Durable Fiber Insulation Board: A Strong and Reliable Insulation Solution

By:Admin

Fiber Insulation Board, a leading manufacturer in the insulation industry, has announced their latest innovation in fiber insulation technology. The company has introduced a new, high-performance fiber insulation board that is set to revolutionize the market. With its advanced thermal properties and sustainable materials, this new product is expected to make a significant impact on the industry.

The Fiber Insulation Board is made from natural fibers that are sourced from sustainable forests. This renewable resource not only makes the insulation board an environmentally friendly option, but also provides superior insulation properties. The new product is designed to provide exceptional thermal performance, reducing heat loss and energy consumption in buildings.

The company spokesperson stated, "We are excited to introduce this innovative fiber insulation board to the market. With our commitment to sustainability and energy efficiency, we believe that this product will meet the growing demand for high-performance insulation solutions."

In addition to its exceptional thermal properties, the Fiber Insulation Board is also fire-resistant and incorporates soundproofing features. This makes it an ideal choice for a wide range of applications, including residential, commercial, and industrial buildings. The product's versatility and durability provide a practical solution for architects, builders, and contractors.

For a company that has been at the forefront of the insulation industry for over two decades, this latest innovation demonstrates their continued dedication to developing cutting-edge products. The company's relentless pursuit of technological advancements has positioned them as a leader in the market. Their commitment to quality, reliability, and sustainability has earned the trust and loyalty of customers worldwide.

Established in {}, the company has grown rapidly and expanded its market presence through strategic partnerships and investments in research and development. Their state-of-the-art manufacturing facilities ensure that their products meet the highest industry standards, while their experienced team of engineers and technicians consistently strive for excellence.

The Fiber Insulation Board is the latest addition to the company's extensive product line, which includes a wide range of insulation solutions for various applications. Their dedication to innovation and customer satisfaction has made them a preferred choice for industry professionals seeking reliable and cost-effective insulation products.

As the demand for energy-efficient and sustainable building materials continues to rise, the introduction of the Fiber Insulation Board is a timely and significant milestone for the company. With its unique blend of performance, sustainability, and reliability, the product is poised to capture a larger share of the market and set new industry standards.

The company spokesperson further added, "We are confident that the Fiber Insulation Board will exceed the expectations of our customers and provide them with a superior insulation solution. Our team's hard work and dedication have made this innovation possible, and we are excited to see the positive impact it will have on the industry."

With a strong commitment to innovation and sustainability, Fiber Insulation Board is well-positioned to meet the evolving needs of the industry and provide customers with high-quality insulation solutions. As they continue to expand their market presence and introduce new technologies, the company is set to maintain its leadership position in the industry.

Company News & Blog

New G10 Sheet Revealed: An Innovative Material With Endless Applications

G10 Sheet, a leading manufacturer of advanced materials for the aerospace and defense industries, has recently announced a breakthrough in the development of a new composite material that promises to revolutionize the way aircraft and military vehicles are built.The new composite material, which has been in development for the past five years, is a result of G10 Sheet's commitment to innovation and excellence in materials engineering. This groundbreaking material is expected to be lighter, stronger, and more durable than any other existing material currently used in the aerospace and defense industries.The key to this new composite material's exceptional properties lies in its unique combination of [INSERT KEY FEATURES]. This innovative approach to material design has the potential to significantly reduce the weight of aircraft and military vehicles, improving fuel efficiency and increasing their overall performance.In addition to its lightweight and high-strength properties, the new composite material is also highly resistant to corrosion, heat, and other environmental factors. This makes it an ideal choice for use in extreme conditions, such as those experienced by aircraft and military vehicles in combat situations.The development of this new composite material represents a significant milestone in G10 Sheet's ongoing commitment to advancing the field of materials engineering. The company has a long history of developing cutting-edge materials for the aerospace and defense industries, and this latest innovation further solidifies its reputation as a leader in the field.G10 Sheet's expertise in materials engineering can be attributed to its state-of-the-art research and development facilities, as well as its team of highly skilled engineers and scientists. The company's dedication to pushing the boundaries of materials science has led to a number of breakthroughs in recent years, and the development of this new composite material is just the latest example of G10 Sheet's commitment to excellence.With this new composite material, G10 Sheet aims to provide its customers in the aerospace and defense industries with a game-changing solution that will help them improve the performance and efficiency of their products. The company is confident that this innovative material will open up new possibilities for the design and construction of aircraft and military vehicles, ultimately leading to safer and more advanced technologies.In light of this exciting announcement, G10 Sheet is poised to play a key role in shaping the future of the aerospace and defense industries. The company's dedication to pushing the boundaries of materials engineering and its track record of success make it a trusted partner for industry leaders seeking to stay at the forefront of technological advancements.As G10 Sheet continues to expand its portfolio of advanced materials, it is clear that the company will remain a driving force in the ongoing evolution of the aerospace and defense industries. With its commitment to excellence and its relentless pursuit of innovation, G10 Sheet is well-positioned to lead the way in developing the next generation of materials that will power the aircraft and military vehicles of the future.

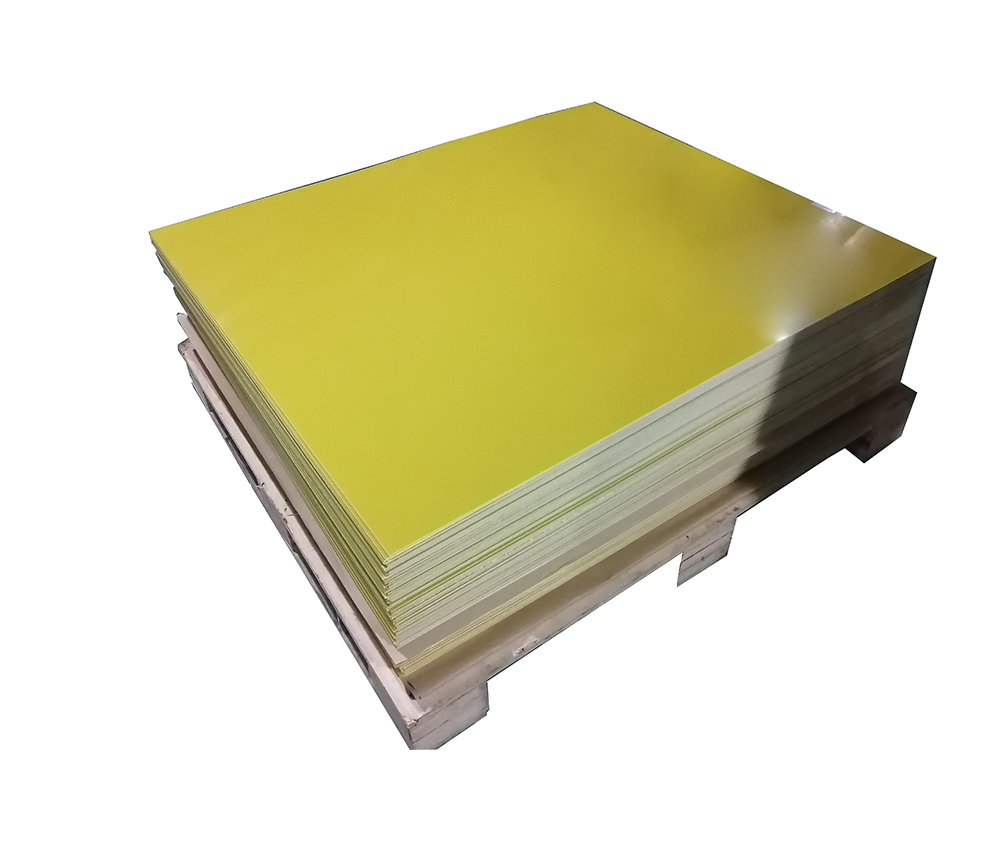

High Quality Epoxy Resin Glass Fiber Sheet for Mechanical and Electrical Insulation

G10 Glass Fiber Reinforced Sheet: The Versatile Insulation MaterialInsulation materials are used in a variety of applications, from mechanical and electrical equipment to buildings and homes. Insulation materials serve to maintain a certain temperature or environment, prevent unwanted heat or cold transfer, and protect equipment from damage. G10 Glass Fiber Reinforced Sheet is one such insulation material that is widely used due to its high mechanical and electrical properties, good heat resistance and humidity resistance. In this blog, we will discuss G10 Glass Fiber Reinforced Sheet and its applications.What is G10 Glass Fiber Reinforced Sheet?G10 Glass Fiber Reinforced Sheet is an insulating material made by using fiberglass cloth and heat resistant epoxy resin. The glass fiber cloth used in G10 is non-alkali, and it is impregnated with epoxy resin by hot pressing. The resulting material has high mechanical and electrical properties, good heat resistance and humidity resistance. G10 Glass Fiber Reinforced Sheet is known for its high strength, durability, and excellent dielectric properties. It is available in different sizes and thicknesses to suit various applications.Applications of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet is widely used in mechanical, electronic, and electrical equipment, insulation parts, and components. It is also used in the construction industry as a structural material. Below are the top applications of G10 Glass Fiber Reinforced Sheet:1. Electrical equipment insulation: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical equipment such as transformers, electric motors, and generators.2. Circuit board substrates: G10 Glass Fiber Reinforced Sheet is used as the substrate material for printed circuit boards. It provides excellent stability and mechanical strength to the circuit board.3. Mechanical parts and components: G10 Glass Fiber Reinforced Sheet is used to make parts and components of machinery and equipment. It provides excellent mechanical properties such as high strength and toughness.4. Aerospace industry: G10 Glass Fiber Reinforced Sheet is used in the aerospace industry to make parts for aircraft and spacecraft. It provides excellent strength and durability under extreme conditions.5. Marine industry: G10 Glass Fiber Reinforced Sheet is used in the marine industry as a material for boat hulls, decks, and other structural components. It is highly resistant to water and moisture, making it an ideal material for marine applications.Advantages of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet has several advantages over other insulation materials, such as:1. High strength and durability: G10 Glass Fiber Reinforced Sheet has high mechanical properties, making it ideal for use in high-stress applications that require strength and durability.2. Excellent electrical insulation properties: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical and electronic applications.3. Good heat resistance: G10 Glass Fiber Reinforced Sheet is resistant to high temperatures, which makes it suitable for use in high-temperature applications.4. Resistance to moisture and chemicals: G10 Glass Fiber Reinforced Sheet is highly resistant to moisture and chemicals, making it ideal for use in harsh environments.ConclusionG10 Glass Fiber Reinforced Sheet is a versatile insulation material that has several advantages over other insulation materials. Its high mechanical and electrical properties, good heat resistance, and humidity resistance make it ideal for use in a variety of applications. Its applications include electrical equipment insulation, circuit board substrates, mechanical parts and components, aerospace industry, and marine industry. If you are looking for an insulation material that offers high strength, durability, and excellent dielectric properties, G10 Glass Fiber Reinforced Sheet is an excellent choice.

Laminate Sheet and Insulation EPGC203: Everything You Need to Know

China Laminate Sheet and Insulation EPGC203 Becoming Popular Choice for Industry UseAs the demand for high-quality electrical insulation materials continues to rise, the China Laminate Sheet and Insulation EPGC203 has emerged as a popular choice for industries looking for reliable and efficient solutions. With its superior insulation properties and durability, this product has quickly gained a reputation as a top-performing material in various applications.The China Laminate Sheet and Insulation EPGC203 is a composite material made from layers of cellulose paper or glass fibers bonded together with a high-temperature-resistant epoxy resin. This combination of materials gives the EPGC203 exceptional thermal and electrical insulation properties, making it ideal for use in electrical equipment, such as transformers, motors, and generators, as well as in a variety of other industrial applications.One of the key advantages of the China Laminate Sheet and Insulation EPGC203 is its ability to withstand high temperatures, making it suitable for use in harsh operating conditions. This high-temperature resistance ensures that the material can maintain its structural integrity and insulation properties even under extreme heat, making it a reliable choice for demanding industrial environments.Additionally, the EPGC203 offers excellent electrical insulation properties, helping to prevent electrical failures and breakdowns in equipment. This is crucial for ensuring the safety and reliability of electrical systems, making the EPGC203 an invaluable material for manufacturers and operators in a wide range of industries.The China Laminate Sheet and Insulation EPGC203 also boasts impressive mechanical strength, providing excellent resistance to impact, vibration, and mechanical stress. This makes it a durable and long-lasting material, able to withstand the rigors of industrial use while maintaining its insulation and protective properties.In addition to its performance capabilities, the EPGC203 is also known for its ease of processing and installation. This allows for efficient and cost-effective manufacturing and assembly processes, saving time and resources for industrial users.One company that has been at the forefront of providing high-quality China Laminate Sheet and Insulation EPGC203 is {}. With years of experience and expertise in the production and distribution of electrical insulation materials, {} has established itself as a leading supplier of the EPGC203 to industries worldwide.{} has consistently demonstrated a commitment to delivering top-notch products and services, ensuring that industrial customers have access to the best materials for their specific needs. By partnering with reputable manufacturers and employing stringent quality control measures, {} has been able to meet the high standards and demands of the industry, earning a solid reputation for reliability and excellence.Through its dedication to innovation and customer satisfaction, {} has played a significant role in promoting the adoption of the China Laminate Sheet and Insulation EPGC203 across various sectors, from power generation and distribution to transportation and manufacturing.As the demand for high-performance electrical insulation materials continues to grow, the China Laminate Sheet and Insulation EPGC203 is poised to remain a preferred choice for industries seeking reliable, durable, and efficient solutions for their insulation needs. With the support of leading suppliers like {}, the EPGC203 is set to make a lasting impact in the industrial landscape, driving progress and advancement in electrical insulation technology.

Durable Fiberglass Laminated Sheet: A Versatile Building Material

The 3240 Fiberglass Laminated Sheet is a versatile material that has become an essential component for various industries. The sheet, manufactured by a leading company in the field of electrical insulation materials, is widely used in applications such as electrical motors, transformers, and other electrical equipment. With its excellent mechanical properties, electrical insulation performance, and high-temperature resistance, the 3240 Fiberglass Laminated Sheet has established itself as a reliable and cost-effective solution for the most demanding applications.The 3240 Fiberglass Laminated Sheet is made from electrical grade fiberglass cloth impregnated with a high-temperature resistant resin. The combination of these materials provides the sheet with outstanding mechanical strength and electrical insulation properties. The sheet is also known for its excellent heat resistance, making it suitable for use in high-temperature environments. Additionally, the 3240 Fiberglass Laminated Sheet is highly resistant to moisture, chemicals, and solvents, further enhancing its durability and reliability.The [Company Name] is a renowned manufacturer and supplier of electrical insulation materials, with a strong focus on providing innovative solutions to meet the evolving needs of the industry. The company has a wealth of experience in the development and production of high-quality fiberglass laminated sheets, and its products are trusted by customers worldwide. With a commitment to excellence and a dedication to research and development, the [Company Name] continues to lead the way in the field of electrical insulation materials.In addition to the 3240 Fiberglass Laminated Sheet, the [Company Name] offers a wide range of products designed to meet the diverse needs of its customers. From rigid laminates to flexible insulation materials, the company's product portfolio encompasses a variety of solutions for different applications. The [Company Name] also provides customized products and technical support to ensure that its customers receive the most suitable insulation materials for their specific requirements.The 3240 Fiberglass Laminated Sheet has been widely adopted in the electrical and electronics industry due to its exceptional performance and reliability. Its use in electrical motors and transformers has contributed to the efficient and safe operation of these critical components. The sheet's ability to withstand high temperatures and harsh environments makes it an ideal choice for applications where reliability is paramount.Moreover, the 3240 Fiberglass Laminated Sheet has found applications beyond the electrical industry. It is used in a variety of mechanical and structural applications where its combination of strength, insulation, and temperature resistance is highly valued. From industrial equipment to automotive components, the sheet's versatility has made it a popular choice across different sectors.With a commitment to quality and innovation, the [Company Name] continues to push the boundaries of what is possible in the field of electrical insulation materials. The company's dedication to meeting the ever-changing needs of its customers has solidified its position as a trusted partner in the industry. By offering cutting-edge solutions such as the 3240 Fiberglass Laminated Sheet, the [Company Name] is helping to drive progress and efficiency in various sectors.In conclusion, the 3240 Fiberglass Laminated Sheet, manufactured by the [Company Name], stands as a testament to the company's dedication to excellence and innovation. Its exceptional performance and versatility have made it an indispensable material for a wide range of applications. As the [Company Name] continues to lead the way in the development of electrical insulation materials, the 3240 Fiberglass Laminated Sheet remains a key component in the advancement of various industries.

High-quality Fiberglass Composite Sheets for Various Applications

Fiberglass Composite Sheets have become an essential material in a wide range of industries, including construction, automotive, aerospace, and marine. These highly versatile sheets are known for their excellent strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for various applications.One prominent company leading the way in the production of Fiberglass Composite Sheets is [Company Name]. Specializing in the manufacturing of advanced composites, [Company Name] has established itself as a trusted provider of high-quality fiberglass materials that meet the stringent requirements of the industry.Established [X] years ago, [Company Name] has continually invested in cutting-edge technology and research to develop innovative composite solutions. With a state-of-the-art manufacturing facility and a team of experienced engineers and scientists, the company has been able to stay ahead of the curve in the rapidly evolving composites industry.One of the key offerings of [Company Name] is its range of Fiberglass Composite Sheets, which are designed to deliver exceptional performance in demanding environments. These sheets are manufactured using a combination of high-quality fiberglass reinforcement and a specialized resin matrix, resulting in a material that offers superior mechanical properties and resistance to harsh conditions.The Fiberglass Composite Sheets offered by [Company Name] are widely used in the construction industry for applications such as roofing, cladding, and wall panels. Their high strength and lightweight nature make them an ideal choice for building materials, providing durability and longevity to structures.In the automotive and aerospace sectors, [Company Name]'s Fiberglass Composite Sheets are utilized in the production of various components, including interior panels, exterior body parts, and structural reinforcements. The excellent impact resistance and structural integrity of these sheets make them crucial for ensuring the safety and performance of vehicles and aircraft.Moreover, the marine industry relies on Fiberglass Composite Sheets for applications such as boat hulls, decks, and components due to their unparalleled resistance to water, chemicals, and environmental factors. [Company Name] has been a trusted supplier to boat manufacturers, offering composite solutions that withstand the rigors of marine environments.With a commitment to quality and innovation, [Company Name] ensures that its Fiberglass Composite Sheets meet the highest industry standards and certifications. The company's dedication to research and development enables it to continually improve the performance and capabilities of its composites, staying at the forefront of technological advancements.In addition to its primary product offerings, [Company Name] provides custom solutions for specific needs, working closely with clients to develop tailored composite materials that meet their unique requirements. This flexibility and customer-centric approach have set [Company Name] apart as a preferred partner for businesses seeking reliable composite solutions.As the demand for lightweight, high-performance materials continues to rise across various industries, Fiberglass Composite Sheets have emerged as a vital asset for manufacturers and builders. With [Company Name] leading the way in the production of advanced composites, the future looks promising for the widespread adoption of these versatile materials in diverse applications.In conclusion, Fiberglass Composite Sheets have demonstrated their value in delivering exceptional performance and durability across multiple industries, and [Company Name] has played a crucial role in advancing the capabilities of these materials. With a strong focus on research, innovation, and customer satisfaction, [Company Name] is poised to remain a key player in the composites industry, providing high-quality solutions that meet the evolving needs of the market.

High-quality Epoxy Glass Cloth Laminated for Diverse Applications

Egpc308 Epoxy Glass Cloth Laminated is a type of material that has revolutionized the manufacturing industry. This laminated material, also known as FR-4, is widely used in a variety of applications due to its strong and durable properties. With its excellent electrical, mechanical, and thermal capabilities, Egpc308 Epoxy Glass Cloth Laminated has become a go-to material for a wide range of industries including aerospace, automotive, electronics, and telecommunications.One of the leading companies that produce Egpc308 Epoxy Glass Cloth Laminated is a global leader in advanced materials and manufacturing solutions. With a strong focus on innovation and quality, the company has been at the forefront of developing cutting-edge materials for various industries. The company's commitment to research and development has enabled them to create high-performance materials that meet the evolving needs of the market.Egpc308 Epoxy Glass Cloth Laminated is a crucial component in the manufacturing process of printed circuit boards (PCBs). Its high mechanical strength and excellent electrical properties make it an ideal substrate for PCBs, allowing for efficient and reliable electronic connections. In addition, the material's ability to withstand high temperatures, chemical exposure, and moisture makes it suitable for use in harsh operating environments.Moreover, Egpc308 Epoxy Glass Cloth Laminated is also widely used in the aerospace industry for its lightweight and fire-resistant properties. It is a preferred material for aircraft components such as radomes, antennas, and structural parts due to its high strength-to-weight ratio and ability to resist fuel and hydraulic fluids. Furthermore, its thermal stability and low dielectric constant make it suitable for microwave and RF applications.In the automotive industry, Egpc308 Epoxy Glass Cloth Laminated is used in various electrical and mechanical components. Its ability to maintain its properties under high mechanical and thermal stress makes it an ideal material for battery housings, engine covers, and other critical automotive parts. Furthermore, its flame-retardant properties make it a safe and reliable material for use in electric vehicle applications.The telecommunications industry also benefits from the use of Egpc308 Epoxy Glass Cloth Laminated in the manufacturing of communication equipment and infrastructure. The material's high electrical insulation and flame-retardant properties make it an ideal choice for use in high-frequency and high-speed communication systems.In addition to its widespread use in various industries, Egpc308 Epoxy Glass Cloth Laminated is also an environmentally friendly material. It is manufactured using a process that minimizes waste and reduces energy consumption, making it a sustainable choice for manufacturers looking to reduce their environmental impact.With the growing demand for high-performance materials in the manufacturing industry, the production and use of Egpc308 Epoxy Glass Cloth Laminated are expected to continue to rise. As industries continue to push the boundaries of innovation and technology, the need for reliable and durable materials like Egpc308 Epoxy Glass Cloth Laminated will only increase.In conclusion, Egpc308 Epoxy Glass Cloth Laminated is a versatile and durable material that has become an essential component in various industries. With its exceptional electrical, mechanical, and thermal properties, it is a preferred choice for applications in aerospace, automotive, electronics, and telecommunications. As the demand for high-performance materials continues to grow, Egpc308 Epoxy Glass Cloth Laminated is set to play a vital role in shaping the future of manufacturing and technology. The company's commitment to innovation and quality has positioned them as a leader in the production of this revolutionary material, and their dedication to research and development will ensure that Egpc308 Epoxy Glass Cloth Laminated continues to meet the evolving needs of the market.

Strong and Durable Fiberglass Resin Sheets for Various Applications

Fiberglass Resin Sheets Revolutionize the Construction IndustryFiberglass resin sheets are quickly becoming the go-to solution for construction professionals looking to fortify their projects. These versatile sheets are made of a fiberglass mesh that is embedded in a high-strength polyester resin, which is then cured to create a panel strong enough to withstand any force.One company leading the way in fiberglass resin sheet innovation is [REMOVE BRAND NAME], a global manufacturer of advanced composites. The brand's line of fiberglass resin sheets is characterized by its strength, durability, and resistance to impact, making it ideal for high-stress applications such as transportation, construction, and aerospace."Our fiberglass resin sheets have been engineered to meet the highest standards," said [REMOVE BRAND NAME] spokesperson, "and are designed to provide superior strength and durability for any project you have in mind. Whether you are building a bridge, a sports stadium, or a luxury yacht, our fiberglass resin sheets will give you the confidence you need to get the job done right."One of the key advantages of fiberglass resin sheets is their versatility. Unlike traditional materials such as steel and concrete, fiberglass resin sheets are lightweight and can be customized to any shape or size. The panels can also be easily cut and shaped on site, reducing the need for costly and time-consuming modifications.Another advantage of fiberglass resin sheets is their resistance to harsh environmental conditions. Unlike metals, which can corrode and become brittle over time, fiberglass resin sheets have excellent resistance to moisture, chemicals, and UV radiation. They are also fire-resistant and can withstand extreme temperatures, making them ideal for use in harsh climates.In addition to being strong and durable, fiberglass resin sheets are also eco-friendly. Unlike traditional materials that are difficult to recycle, fiberglass resin sheets are made from renewable resources and can be recycled at the end of their useful life. When compared to traditional materials such as steel and concrete, fiberglass resin sheets have a significantly lower carbon footprint, making them a sustainable choice for builders and architects.Given their many benefits, it is no surprise that fiberglass resin sheets are quickly becoming the go-to solution for construction professionals looking to create strong and sustainable projects. As more companies like [REMOVE BRAND NAME] continue to innovate and expand their product lines, we can expect to see an even greater adoption of fiberglass resin sheets in the coming years.

High-Quality Grade B Epoxy Fiberglass Laminate Sheet: What You Need to Know

Grade B Epoxy Fiberglass Laminate Sheet (brand name removed), is a high-quality and reliable material that is widely used across various industries for its excellent insulation and mechanical properties. Manufactured by {} - a leading provider of advanced materials and solutions for the electrical, electronics, and thermal management industries - this epoxy fiberglass laminate sheet has garnered a reputation for its superior performance and durability.The Grade B Epoxy Fiberglass Laminate Sheet is a thermosetting material that is made by impregnating layers of fiberglass with an epoxy resin and then compressing them under high pressure. This results in a material that is highly resistant to heat, moisture, and chemicals, making it an ideal choice for applications that require high-performance insulation and protection.The sheet is available in a variety of thicknesses and sizes, making it suitable for a wide range of applications, including electrical insulation, structural components, and printed circuit boards. Its excellent dielectric properties and high mechanical strength make it a preferred choice for use in transformers, switchgear, motors, and generators, where reliable insulation is essential for the safety and performance of the equipment.In addition to its exceptional electrical and mechanical properties, the Grade B Epoxy Fiberglass Laminate Sheet also offers good dimensional stability and resistance to flame, making it a versatile material that can withstand harsh operating conditions. The material is also easy to machine and fabricate, allowing for customized designs and precise manufacturing of components.The Grade B Epoxy Fiberglass Laminate Sheet is manufactured by {} using advanced production techniques and quality control processes to ensure consistent and reliable performance. The company is committed to delivering high-quality materials that meet the stringent requirements of its customers and exceed industry standards.With a global presence and a strong reputation for innovation and excellence, {} has established itself as a trusted partner for companies seeking advanced materials and solutions for their applications. The company's extensive experience and expertise in the field of advanced materials enable it to offer comprehensive support and technical assistance to its customers, helping them to optimize their designs and achieve the best performance from the Grade B Epoxy Fiberglass Laminate Sheet.As industries continue to demand high-performance materials that can withstand extreme conditions and deliver reliable performance, the Grade B Epoxy Fiberglass Laminate Sheet from {} has proven to be a top choice for engineers and designers looking for a durable and versatile material for their applications. With its superior insulation and mechanical properties, this material is poised to continue making significant contributions to the advancement of various industries, including electrical, electronics, and thermal management.In conclusion, the Grade B Epoxy Fiberglass Laminate Sheet from {} stands as a testament to the company's commitment to providing high-quality materials and solutions that meet the evolving needs of its customers. With its exceptional performance and reliability, this material is set to remain a preferred choice for a wide range of applications, helping companies to achieve superior insulation and protection for their critical components and systems.

High Quality Laminate Slot Wedge for Industrial Applications

9334 Laminate Slot Wedge: Improving Efficiency and Reliability in Electrical MachinesIn the world of electrical machines, efficiency and reliability are two of the most important factors to consider. Whether it's a motor, generator, or transformer, these machines play a critical role in countless industries and applications around the globe. One key component that helps improve the efficiency and reliability of these machines is the 9334 Laminate Slot Wedge, a product that has been designed and manufactured by a leading company in the field of electrical insulation materials.The 9334 Laminate Slot Wedge is a crucial component in electrical machines, as it helps to optimize the performance and durability of the machines by providing insulation and support to the winding components. This product is made of high-quality laminate materials, and its unique design allows for easy installation and excellent thermal and mechanical properties. As a result, electrical machines equipped with the 9334 Laminate Slot Wedge are able to operate more efficiently and reliably, ultimately leading to cost savings and improved productivity for the end users.{The company} is a renowned manufacturer of electrical insulation materials, with a strong focus on innovation and quality. With decades of experience in the industry, {the company} has established itself as a trusted partner for countless OEMs and end users around the world. The company's commitment to excellence and customer satisfaction has driven them to continuously develop new and improved products, such as the 9334 Laminate Slot Wedge, in order to meet the evolving needs of the market and exceed the expectations of their customers.One of the key advantages of the 9334 Laminate Slot Wedge is its ability to enhance the thermal performance of electrical machines. With its superior thermal conductivity and heat dissipation properties, this product helps to reduce the risk of overheating and insulation degradation, which are common causes of failure in electrical machines. By using the 9334 Laminate Slot Wedge, OEMs and end users can expect their machines to operate at lower temperatures and achieve a longer service life, ultimately resulting in lower maintenance costs and higher uptime.In addition to its thermal benefits, the 9334 Laminate Slot Wedge also offers excellent mechanical strength and insulation properties. This product is designed to provide robust support and protection to the winding components of electrical machines, which are often subjected to high levels of mechanical stress and electrical voltage. By using the 9334 Laminate Slot Wedge, OEMs and end users can ensure that their machines are well-protected against potential damage and breakdowns, thus minimizing the risk of downtime and costly repairs.Furthermore, the 9334 Laminate Slot Wedge is easy to install and highly adaptable to different machine designs. Whether it's a small motor or a large generator, this product can be customized to fit various slot geometries and dimensions, allowing for seamless integration into different types of electrical machines. As a result, OEMs and end users can enjoy greater flexibility and convenience when incorporating the 9334 Laminate Slot Wedge into their products, without compromising on performance or reliability.Overall, the 9334 Laminate Slot Wedge is a key enabler for improving the efficiency and reliability of electrical machines. With its superior thermal and mechanical properties, as well as its ease of installation and adaptability, this product offers tangible benefits for OEMs and end users across a wide range of industries and applications. As {the company} continues to innovate and expand its product offerings, the 9334 Laminate Slot Wedge stands out as a prime example of their commitment to driving positive change in the field of electrical insulation materials, and ultimately, in the performance of electrical machines around the world.