Semiconductor fiberglass sheets from China: News and Updates

By:Admin

The Chinese semiconductor industry has been experiencing rapid growth in recent years, driven by the increasing demand for electronic devices and advancements in technology. As a result, the demand for high-quality semiconductor materials has been on the rise, with fiberglass sheets playing a vital role in the production of semiconductor components.

One of the key players in the Chinese semiconductor fiberglass sheet market is a leading company, specializing in the manufacturing and supply of high-performance fiberglass sheets for the semiconductor industry. With a strong focus on research and development, the company has been at the forefront of innovation, producing advanced materials that meet the stringent requirements of the semiconductor industry.

The company's fiberglass sheets are widely used in the production of semiconductor components, such as printed circuit boards (PCBs), integrated circuits (ICs), and electronic devices. These sheets are known for their exceptional electrical insulation properties, high mechanical strength, and temperature resistance, making them ideal for use in the demanding environment of semiconductor manufacturing.

In addition to their outstanding performance characteristics, the company's fiberglass sheets are also known for their high reliability and consistency, ensuring the consistent quality of semiconductor components. This has made the company a preferred supplier for many semiconductor manufacturers in China and beyond.

The Chinese semiconductor fiberglass sheet market has been experiencing strong growth, driven by the increasing demand for electronic devices and the rapid expansion of the semiconductor industry. With the ongoing advancements in technology, the demand for advanced semiconductor materials, such as fiberglass sheets, is expected to continue to grow.

One of the key factors driving the growth of the Chinese semiconductor fiberglass sheet market is the rapid expansion of the semiconductor industry in the country. China has been investing heavily in its semiconductor industry, with the goal of becoming a global leader in semiconductor manufacturing. This has led to a surge in the demand for high-quality semiconductor materials, including fiberglass sheets, driving the growth of the market.

In addition, the growing adoption of advanced electronic devices, such as smartphones, tablets, and wearables, has further fueled the demand for semiconductor components, driving the demand for high-performance semiconductor materials. This has created significant opportunities for companies like {} to capitalize on the growing demand for semiconductor fiberglass sheets in China.

Furthermore, the increasing focus on the development of smart cities, Internet of Things (IoT) devices, and artificial intelligence (AI) technologies is expected to drive the demand for semiconductor components, contributing to the growth of the semiconductor materials market in China. As a result, the company is well-positioned to benefit from the booming demand for high-quality semiconductor fiberglass sheets in the country.

With its strong commitment to innovation, quality, and customer satisfaction, {} is poised to play a significant role in the growth of the Chinese semiconductor fiberglass sheet market. The company's advanced manufacturing capabilities, extensive research and development efforts, and longstanding expertise in the semiconductor industry make it a reliable and trusted partner for semiconductor manufacturers in China and beyond.

As the demand for high-quality semiconductor materials continues to surge in China, companies like {} are well-positioned to capitalize on the growth opportunities in the Chinese semiconductor fiberglass sheet market. With a strong focus on technology innovation, product quality, and customer satisfaction, the company is set to play a pivotal role in meeting the growing demand for high-performance semiconductor materials in China's booming semiconductor industry.

Company News & Blog

Top Quality Epoxy Glassfiber Sheet Insulating Sheet: Titanium White/Black EPGC201/EPGC204

Our company is pleased to announce the launch of a new product, Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet insulating sheet, designed to meet the needs of the modern electrical and engineering industries. This innovative product is set to revolutionize the market with its high-quality materials and superior performance.The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a state-of-the-art insulating sheet that offers excellent electrical insulation properties, high dimensional stability, and mechanical strength. It is widely used in electrical equipment, electric motors, PCB drilling pads, and many other industrial applications. The product is available in both white and black colors, offering customers flexibility and choice to suit their specific requirements.Our company has a long-standing reputation for delivering reliable and high-quality products to our customers. With a commitment to innovation and excellence, we are constantly striving to offer the latest advancements in technology and materials. The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a testament to our dedication to meeting the evolving needs of the industry.One of the key features of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is its exceptional thermal and chemical resistance. This makes it suitable for use in harsh and demanding environments, where it can withstand extreme temperatures and exposure to chemicals. The product is also resistant to moisture, making it an ideal choice for outdoor and marine applications.In addition, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet offers outstanding electrical insulation properties, ensuring the safety and reliability of electrical equipment. It has high dielectric strength and low water absorption, providing excellent insulation in a variety of electrical and electronic applications.The mechanical strength of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is another standout feature. It has high flexural and impact strength, as well as excellent dimensional stability, ensuring long-term performance and durability. This makes it a preferred choice for structural and mechanical applications in the engineering and construction industries.Our company is proud to offer the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet in a range of thicknesses and dimensions, catering to the diverse needs of our customers. We understand the importance of providing versatile and customizable solutions, and we are committed to delivering products that meet the specific requirements of each project.With the launch of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet, our company is poised to further solidify its position as a leading provider of high-performance materials for the electrical and engineering industries. We are confident that this product will set a new standard for excellence in insulation and engineering materials, and we look forward to seeing the positive impact it will have on our customers' projects.In conclusion, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a cutting-edge product that offers superior electrical insulation, thermal and chemical resistance, and mechanical strength. Backed by our company's commitment to quality and innovation, this product is set to make a significant impact in the market and provide our customers with a reliable and high-performance solution for their insulation and engineering needs.

High-Quality Flexible Fiberglass Sheets for Versatile Applications

Flexible Fiberglass Sheets: A Versatile Solution for Various ApplicationsFiberglass is a versatile and durable material that has been widely used in the construction and manufacturing industries. It is valued for its strength, flexibility, and resistance to corrosion, making it an ideal choice for a wide range of applications.{Company name} is a leading manufacturer of flexible fiberglass sheets, offering high-quality products that meet the needs of diverse industries. With a strong focus on innovation and product development, the company has established a reputation for delivering reliable and cost-effective solutions to its customers.Flexible fiberglass sheets, also known as FRP (Fiberglass Reinforced Plastic), are made by combining fine glass fibers with polymer resins. This results in a material that is lightweight, yet incredibly strong and durable. The flexibility of fiberglass sheets makes them suitable for a wide range of applications, from construction and automotive to marine and aerospace.One of the key advantages of flexible fiberglass sheets is their resistance to corrosion and weathering. This makes them an ideal choice for outdoor and marine applications, where exposure to moisture and harsh environments can cause traditional materials to deteriorate over time. Additionally, fiberglass sheets are non-conductive and have excellent thermal insulation properties, making them a popular choice for electrical and HVAC applications.{Company name}'s flexible fiberglass sheets are available in a wide range of sizes, thicknesses, and surface finishes to meet the specific requirements of different projects. Whether it's a small-scale DIY project or a large-scale industrial application, the company offers customizable solutions to fit the unique needs of its customers.In addition to their durability and flexibility, fiberglass sheets are also easy to install and maintain. Unlike traditional materials such as steel or wood, fiberglass does not require painting or sealing to protect it from the elements. This reduces the long-term maintenance costs and ensures that the material retains its strength and appearance over time.{Company name}'s commitment to quality and innovation is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. The company invests in the latest technology and equipment to ensure that its products meet the highest industry standards and exceed customer expectations.As the demand for sustainable and eco-friendly materials continues to grow, fiberglass has emerged as a popular choice for architects, engineers, and designers looking to reduce the environmental impact of their projects. Fiberglass is fully recyclable and can be repurposed at the end of its lifespan, making it a more sustainable alternative to traditional building materials.In conclusion, flexible fiberglass sheets are a versatile and cost-effective solution for a wide range of applications, and {company name} is a trusted provider of high-quality fiberglass products. With its commitment to innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry and drive the adoption of fiberglass as a preferred material choice. Whether it's for construction, transportation, or industrial applications, flexible fiberglass sheets offer a durable and sustainable solution for today's most demanding projects.

Discover the Benefits of Epoxy Fiberglass Sheet for Industrial Use

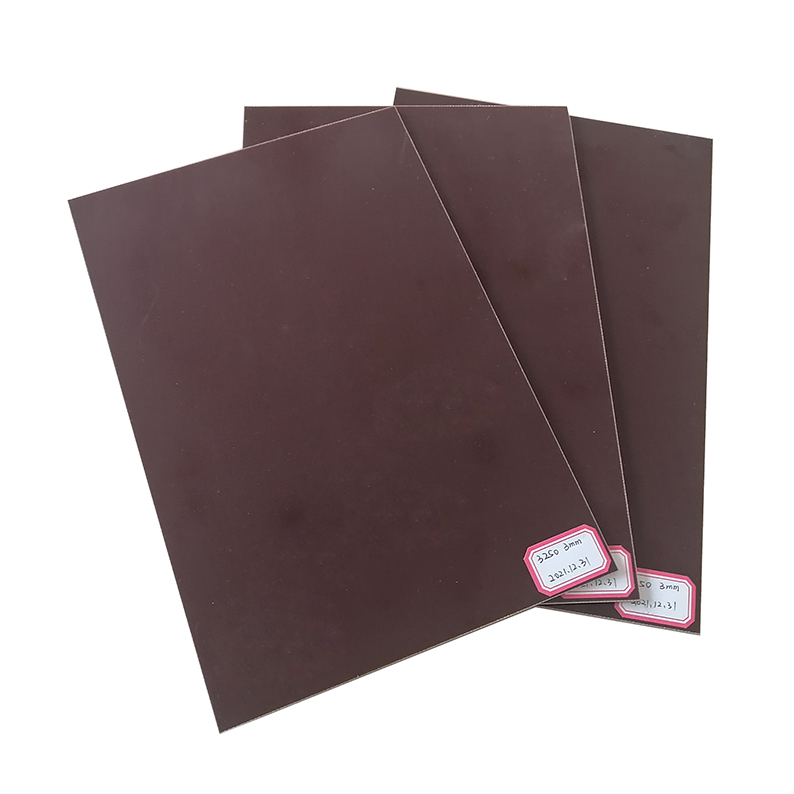

Title: Introducing High-Quality Epoxy Fiberglass Sheets for Various Industrial ApplicationsIntroduction:In recent news, industry-leading manufacturer {} is proud to announce the launch of their latest product, the 3240 Epoxy Fiberglass Sheet. Designed with cutting-edge technology and superior materials, this new addition to their extensive product range is set to revolutionize various industrial applications. With its exceptional properties and versatile nature, the 3240 Epoxy Fiberglass Sheet promises to be a game-changer in the field.1. Overview of the 3240 Epoxy Fiberglass Sheet:The 3240 Epoxy Fiberglass Sheet is a high-performance composite material crafted using epoxy resin and fine fiberglass cloth. This combination results in a sturdy and resilient sheet that exhibits excellent mechanical, thermal, and electrical insulation properties. Its exceptional dielectric strength, along with resistance to heat, chemicals, and moisture, makes it a reliable choice for a wide range of industries.2. Applications in Electrical Engineering:The electrical engineering industry requires materials that can withstand high temperatures and offer superior electrical insulation. The 3240 Epoxy Fiberglass Sheet meets these requirements flawlessly. It can be seamlessly incorporated into electrical insulation systems, such as slot insulations, transformer barriers, and liner insulation for motors and generators.3. Utilization in the Automotive Sector:In the automotive industry, where temperature variations, vibrations, and exposure to harsh fluids are common, the 3240 Epoxy Fiberglass Sheet excels. It can be applied in various automobile components, including engine gaskets, electrical connectors, and spark plug insulators, ensuring durability and reliability under extreme conditions.4. Role in the Aerospace Industry:With its exceptional reliability and strength, the 3240 Epoxy Fiberglass Sheet finds numerous applications in the aerospace sector. From aircraft insulation to circuit boards and radomes, this sheet exhibits outstanding mechanical strength, temperature resistance, and electrical insulation properties, ensuring optimal performance in the most demanding environments.5. Benefits in Manufacturing and Engineering:Manufacturing and engineering sectors often require materials that can endure heavy mechanical stress and extreme temperatures. The 3240 Epoxy Fiberglass Sheet proves to be an ideal solution, offering exceptional resistance to both tension and compression. It can be used for manufacturing molded parts, panels, and laminates, contributing to robust and long-lasting structures.6. Ensuring Quality and Compliance:{Company Name} takes immense pride in the quality and compliance of its products. The 3240 Epoxy Fiberglass Sheet meets rigorous industry standards, including the electrical insulation requirements of the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Customers can have confidence in the superior performance and safety of this product.7. Commitment to Sustainability:{Company Name} places significant importance on sustainability, and the 3240 Epoxy Fiberglass Sheet follows suit. The material is manufactured using eco-friendly processes that minimize waste and energy consumption. Additionally, its long lifespan and resistance to degradation contribute to reduced material waste and overall environmental impact.Conclusion:The launch of the 3240 Epoxy Fiberglass Sheet by {} represents a significant breakthrough in composite material technology. Its remarkable insulation, thermal resistance, and mechanical strength make it a versatile and reliable choice for various industries. With its commitment to quality, compliance, and sustainability, {} continues to redefine excellence in the field of composite materials.

High-Quality Epoxy Glass Cloth Laminate Sheet from China: A Must-Have for Your Projects

China Epoxy Glass Cloth Laminate Sheet is a revolutionary product that is set to take the industrial world by storm. This high-quality laminate sheet is manufactured using advanced technology and top-notch materials to ensure its exceptional performance and durability. The product is specifically designed to meet the diverse needs of various industries, including electrical, electronics, mechanical, and aerospace.The China Epoxy Glass Cloth Laminate Sheet is known for its outstanding electrical insulation properties. It is capable of withstanding high voltage and temperature, making it an ideal choice for electrical and electronic applications. The laminate sheet also offers great mechanical strength and superior dimensional stability, making it suitable for use in demanding industrial environments.In addition to its exceptional technical properties, the China Epoxy Glass Cloth Laminate Sheet is also renowned for its excellent chemical resistance. It can withstand exposure to a wide range of chemicals, acids, and solvents without any deterioration in performance. This makes it a preferred choice for applications where exposure to harsh chemicals is a concern.Furthermore, the China Epoxy Glass Cloth Laminate Sheet is lightweight and easy to work with, allowing for easy fabrication and installation. Its versatility and ease of use have made it a popular choice among engineers and manufacturers across different industries.The company behind the China Epoxy Glass Cloth Laminate Sheet is a leading manufacturer of industrial materials and components. With decades of experience in the industry, the company has established itself as a reliable and trusted supplier of high-quality products. The company's commitment to quality and innovation is reflected in the superior performance and reliability of their products.The China Epoxy Glass Cloth Laminate Sheet is a testament to the company's dedication to providing cutting-edge solutions to its customers. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every sheet produced meets the highest standards of quality and performance.The company also prides itself on its commitment to sustainability and environmental responsibility. The China Epoxy Glass Cloth Laminate Sheet is manufactured using eco-friendly processes and materials, in line with the company's efforts to minimize its environmental footprint.The China Epoxy Glass Cloth Laminate Sheet is available in a variety of grades and specifications to cater to the specific requirements of different industries. Whether it is for electrical insulation, mechanical support, or chemical resistance, there is a China Epoxy Glass Cloth Laminate Sheet that is tailored to meet the unique needs of each application.With its unparalleled performance, reliability, and versatility, the China Epoxy Glass Cloth Laminate Sheet is set to become the go-to choice for engineers and manufacturers across the globe. Its exceptional properties make it a valuable asset in a wide range of industries, from aerospace and automotive to energy and telecommunications.In conclusion, the China Epoxy Glass Cloth Laminate Sheet is a game-changing product that is poised to revolutionize the industrial landscape. Its outstanding technical properties, reliability, and environmental friendliness make it a standout choice for a wide range of applications. With the backing of a reputable and innovative company, the China Epoxy Glass Cloth Laminate Sheet is set to make its mark as a leading solution for industrial needs.

Durable Fiberglass Laminate Sheet for Various Applications

Fiberglass Laminate Sheet Revolutionizes the IndustryFiberglass laminate sheets have been around for years, but the latest innovation in this field is taking the industry by storm. Companies such as {} are leading the way in producing high-quality, durable fiberglass laminate sheets that are revolutionizing the market.{} is a leading manufacturer of fiberglass laminate sheets, with a long history of delivering top-notch products to a wide range of industries. With a strong commitment to innovation and customer satisfaction, the company has quickly become a trusted name in the industry.The latest fiberglass laminate sheets from {} are designed to offer unmatched durability and versatility. These sheets are made from high-quality fiberglass material, which is known for its strength and resilience. This makes them ideal for a wide range of applications, from construction and automotive to marine and aerospace.One of the key advantages of {}'s fiberglass laminate sheets is their exceptional resistance to corrosion and extreme temperatures. This makes them ideal for use in harsh environments where other materials may fail. In addition, the sheets are also lightweight and easy to work with, making them a preferred choice for many manufacturers and builders.Another standout feature of {}'s fiberglass laminate sheets is their ability to provide excellent electrical insulation. This makes them suitable for use in electrical and electronic applications, where safety and reliability are paramount. With their high dielectric strength and low electrical conductivity, these sheets offer peace of mind to users in these industries.In addition to their superior performance, {}'s fiberglass laminate sheets are also available in a wide range of sizes, thicknesses, and finishes to suit different customer needs. This customization is a testament to the company's dedication to meeting the diverse requirements of its clients.Furthermore, {} is committed to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to the highest environmental standards, and it continues to explore ways to reduce its carbon footprint. By choosing {}'s fiberglass laminate sheets, customers can be confident that they are supporting a company that prioritizes environmental stewardship.With a strong focus on research and development, {} continues to push the boundaries of what is possible with fiberglass laminate sheets. The company's team of experts is constantly working on new formulations and manufacturing techniques to further improve the performance and capabilities of its products.Customers who have used {}'s fiberglass laminate sheets have been highly impressed with their quality and reliability. Many have reported significant cost savings and improved product performance after switching to these innovative sheets. With such positive feedback, {} has solidified its position as a leader in the fiberglass laminate sheet industry.Overall, the latest advancements in fiberglass laminate sheets from {} are changing the game for manufacturers and builders across various industries. With their exceptional durability, versatility, and environmental credentials, these sheets are set to become the go-to choice for many applications in the coming years. As {} continues to innovate and refine its products, the future looks bright for fiberglass laminate sheets and the industries they serve.

High Quality Laminate Slot Wedge for Industrial Applications

9334 Laminate Slot Wedge: Improving Efficiency and Reliability in Electrical MachinesIn the world of electrical machines, efficiency and reliability are two of the most important factors to consider. Whether it's a motor, generator, or transformer, these machines play a critical role in countless industries and applications around the globe. One key component that helps improve the efficiency and reliability of these machines is the 9334 Laminate Slot Wedge, a product that has been designed and manufactured by a leading company in the field of electrical insulation materials.The 9334 Laminate Slot Wedge is a crucial component in electrical machines, as it helps to optimize the performance and durability of the machines by providing insulation and support to the winding components. This product is made of high-quality laminate materials, and its unique design allows for easy installation and excellent thermal and mechanical properties. As a result, electrical machines equipped with the 9334 Laminate Slot Wedge are able to operate more efficiently and reliably, ultimately leading to cost savings and improved productivity for the end users.{The company} is a renowned manufacturer of electrical insulation materials, with a strong focus on innovation and quality. With decades of experience in the industry, {the company} has established itself as a trusted partner for countless OEMs and end users around the world. The company's commitment to excellence and customer satisfaction has driven them to continuously develop new and improved products, such as the 9334 Laminate Slot Wedge, in order to meet the evolving needs of the market and exceed the expectations of their customers.One of the key advantages of the 9334 Laminate Slot Wedge is its ability to enhance the thermal performance of electrical machines. With its superior thermal conductivity and heat dissipation properties, this product helps to reduce the risk of overheating and insulation degradation, which are common causes of failure in electrical machines. By using the 9334 Laminate Slot Wedge, OEMs and end users can expect their machines to operate at lower temperatures and achieve a longer service life, ultimately resulting in lower maintenance costs and higher uptime.In addition to its thermal benefits, the 9334 Laminate Slot Wedge also offers excellent mechanical strength and insulation properties. This product is designed to provide robust support and protection to the winding components of electrical machines, which are often subjected to high levels of mechanical stress and electrical voltage. By using the 9334 Laminate Slot Wedge, OEMs and end users can ensure that their machines are well-protected against potential damage and breakdowns, thus minimizing the risk of downtime and costly repairs.Furthermore, the 9334 Laminate Slot Wedge is easy to install and highly adaptable to different machine designs. Whether it's a small motor or a large generator, this product can be customized to fit various slot geometries and dimensions, allowing for seamless integration into different types of electrical machines. As a result, OEMs and end users can enjoy greater flexibility and convenience when incorporating the 9334 Laminate Slot Wedge into their products, without compromising on performance or reliability.Overall, the 9334 Laminate Slot Wedge is a key enabler for improving the efficiency and reliability of electrical machines. With its superior thermal and mechanical properties, as well as its ease of installation and adaptability, this product offers tangible benefits for OEMs and end users across a wide range of industries and applications. As {the company} continues to innovate and expand its product offerings, the 9334 Laminate Slot Wedge stands out as a prime example of their commitment to driving positive change in the field of electrical insulation materials, and ultimately, in the performance of electrical machines around the world.

High-Quality Insulation Laminate Sheet: A Complete Guide

Insulation Laminate Sheet Enhances Thermal Performance and Safety in Electrical ApplicationsWith the ever-growing demand for energy efficiency and safety in the electrical industry, the use of Insulation Laminate Sheet has become increasingly popular. This innovative material is designed to enhance thermal performance and provide a high level of resistance to electrical current, making it an essential component in a wide range of applications.Insulation Laminate Sheet, also known as insulation paper, is a composite material made by impregnating high-quality insulating paper with a phenolic resin or epoxy resin and then laminating it under high pressure and temperature. This process creates a durable and reliable material that provides excellent electrical insulation and thermal resistance, making it suitable for use in transformers, motors, generators, and other electrical devices.The company {} is a leading manufacturer and supplier of insulation laminate sheet, offering a wide range of products to meet the diverse needs of the electrical industry. With a strong focus on quality and innovation, {} has established a solid reputation for delivering high-performance insulation materials that exceed industry standards.One of the key advantages of Insulation Laminate Sheet from {} is its ability to enhance thermal performance in electrical applications. By providing superior thermal conductivity and heat resistance, this material helps to improve the overall efficiency and reliability of electrical devices, ensuring optimum performance even under extreme operating conditions.In addition to its thermal properties, Insulation Laminate Sheet also offers exceptional electrical insulation, effectively preventing the leakage of current and ensuring the safety of electrical equipment and personnel. This is particularly important in high-voltage applications where the risk of electrical arcing and breakdown is a major concern.Furthermore, {} offers a range of Insulation Laminate Sheet products that are specifically designed to meet international safety and quality standards, including UL, CE, and RoHS certifications. This ensures that customers can have confidence in the performance and reliability of the insulation materials they use in their electrical applications.Another notable feature of Insulation Laminate Sheet from {} is its versatility and ease of use. The material can be easily cut, shaped, and bonded to fit the specific requirements of different electrical components, allowing for greater design flexibility and customization in various applications.With a strong emphasis on research and development, {} is continuously innovating and improving its insulation laminate sheet products to meet the evolving needs of the electrical industry. This commitment to innovation has enabled the company to stay ahead of the curve and deliver cutting-edge insulation solutions that drive performance, efficiency, and safety for its customers.As the demand for energy-efficient and safe electrical equipment continues to grow, Insulation Laminate Sheet from {} is expected to play a crucial role in meeting these requirements. With its combination of high thermal performance, excellent electrical insulation, and international certifications, this innovative material is set to be a leading choice for engineers and manufacturers seeking reliable and effective insulation solutions for their electrical applications.In conclusion, Insulation Laminate Sheet from {} is a game-changing material that offers superior thermal performance and safety in electrical applications. With its proven track record of quality and innovation, {} is well-positioned to meet the growing demand for high-performance insulation materials in the electrical industry. As technology continues to advance, Insulation Laminate Sheet is set to play a key role in shaping the future of energy-efficient and safe electrical equipment.

Solutions to Common Decorating Problems: The Problem Solver for Fibreglass

Fibreglass Sheets UK: The Solution to All Your Decorating ProblemsDecorating a home or business can be an exciting task, but it can also be complicated. From choosing the right colours to installing the right materials, the process can be stressful and challenging. However, with the right help and products, these challenges can be mitigated, and the process can become much more manageable. This is where Fibreglass Sheets UK enters the picture.Fibreglass Sheets UK is a leading supplier of high-quality fibreglass materials, providing customers with innovative and reliable solutions to their everyday decorating problems. As an experienced and reputable company, they understand the demands and requirements of modern-day decorating and are dedicated to providing their customers with a range of products that are not only of the highest quality but also deliver value and exceptional performance.Brewers Decorators Centres, in cooperation with Fibreglass Sheets UK, have recently launched a series of products that offer innovative solutions to common decorating problems. These products include the new Everbuild Wonder Wipes, Shield prime and Seal and Fibreglass Surface Tissue. Everbuild Wonder Wipes are the perfect solution for removing paint, sealant, adhesive, bitumen, oil, grease and much more from hands, tools and surfaces. These multi-purpose wipes are strong, absorbent and durable and are suitable for use both indoors and outdoors. They are perfect for everyday use on the job site and can be used to clean up any messes or spills.Shield Prime and Seal is a premium-quality clear sealer that is suitable for use on a range of different surfaces, including plasterboard, cement board, fibre cement, and painted surfaces. It is specially designed to provide a water-resistant and long-lasting seal that protects against moisture and stains, which can damage the underlying surface. It is easy to use and can be applied with a brush or roller in just a few simple steps.Fibreglass Surface Tissue is another exciting product from Fibreglass Sheets UK. It is a high-quality, non-woven fabric that is designed to provide added strength and durability to fibreglass laminates. It is compatible with a wide range of resins and is perfect for use in boats, aircraft, and other applications where strength and durability are essential.These products are just a few examples of how Fibreglass Sheets UK is helping homeowners and decorators solve some of the most common decorating problems. They offer a diverse range of materials that are designed to deliver exceptional performance, and they are continuously exploring new ways to innovate and create practical solutions to everyday problems.Fibreglass Sheets UK has built a reputation for delivering excellent customer service and support, and they are committed to providing their customers with the best possible experience. They work hard to understand their customers' requirements and needs, and they are always available to answer any questions or provide expert advice.In conclusion, decorating a home or business can be overwhelming, but Fibreglass Sheets UK has made the process much more manageable by providing innovative and reliable solutions to common decorating problems. With their help, homeowners and decorators can be assured that they will have the right products and support to get the job done right.

NIA Reveals New Executive Committee and Board of Directors for 2020-2021 Term

Insulation Board: The Key to Energy Efficiency and SustainabilityInsulation is an essential component of any building, playing a crucial role in improving energy efficiency and reducing environmental impact. With the growing emphasis on sustainability and energy conservation, the demand for effective insulation solutions has never been higher. In this blog post, we will discuss the significance of insulation board and its role in creating a sustainable future. Insulation board is a versatile material that is commonly used in residential, commercial, and industrial applications. It is designed to provide thermal insulation, preventing heat loss or gain, thus reducing energy consumption for heating and cooling purposes. The insulation board acts as a barrier, preventing the transfer of heat between the internal and external environments, resulting in improved energy efficiency, lower utility bills, and reduced carbon emissions. One of the key advantages of insulation board is that it offers excellent thermal resistance, providing maximum insulation value with minimal thickness. This allows for greater flexibility in design and construction, enabling architects and engineers to optimize space utilization. Insulation board is available in multiple thicknesses, densities, and materials, including fiberglass, mineral wool, expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (polyiso). Each material has distinct properties, making them suitable for specific applications and environments. Fiberglass insulation board, for instance, is widely used in residential and commercial building projects, offering excellent thermal and sound insulation properties. Mineral wool, a popular choice for industrial applications, provides superior fire resistance and sound absorption. EPS, XPS, and polyiso are highly effective in moisture control, making them ideal for areas prone to water damage, such as basements and crawl spaces. In addition to thermal insulation, insulation board also offers other benefits, such as acoustical insulation, moisture control, and improved indoor air quality. Soundproofing is a crucial requirement in many buildings, especially those located in noisy urban areas or near transportation hubs. Insulation board with sound absorption properties can effectively reduce noise pollution, creating a more peaceful and comfortable indoor environment. Moisture control is equally important, as excessive moisture can lead to mold growth, structural damage, and poor indoor air quality. Insulation board with moisture-resistant properties creates a protective barrier, preventing water vapor from entering the building envelope and safeguarding it against potential issues. This is particularly relevant for regions with high humidity levels or buildings located in flood-prone areas. Indoor air quality is another significant consideration, as poor ventilation and pollutant infiltration can negatively impact occupants' health and well-being. Insulation board with low VOC (volatile organic compounds) emissions and formaldehyde-free composition helps maintain a healthy indoor environment by minimizing the release of harmful chemicals into the air. The use of insulation board aligns with the principles of sustainability, contributing to the overall energy efficiency and environmental performance of a building. Energy-efficient buildings reduce dependency on fossil fuels, lower greenhouse gas emissions, and conserve natural resources. Additionally, insulation board can contribute to certifications such as LEED (Leadership in Energy and Environmental Design) and ENERGY STAR, further enhancing a building's value and marketability. Choosing the right insulation board for a project is crucial for maximizing its benefits. Factors to consider include thermal conductivity, fire resistance, moisture resistance, durability, and environmental impact. It is essential to consult with experts and professionals, such as insulation contractors and engineers, to determine the most appropriate insulation board for specific applications and regulatory requirements. In conclusion, insulation board plays a pivotal role in achieving energy efficiency and sustainability in buildings. Its ability to provide effective thermal insulation, soundproofing, moisture control, and improved indoor air quality makes it an indispensable material for construction projects. By selecting the right insulation board and ensuring proper installation, building owners can reap long-term benefits, including reduced energy consumption, increased comfort, and a greener future.

Durable Epoxy Glass Fabric: A Versatile Material for Various Applications

[Your Company Name] Introduces Innovative Epoxy Glass Fabric for Industrial Applications[City, Date] – [Your Company Name], a leading manufacturer of advanced materials, is proud to announce the launch of a breakthrough product in the field of industrial composites – Epoxy Glass Fabric. This cutting-edge material promises to revolutionize several industries with its superior mechanical properties and exceptional resistance to heat and chemicals.Epoxy Glass Fabric is a high-performance composite material that is formed by impregnating glass fiber fabric with epoxy resin. The resulting material exhibits excellent electrical insulation, mechanical strength, and dimensional stability, making it an ideal choice for a wide range of industrial applications.At the core of this innovative product is the use of high-quality glass fiber and epoxy resin. The glass fiber provides the material with high tensile strength and stiffness, while the epoxy resin enhances its durability and resistance to wear and tear. This unique combination of materials makes Epoxy Glass Fabric an ideal solution for demanding applications in sectors such as aerospace, automotive, electronics, and construction.One of the key advantages of Epoxy Glass Fabric is its exceptional resistance to heat and chemicals. This makes it an ideal material for use in environments where exposure to high temperatures and corrosive substances is common. Additionally, its high electrical insulation properties make it a preferred choice for applications in the electrical and electronics industry.Furthermore, Epoxy Glass Fabric is easy to process and can be molded into complex shapes, making it a versatile material for custom applications. Its lightweight nature also makes it an attractive option for applications where weight reduction is a critical factor.[Your Company Name] has invested considerable resources into research and development to ensure that Epoxy Glass Fabric meets the highest standards of quality and performance. This has been achieved through rigorous testing and validation processes, ensuring that the material complies with industry regulations and standards.“We are thrilled to introduce Epoxy Glass Fabric to the market. This innovative material opens up new possibilities for engineers and designers in various industries, providing them with a reliable and durable solution for their composite needs,” said [Your Company Name], CEO of [Your Company Name].With the launch of Epoxy Glass Fabric, [Your Company Name] aims to cater to the growing demand for advanced materials that offer superior performance and reliability. The company is confident that this new product will not only meet but exceed the expectations of its customers, setting new benchmarks in the industry.In addition to Epoxy Glass Fabric, [Your Company Name] offers a comprehensive range of advanced materials, including carbon fiber composites, thermoplastic composites, and hybrid materials. The company prides itself on its ability to develop innovative solutions that address the evolving needs of the industry.As a company that is committed to sustainability, [Your Company Name] ensures that its manufacturing processes adhere to the highest environmental standards. This includes the responsible sourcing of raw materials, energy-efficient production techniques, and the recycling of waste materials.In conclusion, the introduction of Epoxy Glass Fabric marks a significant milestone for [Your Company Name] and reinforces its position as a pioneering manufacturer of advanced materials. With its exceptional properties and versatile nature, this innovative material is set to make a lasting impact in various industrial sectors, driving efficiency and performance to new heights.For more information about Epoxy Glass Fabric and other advanced materials offered by [Your Company Name], please visit [Your Company Website].About [Your Company Name]:[Your Company Name] is a leading manufacturer of advanced materials, specializing in the production of composites, plastics, and specialty chemicals for various industries. With a commitment to innovation and sustainability, the company has established itself as a trusted partner for organizations seeking high-performance solutions for their industrial needs. [Your Company Name] prides itself on its ability to develop cutting-edge materials that meet the highest standards of quality, performance, and environmental responsibility. For more information, visit [Your Company Website].