seamlessly integrates with diverse structures, ensuring effective thermal insulation and promoting energy efficiency.One of the key highlights of [Company Name]'s insulation sheet is its remarkable resistance to moisture and condensation. This crucial feature ensures that the insulation remains intact over prolonged periods, maintaining its optimum performance. By preventing the formation of moisture on the surface, the insulation sheet not only prolongs its lifespan significantly but also prevents the growth of mold and mildew, creating a healthier and safer environment.In an era characterized by increased awareness of sustainability, the insulation sheet offered by [Company Name] stands out for its commitment to environmental responsibility. The innovative composition of the sheet is free from harmful chemicals, making it an eco-friendly choice for architects, engineers, contractors, and homeowners aiming for sustainable building practices. By embracing this insulation solution, consumers can effectively reduce their energy demands and make a positive impact on the environment.As [Company Name] continues to make strides in the insulation industry, its commitment to quality and customer satisfaction remains unwavering. The company boasts a highly experienced team of professionals dedicated to providing exceptional service and support. With a comprehensive understanding of diverse market requirements, the team collaborates closely with clients to customize insulation solutions and ensure optimal results.Furthermore, [Company Name] has established a robust distribution network to ensure the availability of its insulation sheet nationwide. By strategically partnering with distributors and suppliers, the company aims to make its product easily accessible to customers across different regions.The launch of this innovative insulation sheet by [Company Name] presents an exciting opportunity for companies and individuals seeking to enhance their energy efficiency practices. With its superior thermal performance, resistance to moisture, and commitment to sustainability, this product is set to redefine insulation standards in various industries.As the world continues to grapple with climate change and energy conservation, innovative solutions like [Company Name]'s insulation sheet hold the promise of a more sustainable future. By choosing this groundbreaking product, individuals and organizations can actively contribute to the global effort of reducing energy consumption and mitigating the adverse effects of climate change.About [Company Name]:[Company Name] has been a leading manufacturer and provider of insulation products for over [number] years. With a strong commitment to research and development, the company consistently pushes the boundaries of energy efficiency and sustainability. Offering a wide range of insulation solutions, [Company Name] has earned a reputation for excellence, reliability, and customer satisfaction. For further information, please visit [Company Name]'s official website at [website] or contact their customer service team at [phone number].

Read More

Discover the Benefits of Fiberglass Insulation Sheets for Your Home

Title: Revolutionary Fiberglass Insulation Sheets Revolutionize the Construction IndustryIntroduction:Fiberglass Insulation Sheets, a groundbreaking product designed to enhance energy efficiency and improve insulation in buildings, is set to revolutionize the construction industry. Engineered by [Company Name], this innovative material promises to deliver superior performance and sustainability while meeting the increasing demand for energy conservation. With its numerous benefits and cutting-edge technology, these fiberglass insulation sheets are poised to transform the way buildings are constructed and maintained.Paragraph 1:After years of research and development, [Company Name] has introduced a game-changing solution to the construction market with its Fiberglass Insulation Sheets. These sheets are made from premium quality fiberglass materials that offer excellent thermal insulation properties, effectively reducing heat transfer between indoor and outdoor spaces. With an ever-increasing focus on reducing energy consumption and environmental impact, this new product stands out as a cost-effective and eco-friendly alternative to traditional insulation materials.Paragraph 2:One of the key advantages of Fiberglass Insulation Sheets is their exceptional thermal resistance. The sheets are manufactured using advanced techniques that ensure excellent heat retention, keeping buildings warm during winters and cool during summers. This feature helps to reduce the reliance on heating and cooling systems, resulting in significant energy savings and reduced carbon emissions.Paragraph 3:Additionally, these insulation sheets possess outstanding sound absorption capabilities, making them a perfect choice for both residential and commercial buildings. The Fiberglass Insulation Sheets absorb and dissipate sound waves, effectively reducing noise pollution and creating a more peaceful and comfortable indoor environment. This feature proves to be especially beneficial in crowded urban areas or structures near high-traffic zones.Paragraph 4:Moreover, [Company Name]'s Fiberglass Insulation Sheets are highly versatile and adaptable to various construction applications. The lightweight and flexible nature of the sheets allows for easy installation, ensuring a seamless integration into new and existing structures. Whether utilized in roofs, walls, or floors, these insulation sheets effortlessly conform to irregular shapes and surfaces, enhancing their suitability for a wide range of architectural designs.Paragraph 5:Another notable advantage of Fiberglass Insulation Sheets is their exceptional fire resistance properties. Composed of non-combustible materials, these sheets significantly reduce the flammability risks associated with conventional insulation options. This added safety feature provides peace of mind for homeowners, architects, and construction companies alike, ensuring compliance with stringent fire safety regulations.Paragraph 6:Furthermore, [Company Name] places a strong emphasis on sustainability, making their Fiberglass Insulation Sheets an eco-friendly choice. These sheets are manufactured using recycled and recyclable materials, minimizing waste and reducing the industry's carbon footprint. By opting for this sustainable insulation option, construction projects demonstrate their commitment to environmental stewardship and sustainable development.Paragraph 7:To enhance its product's overall performance, [Company Name] offers a range of additional features and customization options for the Fiberglass Insulation Sheets. These include various thickness options, moisture resistance treatments, and advanced coating technologies. Such customization ensures that the insulation sheets meet the specific needs and requirements of different projects and climates, further enhancing their effectiveness and longevity.Conclusion:With their exceptional thermal and acoustic insulation properties, versatility, fire resistance, and sustainability, Fiberglass Insulation Sheets by [Company Name] are poised to transform the construction industry. The advancements in this groundbreaking material offer unmatched energy efficiency, ensuring reduced energy consumption and enhanced comfort in buildings. As the demand for energy-efficient solutions continues to rise, this remarkable innovation is set to play a pivotal role in shaping the future of sustainable construction practices.

Read More

Durable and Versatile Fiberglass Panel Sheets: A Reliable Building Material Choice

Fiberglass Panel Sheets Revolutionize the Construction IndustryInnovative Fiberglass Panel Sheets have emerged as a game-changer in the construction industry. These lightweight and versatile sheets are manufactured by removing the brand name, using cutting-edge technology, and are rapidly gaining popularity due to their exceptional performance and multitude of applications.Fiberglass Panel Sheets are made by combining fiberglass and resin through a meticulous manufacturing process. This combination results in a material that is sturdy, durable, and resistant to various environmental factors. Its unique composition allows for easy installation and maintenance, making it a preferred choice for architects, engineers, and construction companies alike.One of the primary advantages of Fiberglass Panel Sheets is their lightweight nature. Compared to traditional construction materials such as concrete or steel, these sheets are significantly lighter. This feature not only facilitates quicker installation but also reduces the load on the supporting structure. Consequently, construction projects utilizing Fiberglass Panel Sheets can be completed in a shorter time frame and with fewer resources, leading to substantial cost savings.Furthermore, Fiberglass Panel Sheets are highly versatile in their applications. They can be used for both interior and exterior purposes, providing optimal solutions in various construction projects. From roofing and flooring to wall cladding and insulation, these sheets offer a wide range of possibilities. Their resistance to fire, moisture, and corrosion ensures long-lasting durability even in challenging environments.Moreover, Fiberglass Panel Sheets boast exceptional thermal and acoustic insulation properties. This feature makes them an excellent choice for buildings requiring temperature regulation and soundproofing. The sheets effectively reduce energy consumption and noise levels, creating a comfortable and sustainable living or working environment.The eco-friendly attributes of Fiberglass Panel Sheets further enhance their appeal. They are made from recyclable materials, reducing waste, and promoting a greener approach to construction. The manufacturing process also consumes less energy compared to traditional construction materials, thereby reducing the carbon footprint associated with construction projects.With their extensive range of advantages, Fiberglass Panel Sheets are revolutionizing the construction industry. They are increasingly replacing conventional materials in commercial, residential, and industrial projects worldwide. Builders and developers are realizing the immense potential of these sheets in terms of cost-effectiveness, versatility, and durability.ABC Company, a renowned leader in the fiberglass manufacturing industry, has been at the forefront of producing top-quality Fiberglass Panel Sheets. With years of experience and expertise, ABC Company has perfected the manufacturing process, ensuring consistent and reliable products. Their commitment to innovation and customer satisfaction has made them a trusted name in the industry.ABC Company's Fiberglass Panel Sheets are manufactured using state-of-the-art technology that adheres to stringent quality standards. Every sheet undergoes rigorous testing to ensure its structural integrity, durability, and adherence to industry regulations. The company's team of skilled professionals continuously monitors the production process, guaranteeing the highest quality products.The success and increasing demand for Fiberglass Panel Sheets have prompted ABC Company to expand its production capacity. The company is investing heavily in research and development to introduce new and improved variations of these sheets, catering to the diverse needs of the construction industry. Their commitment to continuous innovation ensures that their products remain at the forefront of technological advancements.In conclusion, Fiberglass Panel Sheets, with their remarkable advantages, are transforming the construction industry. The lightweight, versatile, and eco-friendly nature of these sheets allows for faster, cost-effective, and sustainable construction projects. ABC Company, a leading manufacturer in this field, continues to innovate and produce high-quality Fiberglass Panel Sheets, strengthening its position as a trusted partner in the construction industry.

Read More

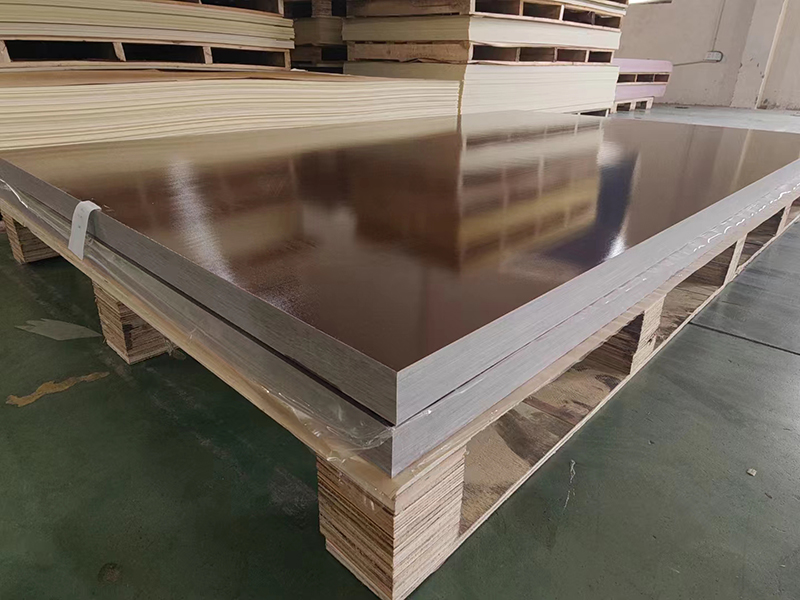

Epoxy Glass Laminate Sheet: A Comprehensive Field Visit by Pakistani Customers

Title: Unveiling the Versatility and Reliability of 3240 Epoxy Fiber Glass Laminate SheetsIntroduction:In the fast-paced world of electrical insulation materials, 3240 epoxy fiber glass laminate sheets hold a prominent position. As an industry leader and pioneer in the manufacturing of quality insulation products, ZTelec Group recently welcomed two Pakistani customers for a field visit. The purpose of their visit was to explore the unparalleled attributes and applications of 3240 epoxy fiber glass laminate sheets, popularly known as G10 FR4 laminate sheets. In this blog post, we will delve deeper into the properties of these composite materials that make them a preferred choice for various industries, providing you with an insightful understanding of their significance in the market.Overview of 3240 Epoxy Fiber Glass Laminate Sheets:3240 epoxy fiber glass laminate sheets are composite materials constructed by impregnating glass fiber fabric with an epoxy resin binder. These sheets offer a wide range of outstanding features, such as excellent electrical insulation properties, high mechanical strength, fire resistance, and exceptional temperature resistance. The high-quality manufacturing of a 3240 epoxy laminate sheet ensures its longevity and contribution to robust insulation systems.Key Properties:1. Electrical Insulation: With a dielectric strength of up to 16kV/mm, these sheets possess exceptional electrical insulation capabilities. They are resistant to high voltage, thereby ensuring safety and reliability in various electrical applications.2. Mechanical Strength: 3240 epoxy fiber glass laminate sheets exhibit excellent mechanical stability due to their high tensile and flexural strength. This makes them ideal for use in components that require resistant and durable insulation against deformation.3. Fire Resistance: Thanks to their incombustible nature, these laminate sheets are self-extinguishing and offer excellent fire resistance properties. They do not propagate flames or generate excessive smoke, ensuring enhanced safety in case of fire accidents.4. Temperature Resistance: One of the most distinctive features of these sheets is their ability to withstand high temperatures. With a heat resistance of up to 180°C, they retain their mechanical strength, electrical properties, and dimensional stability even in extreme environments.Applications:3240 epoxy fiber glass laminate sheets find extensive use in a wide range of industries. Some common applications include:1. Electrical Industry: These sheets are commonly used as insulation components in transformers, switchgear, circuit breakers, and various electrical devices that require reliable and durable insulation against electrical current.2. Automotive Industry: G10 FR4 laminate sheets are used in automotive applications such as ignition systems, electrical connectors, and motor insulation due to their exceptional electrical and thermal properties.3. Aerospace Industry: The aerospace sector utilizes these sheets for electrical insulation in aircraft components, including cockpit equipment, engine control panels, and avionics insulation.4. Electronics Industry: These laminate sheets serve as an ideal material for printed circuit boards (PCBs) due to their low moisture absorption, dimensional stability, and excellent electrical properties.Conclusion:The field visit by the Pakistani customers to ZTelec Group unveiled the remarkable versatility, performance, and reliability of 3240 epoxy fiber glass laminate sheets. These composite materials have become an essential choice across multiple industries due to their exceptional electrical insulation, high mechanical strength, fire resistance, and outstanding temperature stability. From electrical and automotive sectors to aerospace and electronics industries, the applications of these sheets are diverse and critical. The continued advancements in manufacturing technologies ensure that 3240 epoxy laminate sheets will remain at the forefront of the insulation material market, supporting efficient and safe electrical systems around the world.Keywords: 3240 epoxy fiber glass laminate sheet, G10 FR4 laminate sheet, electrical insulation, mechanical strength, fire resistance, temperature resistance, electrical industry, automotive industry, aerospace industry, electronics industry.

Read More

High Quality Epoxy Resin Glass Fiber Sheet for Mechanical and Electrical Insulation

G10 Glass Fiber Reinforced Sheet: The Versatile Insulation MaterialInsulation materials are used in a variety of applications, from mechanical and electrical equipment to buildings and homes. Insulation materials serve to maintain a certain temperature or environment, prevent unwanted heat or cold transfer, and protect equipment from damage. G10 Glass Fiber Reinforced Sheet is one such insulation material that is widely used due to its high mechanical and electrical properties, good heat resistance and humidity resistance. In this blog, we will discuss G10 Glass Fiber Reinforced Sheet and its applications.What is G10 Glass Fiber Reinforced Sheet?G10 Glass Fiber Reinforced Sheet is an insulating material made by using fiberglass cloth and heat resistant epoxy resin. The glass fiber cloth used in G10 is non-alkali, and it is impregnated with epoxy resin by hot pressing. The resulting material has high mechanical and electrical properties, good heat resistance and humidity resistance. G10 Glass Fiber Reinforced Sheet is known for its high strength, durability, and excellent dielectric properties. It is available in different sizes and thicknesses to suit various applications.Applications of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet is widely used in mechanical, electronic, and electrical equipment, insulation parts, and components. It is also used in the construction industry as a structural material. Below are the top applications of G10 Glass Fiber Reinforced Sheet:1. Electrical equipment insulation: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical equipment such as transformers, electric motors, and generators.2. Circuit board substrates: G10 Glass Fiber Reinforced Sheet is used as the substrate material for printed circuit boards. It provides excellent stability and mechanical strength to the circuit board.3. Mechanical parts and components: G10 Glass Fiber Reinforced Sheet is used to make parts and components of machinery and equipment. It provides excellent mechanical properties such as high strength and toughness.4. Aerospace industry: G10 Glass Fiber Reinforced Sheet is used in the aerospace industry to make parts for aircraft and spacecraft. It provides excellent strength and durability under extreme conditions.5. Marine industry: G10 Glass Fiber Reinforced Sheet is used in the marine industry as a material for boat hulls, decks, and other structural components. It is highly resistant to water and moisture, making it an ideal material for marine applications.Advantages of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet has several advantages over other insulation materials, such as:1. High strength and durability: G10 Glass Fiber Reinforced Sheet has high mechanical properties, making it ideal for use in high-stress applications that require strength and durability.2. Excellent electrical insulation properties: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical and electronic applications.3. Good heat resistance: G10 Glass Fiber Reinforced Sheet is resistant to high temperatures, which makes it suitable for use in high-temperature applications.4. Resistance to moisture and chemicals: G10 Glass Fiber Reinforced Sheet is highly resistant to moisture and chemicals, making it ideal for use in harsh environments.ConclusionG10 Glass Fiber Reinforced Sheet is a versatile insulation material that has several advantages over other insulation materials. Its high mechanical and electrical properties, good heat resistance, and humidity resistance make it ideal for use in a variety of applications. Its applications include electrical equipment insulation, circuit board substrates, mechanical parts and components, aerospace industry, and marine industry. If you are looking for an insulation material that offers high strength, durability, and excellent dielectric properties, G10 Glass Fiber Reinforced Sheet is an excellent choice.

Read More