Durable Insulation Pressboard: A Must-Have for Your Home

By:Admin

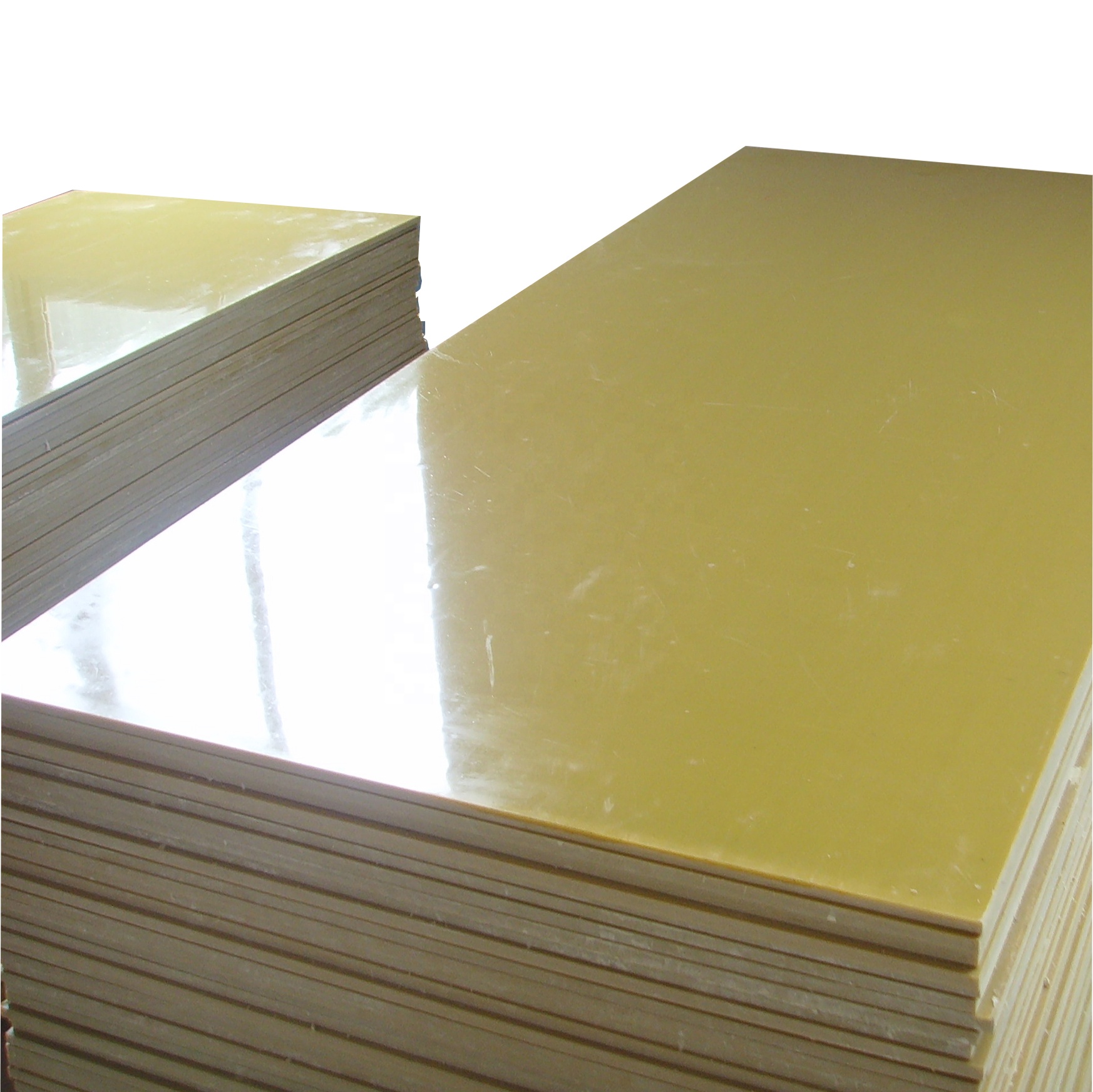

New Insulation Pressboard Material Enhances Energy Efficiency and Safety in Electrical Applications

[City, State, Date] - As the demand for energy-efficient and safe electrical solutions continues to grow, [Company Name] is proud to announce the launch of our latest innovation in insulation pressboard material. Our new product offers enhanced performance and reliability, setting a new standard for insulation materials in the industry.

[Company Name] has been a leading provider of electrical insulation solutions for over [XX] years. Our dedication to innovation and quality has earned us a reputation for delivering products that meet the highest standards of performance and safety. Our new insulation pressboard material is a testament to our ongoing commitment to providing our customers with the best possible solutions for their electrical insulation needs.

The new insulation pressboard material is designed to improve energy efficiency and safety in a wide range of electrical applications. It offers superior thermal and electrical insulation properties, making it an ideal choice for transformers, reactors, and other high-voltage equipment. In addition, the material is engineered to withstand high temperatures and provide excellent mechanical strength, ensuring reliable performance in demanding operating conditions.

One of the key features of our new insulation pressboard material is its ability to enhance energy efficiency in electrical applications. By providing superior thermal insulation, the material helps to minimize heat loss and improve the overall efficiency of electrical equipment. This can result in significant cost savings for our customers, as well as contribute to a more sustainable and eco-friendly operation.

In addition to its energy-efficient properties, our new insulation pressboard material is also designed to enhance safety in electrical applications. The material provides outstanding electrical insulation, reducing the risk of electrical failures and ensuring the reliable performance of equipment. It also offers excellent fire resistance, helping to protect against the risk of electrical fires and ensuring the safety of personnel and sensitive equipment.

"We are thrilled to introduce our new insulation pressboard material to the market," said [Spokesperson Name], [Title] at [Company Name]. "This innovative product represents a significant advancement in insulation technology, offering our customers a solution that delivers unmatched performance, energy efficiency, and safety. We believe that this material will set a new standard for insulation materials in the industry, and we are excited to see the positive impact it will have on our customers' operations."

[Company Name] is dedicated to providing our customers with the highest quality insulation solutions and unparalleled customer service. Our new insulation pressboard material is the latest example of our commitment to innovation and excellence, and we are confident that it will deliver significant benefits to our customers.

For more information about our new insulation pressboard material and other products, please visit our website at [website URL] or contact us directly at [contact information].

About [Company Name]:

[Company Name] is a leading provider of electrical insulation solutions for a wide range of industries. With [XX] years of experience, we have established a reputation for delivering high-quality products and exceptional customer service. Our dedication to innovation and excellence has made us a trusted partner for customers around the world. We are committed to providing reliable, energy-efficient, and safe solutions to meet the evolving needs of the electrical industry.

Contact:

[Contact Name]

[Title]

[Company Name]

[Phone Number]

[Email Address]

[Company Website]

Company News & Blog

Durable Fiberglass FR5: A Strong and Reliable Material for Various Applications

The use of fiberglass FR5 as a key material in the manufacturing industry has been steadily increasing due to its exceptional properties and versatility. [Company name], a leading manufacturer of fiberglass FR5, has been at the forefront of this development, providing high-quality fiberglass products to meet the growing demands of various industries.[Company name] is a renowned company with a strong reputation in the fiberglass industry. With a focus on innovation and quality, the company has established itself as a trusted provider of fiberglass FR5 and other related products. Their commitment to excellence and customer satisfaction has enabled them to build long-lasting relationships with clients worldwide.The use of fiberglass FR5 has become essential in many industrial applications due to its exceptional strength, electrical insulation, and resistance to heat and chemicals. This makes it an ideal material for manufacturing electrical and electronic components, as well as in the construction of industrial equipment and infrastructure. The demand for high-performance materials like fiberglass FR5 is expected to continue to grow as industries strive for more efficient and durable solutions.One of the key advantages of fiberglass FR5 is its excellent resistance to high temperatures and fire, making it a preferred choice for applications where safety is paramount. The material's low thermal conductivity and high mechanical strength make it ideal for use in high-temperature environments, such as in the aerospace and automotive industries. Additionally, fiberglass FR5 is also an excellent electrical insulator, making it suitable for various electrical and electronic applications.[Company name] has been at the forefront of developing advanced fiberglass FR5 materials that meet the evolving needs of the industry. Their state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their products consistently meet the highest industry standards. The company's commitment to research and development has led to the introduction of innovative fiberglass FR5 materials that offer superior performance and reliability.In addition to offering standard fiberglass FR5 products, [Company name] also specializes in customizing solutions to meet the specific requirements of their clients. This flexibility has made them a preferred partner for many companies in various industries, as they can rely on [Company name] to provide tailored solutions that meet their unique needs.The growing demand for fiberglass FR5 has led [Company name] to expand its production capacity and streamline its operations to meet the increasing market demand. The company's investments in technology and infrastructure have enabled them to enhance their manufacturing capabilities and develop new and improved fiberglass FR5 products that offer even greater performance and durability.As the global economy continues to recover and industries ramp up their production, the demand for high-performance materials like fiberglass FR5 is expected to soar. [Company name] is well-positioned to capitalize on this trend, with its extensive experience and expertise in fiberglass manufacturing. Their commitment to quality and innovation makes them a trusted partner for companies seeking reliable and high-quality fiberglass FR5 products.In conclusion, the use of fiberglass FR5 has become increasingly prevalent in various industries due to its exceptional properties and versatility. [Company name] has been a key player in this development, providing high-quality fiberglass FR5 products and customized solutions to meet the growing demands of the industry. With their commitment to excellence and innovation, [Company name] is poised to continue leading the way in the fiberglass manufacturing industry.

Durable and Versatile Glass Fiber Reinforced Sheet: A Top Choice for Various Applications

[Company Name] Introduces Advanced Glass Fiber Reinforced Sheet for Superior Performance[City, State] - [Company Name], a leading manufacturer of advanced materials, is proud to announce the introduction of their new Glass Fiber Reinforced Sheet. This innovative product is designed to provide superior performance and durability for a wide range of applications.The Glass Fiber Reinforced Sheet is manufactured using a proprietary process that results in a high-strength, lightweight material. This makes it an ideal choice for applications where strength and durability are crucial, such as automotive components, aerospace parts, and industrial equipment.One of the key benefits of the Glass Fiber Reinforced Sheet is its exceptional strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is important, without compromising on structural integrity. The material also offers excellent resistance to corrosion, making it suitable for use in harsh environments.In addition to its impressive mechanical properties, the Glass Fiber Reinforced Sheet is also highly customizable. [Company Name] offers a range of options for thickness, color, and finish, allowing customers to tailor the material to their specific requirements. This flexibility makes it a versatile solution for a wide range of industries and applications."We are excited to introduce our new Glass Fiber Reinforced Sheet to the market," said [Name], [Title] at [Company Name]. "This material represents a significant advancement in the field of advanced materials, and we believe it will offer our customers a superior solution for their high-performance applications."[Company Name] has a proven track record of delivering innovative solutions to the market. With state-of-the-art manufacturing facilities and a team of experienced engineers and materials experts, the company is well-positioned to meet the growing demand for high-performance materials.The introduction of the Glass Fiber Reinforced Sheet further solidifies [Company Name]'s commitment to providing cutting-edge solutions to their customers. The company's dedication to research and development, coupled with their focus on quality and customer satisfaction, has established them as a trusted partner for businesses across a wide range of industries.In addition to the Glass Fiber Reinforced Sheet, [Company Name] offers a comprehensive range of advanced materials, including composites, plastics, and specialty alloys. Their extensive product portfolio, combined with their expertise in materials science and engineering, makes them a one-stop solution provider for companies seeking high-performance materials for their products and applications.As industries continue to demand materials that offer superior performance and durability, [Company Name] is poised to meet those needs with their innovative Glass Fiber Reinforced Sheet and other advanced materials. With a commitment to excellence and a focus on continuous improvement, the company is well-positioned to remain a leader in the field of advanced materials for years to come.For more information about [Company Name] and their advanced Glass Fiber Reinforced Sheet, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of advanced materials for a wide range of industries. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-performance materials for their products and applications. With a commitment to research and development, [Company Name] continues to deliver cutting-edge solutions to the market, helping their customers stay ahead of the competition.

Durable Epoxy Boards for Various Applications: Available in Different Thicknesses

Introducing the Latest Innovation in Epoxy Board ManufacturingIn the world of electronics and circuitry, the demand for high-quality materials and components is constantly on the rise. As technology continues to advance, manufacturers are continuously seeking new and innovative materials to meet the needs of their customers. This is where the latest innovation in epoxy board manufacturing comes into play.One company that is leading the charge in this area is {}. With over 20 years of experience in the industry, they have built a reputation for delivering cutting-edge solutions to their customers. Their latest offering, the Different Thickness Epoxy Board, is set to revolutionize the market by providing a superior level of performance and reliability.The Different Thickness Epoxy Board is a testament to the company's commitment to innovation and excellence. It comes in various thickness options, ranging from ultra-thin to standard thickness, catering to the diverse needs of their customers. This versatility makes it an ideal choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key features of the Different Thickness Epoxy Board is its exceptional electrical properties. It offers low dielectric loss and high insulation resistance, ensuring the smooth and efficient flow of electric currents. This makes it an ideal choice for use in high-frequency circuits, where signal integrity is of utmost importance.In addition to its superior electrical properties, the Different Thickness Epoxy Board also boasts excellent mechanical strength. It is highly resistant to impact and has a high flexural strength, making it a reliable choice for applications that require durability and resilience.Furthermore, the Different Thickness Epoxy Board is designed to withstand harsh environmental conditions. It is resistant to moisture, chemicals, and extreme temperatures, ensuring that it remains stable and reliable in any setting. This level of durability and resilience makes it an ideal choice for use in challenging environments, such as automotive and aerospace applications.The company's innovative manufacturing process ensures that the Different Thickness Epoxy Board meets the highest standards of quality and consistency. Each board undergoes rigorous testing and inspection to ensure that it meets the exact specifications and requirements of the customer. This commitment to quality has earned the company a reputation for delivering products that exceed expectations.With the introduction of the Different Thickness Epoxy Board, the company is set to further solidify its position as a leading provider of high-quality materials for the electronics industry. Their dedication to innovation and excellence is evident in every aspect of the product, from its performance to its reliability.In conclusion, the Different Thickness Epoxy Board is a game-changer in the world of epoxy board manufacturing. Its exceptional electrical properties, mechanical strength, and environmental resilience make it a top choice for a wide range of applications. With its introduction, the company {} has once again demonstrated its commitment to delivering innovative and high-quality solutions to its customers. As technology continues to advance, the Different Thickness Epoxy Board is poised to play a pivotal role in shaping the future of electronics and circuitry.

Latest Developments in Board News: Essential Updates You Need to Know

[Company Introduction] is pleased to announce its recent collaboration with 3240 Board, a leading manufacturer of high-quality circuit boards. The partnership aims to bring cutting-edge technology and innovative solutions to the electronics industry, offering customers a wide range of advanced circuit board options.With over [X] years of experience in the industry, [Company Introduction] has established itself as a reputable provider of electronic components and solutions. Their commitment to delivering superior products and excellent customer service has earned them a strong reputation in the market. Through strategic partnerships and continuous innovation, the company has consistently met the evolving needs of their clients and positioned itself as a trusted leader in the industry.[Company Introduction]’s collaboration with 3240 Board is a testament to their dedication to offering top-of-the-line products to their customers. By joining forces with a reputable manufacturer like 3240 Board, [Company Introduction] is expanding its product portfolio and enhancing its ability to meet the demands of the ever-changing electronics market.3240 Board is known for its advanced capabilities in producing high-quality circuit boards that meet the stringent requirements of various industries, including aerospace, automotive, telecommunications, and medical devices. The company’s state-of-the-art facilities and advanced manufacturing processes enable them to deliver reliable and durable circuit boards that are essential for modern electronic devices and systems.The partnership between [Company Introduction] and 3240 Board will bring forth a wide range of benefits for customers. By leveraging 3240 Board’s expertise and cutting-edge technologies, [Company Introduction] will be able to offer an expanded selection of circuit boards that meet the highest standards of quality and performance. This will allow [Company Introduction] to better serve the needs of their customers and provide them with advanced solutions that drive innovation and excellence in their respective industries.Furthermore, the collaboration will enable [Company Introduction] to access 3240 Board’s extensive knowledge and experience in the manufacturing of complex and specialized circuit boards. This will empower [Company Introduction] to address the unique and specific requirements of their clients, catering to a broader range of industries and applications. By incorporating 3240 Board's expertise into their product offerings, [Company Introduction] will solidify its position as a comprehensive provider of electronic solutions.Additionally, the partnership with 3240 Board will enhance [Company Introduction]’s capabilities in customizing circuit boards according to the exact specifications and requirements of their customers. Whether it’s a unique design, specific material, or specialized features, [Company Introduction] will harness the technical expertise of 3240 Board to deliver tailor-made solutions that meet the most demanding requirements of their clients.As the electronic industry continues to evolve and demand for advanced circuit boards grows, the collaboration between [Company Introduction] and 3240 Board comes at a critical time. By working together, the two companies are poised to lead the way in providing state-of-the-art circuit board solutions that drive technological advancements and pave the way for innovation in various sectors.In conclusion, the partnership between [Company Introduction] and 3240 Board represents a significant milestone in delivering exceptional electronic solutions to customers. By combining their strengths and expertise, the two companies are well-positioned to meet the evolving needs of the electronics industry and offer cutting-edge circuit board solutions that empower businesses and drive progress. With a shared commitment to excellence and innovation, this collaboration signifies a promising future for both companies and their customers.

High Quality Epoxy Resin Glass Fiber Sheet for Mechanical and Electrical Insulation

G10 Glass Fiber Reinforced Sheet: The Versatile Insulation MaterialInsulation materials are used in a variety of applications, from mechanical and electrical equipment to buildings and homes. Insulation materials serve to maintain a certain temperature or environment, prevent unwanted heat or cold transfer, and protect equipment from damage. G10 Glass Fiber Reinforced Sheet is one such insulation material that is widely used due to its high mechanical and electrical properties, good heat resistance and humidity resistance. In this blog, we will discuss G10 Glass Fiber Reinforced Sheet and its applications.What is G10 Glass Fiber Reinforced Sheet?G10 Glass Fiber Reinforced Sheet is an insulating material made by using fiberglass cloth and heat resistant epoxy resin. The glass fiber cloth used in G10 is non-alkali, and it is impregnated with epoxy resin by hot pressing. The resulting material has high mechanical and electrical properties, good heat resistance and humidity resistance. G10 Glass Fiber Reinforced Sheet is known for its high strength, durability, and excellent dielectric properties. It is available in different sizes and thicknesses to suit various applications.Applications of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet is widely used in mechanical, electronic, and electrical equipment, insulation parts, and components. It is also used in the construction industry as a structural material. Below are the top applications of G10 Glass Fiber Reinforced Sheet:1. Electrical equipment insulation: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical equipment such as transformers, electric motors, and generators.2. Circuit board substrates: G10 Glass Fiber Reinforced Sheet is used as the substrate material for printed circuit boards. It provides excellent stability and mechanical strength to the circuit board.3. Mechanical parts and components: G10 Glass Fiber Reinforced Sheet is used to make parts and components of machinery and equipment. It provides excellent mechanical properties such as high strength and toughness.4. Aerospace industry: G10 Glass Fiber Reinforced Sheet is used in the aerospace industry to make parts for aircraft and spacecraft. It provides excellent strength and durability under extreme conditions.5. Marine industry: G10 Glass Fiber Reinforced Sheet is used in the marine industry as a material for boat hulls, decks, and other structural components. It is highly resistant to water and moisture, making it an ideal material for marine applications.Advantages of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet has several advantages over other insulation materials, such as:1. High strength and durability: G10 Glass Fiber Reinforced Sheet has high mechanical properties, making it ideal for use in high-stress applications that require strength and durability.2. Excellent electrical insulation properties: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical and electronic applications.3. Good heat resistance: G10 Glass Fiber Reinforced Sheet is resistant to high temperatures, which makes it suitable for use in high-temperature applications.4. Resistance to moisture and chemicals: G10 Glass Fiber Reinforced Sheet is highly resistant to moisture and chemicals, making it ideal for use in harsh environments.ConclusionG10 Glass Fiber Reinforced Sheet is a versatile insulation material that has several advantages over other insulation materials. Its high mechanical and electrical properties, good heat resistance, and humidity resistance make it ideal for use in a variety of applications. Its applications include electrical equipment insulation, circuit board substrates, mechanical parts and components, aerospace industry, and marine industry. If you are looking for an insulation material that offers high strength, durability, and excellent dielectric properties, G10 Glass Fiber Reinforced Sheet is an excellent choice.

Durable Epoxy Electrical Insulation Laminate Sheet for Industrial Applications

*** Company Introduction ***[Company Name] is a leading manufacturer of electrical insulation materials and laminates. With a strong focus on research and development, we have been providing high-quality products to various industries such as electronics, automotive, aerospace, and more for over two decades. Our commitment to innovation and customer satisfaction has enabled us to establish a strong presence in the global market.*** News Content ***[Company Name] has recently introduced a new product to its extensive line of electrical insulation materials – the 3240 Epoxy Electrical Insulation Laminate Sheet. This new addition is aimed at meeting the increasing demand for advanced insulation solutions in the rapidly evolving electronics and electrical engineering sectors.The 3240 Epoxy Electrical Insulation Laminate Sheet is a high-performance material that offers superior electrical insulation properties, mechanical strength, and thermal resistance. It is commonly used in applications such as electrical equipment, bus bars, switchgear, and transformers, where reliability and durability are paramount.One of the key features of the 3240 Epoxy Electrical Insulation Laminate Sheet is its exceptional dielectric strength, which ensures reliable insulation under high voltage conditions. This makes it an ideal choice for use in critical electrical components that are subjected to extreme operating conditions.In addition to its robust electrical insulation properties, the 3240 Epoxy Electrical Insulation Laminate Sheet also offers excellent mechanical strength, making it suitable for applications that require resistance to mechanical stress and impact. This ensures the longevity and reliability of electrical equipment and components in which it is used.Furthermore, the 3240 Epoxy Electrical Insulation Laminate Sheet exhibits outstanding thermal resistance, allowing it to withstand elevated temperatures without compromising its electrical and mechanical performance. This characteristic makes it suitable for use in environments where temperature variations are prevalent, ensuring sustained functionality and safety.As a leading manufacturer of electrical insulation materials, [Company Name] has developed the 3240 Epoxy Electrical Insulation Laminate Sheet with a strong focus on quality and reliability. The product undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards and specifications. This commitment to excellence is a testament to [Company Name]'s dedication to providing customers with superior products that offer exceptional performance and longevity.With the introduction of the 3240 Epoxy Electrical Insulation Laminate Sheet, [Company Name] aims to address the evolving needs of the electronics and electrical engineering industries, providing them with a reliable and high-performance insulation solution that meets their stringent requirements and standards.In conclusion, the introduction of the 3240 Epoxy Electrical Insulation Laminate Sheet further strengthens [Company Name]'s position as a frontrunner in the electrical insulation materials market. By leveraging its expertise in research and development, along with a steadfast commitment to quality and innovation, [Company Name] continues to provide customers with cutting-edge solutions that empower them to excel in their respective industries.

Durable Fiberglass Laminated Sheet: A Versatile Building Material

The 3240 Fiberglass Laminated Sheet is a versatile material that has become an essential component for various industries. The sheet, manufactured by a leading company in the field of electrical insulation materials, is widely used in applications such as electrical motors, transformers, and other electrical equipment. With its excellent mechanical properties, electrical insulation performance, and high-temperature resistance, the 3240 Fiberglass Laminated Sheet has established itself as a reliable and cost-effective solution for the most demanding applications.The 3240 Fiberglass Laminated Sheet is made from electrical grade fiberglass cloth impregnated with a high-temperature resistant resin. The combination of these materials provides the sheet with outstanding mechanical strength and electrical insulation properties. The sheet is also known for its excellent heat resistance, making it suitable for use in high-temperature environments. Additionally, the 3240 Fiberglass Laminated Sheet is highly resistant to moisture, chemicals, and solvents, further enhancing its durability and reliability.The [Company Name] is a renowned manufacturer and supplier of electrical insulation materials, with a strong focus on providing innovative solutions to meet the evolving needs of the industry. The company has a wealth of experience in the development and production of high-quality fiberglass laminated sheets, and its products are trusted by customers worldwide. With a commitment to excellence and a dedication to research and development, the [Company Name] continues to lead the way in the field of electrical insulation materials.In addition to the 3240 Fiberglass Laminated Sheet, the [Company Name] offers a wide range of products designed to meet the diverse needs of its customers. From rigid laminates to flexible insulation materials, the company's product portfolio encompasses a variety of solutions for different applications. The [Company Name] also provides customized products and technical support to ensure that its customers receive the most suitable insulation materials for their specific requirements.The 3240 Fiberglass Laminated Sheet has been widely adopted in the electrical and electronics industry due to its exceptional performance and reliability. Its use in electrical motors and transformers has contributed to the efficient and safe operation of these critical components. The sheet's ability to withstand high temperatures and harsh environments makes it an ideal choice for applications where reliability is paramount.Moreover, the 3240 Fiberglass Laminated Sheet has found applications beyond the electrical industry. It is used in a variety of mechanical and structural applications where its combination of strength, insulation, and temperature resistance is highly valued. From industrial equipment to automotive components, the sheet's versatility has made it a popular choice across different sectors.With a commitment to quality and innovation, the [Company Name] continues to push the boundaries of what is possible in the field of electrical insulation materials. The company's dedication to meeting the ever-changing needs of its customers has solidified its position as a trusted partner in the industry. By offering cutting-edge solutions such as the 3240 Fiberglass Laminated Sheet, the [Company Name] is helping to drive progress and efficiency in various sectors.In conclusion, the 3240 Fiberglass Laminated Sheet, manufactured by the [Company Name], stands as a testament to the company's dedication to excellence and innovation. Its exceptional performance and versatility have made it an indispensable material for a wide range of applications. As the [Company Name] continues to lead the way in the development of electrical insulation materials, the 3240 Fiberglass Laminated Sheet remains a key component in the advancement of various industries.

Benefits of Epoxy Fiberglass for Your Project

NEWLY DEVELOPED FR4 EPOXY FIBERGLASS OFFERS IMPROVED PERFORMANCEThe {Company Name} is excited to announce the launch of their new and innovative {Product Name}, a superior grade FR4 Epoxy Fiberglass. This newly developed material is set to revolutionize the electronics and manufacturing industries with its enhanced performance and durability.FR4 Epoxy Fiberglass has long been the material of choice for a variety of applications due to its excellent electrical insulation properties and high-temperature resistance. However, the {Company Name} has taken this material to the next level with their advanced manufacturing techniques and quality control processes, resulting in a product that outperforms traditional FR4 materials in several key areas.One of the most significant advantages of the {Product Name} is its exceptional mechanical strength and dimensional stability. This makes it an ideal choice for demanding applications such as printed circuit boards (PCBs), electrical insulation, and structural components. The {Company Name} has conducted extensive testing to ensure that their FR4 Epoxy Fiberglass meets the highest industry standards for strength and reliability.In addition to its superior mechanical properties, the {Product Name} also offers improved chemical resistance, allowing it to withstand exposure to a wide range of solvents, oils, and other harsh environments. This makes it an excellent choice for use in industrial settings where traditional materials may fail to perform adequately.Furthermore, the {Company Name} has developed their FR4 Epoxy Fiberglass with an emphasis on environmental sustainability. The material is manufactured using a non-toxic process and is fully recyclable, minimizing its impact on the environment and contributing to a more sustainable supply chain for their customers.The launch of the {Product Name} comes as part of the {Company Name}'s ongoing commitment to research and development, as well as their dedication to providing their customers with the most advanced and reliable materials available on the market. Their team of engineers and material scientists have worked tirelessly to bring this new product to fruition, and they are confident that it will set a new standard for FR4 Epoxy Fiberglass in the industry."We are thrilled to introduce our new {Product Name} to the market," said {Spokesperson Name}, CEO of {Company Name}. "Our team has put in a tremendous amount of effort to develop a material that not only meets but exceeds the expectations of our customers. We believe that the {Product Name} will become the go-to choice for engineers and manufacturers looking for the highest quality FR4 Epoxy Fiberglass available."The {Product Name} is now available for purchase and can be customized to meet the specific requirements of individual applications. With its unparalleled performance and environmental benefits, this new material is poised to make a significant impact across a wide range of industries, from aerospace and automotive to electronics and telecommunications.For more information about the {Product Name} and its potential applications, interested parties are encouraged to contact {Company Name} directly. With their expertise in advanced materials and a commitment to customer satisfaction, the {Company Name} is well-positioned to provide the support and guidance needed to incorporate this groundbreaking material into any project.

High Quality Epoxy Glass Fiber Sheet for Various Applications

Epoxy Glass Fiber Sheet: A Versatile Solution for Various IndustriesWith the increasing demand for high-performance materials in various industries, the need for reliable and durable solutions has become more crucial than ever. This is where Epoxy Glass Fiber Sheet comes into play, offering a versatile and reliable solution for a wide range of applications.Epoxy Glass Fiber Sheet, also known as fiberglass epoxy laminate, is a composite material made of woven glass fabric impregnated with epoxy resin. This combination results in a material that exhibits exceptional strength, durability, and resistance to a wide range of chemicals and environmental conditions. As a result, Epoxy Glass Fiber Sheet has found widespread applications in industries such as electrical, automotive, aerospace, and construction.One of the key advantages of Epoxy Glass Fiber Sheet is its excellent electrical insulation properties. This makes it an ideal material for use in electrical and electronic applications, where high voltage insulation and thermal stability are crucial. In addition, Epoxy Glass Fiber Sheet also offers high mechanical strength and dimensional stability, making it suitable for use in structural applications such as flanges, support beams, and paneling.Another important feature of Epoxy Glass Fiber Sheet is its resistance to chemical corrosion and moisture. This makes it a preferred choice for use in harsh environments where other materials may degrade or fail. In addition, Epoxy Glass Fiber Sheet is also highly resistant to fire and has low smoke emission, making it a safe and reliable material for use in building and construction applications.The company {} is a leading manufacturer and supplier of Epoxy Glass Fiber Sheet, offering a wide range of products to meet the diverse needs of its customers. With state-of-the-art manufacturing facilities and a dedicated research and development team, {} is committed to delivering high-quality and innovative solutions to its customers around the world.{}’s Epoxy Glass Fiber Sheet products are available in various grades and specifications, allowing customers to find the perfect solution for their specific requirements. Whether it's for electrical insulation, structural reinforcement, or chemical resistance, {} offers a comprehensive range of Epoxy Glass Fiber Sheet products to meet the needs of various industries.In addition to its standard product offerings, {} also provides custom fabrication services to accommodate unique customer requirements. This includes precision cutting, machining, and finishing to ensure that the Epoxy Glass Fiber Sheet meets the exact specifications and dimensions needed for a specific application.Furthermore, {} is dedicated to ensuring the highest quality and compliance with industry standards. Its Epoxy Glass Fiber Sheet products undergo rigorous testing and quality control measures to guarantee performance and reliability. With a strong focus on customer satisfaction, {} strives to provide excellent service and support to its customers, ensuring that they receive the best possible solutions for their needs.As industries continue to evolve and demand higher-performing materials, the versatility and reliability of Epoxy Glass Fiber Sheet make it an indispensable solution for a wide range of applications. With the expertise and commitment of companies like {}, customers can trust that they are getting the best Epoxy Glass Fiber Sheet products to meet their needs and exceed their expectations.