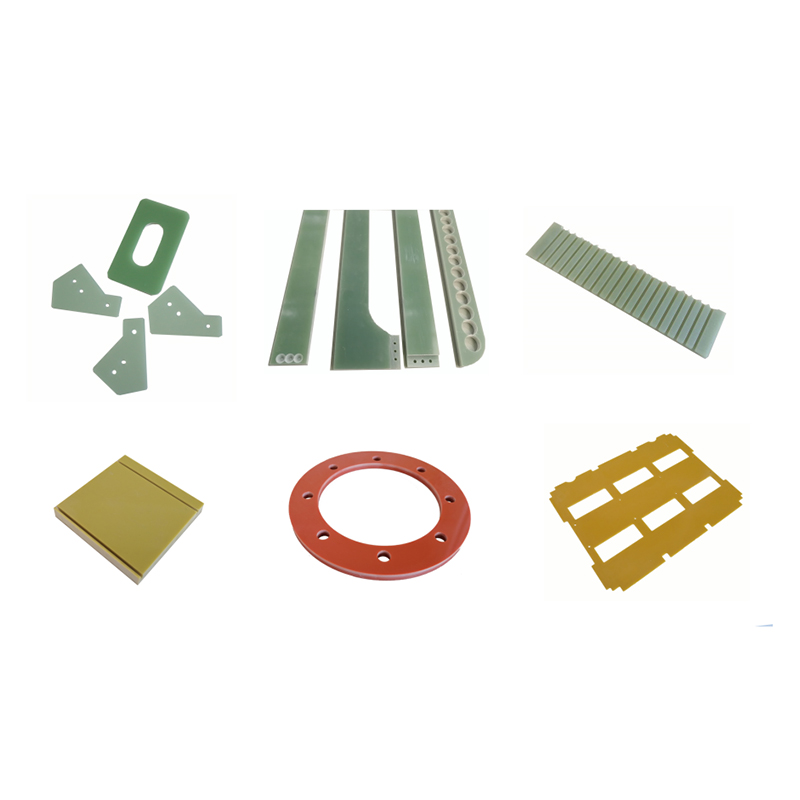

Durable and Versatile Phenolic Resin Board for Multiple Applications

By:Admin

In today's fast-paced world, innovation is the key to staying ahead of the competition. Companies are constantly looking for new materials and technologies that can help improve their products and processes. One such innovative solution that has been gaining attention in various industries is the Phenolic Resin Board. This versatile material has been revolutionizing the way companies design and create their products, offering a wide range of benefits and applications.

Phenolic resin boards are a type of composite material that is made by combining layers of cellulose fibers with phenolic resin. This combination of materials results in a strong, durable, and versatile product that can be used in a wide variety of applications. The boards are known for their high-temperature resistance, chemical resistance, and low moisture absorption, making them an ideal choice for industries such as aerospace, automotive, construction, and manufacturing.

One company that has been at the forefront of developing and producing high-quality phenolic resin boards is {Company Name}. With over 30 years of experience in the composite materials industry, {Company Name} has established itself as a leading supplier of phenolic resin boards, offering a wide range of products that meet the diverse needs of their customers.

{Company Name} prides itself on its commitment to innovation and quality, constantly investing in research and development to improve its products and meet the ever-changing demands of the market. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians ensure that their phenolic resin boards are of the highest quality, meeting the strictest industry standards and regulations.

The versatility of phenolic resin boards makes them suitable for a wide range of applications. In the aerospace industry, these boards are used in the construction of aircraft interiors, providing lightweight, fire-resistant, and durable materials for cabinetry, flooring, and wall panels. In the automotive industry, phenolic resin boards are used in engine compartments, under the hood, and interior components, offering thermal and chemical resistance as well as enhanced mechanical properties.

In the construction industry, phenolic resin boards are used in architectural cladding, exterior wall panels, and balcony flooring, providing a durable and low-maintenance solution for modern buildings. In the manufacturing industry, these boards are used to create molds, patterns, and tooling, offering excellent dimensional stability, high temperature resistance, and low moisture absorption.

{Company Name} understands the importance of sustainability and environmental responsibility, and they are committed to producing phenolic resin boards that are eco-friendly and recyclable. Their production processes are designed to minimize waste and reduce the environmental impact, ensuring that their products are not only high-quality but also sustainable.

In addition to their commitment to quality and sustainability, {Company Name} also prides itself on its dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, offering customized solutions and technical support to ensure that their phenolic resin boards meet and exceed their expectations.

As the demand for innovative and high-performance materials continues to grow, phenolic resin boards are expected to play a key role in driving the future of various industries. With their exceptional properties, versatility, and sustainability, these boards are proving to be a game-changer for companies looking to stay ahead in today's competitive market.

In conclusion, phenolic resin boards are an innovative solution that offers a wide range of benefits and applications for industries such as aerospace, automotive, construction, and manufacturing. {Company Name} has been at the forefront of developing and producing high-quality phenolic resin boards, offering a diverse range of products that meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {Company Name} is poised to continue leading the way in the production and supply of phenolic resin boards for years to come.

Company News & Blog

How to Use Anti-Static Sheets: A Complete Guide for Static Control

[Company Name] Introduces Cutting-Edge Anti-Static Sheet for Industries[City, State] - [Company Name], a leading provider of innovative solutions for industrial applications, has introduced a new and advanced anti-static sheet designed to address the growing concerns of static electricity in various industries. The anti-static sheet, which will be available for purchase from [Company Name], aims to provide a reliable and cost-effective solution for businesses looking to mitigate the adverse effects of static electricity in their operations.Static electricity is a common issue in many industries, particularly in environments where friction and movement of materials can generate high levels of electrostatic charge. This can create a range of problems, from damaging sensitive electronic components to posing a safety hazard for workers. The new anti-static sheet from [Company Name] offers a practical and efficient way to control and neutralize static electricity, helping businesses to maintain a stable and safe working environment.The innovative technology behind the anti-static sheet enables it to effectively dissipate static charges, preventing the build-up of electrostatic discharge and reducing the risk of damage to sensitive equipment. This makes it an ideal solution for industries such as electronics manufacturing, cleanroom environments, pharmaceutical production, and other settings where static control is a critical concern.Moreover, the anti-static sheet is designed to be highly durable and long-lasting, providing businesses with a cost-effective solution for managing static electricity over an extended period. Its robust construction ensures that it can withstand the rigors of industrial operations, making it a practical choice for businesses seeking a reliable static control solution.[Company Name] has a strong track record of delivering high-quality industrial solutions, and the introduction of the new anti-static sheet further demonstrates its commitment to addressing the evolving needs of its customers. With a focus on innovation and practicality, the company continues to develop products that offer tangible benefits for businesses across a range of industries.In addition to offering the new anti-static sheet, [Company Name] provides a comprehensive range of industrial products and solutions, including anti-static mats, ionizing blowers, and static control devices. Its dedication to providing effective static control solutions has established [Company Name] as a trusted partner for businesses looking to enhance the safety and efficiency of their operations.As businesses strive to optimize their manufacturing processes and maintain high standards of product quality, the need for effective static control measures has become increasingly important. The introduction of the new anti-static sheet from [Company Name] reflects the company's commitment to supporting the continued success of its customers by offering practical and reliable solutions to address industry challenges.With its innovative approach to static control and its proven track record of delivering quality industrial solutions, [Company Name] is well-positioned to meet the growing demands of businesses seeking effective anti-static products. The new anti-static sheet is poised to make a significant impact in the industry by providing businesses with a dependable and efficient solution for managing static electricity in their operations.For more information about [Company Name] and its range of industrial solutions, including the new anti-static sheet, please visit [Company Website].About [Company Name]:[Company Name] is a leading provider of industrial solutions, offering a comprehensive range of products and services to support the diverse needs of businesses across various industries. With a focus on innovation, quality, and practicality, the company has established itself as a trusted partner for businesses seeking reliable and effective solutions for their operations.

Everything You Need to Know About Plastic Laminate Sheet 3240 from China" can be rewritten as "A Comprehensive Guide to Plastic Laminate Sheet 3240 Manufactured in China".

Title: China's Plastic Laminate Sheet 3240: A Resilient and Versatile Solution for Various IndustriesIntroduction:China has emerged as a global leader in the production and export of high-quality plastic laminate sheets. Among these, the China Plastic Laminate Sheet 3240 stands out as an exceptional and reliable material. With its exceptional strength, electrical insulation properties, and resistance to various environmental conditions, the 3240 laminate sheet has become an indispensable material across numerous industries. This article explores the features, applications, and benefits of China's Plastic Laminate Sheet 3240, shedding light on its growing popularity in domestic and international markets.Features of China Plastic Laminate Sheet 3240:China Plastic Laminate Sheet 3240 is engineered to possess exceptional mechanical and electrical properties, making it highly suitable for demanding applications. Here are some noteworthy features:1. Superior Electrical Insulation: The 3240 laminate sheet is specifically designed to offer excellent electrical insulation, effectively reducing the risk of electrical short circuits or breakdowns. Its high dielectric strength and low water absorption contribute to its excellent insulating properties.2. Thermal Resistance: This laminate sheet possesses remarkable thermal resistance, allowing it to withstand high temperatures up to 150 degrees Celsius. It maintains its structural integrity even in environments with extreme heat, making it suitable for various applications requiring heat dissipation.3. Mechanical Strength: With its exceptional mechanical strength, China Plastic Laminate Sheet 3240 effectively resists mechanical stresses, impacts, and vibrations. This robustness renders it highly suitable for applications that demand durability and reliability.4. Chemical and Moisture Resistance: The 3240 laminate sheet demonstrates excellent resistance to a wide range of chemicals and moisture, ensuring long-term stability and reliability. This feature makes it suitable for use in humid or corrosive environments.Applications of China Plastic Laminate Sheet 3240:The versatility and reliability of China's Plastic Laminate Sheet 3240 contribute to its widespread application across various industries. Some notable applications include:1. Electrical Industry: The 3240 laminate sheet finds extensive use in electrical equipment such as transformer insulation, switchgears, and electrical motor components. Its excellent electrical insulation and thermal properties make it a preferred choice for these applications.2. Mechanical Engineering: Due to its exceptional mechanical strength and resistance to impacts and vibrations, the 3240 laminate sheet is widely utilized in mechanical engineering for manufacturing components such as gaskets, gears, and bushings.3. Construction and Architecture: China's Plastic Laminate Sheet 3240 is commonly employed in construction and architecture projects. It is utilized for panel insulations, decorative laminates, and structural reinforcements due to its fire resistance, durability, and resistance to extreme environmental conditions.4. Automotive Industry: The 3240 laminate sheet is increasingly used in the automotive industry for various applications, including insulation sheets, battery enclosures, and electric vehicle components. Its thermal resistance and mechanical strength make it a suitable choice for these demanding applications.Benefits and Advantages:The widespread adoption of China's Plastic Laminate Sheet 3240 can be attributed to its numerous benefits and advantages, including:1. Cost-effectiveness: The 3240 laminate sheet offers a cost-effective solution, ensuring value for money due to its long lifespan and durable properties. This makes it an attractive choice for businesses across different industries.2. Versatility: The material's versatility allows it to be tailored to specific requirements, enabling customization and adaptability across various applications.3. Eco-friendly: China's Plastic Laminate Sheet 3240 is also known for its eco-friendly properties. It is manufactured using environmentally friendly processes, contributing to sustainability efforts in today's world.Conclusion:China's Plastic Laminate Sheet 3240 has established itself as a reliable and versatile material, catering to the needs of numerous industries. Its exceptional electrical insulation, thermal resistance, and mechanical strength make it an optimal choice for a wide range of applications. As demand continues to grow, China remains at the forefront of producing and supplying high-quality laminate sheets that meet both domestic and international market requirements.

Durable and Versatile Laminated Sheet for Various Applications

Laminated Sheet Company X Introduces New Innovative ProductCompany X, a leading provider of industrial materials, has recently announced the release of their latest product, the Laminated Sheet. This highly innovative and versatile material is designed to meet the diverse needs of industries such as construction, automotive, aerospace, electronics, and more. With its superior durability, outstanding performance, and exceptional quality, the Laminated Sheet is set to revolutionize the way various industries operate and create products.The Laminated Sheet is a combination of [Company X]’s expertise in material engineering and advanced manufacturing technologies. It is made of multiple layers of high-quality materials that are bonded together through a sophisticated process, resulting in a strong and resilient sheet that can withstand extreme conditions and heavy usage. The product is available in a wide range of thickness, sizes, and finishes to cater to different applications and requirements.One of the key features of the Laminated Sheet is its exceptional strength-to-weight ratio. This makes it an ideal choice for applications where weight reduction is critical without compromising on structural integrity. The material’s high impact resistance also makes it a preferred choice for use in high-traffic areas and demanding environments. Additionally, the Laminated Sheet is resistant to corrosion, moisture, and chemicals, ensuring long-term reliability and performance in harsh conditions.The versatility of the Laminated Sheet extends to its machinability and formability. It can be easily cut, shaped, and molded to create custom components and products, making it a valuable material for manufacturers and designers. This flexibility allows for greater creativity and innovation in product development and opens up new possibilities for various industries.With its outstanding thermal and electrical insulation properties, the Laminated Sheet is also an excellent choice for applications in the electronics and electrical industries. Its ability to effectively insulate and protect components from heat and electrical currents can help improve the safety and reliability of electronic devices and systems.Company X is committed to ensuring the highest standards of quality and performance for the Laminated Sheet. The product is subjected to rigorous testing and quality control measures to meet industry regulations and standards. With a focus on sustainability, the company also ensures that the manufacturing process of the Laminated Sheet adheres to environmental guidelines and reduces waste and energy consumption.In addition to its advanced technical features, the Laminated Sheet is offered with customizable finishes and surface treatments, allowing customers to tailor the aesthetics and functionality of the material to their specific needs. This further enhances the product’s appeal and suitability for a wide range of applications.Company X is excited to bring the Laminated Sheet to the market, and they are confident that it will set new benchmarks for quality and performance in the industry. With its many benefits and applications, the Laminated Sheet is poised to become an indispensable material for manufacturers, engineers, and designers across various sectors.Customers who are interested in learning more about the Laminated Sheet and experiencing its capabilities firsthand are encouraged to contact Company X for more information and product inquiries. The company is dedicated to providing comprehensive support and solutions to help customers integrate the Laminated Sheet into their projects and applications successfully.In conclusion, the introduction of the Laminated Sheet by Company X represents a significant advancement in material technology. Its exceptional strength, versatility, and performance make it a game-changing product that will drive innovation and efficiency across multiple industries. As Company X continues to push the boundaries of what is possible in material engineering, the Laminated Sheet stands out as a testament to their commitment to excellence and their ability to deliver solutions that meet the evolving needs of the market.

Durable and Versatile Phenolic Resin Board for Multiple Applications

Phenolic Resin Board: An Innovative Solution for Various IndustriesIn today's fast-paced world, innovation is the key to staying ahead of the competition. Companies are constantly looking for new materials and technologies that can help improve their products and processes. One such innovative solution that has been gaining attention in various industries is the Phenolic Resin Board. This versatile material has been revolutionizing the way companies design and create their products, offering a wide range of benefits and applications.Phenolic resin boards are a type of composite material that is made by combining layers of cellulose fibers with phenolic resin. This combination of materials results in a strong, durable, and versatile product that can be used in a wide variety of applications. The boards are known for their high-temperature resistance, chemical resistance, and low moisture absorption, making them an ideal choice for industries such as aerospace, automotive, construction, and manufacturing.One company that has been at the forefront of developing and producing high-quality phenolic resin boards is {Company Name}. With over 30 years of experience in the composite materials industry, {Company Name} has established itself as a leading supplier of phenolic resin boards, offering a wide range of products that meet the diverse needs of their customers.{Company Name} prides itself on its commitment to innovation and quality, constantly investing in research and development to improve its products and meet the ever-changing demands of the market. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians ensure that their phenolic resin boards are of the highest quality, meeting the strictest industry standards and regulations.The versatility of phenolic resin boards makes them suitable for a wide range of applications. In the aerospace industry, these boards are used in the construction of aircraft interiors, providing lightweight, fire-resistant, and durable materials for cabinetry, flooring, and wall panels. In the automotive industry, phenolic resin boards are used in engine compartments, under the hood, and interior components, offering thermal and chemical resistance as well as enhanced mechanical properties.In the construction industry, phenolic resin boards are used in architectural cladding, exterior wall panels, and balcony flooring, providing a durable and low-maintenance solution for modern buildings. In the manufacturing industry, these boards are used to create molds, patterns, and tooling, offering excellent dimensional stability, high temperature resistance, and low moisture absorption.{Company Name} understands the importance of sustainability and environmental responsibility, and they are committed to producing phenolic resin boards that are eco-friendly and recyclable. Their production processes are designed to minimize waste and reduce the environmental impact, ensuring that their products are not only high-quality but also sustainable.In addition to their commitment to quality and sustainability, {Company Name} also prides itself on its dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, offering customized solutions and technical support to ensure that their phenolic resin boards meet and exceed their expectations.As the demand for innovative and high-performance materials continues to grow, phenolic resin boards are expected to play a key role in driving the future of various industries. With their exceptional properties, versatility, and sustainability, these boards are proving to be a game-changer for companies looking to stay ahead in today's competitive market.In conclusion, phenolic resin boards are an innovative solution that offers a wide range of benefits and applications for industries such as aerospace, automotive, construction, and manufacturing. {Company Name} has been at the forefront of developing and producing high-quality phenolic resin boards, offering a diverse range of products that meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {Company Name} is poised to continue leading the way in the production and supply of phenolic resin boards for years to come.

Insulation Epoxy Fiberglass Fr4/G10 Sheets from China: A Comprehensive Overview

China Insulation Epoxy Fiberglass Fr4/G10 Sheets are gaining popularity in the global market due to their superior insulation properties and high mechanical strength. These sheets are widely used in various industries such as electronics, aerospace, automotive, and telecommunications for applications that require high-performance insulation materials.The Fr4/G10 Sheets are manufactured using a combination of high-quality epoxy resin and fiberglass cloth. This combination results in a material that exhibits excellent electrical insulation properties, superior mechanical strength, and high heat resistance. These sheets are capable of withstanding high temperatures and have a low thermal expansion coefficient, making them ideal for use in extreme environments.In addition to their exceptional insulation properties, Fr4/G10 Sheets also offer excellent dimensional stability, chemical resistance, and good machinability. These qualities make them suitable for a wide range of applications, including printed circuit boards, electrical insulation components, and structural parts in various electronic devices.The growing demand for high-performance insulation materials has prompted several manufacturers in China to produce Fr4/G10 Sheets that meet international quality standards. These sheets are manufactured using advanced production techniques and are subjected to rigorous quality control measures to ensure that they meet the requirements of the global market.One of the leading manufacturers of China Insulation Epoxy Fiberglass Fr4/G10 Sheets is {}. With years of experience in the industry, they have established themselves as a reliable supplier of high-quality insulation materials. Their Fr4/G10 Sheets are known for their consistent performance, reliability, and durability, making them the preferred choice for many businesses around the world.The company's manufacturing facility is equipped with state-of-the-art machinery and equipment, allowing them to produce Fr4/G10 Sheets that meet the strictest quality standards. They have a team of experienced engineers and technicians who oversee the production process to ensure that all products adhere to international quality norms.In addition to their commitment to quality, the company also places a strong emphasis on research and development. They continuously invest in technology and innovation to enhance the performance of their insulation materials and develop new products that cater to the evolving needs of the market. This dedication to innovation has allowed them to stay ahead of the competition and maintain a leading position in the industry.As part of their dedication to customer satisfaction, the company offers customized solutions for businesses that require specific insulation materials for their applications. They work closely with their clients to understand their requirements and deliver tailored products that meet their unique needs. This personalized approach has earned them a loyal customer base and a strong reputation in the global market.With the increasing demand for high-performance insulation materials, the market for China Insulation Epoxy Fiberglass Fr4/G10 Sheets is expected to grow significantly in the coming years. As industries continue to seek reliable and durable insulation solutions for their applications, manufacturers like {} are well-positioned to meet this demand with their superior products and dedication to excellence.In conclusion, China Insulation Epoxy Fiberglass Fr4/G10 Sheets are becoming increasingly popular in the global market due to their exceptional insulation properties, high mechanical strength, and superior performance in extreme environments. With a strong focus on quality, innovation, and customer satisfaction, manufacturers like {} are meeting the growing demand for high-performance insulation materials and are poised to lead the industry in the years to come.

Top 10 ESD (Electrostatic Discharge) Products for Protection

ESD G10 is the latest innovation by the leading technology company. Designed to meet the growing demand for high-performance and reliable electronic components, the ESD G10 is set to revolutionize the industry with its cutting-edge features and unmatched quality.With the increasing complexity of electronic devices, the need for superior ESD (electrostatic discharge) protection has become more critical than ever. The ESD G10 offers a comprehensive solution to this problem by providing exceptional protection against electrical overloads, ensuring the safety and reliability of sensitive electronic components.The ESD G10 is engineered with state-of-the-art materials and advanced technologies to deliver outstanding performance in a wide range of applications. Its robust construction and precision design make it suitable for use in various industries, including automotive, aerospace, telecommunications, and consumer electronics.In addition to its superior ESD protection capabilities, the ESD G10 also offers excellent thermal conductivity, ensuring efficient heat dissipation and increased component longevity. This feature is particularly beneficial for high-power applications where heat management is crucial for optimal performance.Furthermore, the ESD G10 is designed to meet the highest industry standards for quality and reliability. Rigorously tested and certified, this cutting-edge component provides the assurance of uncompromising performance and durability in the most demanding operating environments.The introduction of the ESD G10 underscores the company's commitment to innovation and excellence. With a proven track record of delivering exceptional electronic components, the company has solidified its position as a trusted partner for industry-leading solutions.By harnessing the latest advancements in technology and incorporating feedback from customers and industry experts, the company has been able to develop the ESD G10 as a game-changing product that will set new benchmarks for ESD protection and performance.In line with its dedication to sustainability and environmental responsibility, the company has ensured that the ESD G10 is manufactured using eco-friendly processes and materials. This demonstrates the company's commitment to minimizing its environmental footprint while delivering cutting-edge solutions to its customers.The launch of the ESD G10 represents a significant milestone for the company and reinforces its position as a leading innovator in the electronic components industry. With its unparalleled performance, robust construction, and commitment to quality, the ESD G10 is poised to make a lasting impact in the market and set new standards for ESD protection and reliability.As the industry continues to evolve and demand for high-performance electronic components grows, the ESD G10 is well-positioned to meet the needs of the most discerning customers and deliver exceptional value in a wide range of applications. With its advanced features and proven capabilities, the ESD G10 is set to become the go-to solution for superior ESD protection and reliable performance in the dynamic world of electronics.

China Produces High-Quality Epoxy Laminates for Reliable Solder Pallets

China Epoxy Laminates for Solder Pallet - Setting New Standards in Electronics Manufacturing(Insert Company Introduction)In the rapidly evolving world of electronics manufacturing, companies are constantly seeking innovative solutions to ensure efficiency and reliability in their production processes. One of the critical components that play a crucial role in this industry is epoxy laminates for solder pallets. These laminates not only provide a robust surface for soldering operations but also offer excellent mechanical and thermal properties. While several manufacturers produce epoxy laminates, one company from China has been making significant strides in the industry, setting new standards for electronics manufacturing.(Insert Company Name), a prominent player in the electronics manufacturing sector, has been at the forefront of producing high-quality epoxy laminates for solder pallets. With a commitment to excellence and customer satisfaction, the company has emerged as a trusted name in the market. Their state-of-the-art manufacturing facilities and cutting-edge technology ensure that their products meet the stringent requirements of the industry.One of the key factors that set (Company Name) apart from its competitors is its relentless focus on research and development. This has allowed the company to introduce innovative additives and reinforcements in their epoxy laminates, enhancing their mechanical properties and heat resistance. By continuously investing in R&D, (Company Name) stays ahead of the curve, providing its customers with laminates that meet and exceed industry standards.The epoxy laminates produced by (Company Name) boast exceptional strength and durability, making them ideal for various applications in electronics manufacturing. These laminates offer excellent insulation properties, ensuring that their performance is maintained even in demanding conditions. The unique formulation developed by (Company Name) ensures that their laminates have exceptional chemical resistance, safeguarding them against corrosive substances commonly found in electronic assemblies.Moreover, (Company Name)'s commitment to sustainability sets them apart from their competitors. Recognizing the need for environmentally friendly solutions, they have made significant efforts to reduce the environmental impact of their manufacturing processes. (Insert specific details about sustainability initiatives like using recycled materials, minimizing waste, etc.)In addition to producing high-quality epoxy laminates, (Company Name) also prioritizes customer satisfaction and provides comprehensive support services. With a team of experienced engineers and technical experts, the company offers consultancy and guidance to their clients, assisting them in selecting the most suitable laminates for their specific needs. Their dedication to after-sales support ensures that customers receive assistance and solutions even after the purchase.The success of (Company Name) in the market can be attributed to their strong emphasis on quality control. Rigorous testing procedures are implemented at every stage of the manufacturing process to ensure that each laminate meets the highest standards. As a result, (Company Name) has been awarded various certifications, underscoring their commitment to consistent quality delivery.Looking ahead, (Company Name) aims to continue leading the way in the production of epoxy laminates for solder pallets. With a relentless pursuit of excellence and a customer-centric approach, the company strives to develop new and improved laminates that cater to the ever-evolving needs of the electronics manufacturing industry. By prioritizing innovation, sustainability, and customer satisfaction, (Company Name) is well-positioned to set new benchmarks in the market.In conclusion, (Company Name) has revolutionized the electronics manufacturing industry with its high-quality epoxy laminates for solder pallets. Through their research and development efforts, commitment to sustainability, and dedication to customer satisfaction, the company has become a trusted name in the market. As the industry continues to grow and evolve, (Company Name) will undoubtedly play a crucial role in setting new standards for electronics manufacturing worldwide.

Cost-Effective Thin Insulation Sheets: A Key Solution for Efficient Thermal Control

[Company Name] Develops Innovative Thin Insulation Sheets for Various Applications[City, Date] - [Company Name], a renowned leader in the field of insulation solutions, has recently unveiled its latest product innovation - Thin Insulation Sheets. These sheets, designed to provide effective thermal insulation, offer significant benefits over traditional insulation materials. With this groundbreaking development, [Company Name] aims to revolutionize the insulation industry and meet the growing demands for energy-efficient solutions.Utilizing state-of-the-art technology, [Company Name] has successfully produced insulation sheets that are incredibly thin yet highly efficient. These sheets have unique properties that allow them to effectively reduce heat transfer, providing optimal insulation for both residential and commercial applications. The innovative design of the Thin Insulation Sheets makes them versatile and adaptable to various environments, making them an ideal choice for a wide range of projects.One of the key advantages of the Thin Insulation Sheets is their superior thermal performance. By effectively minimizing heat loss or gain, these sheets help maintain a comfortable indoor temperature while significantly reducing energy consumption. This thermal efficiency contributes to cost savings for homeowners and businesses alike, as it reduces the need for excessive heating or cooling usage.In addition to their exceptional insulating capabilities, the Thin Insulation Sheets are also incredibly lightweight and easy to handle. This makes them an ideal choice for retrofitting existing structures, allowing for hassle-free installation without the need for extensive modifications. Moreover, their thin profile provides more space for additional insulation or accomodates architectural designs that require minimal thickness.[Company Name] takes pride in offering environmentally friendly solutions, and the Thin Insulation Sheets are no exception. Made from sustainable materials, these sheets are non-toxic and do not emit harmful substances, ensuring a healthy living environment. By incorporating these insulation sheets into their projects, individuals and businesses can contribute to a greener future while enjoying the benefits of reduced energy consumption.To cater to diverse insulation needs, [Company Name] manufactures Thin Insulation Sheets in various sizes and thicknesses. Customers can choose the most suitable option based on the specific requirements of their project. The sheets can be easily customized to fit different shapes and sizes, ensuring a perfect fit and maximum thermal performance.The versatility of the Thin Insulation Sheets opens up a world of potential applications. From residential buildings and commercial spaces to industrial facilities and transportation, these sheets can be used in a wide range of environments. Whether it is for new construction projects, renovations, or insulation upgrades, [Company Name]'s Thin Insulation Sheets are a cost-effective and efficient solution.As a frontrunner in the insulation industry, [Company Name] has established a solid reputation for delivering high-quality products and innovative solutions. With the introduction of the Thin Insulation Sheets, the company reaffirms its commitment to meeting the evolving needs of its customers and driving sustainability in the industry.[Company Name]'s Thin Insulation Sheets are now available to customers worldwide. By choosing these revolutionary insulation sheets, individuals, architects, and construction professionals can enjoy the benefits of superior thermal performance, ease of installation, and environmental sustainability. With [Company Name] leading the way, the future of insulation is thin, efficient, and eco-friendly.About [Company Name]:[Company Name] is a renowned company specializing in insulation solutions. With years of experience and a dedication to quality and innovation, [Company Name] has become a trusted name in the industry. The company takes pride in its commitment to delivering energy-efficient products that meet international standards while minimizing the environmental impact. From residential to commercial projects, [Company Name] provides reliable insulation solutions for a sustainable future. For more information, visit [Company Website].Contact:[Company Name][Company Address][Phone Number][Email Address][Website]

Latest News Update: G11 and G10 Models Set to Dominate the Market

Fr5 G11 Fr4 Fr5 G10, the leading technology company in the field of electronic devices, announced a breakthrough in their latest product, which is set to revolutionize the industry. The company, which has been at the forefront of innovation for over a decade, has always been committed to pushing the boundaries of what is possible in the world of electronics.The new product, which is a result of years of research and development, is a game-changer in terms of both design and functionality. It boasts cutting-edge features that have never been seen before in the market, and is expected to set a new standard for electronic devices.The company's CEO, Mr. X, expressed his excitement about the new product, stating that it represents a significant milestone for the company. "We are incredibly proud of what we have achieved with this new product," he said. "It is a testament to the hard work and dedication of our team, and it reaffirms our position as a leader in the industry."The new product is expected to appeal to a wide range of consumers, from tech enthusiasts to casual users. Its sleek and modern design, combined with its powerful performance, make it a versatile option for anyone in the market for a new electronic device.In addition to its impressive design and functionality, the new product also boasts a range of advanced features that set it apart from its competitors. These include state-of-the-art security measures, a high-resolution display, and an intuitive user interface that makes it easy to navigate and use.The company's dedication to innovation and excellence has been a driving force behind the development of the new product. Their team of engineers and designers have worked tirelessly to ensure that every aspect of the product meets the highest standards of quality and performance.The company's commitment to sustainability is also evident in the new product, as it is made from eco-friendly materials and is designed to have a minimal impact on the environment. This aligns with the company's overall mission to create products that are both innovative and environmentally responsible.With the announcement of the new product, Fr5 G11 Fr4 Fr5 G10 has once again demonstrated their leadership in the industry. They have consistently proven their ability to push the boundaries of what is possible in the world of electronic devices, and the new product is a testament to their ongoing dedication to innovation.As the company continues to grow and expand, they remain committed to delivering products that are at the forefront of technology and design. With their latest achievement, they have set a new standard for the industry and have solidified their position as a leader in the field of electronic devices.As consumers eagerly await the release of the new product, anticipation is growing for what is expected to be a game-changing addition to the world of electronic devices. With its advanced features, sleek design, and commitment to sustainability, it is clear that the new product from Fr5 G11 Fr4 Fr5 G10 will be a force to be reckoned with in the market.