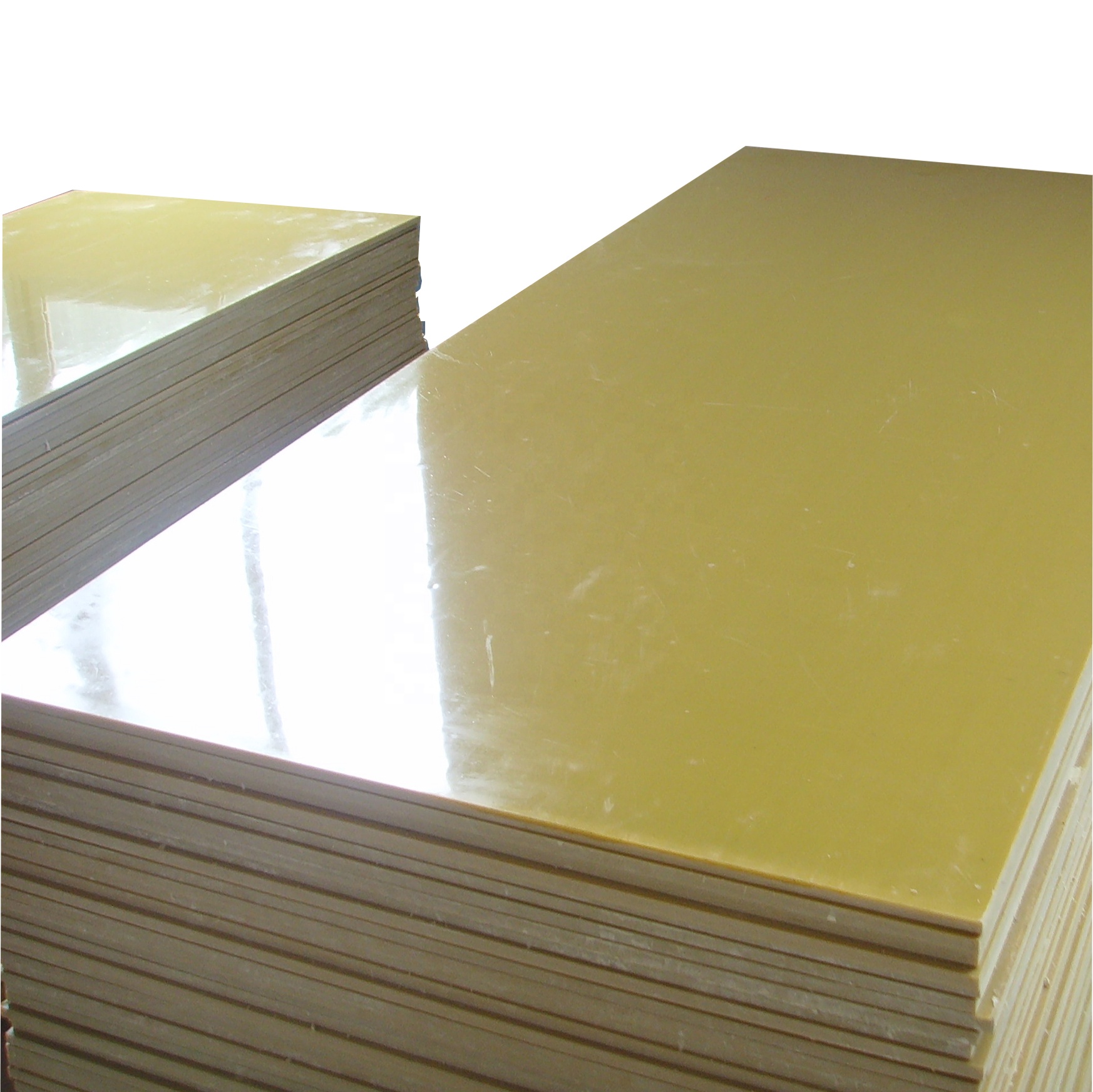

Durable Epoxy Boards of Various Thickness for Multiple Applications

By:Admin

In the world of industrial materials, innovation is the key to success. Companies are constantly looking for new ways to improve their products, increase efficiency, and reduce costs. One such company that is leading the way in this regard is {Company Name}.

{Company Name} is a leading manufacturer of industrial materials, specializing in epoxy boards. These boards are widely used in a variety of industries, including electronics, aerospace, automotive, and more. They are known for their durability, strength, and versatility. However, the team at {Company Name} is constantly looking for ways to improve upon their products, and they have recently done just that with the introduction of different thickness epoxy boards.

The new different thickness epoxy boards have been developed to meet the specific needs of different industries. They are available in a range of thicknesses, from thin and flexible to thick and rigid, making them suitable for a wide range of applications. This level of customization is something that has never been seen before in the industry, and it is sure to revolutionize the way epoxy boards are used.

One of the key benefits of the different thickness epoxy boards is their ability to provide the same high level of performance and durability, regardless of their thickness. This means that companies can now choose the thickness of the board that best suits their needs, without having to worry about sacrificing quality. This level of flexibility is a game changer for the industry, and it is sure to be welcomed by companies across the board.

In addition to their performance benefits, the different thickness epoxy boards also offer significant cost savings. By being able to choose the exact thickness of board they need, companies can avoid wasting money on unnecessarily thick or thin boards. This level of precision in materials selection can have a significant impact on the bottom line, and it is sure to be welcomed by cost-conscious companies.

{Company Name} is no stranger to innovation. The company has a long history of pushing the boundaries of what is possible with industrial materials, and the introduction of the different thickness epoxy boards is just the latest example of this. The team at {Company Name} is constantly looking for ways to improve upon their products, and they are already working on the next generation of epoxy boards that will further push the boundaries of what is possible in the industry.

The different thickness epoxy boards are just one of many exciting products that {Company Name} has to offer. The company also specializes in a wide range of other industrial materials, including laminates, prepregs, and more. All of their products are known for their exceptional quality, performance, and versatility, and the company has a long history of providing the highest level of customer satisfaction.

In conclusion, the introduction of the different thickness epoxy boards from {Company Name} is sure to revolutionize the industrial materials industry. These boards offer a level of customization and flexibility that has never been seen before, and they are already being welcomed by companies across a wide range of industries. With their exceptional performance, cost savings, and potential for customization, these boards are sure to be a game changer for the industry as a whole. Keep an eye on {Company Name} as they continue to push the boundaries of what is possible in the world of industrial materials.

Company News & Blog

Durable Epoxy Fiber Glass Laminate Sheet: A Reliable Choice for Various Applications

3240 Epoxy Fiber Glass Laminate Sheet: The Ultimate Choice for Electrical Insulation SolutionsWhen it comes to electrical insulation solutions, one name stands out above the rest - 3240 Epoxy Fiber Glass Laminate Sheet. This high-quality, versatile material has become the go-to choice for professionals across a wide range of industries, and for good reason. With its exceptional electrical insulation properties, durability, and ease of use, it's no wonder that 3240 Epoxy Fiber Glass Laminate Sheet has become the top choice for businesses worldwide.But what exactly sets 3240 Epoxy Fiber Glass Laminate Sheet apart from other materials on the market? To answer that question, we need to take a closer look at what makes this product so special.First and foremost, 3240 Epoxy Fiber Glass Laminate Sheet is known for its outstanding electrical insulation properties. With a high dielectric strength and excellent resistance to electric current, this material provides reliable insulation for a wide range of electrical applications. Whether it's being used to insulate transformers, motors, or electrical panels, 3240 Epoxy Fiber Glass Laminate Sheet delivers the performance and reliability that professionals demand.In addition to its exceptional electrical insulation properties, 3240 Epoxy Fiber Glass Laminate Sheet is also prized for its durability. Made from high-quality materials, this laminate sheet is designed to withstand the rigors of daily use in industrial and commercial settings. It is resistant to heat, moisture, and various chemicals, making it a long-lasting solution for even the most demanding applications.Furthermore, 3240 Epoxy Fiber Glass Laminate Sheet is incredibly versatile. It can be easily cut, drilled, and machined to meet the specific requirements of a given project. This flexibility makes it a popular choice for custom applications, where precise dimensions and shapes are necessary.Another key advantage of 3240 Epoxy Fiber Glass Laminate Sheet is its ease of use. Whether it's being used in a small-scale project or a large industrial application, this material is easy to handle and install. This saves valuable time and labor costs, making it a cost-effective choice for businesses of all sizes.But perhaps the most impressive aspect of 3240 Epoxy Fiber Glass Laminate Sheet is its reliability. With a proven track record of performance in a wide range of applications, this material has earned the trust of professionals worldwide. Businesses can rely on 3240 Epoxy Fiber Glass Laminate Sheet to deliver consistent, long-lasting insulation solutions, time and time again.All of these qualities have made 3240 Epoxy Fiber Glass Laminate Sheet the ultimate choice for electrical insulation solutions. Whether it's being used in the manufacturing of electrical equipment, the construction of industrial machinery, or the maintenance of commercial infrastructure, this material has proven itself to be an indispensable part of modern industry.In conclusion, 3240 Epoxy Fiber Glass Laminate Sheet is the go-to choice for professionals who demand the best in electrical insulation solutions. With its exceptional electrical insulation properties, durability, versatility, ease of use, and reliability, it's no wonder that this material has become the top choice for businesses around the world. For all of these reasons and more, 3240 Epoxy Fiber Glass Laminate Sheet is the clear leader in its field, and the ultimate choice for any project that demands top-quality electrical insulation.

Benefits of Using Fiberglass Plain Sheets for Construction Projects

Fiberglass Plain Sheet Enhances Durability and Versatility in Construction Industry{Company Name}, a leading manufacturer and distributor of construction materials, is proud to introduce their latest innovative product, the Fiberglass Plain Sheet. Designed to revolutionize the construction industry, this lightweight and durable material offers enhanced durability and versatility for a wide range of applications.With the increasing demand for high-performance building materials, contractors and architects are constantly seeking innovative solutions that balance strength, cost-efficiency, and sustainability. Fiberglass has emerged as a popular choice, thanks to its superior structural properties and resistance to corrosion, chemicals, and extreme weather conditions.The Fiberglass Plain Sheet, produced by {Company Name}, encapsulates these desirable qualities, taking them to a whole new level. Made from premium quality fiberglass reinforced polymer, this sheet offers exceptional strength-to-weight ratio, ensuring long-lasting and reliable performance. Its unique composition allows it to withstand heavy loads and impacts without compromising its structural integrity.One of the standout features of the Fiberglass Plain Sheet is its high resistance to fire. Unlike traditional construction materials, such as wood or steel, fiberglass does not burn easily and does not support the spread of flames. This makes it an ideal choice for applications that require fire-resistant properties, such as facades, roofing, and partitions.Additionally, the Fiberglass Plain Sheet exhibits excellent thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. This not only enhances the overall comfort of the building occupants but also contributes to the sustainability and energy efficiency goals of the project. By reducing the reliance on heating and cooling systems, the Fiberglass Plain Sheet aids in minimizing the building's carbon footprint.Furthermore, the versatility of the Fiberglass Plain Sheet makes it suitable for a wide array of applications. Whether it's used for interior or exterior purposes, this material can be easily installed and provides a seamless aesthetic appeal. Its smooth, plain surface is an ideal canvas for various finishes, including paints, laminates, and coatings, allowing architects and designers to customize the appearance according to their vision.The lightweight nature of the Fiberglass Plain Sheet simplifies transportation and installation, resulting in reduced labor costs and time. In addition, its non-porous surface prevents the accumulation of dirt, moisture, or mould growth, ensuring a low-maintenance solution that retains its pristine condition over time.Manufactured in accordance with international quality standards, the Fiberglass Plain Sheet is rigorously tested to meet or exceed industry requirements. It's available in various sizes and thicknesses, providing flexibility for different project specifications. Whether it's a small-scale residential construction or a large-scale commercial development, {Company Name} guarantees reliable supply and professional support throughout the project."Through our years of industry experience, we understand the evolving needs of construction professionals," says {Company Name}'s spokesperson. "We are committed to delivering cutting-edge products that surpass expectations and contribute to the success of every project. The Fiberglass Plain Sheet is a testament to our dedication to quality, sustainability, and customer satisfaction."With its remarkable durability, versatility, and sustainable attributes, the Fiberglass Plain Sheet has the potential to become the go-to material for construction projects worldwide. As architects and contractors continue to prioritize performance, cost-efficiency, and environmental sustainability, {Company Name}'s innovative product is set to redefine the construction landscape.As the construction industry embraces change and innovation, the introduction of the Fiberglass Plain Sheet opens doors to endless possibilities. With its exceptional properties and the reliability of {Company Name}'s brand, this new construction material is poised to make a significant impact on the industry, setting new benchmarks for structural integrity, fire resistance, thermal insulation, and design possibilities.

Durable Epoxy Phenolic Glass Cloth Laminate Sheet for Various Applications

Epoxy Phenolic Glass Cloth Laminated Sheet, also known as G10, is a versatile and high-performance material that is used in a wide range of applications across various industries. G10 is a composite material made from layers of glass cloth that are impregnated with epoxy resin and then cured under high pressure and temperature. The result is a strong, durable, and heat-resistant material that is ideal for use in electrical and electronic insulation, aerospace components, and marine applications.G10 is well-known for its exceptional electrical insulation properties, making it a popular choice for use in electrical devices and equipment. It is also resistant to moisture, chemicals, and extreme temperatures, making it suitable for use in harsh and demanding environments. In addition, G10 is lightweight and has a high strength-to-weight ratio, making it an ideal material for use in aerospace and marine applications.The company {} has established itself as a leading manufacturer and supplier of high-quality G10 materials. With a strong focus on research and development, the company has been able to continuously improve the performance and reliability of their G10 products. They utilize state-of-the-art manufacturing processes and adhere to strict quality control standards to ensure that their G10 materials meet the highest industry standards.The company's G10 materials are used in a wide range of applications, including electrical insulation for transformers, switchgear, and motors, as well as structural components for aircraft, marine vessels, and industrial equipment. Their G10 materials are also used in high-performance sporting goods, such as archery bows and fishing rods, where strength, durability, and light weight are essential.In addition to their standard G10 materials, the company also offers custom fabrication services to meet the specific needs of their customers. They have the capability to produce G10 materials in a wide range of sizes, thicknesses, and colors, and can also provide machining and finishing services to create complex shapes and designs.With a commitment to innovation and customer satisfaction, the company has earned a reputation for delivering high-quality G10 materials that meet the unique needs of their customers. Their team of experienced engineers and technical experts work closely with their customers to understand their requirements and develop custom solutions that meet their exact specifications.As the demand for high-performance materials continues to grow across various industries, the company remains at the forefront of providing innovative and reliable G10 solutions. With a strong focus on quality, performance, and customer service, they are positioned to meet the evolving needs of their customers and continue to be a trusted partner for high-performance composite materials.In conclusion, Epoxy Phenolic Glass Cloth Laminated Sheet, or G10, is a versatile and high-performance material that is used in a wide range of applications across various industries. The company {} has established itself as a leading manufacturer and supplier of high-quality G10 materials, with a strong focus on research and development, custom fabrication services, and customer satisfaction. With a commitment to innovation and quality, the company remains at the forefront of providing innovative and reliable G10 solutions to meet the evolving needs of their customers.

New Resistance Sheet: The Latest in Resistance Training Technology

Resistance Sheet, a leading provider of innovative technology solutions, has recently announced the launch of their newest product, the Resistance Sheet Pro. This cutting-edge product is designed to revolutionize the way individuals and businesses approach fitness and training.The Resistance Sheet Pro is a high-quality, durable resistance band that can be used for a wide range of exercises, including strength training, flexibility exercises, and physical therapy. Its unique design and construction make it the perfect choice for individuals of all fitness levels, from beginners to fitness enthusiasts.One of the key features of the Resistance Sheet Pro is its versatility. The band can be easily adjusted to provide different levels of resistance, making it suitable for a variety of exercises and training routines. Its compact and portable design also makes it ideal for use at home, in the gym, or while traveling.In addition to its practical design, the Resistance Sheet Pro is also equipped with a range of features that set it apart from traditional resistance bands. These include built-in sensors that can track performance and provide real-time feedback, as well as a companion app that offers a wide range of guided workouts and training programs."We are thrilled to introduce the Resistance Sheet Pro to the market," said [Company CEO]. "This product represents the culmination of years of research and development, and we believe it has the potential to revolutionize the way people approach their fitness and training goals."In addition to its innovative features, the Resistance Sheet Pro is also backed by [Company]'s commitment to quality and customer satisfaction. The company is known for its exceptional customer service and dedication to producing high-quality products that stand the test of time.As part of the launch of the Resistance Sheet Pro, [Company] is offering a range of special promotions and discounts to customers. This includes the opportunity to pre-order the product at a discounted rate, as well as special bundles that include additional accessories and training materials.With the launch of the Resistance Sheet Pro, [Company] continues to solidify its position as a leader in the fitness and technology industries. The company's dedication to innovation and quality has earned it a strong reputation among customers and industry professionals alike.As the fitness and wellness industries continue to evolve, [Company] remains at the forefront of new developments, consistently striving to provide cutting-edge solutions that help individuals and businesses achieve their health and fitness goals.For more information about the Resistance Sheet Pro and other products offered by [Company], please visit their website or contact their customer service team.

Quality Phenolic Resin Sheet Suppliers - Find the Top Suppliers for Your Needs

Phenolic Resin Sheet Suppliers, a leading supplier of high-quality phenolic resin sheets, recently announced the launch of their new line of innovative products designed to meet the growing demand for high-performance materials in various industries. With a strong focus on quality and customer satisfaction, Phenolic Resin Sheet Suppliers has become a trusted name in the industry, offering a wide range of solutions for industrial and commercial applications.Founded in [Year], [Company Name] has quickly established itself as a reliable and innovative supplier of phenolic resin sheets, serving a diverse customer base across the globe. The company prides itself on its commitment to quality, innovation, and customer service, and has earned a strong reputation for delivering top-notch products and solutions tailored to meet the specific needs of its customers.Phenolic resin sheets are widely used in a variety of applications, including electrical insulators, thermal insulation, and structural components, due to their excellent mechanical, electrical, and thermal properties. [Company Name] has recognized the growing demand for high-quality phenolic resin sheets and has invested in research and development to create a new line of products that meet the evolving needs of its customers.One of the key features of the new product line is its enhanced durability and resistance to harsh environmental conditions, making it ideal for use in demanding industrial and commercial settings. The company's commitment to quality is evident in the rigorous testing and quality control measures that are implemented throughout the manufacturing process, ensuring that each product meets the highest standards of performance and reliability.In addition to its focus on quality, Phenolic Resin Sheet Suppliers is also dedicated to providing exceptional customer service, offering personalized solutions and support to help customers find the right products for their specific needs. The company's team of experienced professionals is readily available to provide technical expertise and guidance, ensuring that customers can make informed decisions and achieve the best possible outcomes for their projects.As the demand for high-performance materials continues to grow, [Company Name] is well-positioned to meet the needs of its customers with its comprehensive range of phenolic resin sheets and related products. The company's dedication to innovation and quality, combined with its customer-centric approach, sets it apart as a leader in the industry, and it is poised to continue making significant contributions to the advancement of material science and technology.For more information about Phenolic Resin Sheet Suppliers and its range of products and solutions, visit their website at [Website], where customers can explore the company's offerings and connect with their team to discuss their specific requirements. With a solid track record of delivering excellence and a strong commitment to customer satisfaction, Phenolic Resin Sheet Suppliers is a trusted partner for businesses seeking high-quality phenolic resin sheets and related products.

Innovative Glass Fiber Laminate Sheet: Unveiling a Revolutionary Material

Title: Revolutionizing the Industry: Cutting-edge Glass Fiber Laminate Sheet UnveiledIntroduction (80 words):In a major breakthrough, a pioneering company has introduced the Epgc203 Glass Fiber Laminate Sheet, an innovative product set to revolutionize numerous industries. This ground-breaking material is poised to offer unmatched durability, superior strength, and exceptional versatility, making it a game-changer in the market. This transformative product opens up a world of possibilities for various sectors, ensuring improved performance and enhancing the overall quality of end products. Let's delve into the features, applications, and potential impact of this glass fiber laminate sheet.Body:1. The Evolution of Epgc203 Glass Fiber Laminate Sheet (120 words):The Epgc203 Glass Fiber Laminate Sheet is a result of cutting-edge research and development, incorporating the latest advancements in material sciences. Meticulously engineered, this state-of-the-art composite combines the robustness of glass fiber reinforcement with a resin matrix, exhibiting superior mechanical and electrical properties. Its exceptional thermal stability coupled with its insulating properties makes it an optimum choice for various applications. The product is specifically formulated to offer increased resistance against chemicals, moisture, and extreme temperatures, making it suitable for demanding environments.2. Unleashing the Versatility (120 words):The Epgc203 Glass Fiber Laminate Sheet is designed to cater to diverse industries and applications. From industrial equipment and electrical components to aerospace and automotive sectors, this innovative product is hailed for its remarkable versatility. Its high strength-to-weight ratio ensures superior load-bearing capabilities while reducing overall product weight. The glass fiber laminate sheet further enhances structural integrity, offering a cost-effective alternative to traditional materials. Manufacturers can now explore new designs and applications, thanks to the unparalleled flexibility of this game-changing material.3. Advantages of Epgc203 Glass Fiber Laminate Sheet (120 words):This ground-breaking glass fiber laminate sheet brings a plethora of benefits for end-users and manufacturers. The exceptional durability and resistance of this material ensure longevity and reduced maintenance costs. Moreover, the insulating properties of the laminate sheet provide enhanced safety for electrical applications. The material exhibits remarkable dimensional stability, ensuring that end products maintain their intended shape and structural integrity over time. Its unique composition allows for streamlined fabrication processes, saving manufacturers both time and resources. The Epgc203 Glass Fiber Laminate Sheet thus unlocks a competitive edge in the market and increases overall product reliability.4. Applications in various Industries (160 words):With its vast array of properties, the Epgc203 Glass Fiber Laminate Sheet has found applications in multiple industries. In the electrical sector, the material is ideal for circuit boards, insulators, and electrical panels due to its exceptional electrical insulation properties. In aerospace, it serves as a reliable and lightweight material for aircraft interiors, cabin components, and structural elements. The automotive industry has also embraced the laminate sheet for designing engine components, interior trims, and panels, thanks to its excellent mechanical properties. Its resistance to chemicals and moisture make it a preferred choice for various industrial equipment and machinery. Additionally, the construction industry benefits from this laminate sheet's weather resistance and structural reinforcement capabilities.Conclusion (100 words):The introduction of Epgc203 Glass Fiber Laminate Sheet has ushered in a new era of possibilities for multiple sectors. Its unrivaled strength, durability, and versatility have found application in various key industries, propelling innovation and change. The benefits offered by this game-changing material are set to reshape manufacturing processes, optimize performance, and deliver cost-effective solutions. As manufacturers embrace this groundbreaking product, we anticipate significant advancements in engineering designs, improved product reliability, and enhanced safety standards. Epgc203 Glass Fiber Laminate Sheet has undoubtedly set a new benchmark in the industry, setting the stage for future developments and pushing boundaries in the world of composite materials.

New Study Finds Alarming Trends in EPGC203 Sheet Usage

ABC Company, a leading manufacturer in the electrical insulation industry, has recently launched a new product, Epgc203 Sheet, designed to meet the growing demand for high-performance insulation materials in various industrial applications. The company has long been recognized for its commitment to innovation and quality, and the introduction of the Epgc203 Sheet is a testament to their dedication to providing cutting-edge solutions to their customers.The Epgc203 Sheet is a high-pressure, thermosetting industrial laminate that offers exceptional electrical insulation properties, mechanical strength, and thermal performance. It is specifically engineered for applications that require reliable and durable insulation, such as electrical equipment, switchgear, transformers, and other industrial machinery. The sheet is made of high-quality insulating kraft paper and epoxy resin, which are compressed and heated to form a rigid laminate material that can withstand high temperatures and harsh environmental conditions.With the increasing demand for advanced insulation materials in the industrial sector, ABC Company has invested significant resources in research and development to create the Epgc203 Sheet, which represents a breakthrough in insulation technology. The company has leveraged its extensive expertise in materials science and engineering to develop a product that exceeds industry standards and offers superior performance in demanding applications."We are thrilled to introduce the Epgc203 Sheet to the market, as it embodies our commitment to delivering innovative solutions that meet the evolving needs of our customers," said [Company Spokesperson]. "This new product showcases our dedication to pushing the boundaries of insulation technology and providing our clients with reliable, high-performance materials that contribute to the efficiency and safety of their operations."In addition to its outstanding electrical insulation properties, the Epgc203 Sheet also offers excellent mechanical strength, impact resistance, and dimensional stability, making it an ideal choice for critical applications where reliability and longevity are paramount. Its superior thermal performance allows it to withstand temperature extremes without compromising its insulating capabilities, providing added peace of mind for end-users in challenging environments.Furthermore, the Epgc203 Sheet is designed with ease of fabrication in mind, allowing for seamless integration into existing manufacturing processes. Its versatility and adaptability make it a cost-effective solution for companies looking to enhance the performance and reliability of their products and equipment.As a company committed to sustainability and environmental responsibility, ABC Company has ensured that the Epgc203 Sheet is manufactured with the highest standards of quality and compliance. The materials used in its production are sourced responsibly, and the manufacturing process is optimized for minimal waste and energy efficiency, aligning with the company's broader initiatives to minimize its environmental footprint.The introduction of the Epgc203 Sheet represents a significant milestone for ABC Company, solidifying its position as a leader in the electrical insulation industry. By staying at the forefront of innovation and investing in new product development, the company continues to provide value and support to its customers, helping them achieve their operational objectives with confidence and peace of mind.As the demand for high-performance insulation materials continues to grow across various industries, ABC Company remains committed to meeting the evolving needs of its customers and providing them with reliable, cutting-edge solutions for their insulation challenges. With the Epgc203 Sheet, the company has once again demonstrated its ability to innovate and deliver products that set new benchmarks for quality, performance, and reliability in the industrial insulation sector.

Durable Antistatic G10 Epoxy Laminated Sheet: A Comprehensive Guide

Epoxy Laminated Sheet Antistatic G10 - The Next Innovation in Electrical Insulation TechnologyIn the world of electrical insulation materials, one product has been making waves for its cutting-edge technology and innovative design - Epoxy Laminated Sheet Antistatic G10. This revolutionary material is changing the game for electrical insulation, offering a range of benefits and features that are setting a new standard for the industry.Insulation materials are crucial for the safe and efficient operation of electrical equipment and systems. They prevent electrical current from flowing through unintended paths, which can cause malfunctions, equipment damage, and even electrical hazards. However, not all insulation materials are created equal, and the need for better, more advanced solutions is constantly growing. This is where Epoxy Laminated Sheet Antistatic G10 comes into play.First and foremost, Epoxy Laminated Sheet Antistatic G10 is known for its excellent anti-static properties. This means that it effectively prevents the build-up of static electricity, which can be a major concern in electrical systems and equipment. By using this material, manufacturers can ensure that their products are resistant to static discharge, reducing the risk of damage and enhancing the overall safety and reliability of the electrical systems.Moreover, Epoxy Laminated Sheet Antistatic G10 offers exceptional mechanical and electrical properties. It is extremely strong and durable, with high tensile strength and excellent resistance to heat, moisture, and chemicals. This makes it an ideal choice for a wide range of applications, from electrical insulation in motors, generators, and transformers to structural components in aerospace, automotive, and marine industries. Its high dielectric strength and low water absorption also contribute to its superior performance in demanding environments.In addition to its technical capabilities, Epoxy Laminated Sheet Antistatic G10 is also environmentally friendly. It is made from non-toxic and sustainable materials, and its production process is designed to minimize waste and energy consumption. By choosing this material, companies can demonstrate their commitment to sustainability and responsible manufacturing practices, aligning with the global trend towards greener and cleaner technologies.The company behind Epoxy Laminated Sheet Antistatic G10 is a leading provider of advanced materials and solutions for a wide range of industries. With a long history of innovation and expertise in material science, they have developed a strong reputation for delivering high-quality products that meet the most demanding technical requirements. Their relentless pursuit of excellence and continuous investment in research and development have enabled them to stay ahead of the curve and make significant contributions to the advancement of various industries.Furthermore, the company is dedicated to customer satisfaction and collaboration. They work closely with their clients to understand their specific needs and challenges, providing tailored solutions that address their unique requirements. Whether it's developing custom formulations, optimizing production processes, or offering technical support, the company is committed to building long-term partnerships and adding value to their customers' businesses.Looking ahead, the future of Epoxy Laminated Sheet Antistatic G10 and the company behind it is bright. With ongoing innovation and a relentless pursuit of excellence, they are well-positioned to continue leading the way in the development of advanced materials and solutions for the ever-evolving needs of the industry. As technology advances and new challenges emerge, companies can rely on Epoxy Laminated Sheet Antistatic G10 to deliver the performance, reliability, and sustainability they need to succeed.In conclusion, Epoxy Laminated Sheet Antistatic G10 represents a significant advancement in electrical insulation technology. Its unique combination of anti-static properties, exceptional mechanical and electrical performance, and environmental sustainability makes it a standout choice for a wide range of applications. With the expertise and dedication of the company behind it, Epoxy Laminated Sheet Antistatic G10 is set to make a lasting impact on the industry, driving progress and innovation for years to come.

High-quality Phenolic Resin Board: A Durable and Versatile Building Material

The Phenolic Resin Board Market is expected to witness significant growth in the coming years. Phenolic resin boards are known for their durability, high-temperature resistance, and excellent mechanical properties, making them ideal for a wide range of applications in industries such as construction, transportation, and electronics.One of the leading companies in the production of Phenolic resin boards is {Company Name}, a global leader in the chemical industry. {Company Name} has established itself as a trusted provider of high-quality Phenolic resin boards, offering a wide range of products to meet the diverse needs of its customers.The company's Phenolic resin boards are manufactured using advanced technology and stringent quality control measures to ensure superior performance and reliability. With a strong focus on research and development, {Company Name} continues to innovate and improve its Phenolic resin board products to meet the evolving requirements of various industries.{Company Name} takes pride in its commitment to sustainability and environmental responsibility. The company has implemented eco-friendly production practices and actively seeks to minimize its environmental footprint. This dedication to sustainability has earned {Company Name} a strong reputation as a responsible and ethical producer of Phenolic resin boards.As the demand for durable and high-performance materials continues to grow, {Company Name} is well-positioned to capitalize on the opportunities in the Phenolic resin board market. The company's extensive experience and proven track record in the industry make it a preferred choice for customers seeking reliable and innovative Phenolic resin board solutions.In addition to its commitment to quality and sustainability, {Company Name} also places a strong emphasis on customer satisfaction. The company's dedicated team of professionals works closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. This customer-centric approach has earned {Company Name} a loyal and satisfied customer base.The global Phenolic resin board market is projected to experience robust growth in the coming years, driven by increasing demand from key industries such as construction, automotive, and electronics. {Company Name} is well-equipped to capitalize on this growth, owing to its extensive product range, technological expertise, and commitment to excellence.With a strong focus on innovation and continuous improvement, {Company Name} is poised to maintain its leadership position in the Phenolic resin board market. The company's relentless pursuit of excellence, coupled with its uncompromising commitment to quality and customer satisfaction, sets it apart as a preferred partner for businesses seeking reliable and high-performance Phenolic resin board solutions.The future looks promising for the Phenolic resin board market, and {Company Name} is poised to play a pivotal role in driving the industry forward. With its unwavering dedication to quality, innovation, and customer satisfaction, {Company Name} is set to make a significant impact on the global Phenolic resin board market in the years to come.

Durable Fiberglass Laminated Sheet for Various Applications

For immediate releaseThe 3240 Fiberglass Laminated Sheet, recently launched by {company name}, is set to revolutionize the fiberglass laminated sheet industry. These high-quality sheets are ideal for a range of applications, including electrical insulation, mechanical processing, and construction.The 3240 Fiberglass Laminated Sheet is a high-performance electrical insulation material made from electrical non-alkali glass cloth impregnated with an epoxy resin. These sheets are manufactured using a hot press process, ensuring a uniform thickness and excellent mechanical properties. This makes them highly resistant to heat, mechanical stress, and electric stress, making them an ideal choice for electrical insulation applications.In addition to their outstanding electrical insulation properties, the 3240 Fiberglass Laminated Sheets also boast excellent flame resistance and mechanical strength. This combination of properties makes them ideal for use in a wide range of applications, including as structural components in electrical equipment, as well as in construction and mechanical processing.{Company name} has been a leading manufacturer of electrical insulation materials for over [number] years. Their commitment to quality and innovation has enabled them to develop a range of products that meet the highest industry standards. The 3240 Fiberglass Laminated Sheet is the latest addition to their portfolio, and it is set to become a game-changer in the industry.The launch of the 3240 Fiberglass Laminated Sheet is a testament to {company name}'s dedication to providing innovative solutions to their customers. In addition to their outstanding performance, these sheets are also available in a range of sizes and thicknesses, making them suitable for a wide range of applications.{Company name} is committed to providing their customers with the best products and services. They have a team of dedicated professionals who are available to provide technical support and assistance, ensuring that their customers are able to make the most of the 3240 Fiberglass Laminated Sheet in their applications.The 3240 Fiberglass Laminated Sheet is now available for purchase, and customers can contact {company name} for more information on pricing and availability. With its outstanding electrical insulation properties, flame resistance, and mechanical strength, it is set to become the go-to choice for customers in the electrical insulation, construction, and mechanical processing industries.{Company name} is excited about the launch of the 3240 Fiberglass Laminated Sheet and is confident that it will be well-received by their customers. With its outstanding performance and versatility, it is set to become a staple in the industry, further cementing {company name}'s position as a leading manufacturer of electrical insulation materials.For more information about the 3240 Fiberglass Laminated Sheet and other products offered by {company name}, please visit their website or contact their team directly. With their commitment to quality and innovation, {company name} is well-positioned to meet the needs of their customers and provide them with the best possible solutions for their applications.