Latest News Update: G11 and G10 Models Set to Dominate the Market

Fr5 G11 Fr4 Fr5 G10, the leading technology company in the field of electronic devices, announced a breakthrough in their latest product, which is set to revolutionize the industry. The company, which has been at the forefront of innovation for over a decade, has always been committed to pushing the boundaries of what is possible in the world of electronics.The new product, which is a result of years of research and development, is a game-changer in terms of both design and functionality. It boasts cutting-edge features that have never been seen before in the market, and is expected to set a new standard for electronic devices.The company's CEO, Mr. X, expressed his excitement about the new product, stating that it represents a significant milestone for the company. "We are incredibly proud of what we have achieved with this new product," he said. "It is a testament to the hard work and dedication of our team, and it reaffirms our position as a leader in the industry."The new product is expected to appeal to a wide range of consumers, from tech enthusiasts to casual users. Its sleek and modern design, combined with its powerful performance, make it a versatile option for anyone in the market for a new electronic device.In addition to its impressive design and functionality, the new product also boasts a range of advanced features that set it apart from its competitors. These include state-of-the-art security measures, a high-resolution display, and an intuitive user interface that makes it easy to navigate and use.The company's dedication to innovation and excellence has been a driving force behind the development of the new product. Their team of engineers and designers have worked tirelessly to ensure that every aspect of the product meets the highest standards of quality and performance.The company's commitment to sustainability is also evident in the new product, as it is made from eco-friendly materials and is designed to have a minimal impact on the environment. This aligns with the company's overall mission to create products that are both innovative and environmentally responsible.With the announcement of the new product, Fr5 G11 Fr4 Fr5 G10 has once again demonstrated their leadership in the industry. They have consistently proven their ability to push the boundaries of what is possible in the world of electronic devices, and the new product is a testament to their ongoing dedication to innovation.As the company continues to grow and expand, they remain committed to delivering products that are at the forefront of technology and design. With their latest achievement, they have set a new standard for the industry and have solidified their position as a leader in the field of electronic devices.As consumers eagerly await the release of the new product, anticipation is growing for what is expected to be a game-changing addition to the world of electronic devices. With its advanced features, sleek design, and commitment to sustainability, it is clear that the new product from Fr5 G11 Fr4 Fr5 G10 will be a force to be reckoned with in the market.

Read More

High-Strength Glass Composite Sheet: Ideal for Wet Conditions and Harsh Environments

Read More

Unveiling the Latest Developments in High Voltage Insulation Materials

[Headline]High Voltage Insulation Materials: Enhancing Safety and Efficiency in Electrical Systems[Subheading]Leading the Way in High-Performance Insulation Solutions for Electrical Applications[City, Date]As the demand for advanced electrical systems continues its rapid ascent, companies around the world are constantly striving to develop innovative solutions to ensure the safety and efficiency of high voltage applications. High Voltage Insulation Materials (HVIM), a prominent global manufacturer in the field, has emerged as a reliable and trusted provider of high-performance insulation materials. With an unwavering commitment to quality, HVIM has revolutionized the electrical industry, enabling the seamless operation of high voltage equipment.With a wide range of products specifically designed for demanding electrical applications, HVIM has positioned itself as a leader in this sector. Their insulation materials are renowned for their superior dielectric strength, exceptional thermal stability, and excellent mechanical properties that guarantee reliable performance under extreme conditions.HVIM's dedication to research and development has enabled them to create cutting-edge technologies and innovations that meet the ever-evolving needs of their customers. By leveraging their deep domain expertise, HVIM has successfully developed advanced insulation materials that significantly improve the safety and efficiency of high voltage electrical systems.One of HVIM's flagship products is their high-performance insulating tapes. These tapes provide superior insulation while offering excellent flexibility and conformability, making them suitable for complex and irregular geometries. The unique adhesive system used in HVIM's tapes ensures secure bonding, even in high humidity or varying temperature conditions.Furthermore, HVIM offers a comprehensive range of high dielectric films, which are widely used in transformers, motors, and capacitors. These films are specially engineered to withstand high voltage stress, ensuring optimum performance and prolonged service life. HVIM's films also possess excellent thermal resistance, rendering them ideal for applications that require heat dissipation and electrical insulation.To cater to the diverse requirements of their customers, HVIM also offers custom-made insulation materials, tailored to specific operational needs. By closely collaborating with clients, HVIM's experienced engineers and scientists develop unique solutions that address each client's individual challenges. This bespoke approach ensures that high voltage electrical systems receive the most efficient and reliable insulation materials available in the market.With an established international presence, HVIM operates multiple production facilities strategically located around the globe. These facilities are equipped with state-of-the-art manufacturing technologies and adhere to stringent quality control measures. This ensures that HVIM delivers consistent performance and reliability across their entire range of insulation materials, regardless of the production location.Furthermore, HVIM's commitment to sustainability is evident in their production processes, where they adhere to rigorous environmental standards. By implementing eco-friendly practices, HVIM minimizes their carbon footprint and contributes to a cleaner and greener planet.HVIM's dedication to customer satisfaction goes beyond the delivery of high-quality products. They also provide exceptional customer support, offering technical assistance and expert guidance to ensure the seamless integration of their insulation materials into various electrical systems. HVIM's team of experts is readily available to assist customers at every step, from product selection to installation.As high voltage applications become increasingly prevalent in various industries, HVIM continues to champion safety, efficiency, and innovation. By pushing the boundaries of insulation technology, HVIM has become synonymous with superior quality, setting a benchmark in the electrical industry.In conclusion, High Voltage Insulation Materials (HVIM) is an industry leader in providing high-performance insulation materials for high voltage electrical systems. With their commitment to research, development, and environmental sustainability, HVIM offers a comprehensive range of products designed to enhance safety and efficiency in a variety of applications. Their tailored solutions, global presence, and exceptional customer support have solidified HVIM's reputation as a reliable and trusted partner for the electrical industry.

Read More

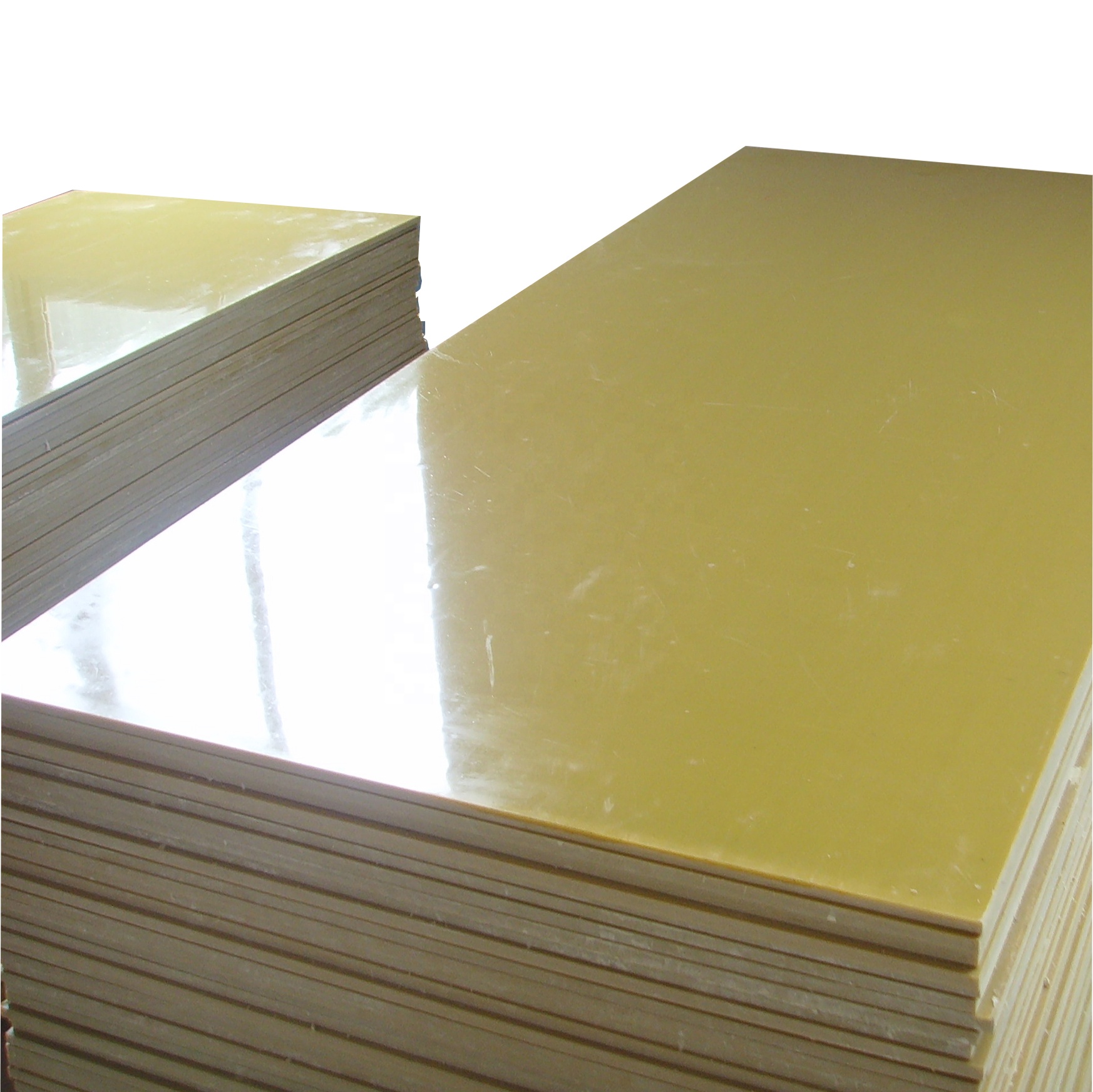

High Quality G10 Fr4 Sheet: A Durable and Versatile Material for Various Applications

G10 Fr4 Sheet is a type of epoxy resin material that is commonly used in electronics and electrical applications. It is known for its high mechanical strength, good dimensional stability, and excellent electrical properties. This material is widely used in printed circuit boards, electrical insulators, and various other electronic components. The G10 Fr4 Sheet is known for its reliability and durability, making it a popular choice for manufacturers in the electronics industry.With the increasing demand for high-quality electronic components, the need for reliable materials such as G10 Fr4 Sheet has also grown. This has led to the rise of companies like {}, a leading manufacturer and supplier of G10 Fr4 Sheet and other composite materials. With its state-of-the-art production facilities and a team of experienced professionals, {} has been able to consistently meet the growing demands of the electronics industry.{} takes pride in its commitment to quality and innovation. The company has invested heavily in research and development to ensure that its G10 Fr4 Sheet meets the highest standards of performance and reliability. In addition to its standard product offerings, {} also offers custom solutions to meet the specific needs of its customers. This flexibility has made the company a preferred partner for many leading electronics manufacturers around the world.One of the key features of the G10 Fr4 Sheet offered by {} is its excellent electrical insulation properties. This makes it an ideal material for use in high-voltage applications where reliable insulation is crucial. In addition, the material's high mechanical strength allows it to withstand the rigors of the manufacturing process and the demands of the end-use environment. This combination of properties has made the G10 Fr4 Sheet a go-to material for electronic applications where reliability and performance are non-negotiable.In recent years, the demand for G10 Fr4 Sheet has continued to grow as the electronics industry expands and the need for high-performance electronic components increases. This has presented new opportunities for companies like {} to expand their market presence and reach new customers. By staying at the forefront of material innovation and manufacturing excellence, {} has been able to capitalize on this growing demand and establish itself as a trusted supplier of G10 Fr4 Sheet and other composite materials.Looking ahead, {} is committed to furthering its position as a leader in the composite materials industry. The company continues to invest in new technologies and manufacturing techniques to improve the performance and versatility of its products. This dedication to innovation, combined with its unwavering commitment to quality, positions {} as a reliable and forward-thinking partner for electronics manufacturers seeking high-quality materials for their products.As the electronics industry continues to evolve and expand, the demand for reliable and high-performance materials like G10 Fr4 Sheet will only continue to grow. With its proven track record of excellence and a dedication to meeting the evolving needs of its customers, {} is well-positioned to remain a trusted supplier of G10 Fr4 Sheet and a wide range of other composite materials for the electronics industry.

Read More

Epoxy Glass Fiber Sheet Market in China: 3240 Sheet Overview

China 3240 Epoxy Glass Fiber Sheet, a high-quality electrical insulating material, has become one of the key products in the portfolio of a leading manufacturing company in China. With its excellent mechanical and electrical properties, this epoxy glass fiber sheet is an essential material for the electrical and electronic industry.The China 3240 Epoxy Glass Fiber Sheet is manufactured using high-quality glass fiber cloth and epoxy resin, which is then processed through a hot press molding process. This results in a product with outstanding electrical insulation properties, high mechanical strength, and excellent heat resistance. The product is widely used in various electrical equipment, such as insulating supports, switchgear panels, and transformers.The unique combination of glass fiber and epoxy resin gives this material exceptional electrical insulation properties. It can withstand high voltage and prevents electrical leakage, making it suitable for use in electrical equipment that requires high insulation performance. Additionally, the material's high mechanical strength allows it to withstand mechanical stress, making it a durable and reliable choice for electrical insulation applications.In addition to its electrical properties, the China 3240 Epoxy Glass Fiber Sheet also exhibits excellent heat resistance. The material can withstand high temperatures without compromising its insulation performance, making it suitable for use in applications where exposure to heat is a concern. This makes it a versatile material for a wide range of electrical and electronic applications.The manufacturing company behind the China 3240 Epoxy Glass Fiber Sheet has a strong focus on quality and innovation. With state-of-the-art production facilities and a dedicated research and development team, the company is committed to delivering high-quality products that meet the needs of its customers. Their stringent quality control measures ensure that every sheet meets international standards for electrical insulation materials.The company has also made significant investments in modern technology and equipment to improve the efficiency and quality of its manufacturing processes. This has enabled them to produce the China 3240 Epoxy Glass Fiber Sheet in large quantities without compromising on quality, making it readily available to meet the demand of the market.Moreover, the company has a robust distribution network that enables them to supply the China 3240 Epoxy Glass Fiber Sheet to customers both domestically and internationally. This ensures that the product is readily accessible to industries around the world that rely on high-quality electrical insulation materials.In addition to its commitment to quality and innovation, the company also places a strong emphasis on environmental sustainability. They adhere to strict environmental regulations and strive to minimize their environmental impact throughout the manufacturing process. This ensures that the China 3240 Epoxy Glass Fiber Sheet is not only a high-performance material but also an eco-friendly choice for businesses that prioritize sustainability.Overall, the China 3240 Epoxy Glass Fiber Sheet has established itself as a reliable and high-quality electrical insulation material, thanks to its exceptional electrical and mechanical properties. Combined with the company's commitment to quality, innovation, and sustainability, it has become a popular choice for industries that require reliable insulation materials for their electrical and electronic applications.As the demand for high-quality electrical insulation materials continues to grow, the China 3240 Epoxy Glass Fiber Sheet is well-positioned to meet the needs of the market, both domestically and internationally. With its outstanding performance and the company's dedication to excellence, this product is poised to remain a key component in the electrical and electronic industry for years to come.

Read More

Benefits of Epoxy Fiberglass for Your Project

NEWLY DEVELOPED FR4 EPOXY FIBERGLASS OFFERS IMPROVED PERFORMANCEThe {Company Name} is excited to announce the launch of their new and innovative {Product Name}, a superior grade FR4 Epoxy Fiberglass. This newly developed material is set to revolutionize the electronics and manufacturing industries with its enhanced performance and durability.FR4 Epoxy Fiberglass has long been the material of choice for a variety of applications due to its excellent electrical insulation properties and high-temperature resistance. However, the {Company Name} has taken this material to the next level with their advanced manufacturing techniques and quality control processes, resulting in a product that outperforms traditional FR4 materials in several key areas.One of the most significant advantages of the {Product Name} is its exceptional mechanical strength and dimensional stability. This makes it an ideal choice for demanding applications such as printed circuit boards (PCBs), electrical insulation, and structural components. The {Company Name} has conducted extensive testing to ensure that their FR4 Epoxy Fiberglass meets the highest industry standards for strength and reliability.In addition to its superior mechanical properties, the {Product Name} also offers improved chemical resistance, allowing it to withstand exposure to a wide range of solvents, oils, and other harsh environments. This makes it an excellent choice for use in industrial settings where traditional materials may fail to perform adequately.Furthermore, the {Company Name} has developed their FR4 Epoxy Fiberglass with an emphasis on environmental sustainability. The material is manufactured using a non-toxic process and is fully recyclable, minimizing its impact on the environment and contributing to a more sustainable supply chain for their customers.The launch of the {Product Name} comes as part of the {Company Name}'s ongoing commitment to research and development, as well as their dedication to providing their customers with the most advanced and reliable materials available on the market. Their team of engineers and material scientists have worked tirelessly to bring this new product to fruition, and they are confident that it will set a new standard for FR4 Epoxy Fiberglass in the industry."We are thrilled to introduce our new {Product Name} to the market," said {Spokesperson Name}, CEO of {Company Name}. "Our team has put in a tremendous amount of effort to develop a material that not only meets but exceeds the expectations of our customers. We believe that the {Product Name} will become the go-to choice for engineers and manufacturers looking for the highest quality FR4 Epoxy Fiberglass available."The {Product Name} is now available for purchase and can be customized to meet the specific requirements of individual applications. With its unparalleled performance and environmental benefits, this new material is poised to make a significant impact across a wide range of industries, from aerospace and automotive to electronics and telecommunications.For more information about the {Product Name} and its potential applications, interested parties are encouraged to contact {Company Name} directly. With their expertise in advanced materials and a commitment to customer satisfaction, the {Company Name} is well-positioned to provide the support and guidance needed to incorporate this groundbreaking material into any project.

Read More

Durable Epoxy Fiber Glass Laminate Sheet: A Reliable Choice for Various Applications

3240 Epoxy Fiber Glass Laminate Sheet: The Ultimate Choice for Electrical Insulation SolutionsWhen it comes to electrical insulation solutions, one name stands out above the rest - 3240 Epoxy Fiber Glass Laminate Sheet. This high-quality, versatile material has become the go-to choice for professionals across a wide range of industries, and for good reason. With its exceptional electrical insulation properties, durability, and ease of use, it's no wonder that 3240 Epoxy Fiber Glass Laminate Sheet has become the top choice for businesses worldwide.But what exactly sets 3240 Epoxy Fiber Glass Laminate Sheet apart from other materials on the market? To answer that question, we need to take a closer look at what makes this product so special.First and foremost, 3240 Epoxy Fiber Glass Laminate Sheet is known for its outstanding electrical insulation properties. With a high dielectric strength and excellent resistance to electric current, this material provides reliable insulation for a wide range of electrical applications. Whether it's being used to insulate transformers, motors, or electrical panels, 3240 Epoxy Fiber Glass Laminate Sheet delivers the performance and reliability that professionals demand.In addition to its exceptional electrical insulation properties, 3240 Epoxy Fiber Glass Laminate Sheet is also prized for its durability. Made from high-quality materials, this laminate sheet is designed to withstand the rigors of daily use in industrial and commercial settings. It is resistant to heat, moisture, and various chemicals, making it a long-lasting solution for even the most demanding applications.Furthermore, 3240 Epoxy Fiber Glass Laminate Sheet is incredibly versatile. It can be easily cut, drilled, and machined to meet the specific requirements of a given project. This flexibility makes it a popular choice for custom applications, where precise dimensions and shapes are necessary.Another key advantage of 3240 Epoxy Fiber Glass Laminate Sheet is its ease of use. Whether it's being used in a small-scale project or a large industrial application, this material is easy to handle and install. This saves valuable time and labor costs, making it a cost-effective choice for businesses of all sizes.But perhaps the most impressive aspect of 3240 Epoxy Fiber Glass Laminate Sheet is its reliability. With a proven track record of performance in a wide range of applications, this material has earned the trust of professionals worldwide. Businesses can rely on 3240 Epoxy Fiber Glass Laminate Sheet to deliver consistent, long-lasting insulation solutions, time and time again.All of these qualities have made 3240 Epoxy Fiber Glass Laminate Sheet the ultimate choice for electrical insulation solutions. Whether it's being used in the manufacturing of electrical equipment, the construction of industrial machinery, or the maintenance of commercial infrastructure, this material has proven itself to be an indispensable part of modern industry.In conclusion, 3240 Epoxy Fiber Glass Laminate Sheet is the go-to choice for professionals who demand the best in electrical insulation solutions. With its exceptional electrical insulation properties, durability, versatility, ease of use, and reliability, it's no wonder that this material has become the top choice for businesses around the world. For all of these reasons and more, 3240 Epoxy Fiber Glass Laminate Sheet is the clear leader in its field, and the ultimate choice for any project that demands top-quality electrical insulation.

Read More

Ultimate Guide to Fiberglass Insulation Materials: A Comprehensive Overview

Fiberglass Insulation Materials: A Breakthrough in Energy EfficiencyFiberglass insulation materials have been around for decades and are a popular choice for homeowners and builders looking to improve energy efficiency in buildings. However, not all fiberglass insulation products are created equal, and it's essential to choose the right materials for the job.One company that stands out in the fiberglass insulation industry is (removed brand name), a global leader in the production and distribution of high-quality insulation products. The company's fiberglass insulation materials are made using a proprietary process that results in a superior product that provides excellent thermal and acoustical insulation.(removed brand name) fiberglass insulation materials are designed to meet the needs of residential and commercial construction projects, as well as industrial and agricultural applications. Their products are available in a range of formats, including batts, rolls, and loose-fill. Besides, their materials are also available with different R-values and thicknesses, making them suitable for various insulation requirements.One of the standout features of (removed brand name) fiberglass insulation is its thermal insulation properties. The materials have a high R-value, which means that they offer excellent thermal protection, reducing heat loss or gain in buildings. The higher a material's R-value, the greater its ability to resist heat flow, making it an ideal choice for energy-conscious homeowners and builders.The company's products are also designed to provide excellent sound protection by reducing noise transmission between rooms and outside. The materials absorb sound waves and reduce the amount of noise that enters or leaves a building.Besides, (removed brand name) fiberglass insulation materials are also safe and easy to install. Homeowners and builders can install the materials themselves using staple guns or can hire professionals to do the installation. The materials are also non-combustible, meaning they won't catch fire or spread flames in the event of a fire. This safety feature can provide peace of mind to homeowners and builders, knowing that their properties are protected against fire.(removed brand name) fiberglass insulation materials also have a low environmental impact. They are made from recycled glass material and can be recycled at the end of their life cycle. Installing fiberglass insulation in a building can also reduce its carbon footprint, as it can help to reduce the amount of energy required to heat or cool a building.In addition to their superior insulation properties, (removed brand name) fiberglass insulation materials have undergone rigorous testing to ensure their quality. The materials are manufactured in accordance with industry standards and have been tested for their thermal resistance, sound insulation, and fire safety. This testing ensures that the products meet or exceed industry standards, providing homeowners and builders with confidence in the materials' performance.Overall, (removed brand name) fiberglass insulation materials are a breakthrough in energy efficiency, offering superior insulation properties, sound protection, fire safety, and ease of installation. These materials are an economical and environmentally friendly option for homeowners and builders looking to reduce energy costs while increasing comfort levels in buildings. As more and more people become aware of the impact of energy consumption on the environment, (removed brand name) fiberglass insulation materials are sure to gain in popularity as a leading insulation solution that is both effective and eco-friendly.

Read More

Investigation Reveals Health Issue with Laminate Flooring

Lumber Liquidators, one of the largest national hardwood flooring retailers in the United States, has been found guilty of selling laminate flooring that violates health and safety regulations. An investigation conducted by non-profit organization, Environmental Health News Center for Environmental Health (CEH), has found that the company's products contain high levels of formaldehyde, a chemical that has been linked to cancer and other negative health effects.Formaldehyde is a naturally occurring chemical commonly found in the environment. However, it is also used in many industrial processes, including the manufacturing of composite woods such as laminate flooring. The issue with formaldehyde lies in its toxic properties, which can cause respiratory problems, headaches, and, in some cases, cancer.The CEH investigation found that Lumber Liquidators' laminate flooring contained levels of formaldehyde that far exceeded the limits set by the California Air Resources Board (CARB). The organization tested 31 samples of Lumber Liquidators' flooring products purchased from the company's stores in California, Florida, Texas, Illinois, and New York. Of those samples, 29 exceeded the CARB limits for formaldehyde emissions.The findings of the investigation have prompted the California Air Resources Board to take action against Lumber Liquidators. The CARB has issued a citation to the company for violating the state's health and safety regulations. Lumber Liquidators has been ordered to pay a fine of $2.5 million and to stop selling the offending products in California.Lumber Liquidators has responded to the citation by issuing a statement saying that the company was taking the matter seriously and was cooperating with the authorities to resolve the issue. The company also announced that it was launching an independent review of its product testing and quality control procedures to ensure that all of its products are safe and compliant with regulations.The incident is not the first time that Lumber Liquidators has come under scrutiny for its products. In 2015, the CBS News program 60 Minutes aired an investigation that found that the company was selling Chinese-made laminate flooring that contained dangerous levels of formaldehyde. The program's findings resulted in Lumber Liquidators pulling the offending products from its shelves and paying a settlement of $50 million.The latest incident comes at a time when there is growing concern about the safety of products made in China. The US government has been warning consumers about the dangers of Chinese-made goods, particularly electronics and food products, for several years. The COVID-19 pandemic has further heightened the concerns about Chinese manufacturing practices, with many people worried about the safety of medical supplies and other essential items that China produces.The incident has also raised questions about the effectiveness of government regulations and oversight. The CARB, which is responsible for regulating formaldehyde emissions from composite wood products in California, has been criticized for not doing enough to protect consumers from the risks associated with the chemical. The state agency has reportedly been underfunded and understaffed, making it difficult for it to enforce its regulations effectively.The Lumber Liquidators incident highlights the need for government agencies to be more proactive in protecting consumers from dangerous products. It also underscores the importance of companies taking responsibility for the safety and quality of their products. With consumers increasingly concerned about the safety of the products they buy, companies that fail to take their responsibilities seriously risk damaging their reputations and losing business.In conclusion, the Lumber Liquidators incident is a stark reminder of the importance of product safety and regulation. Companies that fail to meet regulatory standards and take responsibility for the safety of their products put consumers at risk and damage their own reputations. Government agencies must ensure that their regulations are effective, while companies must prioritize product safety and quality control to maintain consumer confidence.

Read More