Slot Wedge: A New and Innovative Product for Good 9334

By:Admin

In the world of industrial machinery, the importance of precision and efficiency cannot be overstated. Every small component plays a crucial role in the smooth and reliable operation of heavy-duty equipment. This is why the introduction of the Good 9334 Slot Wedge has been making waves in the industry. This innovative product is set to revolutionize the way machines are built and maintained, offering improved performance, durability, and ease of use.

The Good 9334 Slot Wedge, produced by the reputable company {}, is a specially designed component that has been engineered to perfection. It is made from high-quality materials and boasts impressive mechanical properties that make it a standout product in its category. This slot wedge has been designed to fit various industrial machinery, providing a secure and stable connection that enhances the overall performance and longevity of the equipment.

One of the key features of the Good 9334 Slot Wedge is its versatility. It can be used in a wide range of applications, making it an indispensable part for maintenance and repair professionals. Its universal design means that it can be easily integrated into different types of machinery, saving time and effort when it comes to sourcing specific components for specific equipment.

Another notable aspect of the Good 9334 Slot Wedge is its durability. Made from robust materials, this slot wedge is built to withstand the harsh conditions of industrial environments, including heavy loads, high temperatures, and extensive wear and tear. This durability ensures that the machinery remains in optimal condition for longer periods, reducing the need for frequent replacements and repairs.

In addition to its robust construction, the Good 9334 Slot Wedge also offers ease of installation and maintenance. It has been designed with user-friendliness in mind, allowing for quick and hassle-free assembly. This not only saves time but also minimizes the risk of errors during installation, ensuring that the equipment operates at its best from the get-go. Furthermore, its low-maintenance nature means that it requires minimal attention once installed, contributing to overall efficiency and cost-effectiveness.

The impact of the Good 9334 Slot Wedge goes beyond its impressive features. Its introduction has been met with enthusiasm by industry professionals, who recognize its potential to enhance the performance and reliability of their machinery. As a result, many companies are considering integrating this innovative product into their existing equipment, with the aim of optimizing their operations and staying ahead of the competition.

{"Company name} is dedicated to providing cutting-edge solutions for the industrial sector. With a strong focus on quality, innovation, and customer satisfaction, the company has earned a reputation as a reliable and forward-thinking manufacturer of industrial components. The Good 9334 Slot Wedge is a testament to their commitment to excellence, delivering a product that meets the high standards of the industry and exceeds the expectations of their customers.

In conclusion, the introduction of the Good 9334 Slot Wedge marks a significant advancement in the field of industrial machinery. Its exceptional quality, versatility, durability, and user-friendliness make it a game-changer for professionals in the industry. As companies continue to seek ways to improve the performance and reliability of their equipment, this innovative product is poised to play a vital role in shaping the future of industrial machinery. With the backing of a reputable company like {}, the Good 9334 Slot Wedge is set to make a lasting impact on the industry, setting new standards for excellence and innovation.

Company News & Blog

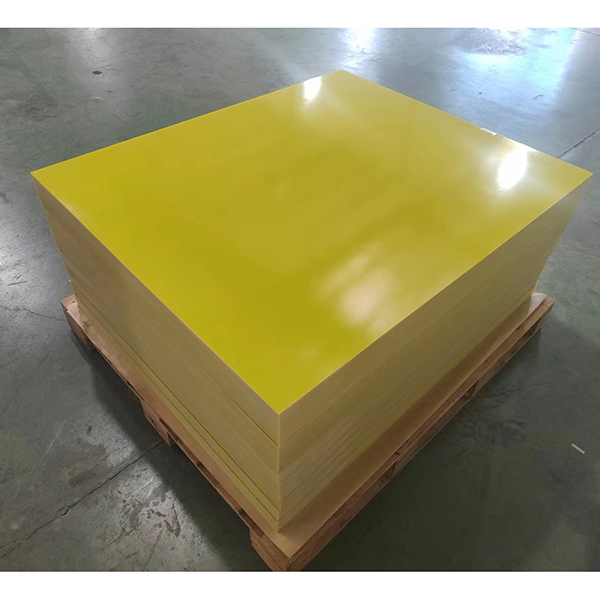

China High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet – Top-Grade Insulation Product Revealed

China High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet: A Game-Changer in Electrical Insulation MaterialsChina's technological advancements have always been a subject of admiration, and the country's achievements in the electrical insulation materials sector are no different. The introduction of the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has left experts impressed with the technological finesse, unprecedented quality, and their sustainability quotient. This breakthrough product in the market offers a unique set of characteristics that make it stand out from the rest.Designed by a top-tier Chinese materials and technology company, the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent component for transformer insulation, as well as electrical and mechanical equipment. The unique features of this innovative product make it an ideal choice in the electrical industry, allowing for unmatched performance, durability, and efficiency.As we embark upon a new era of energy transition and witnessing an unprecedented surge in demand for clean energy, the demand for high-quality electrical insulation materials has increased significantly. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet's entry into the market is expected to change the game for the better, meeting the industry's evolving demands.Overview of the ProductThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is a composite laminate material that comprises high-quality epoxy resin-reinforced with glass fiber. The result of this combination is an electrically insulating material that boasts exceptional mechanical strength, improved heat resistance, and is chemical-resistant. Additionally, the product's self-extinguishing properties ensure that it is a fire-safe component, adding an extra layer of safety in high electrical load equipment.The epoxy resin used in the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet exhibits excellent dielectric properties, making it an ideal insulating material for high voltage and high-frequency applications. The high dielectric strength and low dielectric loss exhibited by this product are vital for electrical equipment and transformers' insulation, which require a high degree of insulation.Furthermore, the product's mechanical strength allows it to withstand external forces, making it an ideal component for high-vibration equipment commonly found in power plants and other heavy industries.Features and BenefitsThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has numerous exceptional features and benefits that make it stand out, including:1. Great Resistance to High TemperaturesThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is designed to withstand high temperatures. Its unique composition allows it to resist thermal degradation, ensuring that it retains its mechanical strength and electric insulating properties in high-temperature conditions. The product can withstand ambient temperatures ranging from -60 to 150 degrees Celsius without impacting its functionality.2. Exceptional Mechanical StrengthThe Fr4 Sheet has exceptional mechanical strength, making it an essential component in high vibration equipment. This mechanical strength also allows the product to handle large electrical loads without degrading.3. High Dielectric StrengthThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has a high dielectric strength. This property makes it an ideal insulating material for transformers, capacitors, and high voltage electrical equipment.4. Highly Resistant to ChemicalsThe Fr4 Sheet is highly resistant to chemicals, making it an excellent material for applications that involve exposure to chemicals such as acids, oils, and solvents.5. Self-Extinguishing PropertiesThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is self-extinguishing, making it safe to use in high electrical load equipment where the risk of fire is high.Applications of the High Voltage Unclad Epoxy Glass Fiber Fr4 SheetThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent insulating material for a range of applications. Its mechanical strength, heat resistance, and chemical resistance make it an ideal material for several industries. Some common uses of the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet are:1. Transformer InsulationTransformers use high voltage electricity to operate, and as such, require an ideal insulating material to prevent electrical leaks. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent insulating material for transformers, as it has a high dielectric strength and is temperature resistant.2. High-Vibration EquipmentEquipment in heavy industries experiences high levels of vibration. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet’s mechanical strength makes it an ideal component for high-vibration equipment, such as engines, turbines, and separators.3. Printed Circuit BoardsPrinted Circuit Boards (PCBs) require insulating materials that are both hard-wearing and able to withstand high temperatures. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an ideal choice for PCB fabrication because of its high dielectric strength, heat resistance, and chemical resistance.ConclusionThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet represents a massive leap forward in electrical insulation materials' quality. It's outstanding mechanical strength, high dielectric strength, and self-extinguishing properties make it an ideal material for high-voltage electrical equipment, transformers, and high vibration equipment. Its applications are varied and numerous, ranging from use in transformers and heavy industries to printed circuit board fabrication. As China continues to lead the world in technological innovation, products like the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet will continue to set the standard for electrical insulation materials.

Top 10 Benefits of Fiberglass Insulation Sheets for Your Home

Insulation Fiberglass Sheet Enhances Thermal Efficiency and Sustainability in Building ConstructionIn today's global push towards sustainability and energy efficiency, the demand for innovative building materials that can enhance thermal insulation has grown exponentially. Insulation Fiberglass Sheet, developed by an industry-leading company, is at the forefront of this technological revolution. With its exceptional insulating capabilities and commitment to sustainable practices, Insulation Fiberglass Sheet is set to transform the construction industry.Insulation plays a vital role in improving energy efficiency and comfort in buildings. By reducing heat transfer between indoor and outdoor environments, it promotes quality indoor air, minimizes energy consumption, and lowers carbon emissions. Recognizing these critical factors, Insulation Fiberglass Sheet has been engineered to meet the highest standards of thermal efficiency, making it an ideal choice for both residential and commercial buildings.One of the key features of Insulation Fiberglass Sheet is its exceptional thermal conductivity. By offering an excellent resistance to heat flow, it acts as a barrier that prevents the escape of warm air during colder months and restricts the entry of heat during hotter seasons. This feature significantly reduces the need for artificial heating and cooling, leading to substantial energy savings for building owners. Additionally, the improved thermal insulation provided by Insulation Fiberglass Sheet allows for greater control over indoor temperatures, ensuring comfortable living and working environments throughout the year.Apart from its impressive thermal insulation properties, Insulation Fiberglass Sheet also stands out for its eco-friendly attributes. The manufacturing process incorporates cutting-edge technology and sustainable practices, resulting in a product that has minimal impact on the environment. Insulation Fiberglass Sheet is made from recycled glass, reducing the demand for raw materials and promoting the circular economy. Furthermore, it is free from harmful chemicals and volatile organic compounds (VOCs), ensuring a healthy indoor environment for occupants.To demonstrate its commitment to sustainability, the company behind Insulation Fiberglass Sheet has implemented a comprehensive recycling program. This program allows customers to return used sheets for recycling, reducing waste and promoting a closed-loop product lifecycle. By adopting such initiatives, the company aims to contribute towards a greener and more sustainable future.In terms of application, Insulation Fiberglass Sheet is versatile and can be easily installed in various building components. It can be used to insulate walls, floors, roofs, and HVAC systems, providing a comprehensive solution for improving energy efficiency in buildings. Its flexibility enables it to fit into intricate spaces, ensuring uniform insulation throughout the entire building envelope. With its ease of installation and proven performance, Insulation Fiberglass Sheet offers architects, builders, and contractors a durable and efficient insulation material that is adaptable to diverse construction requirements.Furthermore, Insulation Fiberglass Sheet complies with international safety and quality standards, providing customers with peace of mind. It is tested and certified to withstand fire, moisture, and other environmental factors, ensuring the longevity and performance of the insulation system. Its durability guarantees that it will remain effective throughout the lifespan of the building, reducing the need for frequent replacements and minimizing waste.As the demand for energy-efficient buildings continues to rise, Insulation Fiberglass Sheet is well-positioned to meet the needs of the construction industry. Its exceptional thermal insulation properties, coupled with sustainable manufacturing practices, make it an attractive option for building professionals striving to achieve sustainability goals. By incorporating Insulation Fiberglass Sheet into their projects, architects and contractors can contribute to a greener future while providing occupants with comfortable and energy-efficient spaces.In conclusion, Insulation Fiberglass Sheet sets new standards in thermal insulation materials for construction. With its exceptional thermal conductivity, eco-friendly composition, and versatile application, it has the potential to revolutionize the building industry. By adopting this innovative solution, stakeholders can contribute towards a more sustainable and energy-efficient future while reaping the benefits of reduced energy consumption and improved occupant comfort.

Epoxy Glass Fiber Sheet Market in China: 3240 Sheet Overview

China 3240 Epoxy Glass Fiber Sheet, a high-quality electrical insulating material, has become one of the key products in the portfolio of a leading manufacturing company in China. With its excellent mechanical and electrical properties, this epoxy glass fiber sheet is an essential material for the electrical and electronic industry.The China 3240 Epoxy Glass Fiber Sheet is manufactured using high-quality glass fiber cloth and epoxy resin, which is then processed through a hot press molding process. This results in a product with outstanding electrical insulation properties, high mechanical strength, and excellent heat resistance. The product is widely used in various electrical equipment, such as insulating supports, switchgear panels, and transformers.The unique combination of glass fiber and epoxy resin gives this material exceptional electrical insulation properties. It can withstand high voltage and prevents electrical leakage, making it suitable for use in electrical equipment that requires high insulation performance. Additionally, the material's high mechanical strength allows it to withstand mechanical stress, making it a durable and reliable choice for electrical insulation applications.In addition to its electrical properties, the China 3240 Epoxy Glass Fiber Sheet also exhibits excellent heat resistance. The material can withstand high temperatures without compromising its insulation performance, making it suitable for use in applications where exposure to heat is a concern. This makes it a versatile material for a wide range of electrical and electronic applications.The manufacturing company behind the China 3240 Epoxy Glass Fiber Sheet has a strong focus on quality and innovation. With state-of-the-art production facilities and a dedicated research and development team, the company is committed to delivering high-quality products that meet the needs of its customers. Their stringent quality control measures ensure that every sheet meets international standards for electrical insulation materials.The company has also made significant investments in modern technology and equipment to improve the efficiency and quality of its manufacturing processes. This has enabled them to produce the China 3240 Epoxy Glass Fiber Sheet in large quantities without compromising on quality, making it readily available to meet the demand of the market.Moreover, the company has a robust distribution network that enables them to supply the China 3240 Epoxy Glass Fiber Sheet to customers both domestically and internationally. This ensures that the product is readily accessible to industries around the world that rely on high-quality electrical insulation materials.In addition to its commitment to quality and innovation, the company also places a strong emphasis on environmental sustainability. They adhere to strict environmental regulations and strive to minimize their environmental impact throughout the manufacturing process. This ensures that the China 3240 Epoxy Glass Fiber Sheet is not only a high-performance material but also an eco-friendly choice for businesses that prioritize sustainability.Overall, the China 3240 Epoxy Glass Fiber Sheet has established itself as a reliable and high-quality electrical insulation material, thanks to its exceptional electrical and mechanical properties. Combined with the company's commitment to quality, innovation, and sustainability, it has become a popular choice for industries that require reliable insulation materials for their electrical and electronic applications.As the demand for high-quality electrical insulation materials continues to grow, the China 3240 Epoxy Glass Fiber Sheet is well-positioned to meet the needs of the market, both domestically and internationally. With its outstanding performance and the company's dedication to excellence, this product is poised to remain a key component in the electrical and electronic industry for years to come.

Durable Fiberglass Laminate Sheet for Various Applications

Fiberglass Laminate Sheet Revolutionizes the IndustryFiberglass laminate sheets have been around for years, but the latest innovation in this field is taking the industry by storm. Companies such as {} are leading the way in producing high-quality, durable fiberglass laminate sheets that are revolutionizing the market.{} is a leading manufacturer of fiberglass laminate sheets, with a long history of delivering top-notch products to a wide range of industries. With a strong commitment to innovation and customer satisfaction, the company has quickly become a trusted name in the industry.The latest fiberglass laminate sheets from {} are designed to offer unmatched durability and versatility. These sheets are made from high-quality fiberglass material, which is known for its strength and resilience. This makes them ideal for a wide range of applications, from construction and automotive to marine and aerospace.One of the key advantages of {}'s fiberglass laminate sheets is their exceptional resistance to corrosion and extreme temperatures. This makes them ideal for use in harsh environments where other materials may fail. In addition, the sheets are also lightweight and easy to work with, making them a preferred choice for many manufacturers and builders.Another standout feature of {}'s fiberglass laminate sheets is their ability to provide excellent electrical insulation. This makes them suitable for use in electrical and electronic applications, where safety and reliability are paramount. With their high dielectric strength and low electrical conductivity, these sheets offer peace of mind to users in these industries.In addition to their superior performance, {}'s fiberglass laminate sheets are also available in a wide range of sizes, thicknesses, and finishes to suit different customer needs. This customization is a testament to the company's dedication to meeting the diverse requirements of its clients.Furthermore, {} is committed to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to the highest environmental standards, and it continues to explore ways to reduce its carbon footprint. By choosing {}'s fiberglass laminate sheets, customers can be confident that they are supporting a company that prioritizes environmental stewardship.With a strong focus on research and development, {} continues to push the boundaries of what is possible with fiberglass laminate sheets. The company's team of experts is constantly working on new formulations and manufacturing techniques to further improve the performance and capabilities of its products.Customers who have used {}'s fiberglass laminate sheets have been highly impressed with their quality and reliability. Many have reported significant cost savings and improved product performance after switching to these innovative sheets. With such positive feedback, {} has solidified its position as a leader in the fiberglass laminate sheet industry.Overall, the latest advancements in fiberglass laminate sheets from {} are changing the game for manufacturers and builders across various industries. With their exceptional durability, versatility, and environmental credentials, these sheets are set to become the go-to choice for many applications in the coming years. As {} continues to innovate and refine its products, the future looks bright for fiberglass laminate sheets and the industries they serve.

Essential Guide to High-Quality Electrical Parts: A Resource for Professionals and DIY Enthusiasts

Electrical Parts Company Continues to Innovate and Expand in the Global MarketSince its establishment, Electrical Parts (name removed for confidentiality) has been committed to providing innovative products and solutions to its customers all over the world. With a focus on electrical components and power distribution, Electrical Parts has become one of the major industry players in the global market.Based in the United States, Electrical Parts has developed a robust network of suppliers and customers across the globe, allowing the company to offer a wide range of products and services to meet the diverse needs of its clients. The company has a strong reputation for quality, reliability, and exceptional customer service, which have been key factors in its success.One of the core areas of expertise for Electrical Parts is electrical components. The company offers a broad range of products in this category, including transformers, connectors, wiring devices, and more. These products are designed to meet the high standards of the industry and are tested rigorously to ensure that they are reliable and safe for the end user.In addition to its electrical components, Electrical Parts also specializes in power distribution solutions. The company offers a range of products and services in this area, including switchgear, control panels, and power distribution units. These products are designed to help customers manage their power requirements efficiently and effectively, whether they are looking to power a factory, a data center, or any other type of facility.One of the things that sets Electrical Parts apart from its competitors is its commitment to innovation. The company invests heavily in research and development to ensure that it is always at the forefront of the latest trends and advancements in the industry. By staying ahead of the curve, Electrical Parts is able to provide its customers with cutting-edge solutions that are tailored to their specific needs.Another key factor in Electrical Parts' success is its dedication to customer service. The company operates on a customer-centric model, which means that it always puts the needs of its clients first. From providing personalized solutions to offering prompt and reliable support, Electrical Parts goes above and beyond to ensure that its customers are satisfied with their products and services.Looking to the future, Electrical Parts has ambitious plans for expansion and growth. The company is already established in a number of international markets, but it is looking to expand its reach even further. Through strategic partnerships, acquisitions, and investments, Electrical Parts is aiming to become a truly global player in the industry.At the same time, the company is continuing to innovate and develop new products and solutions that will help its customers meet their evolving needs. With a focus on sustainability and energy efficiency, Electrical Parts is working to create products that are both environmentally friendly and cost-effective.Overall, Electrical Parts has demonstrated its commitment to excellence, innovation, and customer service over the years. With a strong foundation and a clear vision for the future, the company is well-positioned to continue its growth and success in the years to come.

Ultimate Guide to Fiberglass Insulation: Benefits, Installation Tips and Uses Revealed

Title: Driven by Innovation and Quality, Transforming the Insulation Industry: Fiberglass InsulationIntroduction:In today's rapidly evolving world, energy efficiency has become a top priority for individuals, businesses, and governments. As the demand for sustainable solutions continues to grow, companies are focusing on developing innovative products that not only reduce energy consumption but also enhance overall comfort. One such company at the forefront of this revolution is Fiberglass Insulation.Company Overview:Fiberglass Insulation, a leading provider in the insulation industry, has built a solid reputation for its commitment to quality, innovation, and sustainability. With a rich history spanning over 50 years, the company has continuously transformed the industry landscape through its cutting-edge products and techniques.A pioneer in fiberglass insulation, the company has garnered substantial recognition for its remarkable breakthroughs, ensuring that thermal efficiency and environmental consciousness go hand in hand. By leveraging advanced manufacturing processes and state-of-the-art technology, Fiberglass Insulation has successfully contributed to improving energy efficiency and reducing the carbon footprint of countless homes and commercial buildings.Key Products and Technology:Fiberglass Insulation offers a comprehensive range of insulation products, tailored to meet the specific needs of residential, commercial, and industrial sectors. With a focus on maximizing thermal performance, while minimizing environmental impact, their product line showcases a remarkable blend of innovation, sustainability, and functionality.1. Fiberglass Batts and Rolls:Engineered for optimal heat retention and acoustic control, fiberglass batts and rolls are designed to fit seamlessly between stud frames, floor joists, and ceilings. These highly flexible and easy-to-install insulation solutions provide a superior thermal barrier, reducing energy consumption and enhancing comfort.2. Blown-in Fiberglass:Blown-in fiberglass insulation offers a cost-effective solution for attics, walls, and hard-to-reach spaces. Utilizing a specially formulated adhesive, this product adheres to the substrate, ensuring uniform coverage and eliminating voids. With its remarkable heat resistance and sound absorption capabilities, blown-in fiberglass insulation guarantees long-lasting energy efficiency.3. Spray-Foam Hybrid Insulation:Fiberglass Insulation's innovative spray-foam hybrid insulation combines the benefits of traditional fiberglass insulation with the superior air sealing properties of spray foam. This revolutionary product not only provides exceptional thermal performance but also acts as a barrier against moisture, allergens, and pollutants, ensuring a healthier and more sustainable living environment.Sustainability Initiatives:Fiberglass Insulation is committed to sustainable manufacturing practices and reducing its environmental impact throughout the product life cycle. The company employs an extensive recycling program, ensuring that waste materials are transformed into usable products, significantly reducing landfill waste.With an emphasis on energy efficiency, their manufacturing processes utilize renewable energy sources, further minimizing carbon emissions. With its LEED-certified products, the company actively supports green building initiatives to create a more environmentally conscious future.Conclusion:Fiberglass Insulation's unwavering dedication to innovation, quality, and sustainability has cemented its position as an industry leader. By continuously developing cutting-edge insulation solutions, the company has successfully contributed to reducing energy consumption, providing optimal comfort, and minimizing the environmental impact of buildings.As the demand for sustainable solutions continues to rise, Fiberglass Insulation remains committed to its mission of transforming the insulation industry. With advanced technology, a focus on energy efficiency, and an unwavering commitment to quality, the company is well-positioned to shape a greener, more sustainable future.

NIA Reveals New Executive Committee and Board of Directors for 2020-2021 Term

Insulation Board: The Key to Energy Efficiency and SustainabilityInsulation is an essential component of any building, playing a crucial role in improving energy efficiency and reducing environmental impact. With the growing emphasis on sustainability and energy conservation, the demand for effective insulation solutions has never been higher. In this blog post, we will discuss the significance of insulation board and its role in creating a sustainable future. Insulation board is a versatile material that is commonly used in residential, commercial, and industrial applications. It is designed to provide thermal insulation, preventing heat loss or gain, thus reducing energy consumption for heating and cooling purposes. The insulation board acts as a barrier, preventing the transfer of heat between the internal and external environments, resulting in improved energy efficiency, lower utility bills, and reduced carbon emissions. One of the key advantages of insulation board is that it offers excellent thermal resistance, providing maximum insulation value with minimal thickness. This allows for greater flexibility in design and construction, enabling architects and engineers to optimize space utilization. Insulation board is available in multiple thicknesses, densities, and materials, including fiberglass, mineral wool, expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (polyiso). Each material has distinct properties, making them suitable for specific applications and environments. Fiberglass insulation board, for instance, is widely used in residential and commercial building projects, offering excellent thermal and sound insulation properties. Mineral wool, a popular choice for industrial applications, provides superior fire resistance and sound absorption. EPS, XPS, and polyiso are highly effective in moisture control, making them ideal for areas prone to water damage, such as basements and crawl spaces. In addition to thermal insulation, insulation board also offers other benefits, such as acoustical insulation, moisture control, and improved indoor air quality. Soundproofing is a crucial requirement in many buildings, especially those located in noisy urban areas or near transportation hubs. Insulation board with sound absorption properties can effectively reduce noise pollution, creating a more peaceful and comfortable indoor environment. Moisture control is equally important, as excessive moisture can lead to mold growth, structural damage, and poor indoor air quality. Insulation board with moisture-resistant properties creates a protective barrier, preventing water vapor from entering the building envelope and safeguarding it against potential issues. This is particularly relevant for regions with high humidity levels or buildings located in flood-prone areas. Indoor air quality is another significant consideration, as poor ventilation and pollutant infiltration can negatively impact occupants' health and well-being. Insulation board with low VOC (volatile organic compounds) emissions and formaldehyde-free composition helps maintain a healthy indoor environment by minimizing the release of harmful chemicals into the air. The use of insulation board aligns with the principles of sustainability, contributing to the overall energy efficiency and environmental performance of a building. Energy-efficient buildings reduce dependency on fossil fuels, lower greenhouse gas emissions, and conserve natural resources. Additionally, insulation board can contribute to certifications such as LEED (Leadership in Energy and Environmental Design) and ENERGY STAR, further enhancing a building's value and marketability. Choosing the right insulation board for a project is crucial for maximizing its benefits. Factors to consider include thermal conductivity, fire resistance, moisture resistance, durability, and environmental impact. It is essential to consult with experts and professionals, such as insulation contractors and engineers, to determine the most appropriate insulation board for specific applications and regulatory requirements. In conclusion, insulation board plays a pivotal role in achieving energy efficiency and sustainability in buildings. Its ability to provide effective thermal insulation, soundproofing, moisture control, and improved indoor air quality makes it an indispensable material for construction projects. By selecting the right insulation board and ensuring proper installation, building owners can reap long-term benefits, including reduced energy consumption, increased comfort, and a greener future.

Top 5 Best Insulation Panels for Your Home

Insulation Panel Company Announces Breakthrough TechnologyInsulation Panels is a leading provider of insulation products to the construction and building industry. The company has recently announced the launch of its new, breakthrough insulation panel technology that can help to improve energy efficiency in buildings while reducing costs.According to a spokesperson for the company, "Our new insulation panel technology is a game-changer for the industry. It offers superior thermal resistance, making it the perfect solution for colder climates. Additionally, our insulation panels have excellent air and moisture barriers, which results in a much more energy-efficient building."The insulation panels are made from a combination of high-density foam and a reflective layer that helps to reflect radiant heat back into the building. This design helps to maintain a comfortable temperature in all seasons, making it perfect for use in residential and commercial buildings alike.One of the key features of this innovative insulation panel technology is its exceptional fire resistance. It can stop the spread of flames for up to two hours, making it the ideal choice for structures that require increased fire protection.Insulation Panels are available in a range of sizes, making them suitable for a variety of applications. They are also incredibly easy to install, helping to reduce installation times and labor costs.The company's insulation panels are also environmentally friendly, boasting low VOC (volatile organic compound) emissions. This means that they are a safer choice for the environment and for the people who will be using these buildings.One of the key advantages of Insulation Panels' products is that they can help reduce energy costs for homeowners and businesses alike. By reducing the amount of energy required to heat or cool a building, this new technology can help to reduce energy bills significantly. This has the added benefit of reducing a building's carbon footprint, making it a more sustainable choice."A lot of people are looking to reduce their energy consumption and carbon footprint," says the company spokesperson. "Our insulation panels are the perfect solution for this. They use the latest technology to keep buildings comfortable and energy-efficient while remaining incredibly cost-effective."In addition to its new insulation panel technology, the company also offers a range of other insulation products and services. These include traditional batt insulation, as well as spray foam, rigid board insulation, and even custom insulation solutions.Insulation Panels have been serving the construction and building industry for over 20 years. They have a strong reputation for providing high-quality insulation products at extremely competitive prices. The company's experienced staff can also help customers choose the best insulation solution for their needs and answer any questions they may have.With its new breakthrough technology, Insulation Panels is set to continue leading the way in the insulation industry, providing its customers with the latest and most advanced insulation products and technologies on the market.

Durable Fiberglass FR5: A Strong and Reliable Material for Various Applications

The use of fiberglass FR5 as a key material in the manufacturing industry has been steadily increasing due to its exceptional properties and versatility. [Company name], a leading manufacturer of fiberglass FR5, has been at the forefront of this development, providing high-quality fiberglass products to meet the growing demands of various industries.[Company name] is a renowned company with a strong reputation in the fiberglass industry. With a focus on innovation and quality, the company has established itself as a trusted provider of fiberglass FR5 and other related products. Their commitment to excellence and customer satisfaction has enabled them to build long-lasting relationships with clients worldwide.The use of fiberglass FR5 has become essential in many industrial applications due to its exceptional strength, electrical insulation, and resistance to heat and chemicals. This makes it an ideal material for manufacturing electrical and electronic components, as well as in the construction of industrial equipment and infrastructure. The demand for high-performance materials like fiberglass FR5 is expected to continue to grow as industries strive for more efficient and durable solutions.One of the key advantages of fiberglass FR5 is its excellent resistance to high temperatures and fire, making it a preferred choice for applications where safety is paramount. The material's low thermal conductivity and high mechanical strength make it ideal for use in high-temperature environments, such as in the aerospace and automotive industries. Additionally, fiberglass FR5 is also an excellent electrical insulator, making it suitable for various electrical and electronic applications.[Company name] has been at the forefront of developing advanced fiberglass FR5 materials that meet the evolving needs of the industry. Their state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their products consistently meet the highest industry standards. The company's commitment to research and development has led to the introduction of innovative fiberglass FR5 materials that offer superior performance and reliability.In addition to offering standard fiberglass FR5 products, [Company name] also specializes in customizing solutions to meet the specific requirements of their clients. This flexibility has made them a preferred partner for many companies in various industries, as they can rely on [Company name] to provide tailored solutions that meet their unique needs.The growing demand for fiberglass FR5 has led [Company name] to expand its production capacity and streamline its operations to meet the increasing market demand. The company's investments in technology and infrastructure have enabled them to enhance their manufacturing capabilities and develop new and improved fiberglass FR5 products that offer even greater performance and durability.As the global economy continues to recover and industries ramp up their production, the demand for high-performance materials like fiberglass FR5 is expected to soar. [Company name] is well-positioned to capitalize on this trend, with its extensive experience and expertise in fiberglass manufacturing. Their commitment to quality and innovation makes them a trusted partner for companies seeking reliable and high-quality fiberglass FR5 products.In conclusion, the use of fiberglass FR5 has become increasingly prevalent in various industries due to its exceptional properties and versatility. [Company name] has been a key player in this development, providing high-quality fiberglass FR5 products and customized solutions to meet the growing demands of the industry. With their commitment to excellence and innovation, [Company name] is poised to continue leading the way in the fiberglass manufacturing industry.