Durable and Heat-Resistant Phenolic Sheet Gaining Popularity in Multiple Industries

By:Admin

Introduction:

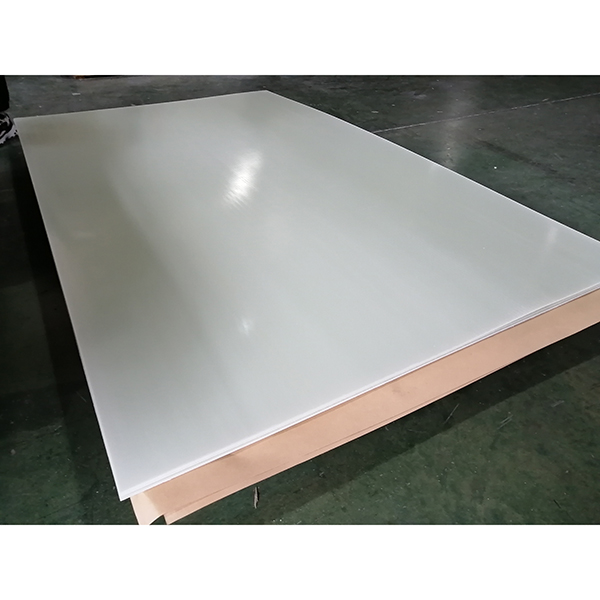

Throughout various industries, the need for durable and reliable materials is paramount. One such material garnering attention is the G10 Phenolic Sheet. This high-performance laminate is gaining recognition for its exceptional mechanical strength, excellent electrical properties, and chemical resistance. It has become a sought-after choice for professionals across sectors, ranging from aerospace and automotive to electronics and construction.

Company Introduction:

{Insert company name} is a leading provider of advanced materials, specializing in manufacturing and distributing high-quality G10 Phenolic Sheets. With years of expertise in the field, our company has established a strong reputation for delivering top-notch solutions that meet and exceed industry standards. We prioritize innovation and sustainability, ensuring our products align with the evolving needs of modern industries.

Article:

The versatility of G10 Phenolic Sheet has made it an indispensable material in a wide range of applications. With its exceptional durability and resistance to extreme conditions, it has proven itself as a valuable asset in demanding environments. Let us explore the key characteristics and applications of this remarkable material.

1. Mechanical Strength:

G10 Phenolic Sheet offers impressive mechanical properties, including high tensile strength, impact resistance, and dimensional stability. These features make it an ideal choice for applications requiring structural integrity, such as load-bearing components, gears, and bushings. Its resilience to wear and tear ensures a prolonged lifespan, reducing replacement costs.

2. Electrical Properties:

The G10 Phenolic Sheet possesses outstanding electrical insulation properties, making it an excellent choice for applications in the electronics industry. With superior dielectric strength, this material provides a reliable barrier against electrical current flow. It is commonly used as insulating supports, terminal boards, and electrical housings in various electronic devices.

3. Chemical Resistance:

G10 Phenolic Sheet exhibits excellent resistance to various chemicals, making it suitable for applications exposed to corrosive environments. It can withstand exposure to oils, solvents, acids, and alkalis, ensuring durability in demanding industries such as chemical processing, oil and gas, and marine sectors. This resistance prevents degradation and ensures the long-term reliability of equipment and structures.

4. Thermal Stability:

The G10 Phenolic Sheet offers exceptional thermal stability, enabling it to withstand elevated temperatures without significant degradation. This characteristic makes it suitable for applications where heat resistance is crucial, such as high-temperature insulation, electrical and electronics equipment, and automotive components.

5. Aerospace and Defense:

The aerospace and defense industries heavily rely on the superior properties of the G10 Phenolic Sheet. Its lightweight yet robust nature makes it ideal for manufacturing aircraft interior panels, structural components, as well as missile and weapon systems. The material's flame-retardant qualities also ensure compliance with safety regulations.

6. Automotive Industry:

G10 Phenolic Sheet has become a preferred choice in the automotive sector due to its excellent mechanical strength, durability, and resistance to high temperatures. It finds application in engine gaskets, electrical insulation components, friction materials, and composite structures, enhancing overall performance and extending the lifespan of vehicles.

7. Construction and Electrical Engineering:

The construction industry benefits from G10 Phenolic Sheet's ability to withstand extreme weather conditions, chemical exposure, and mechanical stress. It is commonly used in wall panels, flooring, insulation, and electrical insulation systems. Its resistance to fire and electrical conductivity ensures the safety and performance of infrastructure.

Conclusion:

The G10 Phenolic Sheet has emerged as a versatile and highly durable material, finding applications across multiple industries. Its mechanical strength, excellent electrical properties, chemical resistance, and thermal stability make it an invaluable asset for aerospace, automotive, electronics, construction, and other sectors. As technological advancements continue, the demand for reliable and resilient materials like the G10 Phenolic Sheet is expected to rise, fueling further innovation in the industry.