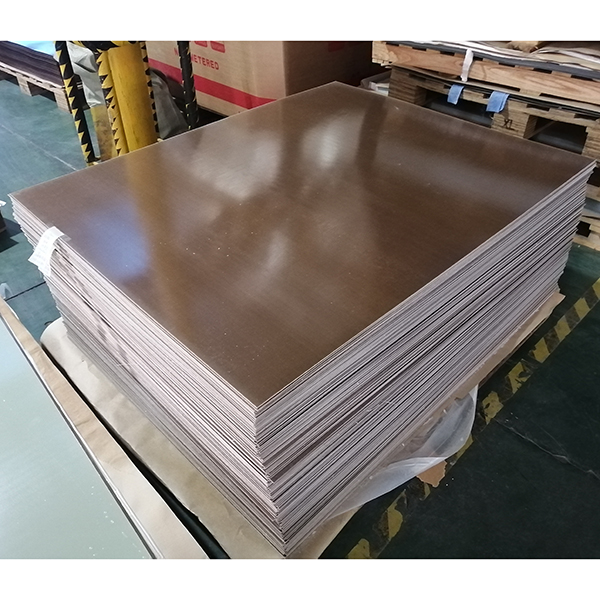

High-Quality 8mm Fiberglass Sheet for Various Applications

By:Admin

The company, with over 20 years of experience in the industry, has established itself as a leading manufacturer and supplier of fiberglass products. They have a strong commitment to providing high-quality products and excellent customer service. Their 8mm Fiberglass Sheets are manufactured with state-of-the-art technology and are designed to meet the highest industry standards.

The 8mm Fiberglass Sheets offered by the company are suitable for a wide range of applications in construction and industrial settings. The sheets are lightweight, making them easy to handle and install. They are also resistant to fire, chemicals, and corrosion, making them an ideal choice for areas that require high-performance materials.

One of the key features of the 8mm Fiberglass Sheets is their excellent thermal and acoustic insulation properties. This makes them an ideal choice for building construction, where energy efficiency and noise control are important factors. The sheets also provide superior protection against weather elements, making them suitable for outdoor applications.

The company takes pride in its ability to customize the 8mm Fiberglass Sheets according to the specific requirements of their customers. They offer a wide range of colors, sizes, and finishes to suit different applications. Whether it’s a residential, commercial, or industrial project, the company can provide tailored solutions to meet the needs of their clients.

In addition to their high-quality products, the company also places a strong emphasis on sustainability and environmental responsibility. The 8mm Fiberglass Sheets are manufactured using eco-friendly processes and materials, making them a green choice for construction projects. The company is committed to reducing its carbon footprint and promoting sustainable practices in the industry.

With a comprehensive understanding of the construction and industrial markets, the company has established a strong distribution network to ensure timely delivery of their products. Their dedicated team of professionals is always ready to provide expert advice and support to their customers, ensuring that they get the right products for their specific needs.

In conclusion, the 8mm Fiberglass Sheets offered by the company are a premium choice for construction and industrial applications. With their exceptional strength, durability, and flexibility, these sheets are a cost-effective solution for a wide range of projects. Customers can rely on the company’s expertise and commitment to quality to deliver the best fiberglass products for their needs.

Company News & Blog

Discover the Benefits of Fiberglass Insulation Sheets for Your Home

Title: Revolutionary Fiberglass Insulation Sheets Revolutionize the Construction IndustryIntroduction:Fiberglass Insulation Sheets, a groundbreaking product designed to enhance energy efficiency and improve insulation in buildings, is set to revolutionize the construction industry. Engineered by [Company Name], this innovative material promises to deliver superior performance and sustainability while meeting the increasing demand for energy conservation. With its numerous benefits and cutting-edge technology, these fiberglass insulation sheets are poised to transform the way buildings are constructed and maintained.Paragraph 1:After years of research and development, [Company Name] has introduced a game-changing solution to the construction market with its Fiberglass Insulation Sheets. These sheets are made from premium quality fiberglass materials that offer excellent thermal insulation properties, effectively reducing heat transfer between indoor and outdoor spaces. With an ever-increasing focus on reducing energy consumption and environmental impact, this new product stands out as a cost-effective and eco-friendly alternative to traditional insulation materials.Paragraph 2:One of the key advantages of Fiberglass Insulation Sheets is their exceptional thermal resistance. The sheets are manufactured using advanced techniques that ensure excellent heat retention, keeping buildings warm during winters and cool during summers. This feature helps to reduce the reliance on heating and cooling systems, resulting in significant energy savings and reduced carbon emissions.Paragraph 3:Additionally, these insulation sheets possess outstanding sound absorption capabilities, making them a perfect choice for both residential and commercial buildings. The Fiberglass Insulation Sheets absorb and dissipate sound waves, effectively reducing noise pollution and creating a more peaceful and comfortable indoor environment. This feature proves to be especially beneficial in crowded urban areas or structures near high-traffic zones.Paragraph 4:Moreover, [Company Name]'s Fiberglass Insulation Sheets are highly versatile and adaptable to various construction applications. The lightweight and flexible nature of the sheets allows for easy installation, ensuring a seamless integration into new and existing structures. Whether utilized in roofs, walls, or floors, these insulation sheets effortlessly conform to irregular shapes and surfaces, enhancing their suitability for a wide range of architectural designs.Paragraph 5:Another notable advantage of Fiberglass Insulation Sheets is their exceptional fire resistance properties. Composed of non-combustible materials, these sheets significantly reduce the flammability risks associated with conventional insulation options. This added safety feature provides peace of mind for homeowners, architects, and construction companies alike, ensuring compliance with stringent fire safety regulations.Paragraph 6:Furthermore, [Company Name] places a strong emphasis on sustainability, making their Fiberglass Insulation Sheets an eco-friendly choice. These sheets are manufactured using recycled and recyclable materials, minimizing waste and reducing the industry's carbon footprint. By opting for this sustainable insulation option, construction projects demonstrate their commitment to environmental stewardship and sustainable development.Paragraph 7:To enhance its product's overall performance, [Company Name] offers a range of additional features and customization options for the Fiberglass Insulation Sheets. These include various thickness options, moisture resistance treatments, and advanced coating technologies. Such customization ensures that the insulation sheets meet the specific needs and requirements of different projects and climates, further enhancing their effectiveness and longevity.Conclusion:With their exceptional thermal and acoustic insulation properties, versatility, fire resistance, and sustainability, Fiberglass Insulation Sheets by [Company Name] are poised to transform the construction industry. The advancements in this groundbreaking material offer unmatched energy efficiency, ensuring reduced energy consumption and enhanced comfort in buildings. As the demand for energy-efficient solutions continues to rise, this remarkable innovation is set to play a pivotal role in shaping the future of sustainable construction practices.

Benefits of Using Fiberglass Plain Sheets for Construction Projects

Fiberglass Plain Sheet Enhances Durability and Versatility in Construction Industry{Company Name}, a leading manufacturer and distributor of construction materials, is proud to introduce their latest innovative product, the Fiberglass Plain Sheet. Designed to revolutionize the construction industry, this lightweight and durable material offers enhanced durability and versatility for a wide range of applications.With the increasing demand for high-performance building materials, contractors and architects are constantly seeking innovative solutions that balance strength, cost-efficiency, and sustainability. Fiberglass has emerged as a popular choice, thanks to its superior structural properties and resistance to corrosion, chemicals, and extreme weather conditions.The Fiberglass Plain Sheet, produced by {Company Name}, encapsulates these desirable qualities, taking them to a whole new level. Made from premium quality fiberglass reinforced polymer, this sheet offers exceptional strength-to-weight ratio, ensuring long-lasting and reliable performance. Its unique composition allows it to withstand heavy loads and impacts without compromising its structural integrity.One of the standout features of the Fiberglass Plain Sheet is its high resistance to fire. Unlike traditional construction materials, such as wood or steel, fiberglass does not burn easily and does not support the spread of flames. This makes it an ideal choice for applications that require fire-resistant properties, such as facades, roofing, and partitions.Additionally, the Fiberglass Plain Sheet exhibits excellent thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. This not only enhances the overall comfort of the building occupants but also contributes to the sustainability and energy efficiency goals of the project. By reducing the reliance on heating and cooling systems, the Fiberglass Plain Sheet aids in minimizing the building's carbon footprint.Furthermore, the versatility of the Fiberglass Plain Sheet makes it suitable for a wide array of applications. Whether it's used for interior or exterior purposes, this material can be easily installed and provides a seamless aesthetic appeal. Its smooth, plain surface is an ideal canvas for various finishes, including paints, laminates, and coatings, allowing architects and designers to customize the appearance according to their vision.The lightweight nature of the Fiberglass Plain Sheet simplifies transportation and installation, resulting in reduced labor costs and time. In addition, its non-porous surface prevents the accumulation of dirt, moisture, or mould growth, ensuring a low-maintenance solution that retains its pristine condition over time.Manufactured in accordance with international quality standards, the Fiberglass Plain Sheet is rigorously tested to meet or exceed industry requirements. It's available in various sizes and thicknesses, providing flexibility for different project specifications. Whether it's a small-scale residential construction or a large-scale commercial development, {Company Name} guarantees reliable supply and professional support throughout the project."Through our years of industry experience, we understand the evolving needs of construction professionals," says {Company Name}'s spokesperson. "We are committed to delivering cutting-edge products that surpass expectations and contribute to the success of every project. The Fiberglass Plain Sheet is a testament to our dedication to quality, sustainability, and customer satisfaction."With its remarkable durability, versatility, and sustainable attributes, the Fiberglass Plain Sheet has the potential to become the go-to material for construction projects worldwide. As architects and contractors continue to prioritize performance, cost-efficiency, and environmental sustainability, {Company Name}'s innovative product is set to redefine the construction landscape.As the construction industry embraces change and innovation, the introduction of the Fiberglass Plain Sheet opens doors to endless possibilities. With its exceptional properties and the reliability of {Company Name}'s brand, this new construction material is poised to make a significant impact on the industry, setting new benchmarks for structural integrity, fire resistance, thermal insulation, and design possibilities.

A Guide to FRP Molded Grating: Key Features, Manufacturing Process, and Applications

China FRP Molded Grating: The Future of Safe, Long-Lasting InfrastructureIn recent years, there has been a growing demand for durable and sturdy materials in the construction industry. In line with this, China is making significant progress in the installation of Fiber Reinforced Polymer (FRP) molded grating for secure infrastructure. This innovative material boasts superior strength and durability over traditional construction materials like steel and wood. With its lightweight, non-corrosive, and slip-resistant features, FRP molded grating is perfect for walkways, industrial flooring, stair treads, and other applications.One of the top companies leading the charge in the production of this material in China is **(remove brand name)**. With cutting-edge technology, state-of-the-art equipment, and experienced engineers and workers, **(remove brand name)** is making a name for itself in the FRP industry. The company has specialized in the design, manufacture, and installation of high-quality FRP molded grating for offshore drilling platforms, petrochemical plants, power plants, and other industrial facilities.One of the primary applications of China FRP molded grating is in offshore drilling platforms. Unlike traditional materials like wood or steel, FRP grating is resistant to corrosion and water damage, making it the perfect choice for marine environments. It is also lightweight, so it does not add to the overall weight of the platform, which is essential for floating structures. Since it is slip-resistant, it reduces the risk of accidents and injuries on the platform.In petrochemical plants, FRP molded grating is replacing steel grating. Steel grating can corrode over time, resulting in safety hazards like falling through holes or slipping on metal surfaces. FRP grating is non-corrosive and can withstand harsh weather conditions, making it a more cost-effective and safer option for petrochemical applications. Additionally, FRP grating is fire-retardant, reducing the risk of ignition and damage from fire.Another area where FRP molded gratings are being increasingly used is in power plants. In power plants, it is essential to maintain a safe walking surface around the equipment, which can be difficult with traditional flooring materials. FRP grating comes in various sizes and shapes, making it easy to install around the machinery. The non-slip surface also enhances safety in areas with high foot traffic.Outside the industrial sector, FRP molded grating can also be used in commercial and residential construction. The lightweight design of the material makes it perfect for applications where the weight-bearing capacity of the floor is limited. The slip-resistant feature of FRP molded grating ensures enhanced safety, making it a popular choice for stair treads and walkways. Moreover, it is low-maintenance, reducing the overall cost of ownership.Overall, it is clear that the future of infrastructure lies in lightweight, durable, and slip-resistant materials like FRP molded grating. In China, the manufacturing of these materials is growing rapidly, with companies like **(remove brand name)** leading the way. Not only does FRP grating provide safety and durability, but it also saves on maintenance costs and extends the lifespan of infrastructure. The benefits of this innovative material are clear, and it is only a matter of time before it becomes the dominant material in construction and industrial applications in China and around the world.

How Electrical Laminated Sheet is Revolutionizing the Industry

[News Content]Electrical Laminated Sheet Revolutionizes Power Distribution EfficiencyIn today's rapidly advancing world, technological advancements play a crucial role in shaping the landscape of various industries. Power distribution is one such sector that consistently necessitates innovation to meet growing demands and improve efficiency. Enter Electrical Laminated Sheet, a groundbreaking development designed to transform the way electricity is distributed.Electrical Laminated Sheet, developed by cutting-edge materials engineering company {}, boasts an array of features that make it an ideal choice for power distribution applications. With its superior electrical insulation properties, excellent mechanical strength, and high temperature resistance, this innovative solution ensures optimal performance in even the most demanding environments.The electrical laminated sheet category has traditionally been dominated by outdated materials, resulting in limited efficiency and effectiveness. However, with this latest offering from {}, the industry will witness a paradigm shift. The unique composition of the Electrical Laminated Sheet facilitates reduced energy losses during power transmission, thereby enhancing overall system efficiency.Furthermore, the material's remarkable mechanical strength provides exceptional protection against mechanical stress, vibration, and thermal expansion, ensuring long-term reliability. This enhanced durability translates to reduced maintenance costs and increased operational lifespan, making it an economically viable choice for power distribution systems worldwide.A significant advantage of Electrical Laminated Sheet is its ability to withstand high temperatures. Traditionally, extreme heat adversely affects the performance of electrical insulation materials, leading to compromised safety and reliability. The innovative design of this new solution equips it with the capability to operate flawlessly at elevated temperatures, thereby ensuring uninterrupted power distribution even in harsh conditions.Beyond its exceptional technical specifications, the Electrical Laminated Sheet also satisfies industry demands for sustainable solutions. The materials used in its manufacturing prioritize environmental safety and adhere to strict regulatory standards. With the growing focus on environmental consciousness, this product aligns perfectly with the shift towards sustainable practices in the power distribution sector.The advent of Electrical Laminated Sheet marks an exciting milestone in the power distribution industry. Its ability to revolutionize efficiency, reliability, and sustainability in electrical systems positions it as the trailblazer in the market. Companies around the world are eagerly embracing this groundbreaking solution to enhance the performance and longevity of their power distribution networks.Leading businesses have already recognized the benefits of Electrical Laminated Sheet and incorporated it into their operations. Testimonials from satisfied customers highlight the significant improvement in system efficiency and reduced maintenance costs achieved after implementing this innovative solution. As demand continues to rise, industry experts predict a bright future for Electrical Laminated Sheet, forecasting its rapid adoption worldwide.In conclusion, Electrical Laminated Sheet, introduced by {}, is a game-changing development in the power distribution industry. Its exceptional electrical insulation properties, mechanical strength, and high-temperature resistance contribute to enhanced efficiency, reliability, and sustainability. With its eco-friendly manufacturing process and adherence to rigorous standards, it aligns perfectly with the growing focus on sustainable practices. As more companies recognize its unparalleled performance, Electrical Laminated Sheet is set to transform power distribution systems across the globe.

Explore the Benefits of Laminate Slot Wedges in Industry Applications

[Company Name] Introduces Revolutionary 9334 Laminate Slot Wedge for Enhanced Efficiency in Electrical Systems[City, State] - [Company Name], a leading provider of innovative solutions for the electrical and power generation industries, has recently introduced the 9334 Laminate Slot Wedge, a cutting-edge product designed to optimize the performance of electrical machines and generators.The 9334 Laminate Slot Wedge is a key component in electrical systems, providing insulation and support for the stator windings in rotating machinery. It is specifically engineered to meet the demanding requirements of modern electrical machines, offering superior insulation properties and mechanical strength to ensure reliable and efficient operation.One of the key features of the 9334 Laminate Slot Wedge is its high temperature resistance, making it suitable for use in generators and motors that operate at elevated temperatures. This allows for extended service life and increased reliability, even in the harshest operating conditions.In addition to its exceptional thermal performance, the 9334 Laminate Slot Wedge also offers excellent electrical insulation properties, helping to minimize the risk of electrical breakdown and ensuring the safety and longevity of the electrical system.Furthermore, the 9334 Laminate Slot Wedge is designed for easy installation, with a precision-engineered shape and size that allows for seamless integration into a wide range of electrical machines and generators. This helps to streamline the manufacturing and assembly process, saving time and costs for the end user.The introduction of the 9334 Laminate Slot Wedge underscores [Company Name]'s commitment to innovation and excellence in the electrical industry. With a focus on providing cutting-edge solutions to meet the evolving needs of the market, [Company Name] continues to drive advancements in electrical technology and contribute to the overall efficiency and reliability of electrical systems.The 9334 Laminate Slot Wedge is the latest addition to [Company Name]'s extensive portfolio of products for the electrical and power generation industries. With a proven track record of delivering high-quality and reliable solutions, [Company Name] is trusted by customers around the world to provide the critical components and services needed to ensure the smooth operation of electrical systems."We are excited to introduce the 9334 Laminate Slot Wedge to the market, as we believe it represents a significant advancement in the field of electrical insulation and support," said [Spokesperson], [Title] at [Company Name]. "With its exceptional thermal and electrical properties, the 9334 Laminate Slot Wedge is poised to make a positive impact on the performance and reliability of electrical machines and generators."As the demand for more efficient and reliable electrical systems continues to grow, the introduction of the 9334 Laminate Slot Wedge is expected to address the needs of manufacturers and operators in various industries, including power generation, industrial automation, and renewable energy.With its focus on innovation and customer satisfaction, [Company Name] is well-positioned to play a critical role in shaping the future of the electrical industry, providing the vital components and technologies needed to power the world's infrastructure.For more information about the 9334 Laminate Slot Wedge and other innovative products from [Company Name], please visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading provider of advanced solutions for the electrical and power generation industries. With a comprehensive portfolio of products and services, [Company Name] is committed to delivering reliable, high-quality solutions that meet the evolving needs of the market. From critical components to cutting-edge technologies, [Company Name] is dedicated to driving advancements in electrical systems and ensuring the efficiency and reliability of power generation and distribution.

Durable Epoxy Glass Fabric: A Versatile Material for Various Applications

[Your Company Name] Introduces Innovative Epoxy Glass Fabric for Industrial Applications[City, Date] – [Your Company Name], a leading manufacturer of advanced materials, is proud to announce the launch of a breakthrough product in the field of industrial composites – Epoxy Glass Fabric. This cutting-edge material promises to revolutionize several industries with its superior mechanical properties and exceptional resistance to heat and chemicals.Epoxy Glass Fabric is a high-performance composite material that is formed by impregnating glass fiber fabric with epoxy resin. The resulting material exhibits excellent electrical insulation, mechanical strength, and dimensional stability, making it an ideal choice for a wide range of industrial applications.At the core of this innovative product is the use of high-quality glass fiber and epoxy resin. The glass fiber provides the material with high tensile strength and stiffness, while the epoxy resin enhances its durability and resistance to wear and tear. This unique combination of materials makes Epoxy Glass Fabric an ideal solution for demanding applications in sectors such as aerospace, automotive, electronics, and construction.One of the key advantages of Epoxy Glass Fabric is its exceptional resistance to heat and chemicals. This makes it an ideal material for use in environments where exposure to high temperatures and corrosive substances is common. Additionally, its high electrical insulation properties make it a preferred choice for applications in the electrical and electronics industry.Furthermore, Epoxy Glass Fabric is easy to process and can be molded into complex shapes, making it a versatile material for custom applications. Its lightweight nature also makes it an attractive option for applications where weight reduction is a critical factor.[Your Company Name] has invested considerable resources into research and development to ensure that Epoxy Glass Fabric meets the highest standards of quality and performance. This has been achieved through rigorous testing and validation processes, ensuring that the material complies with industry regulations and standards.“We are thrilled to introduce Epoxy Glass Fabric to the market. This innovative material opens up new possibilities for engineers and designers in various industries, providing them with a reliable and durable solution for their composite needs,” said [Your Company Name], CEO of [Your Company Name].With the launch of Epoxy Glass Fabric, [Your Company Name] aims to cater to the growing demand for advanced materials that offer superior performance and reliability. The company is confident that this new product will not only meet but exceed the expectations of its customers, setting new benchmarks in the industry.In addition to Epoxy Glass Fabric, [Your Company Name] offers a comprehensive range of advanced materials, including carbon fiber composites, thermoplastic composites, and hybrid materials. The company prides itself on its ability to develop innovative solutions that address the evolving needs of the industry.As a company that is committed to sustainability, [Your Company Name] ensures that its manufacturing processes adhere to the highest environmental standards. This includes the responsible sourcing of raw materials, energy-efficient production techniques, and the recycling of waste materials.In conclusion, the introduction of Epoxy Glass Fabric marks a significant milestone for [Your Company Name] and reinforces its position as a pioneering manufacturer of advanced materials. With its exceptional properties and versatile nature, this innovative material is set to make a lasting impact in various industrial sectors, driving efficiency and performance to new heights.For more information about Epoxy Glass Fabric and other advanced materials offered by [Your Company Name], please visit [Your Company Website].About [Your Company Name]:[Your Company Name] is a leading manufacturer of advanced materials, specializing in the production of composites, plastics, and specialty chemicals for various industries. With a commitment to innovation and sustainability, the company has established itself as a trusted partner for organizations seeking high-performance solutions for their industrial needs. [Your Company Name] prides itself on its ability to develop cutting-edge materials that meet the highest standards of quality, performance, and environmental responsibility. For more information, visit [Your Company Website].

Essential Guide to Transformer Insulation Pressboard

Transformer Insulation Pressboard is a critical component in the construction of transformers, playing a key role in insulating the electrical components and ensuring the safe and efficient operation of these essential devices. In recent years, the demand for high-quality transformer insulation pressboard has been on the rise, driven by the increasing reliance on electrical power systems and the need for reliable and sustainable energy infrastructure. One company that has been at the forefront of this industry is {}. With a long history of expertise and innovation in the field of transformer insulation materials, {} has established itself as a leading supplier of pressboard products for transformer manufacturers and utilities around the world.Established in [year], {} has grown to become a trusted name in the global electrical insulation industry, known for its commitment to quality, reliability, and customer satisfaction. The company's pressboard products are manufactured using state-of-the-art processes and technologies, ensuring that they meet the highest standards for performance and durability. With a focus on sustainability and environmental responsibility, {} has also developed a range of eco-friendly pressboard materials that are designed to minimize the environmental impact of transformer insulation production and use.In addition to its dedication to product excellence, {} has also built a reputation for its technical expertise and customer support. The company's team of engineers and technical specialists are available to provide guidance and support to transformer manufacturers and end-users, helping them to select the right pressboard products for their specific applications and requirements. With a strong emphasis on collaboration and partnership, {} works closely with its customers to develop customized solutions that meet their unique needs and challenges.One of the key strengths of {} is its global presence and distribution network. With manufacturing facilities and sales offices in multiple countries, the company is able to serve customers around the world with efficiency and flexibility. This global reach also enables {} to stay at the forefront of industry trends and developments, ensuring that its products and services remain at the cutting edge of transformer insulation technology.Looking to the future, {} remains committed to driving innovation and advancement in the field of transformer insulation pressboard. The company continues to invest in research and development, exploring new materials, technologies, and processes that will further enhance the performance, reliability, and sustainability of its products. At the same time, {} is dedicated to fostering strong relationships with its customers and partners, working together to address the evolving needs and challenges of the electrical power industry.As the demand for electrical power continues to grow, the role of transformer insulation pressboard in ensuring the reliable and safe operation of electrical infrastructure will only become more critical. With its proven track record of excellence, innovation, and customer focus, {} is well-positioned to continue leading the way in this important sector, providing the high-quality pressboard products and support that the industry relies on.

Everything You Need to Know About Plastic Laminate Sheet 3240 from China" can be rewritten as "A Comprehensive Guide to Plastic Laminate Sheet 3240 Manufactured in China".

Title: China's Plastic Laminate Sheet 3240: A Resilient and Versatile Solution for Various IndustriesIntroduction:China has emerged as a global leader in the production and export of high-quality plastic laminate sheets. Among these, the China Plastic Laminate Sheet 3240 stands out as an exceptional and reliable material. With its exceptional strength, electrical insulation properties, and resistance to various environmental conditions, the 3240 laminate sheet has become an indispensable material across numerous industries. This article explores the features, applications, and benefits of China's Plastic Laminate Sheet 3240, shedding light on its growing popularity in domestic and international markets.Features of China Plastic Laminate Sheet 3240:China Plastic Laminate Sheet 3240 is engineered to possess exceptional mechanical and electrical properties, making it highly suitable for demanding applications. Here are some noteworthy features:1. Superior Electrical Insulation: The 3240 laminate sheet is specifically designed to offer excellent electrical insulation, effectively reducing the risk of electrical short circuits or breakdowns. Its high dielectric strength and low water absorption contribute to its excellent insulating properties.2. Thermal Resistance: This laminate sheet possesses remarkable thermal resistance, allowing it to withstand high temperatures up to 150 degrees Celsius. It maintains its structural integrity even in environments with extreme heat, making it suitable for various applications requiring heat dissipation.3. Mechanical Strength: With its exceptional mechanical strength, China Plastic Laminate Sheet 3240 effectively resists mechanical stresses, impacts, and vibrations. This robustness renders it highly suitable for applications that demand durability and reliability.4. Chemical and Moisture Resistance: The 3240 laminate sheet demonstrates excellent resistance to a wide range of chemicals and moisture, ensuring long-term stability and reliability. This feature makes it suitable for use in humid or corrosive environments.Applications of China Plastic Laminate Sheet 3240:The versatility and reliability of China's Plastic Laminate Sheet 3240 contribute to its widespread application across various industries. Some notable applications include:1. Electrical Industry: The 3240 laminate sheet finds extensive use in electrical equipment such as transformer insulation, switchgears, and electrical motor components. Its excellent electrical insulation and thermal properties make it a preferred choice for these applications.2. Mechanical Engineering: Due to its exceptional mechanical strength and resistance to impacts and vibrations, the 3240 laminate sheet is widely utilized in mechanical engineering for manufacturing components such as gaskets, gears, and bushings.3. Construction and Architecture: China's Plastic Laminate Sheet 3240 is commonly employed in construction and architecture projects. It is utilized for panel insulations, decorative laminates, and structural reinforcements due to its fire resistance, durability, and resistance to extreme environmental conditions.4. Automotive Industry: The 3240 laminate sheet is increasingly used in the automotive industry for various applications, including insulation sheets, battery enclosures, and electric vehicle components. Its thermal resistance and mechanical strength make it a suitable choice for these demanding applications.Benefits and Advantages:The widespread adoption of China's Plastic Laminate Sheet 3240 can be attributed to its numerous benefits and advantages, including:1. Cost-effectiveness: The 3240 laminate sheet offers a cost-effective solution, ensuring value for money due to its long lifespan and durable properties. This makes it an attractive choice for businesses across different industries.2. Versatility: The material's versatility allows it to be tailored to specific requirements, enabling customization and adaptability across various applications.3. Eco-friendly: China's Plastic Laminate Sheet 3240 is also known for its eco-friendly properties. It is manufactured using environmentally friendly processes, contributing to sustainability efforts in today's world.Conclusion:China's Plastic Laminate Sheet 3240 has established itself as a reliable and versatile material, catering to the needs of numerous industries. Its exceptional electrical insulation, thermal resistance, and mechanical strength make it an optimal choice for a wide range of applications. As demand continues to grow, China remains at the forefront of producing and supplying high-quality laminate sheets that meet both domestic and international market requirements.