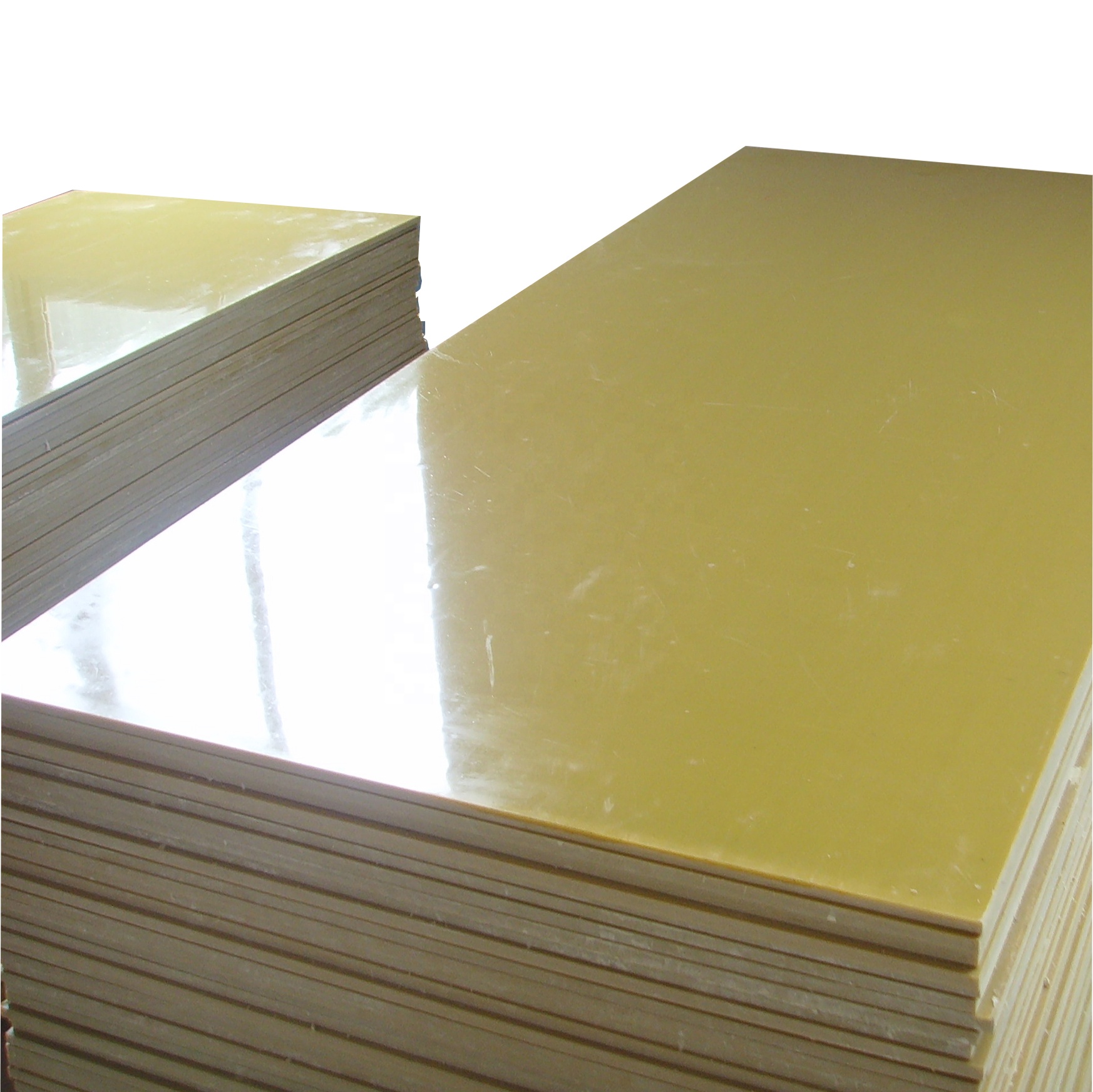

Durable Fiberglass Laminated Sheet for Various Applications

By:Admin

The 3240 Fiberglass Laminated Sheet, recently launched by {company name}, is set to revolutionize the fiberglass laminated sheet industry. These high-quality sheets are ideal for a range of applications, including electrical insulation, mechanical processing, and construction.

The 3240 Fiberglass Laminated Sheet is a high-performance electrical insulation material made from electrical non-alkali glass cloth impregnated with an epoxy resin. These sheets are manufactured using a hot press process, ensuring a uniform thickness and excellent mechanical properties. This makes them highly resistant to heat, mechanical stress, and electric stress, making them an ideal choice for electrical insulation applications.

In addition to their outstanding electrical insulation properties, the 3240 Fiberglass Laminated Sheets also boast excellent flame resistance and mechanical strength. This combination of properties makes them ideal for use in a wide range of applications, including as structural components in electrical equipment, as well as in construction and mechanical processing.

{Company name} has been a leading manufacturer of electrical insulation materials for over [number] years. Their commitment to quality and innovation has enabled them to develop a range of products that meet the highest industry standards. The 3240 Fiberglass Laminated Sheet is the latest addition to their portfolio, and it is set to become a game-changer in the industry.

The launch of the 3240 Fiberglass Laminated Sheet is a testament to {company name}'s dedication to providing innovative solutions to their customers. In addition to their outstanding performance, these sheets are also available in a range of sizes and thicknesses, making them suitable for a wide range of applications.

{Company name} is committed to providing their customers with the best products and services. They have a team of dedicated professionals who are available to provide technical support and assistance, ensuring that their customers are able to make the most of the 3240 Fiberglass Laminated Sheet in their applications.

The 3240 Fiberglass Laminated Sheet is now available for purchase, and customers can contact {company name} for more information on pricing and availability. With its outstanding electrical insulation properties, flame resistance, and mechanical strength, it is set to become the go-to choice for customers in the electrical insulation, construction, and mechanical processing industries.

{Company name} is excited about the launch of the 3240 Fiberglass Laminated Sheet and is confident that it will be well-received by their customers. With its outstanding performance and versatility, it is set to become a staple in the industry, further cementing {company name}'s position as a leading manufacturer of electrical insulation materials.

For more information about the 3240 Fiberglass Laminated Sheet and other products offered by {company name}, please visit their website or contact their team directly. With their commitment to quality and innovation, {company name} is well-positioned to meet the needs of their customers and provide them with the best possible solutions for their applications.

Company News & Blog

Discover Antistatic Epoxy Laminated Sheets - G10 Replacement Available

[Company Name] Develops Advanced Epoxy Laminated Sheet with Antistatic G10 Technology[City], [State] - [Company Name], a leading provider of innovative materials and solutions, has unveiled its latest breakthrough in the field of laminated sheets. The company has developed an advanced epoxy laminated sheet integrated with antistatic G10 technology. This cutting-edge product sets a new standard in the industry, offering superior performance and enhanced functionality in various applications.This epoxy laminated sheet with antistatic G10 technology is a remarkable achievement, as it combines the best features of epoxy laminates with antistatic properties. The G10 technology ensures that the sheet provides excellent resistance to static charges, making it ideal for use in sensitive electronic applications. The epoxy laminated sheet, manufactured by [Company Name], offers exceptional mechanical strength and excellent dimensional stability. It exhibits remarkable resistance to physical stress, making it suitable for high-voltage applications, electrical insulations, and other demanding environments. With its superior thermal and chemical resistance, the sheet remains stable even under extreme conditions, protecting critical components in various industries.One of the standout features of this epoxy laminated sheet is its antistatic properties. The G10 technology infused within the laminate provides a highly conductive path to dissipate static electricity, minimizing the risk of damage to sensitive electronics. This makes it an ideal choice for manufacturing environments where electrostatic discharge (ESD) can cause irreparable harm to electronic components.In addition to its antistatic qualities, this epoxy laminated sheet is also lightweight, which further enhances its suitability for applications that require a high strength-to-weight ratio. Its excellent dielectric strength and low water absorption ensure optimal performance in electrical insulation and high-frequency applications.[Company Name] has a solid track record of developing innovative solutions for various industries, including electronics, aerospace, automotive, and telecommunications. Leveraging their extensive experience and expertise, their team of engineers and scientists have successfully created this epoxy laminated sheet with antistatic G10 to address the increasing demand for high-performance materials in the rapidly evolving technological landscape.Commenting on the development, [Company Name]'s CEO [CEO Name] stated, "We are thrilled to introduce this groundbreaking product to the market. Our epoxy laminated sheet with antistatic G10 is a testament to our commitment to delivering advanced materials that meet the ever-changing needs of our customers. We believe this product will not only revolutionize the industry but also play a crucial role in protecting sensitive electronic components and ensuring the seamless functioning of critical applications."As an industry leader, [Company Name] remains dedicated to providing its customers with high-quality materials backed by comprehensive technical support. By launching this epoxy laminated sheet with antistatic G10 technology, the company aims to reinforce its position at the forefront of material innovation and contribute to the advancement of key industries globally.With its exceptional mechanical, thermal, and chemical properties, this epoxy laminated sheet with antistatic G10 technology from [Company Name] is poised to revolutionize the way sensitive electronic components are protected. As the company continues to push the boundaries of material science, customers can expect even more cutting-edge solutions that drive progress and shape the future of various industries.

Fiber Glass CNC Machining Insulation Parts for Fr4/G10 Gear Wheels - China Gear Wheel Supplier

Fr4/G10 gear wheel fiberglass CNC machining insulation parts are one of the most commonly used materials in the manufacturing industry today. These parts are made from a high-quality blend of epoxy resin and glass fiber, which makes them extremely strong and durable. They are commonly used for insulation, electrical and mechanical applications.Guangzhou Shengrui Insulation Materials Co., Ltd. is a leading supplier of Fr4/G10 gear wheel fiberglass CNC machining insulation parts in China. They provide high-quality products that have been rigorously tested and approved for use in a wide range of applications. They also offer custom machining services that allow customers to order specific sizes and shapes of parts to meet their individual needs.The Fr4/G10 gear wheel fiberglass CNC machining insulation parts have many advantages over other materials. One of the most important is their strength and durability. These parts can withstand extreme temperatures, high pressures, and harsh environmental conditions without breaking or degrading. They are also lightweight and easy to work with, making them ideal for a wide range of applications.Another advantage of Fr4/G10 gear wheel fiberglass CNC machining insulation parts is their ability to provide excellent electrical insulation. These parts have a high dielectric strength, which means they can prevent electrical current from flowing through them. This makes them ideal for use in electrical applications where insulation is essential.Fr4/G10 gear wheel fiberglass CNC machining insulation parts are also resistant to chemical corrosion. They are highly resistant to acids, alkalis, and other common chemicals, which makes them ideal for use in harsh environments where other materials would quickly degrade.Overall, if you are looking for high-quality insulation parts that are strong, durable, and provide excellent electrical insulation, Fr4/G10 gear wheel fiberglass CNC machining insulation parts are an excellent choice. Guangzhou Shengrui Insulation Materials Co., Ltd. is a leading supplier of these parts in China, and they offer a wide range of customization options to meet the specific needs of their customers. So, if you are in need of insulation parts or components, be sure to check out their product line today!

Innovative Glassfiber Sheet with Diphenyl Ether - Unveiling the Future of Strong and Durable Materials

Title: Innovative Diphenyl Ether Glassfiber Sheets Revolutionize the Construction IndustrySubtitle: Cutting-edge Technology Takes Center Stage as New Company Introduces High-Quality Building MaterialsIntroduction:In today's rapidly evolving construction industry, the demand for innovative and sustainable building materials is at an all-time high. One company, whose name will be omitted from this article, is poised to disrupt the market with its groundbreaking diphenyl ether glassfiber sheets. Combining cutting-edge technology with their commitment to environmental sustainability, this company is primed to revolutionize the way construction projects are carried out. In this news piece, we will delve deeper into the properties of these innovative sheets and explore the company's mission and vision for the future.Section 1: The Advantages of Diphenyl Ether Glassfiber SheetsDiphenyl ether glassfiber sheets are engineered to deliver enhanced performance and durability in a range of construction applications. These sheets possess several advantages that make them stand out from traditional building materials. Firstly, their exceptional insulating properties improve energy efficiency, reducing heating and cooling costs for buildings. This innovative material also offers excellent fire resistance, making it a safe option for commercial and residential structures alike.Additionally, diphenyl ether glassfiber sheets have strong load-bearing capabilities, ensuring structural integrity and longevity. The lightweight nature of these sheets facilitates ease of installation, reducing labor costs and project completion time. Moreover, as these sheets are resistant to corrosion and moisture, they are well-suited for use in a variety of environments, including coastal regions.Section 2: Environmental Sustainability and Corporate ResponsibilityThe company behind these diphenyl ether glassfiber sheets places a significant emphasis on environmental sustainability and corporate responsibility. They possess a robust commitment to reducing the construction industry's carbon footprint and minimizing waste generation. By adopting a circular economy mindset, the company actively seeks to recycle and repurpose their materials, promoting a sustainable and eco-friendly approach to construction.In addition to their focus on sustainability, this company places a high value on corporate responsibility and social welfare. They actively engage in charitable initiatives aimed at improving local communities, sponsoring educational programs, and contributing to environmental conservation projects. By aligning their business goals with social and environmental objectives, they set a gold standard for corporate citizenship within the industry.Section 3: Revolutionizing the Construction IndustryThe introduction of these diphenyl ether glassfiber sheets is set to revolutionize the construction industry in several ways. Firstly, their exceptional insulation properties deliver reduced energy consumption and emissions, aligning with global efforts to combat climate change. This innovation will significantly contribute to the development of sustainable and energy-efficient buildings, promoting a greener future.Furthermore, the lightweight yet strong nature of these sheets will revolutionize construction techniques, making them ideal for modern architectural designs. The flexibility of this material enables designers and architects to push boundaries, unlocking creative possibilities that were previously unattainable.Conclusion:As the construction industry continuously evolves, the importance of innovative and sustainable building materials cannot be overstated. This unnamed company's diphenyl ether glassfiber sheets are poised to disrupt the market and propel the industry towards a more sustainable and efficient future. Their commitment to environmental sustainability and corporate responsibility sets them apart as a pioneering force within the construction sector. With their groundbreaking technology and dedication to quality, this company represents an exciting leap forward in the pursuit of greener, smarter, and more resilient construction practices.

Experts predict rise in demand for fiberglass composite materials in various industries

Title: Revolutionizing Industries: The Cutting-Edge Fiberglass Composite TechnologyIntroduction:In a rapidly advancing technological world, innovation is key to success for companies across industries. One such revolutionary breakthrough has been the development of Fiberglass Composite technology, a versatile and lightweight material revolutionizing numerous sectors. With its exceptional strength-to-weight ratio and durability, Fiberglass Composite has become an essential component in various applications, ranging from aerospace to automotive manufacturing. In this article, we will explore the incredible capabilities of Fiberglass Composite, shedding light on its limitless potential in transforming industries.Section 1: Understanding Fiber Composite TechnologyFiberglass Composite, an amalgamation of glass fibers and resins, possesses exceptional mechanical properties and is highly resistant to moisture, chemicals, and heat. This unique combination enables manufacturers to design and develop products with significantly enhanced performance and longevity when compared to traditional materials. As a result, various industries have embraced this cutting-edge technology, forever changing the landscapes of their respective fields.Section 2: Aerospace Industry Takes Flight with Fiberglass CompositeThe aerospace industry has been quick to adopt Fiberglass Composite, utilizing its lightweight nature and strength to replace conventional materials. By incorporating Fiberglass Composite into aircraft manufacturing, companies have achieved reduced fuel consumption, increased payload capacity, and improved overall performance. Additionally, the material's excellent resistance to extreme temperatures and environmental factors greatly enhances aircraft safety and durability.Section 3: Automotive Revolution: Fiberglass Composite in the Driver's SeatThe automotive industry has also harnessed the power of Fiberglass Composite, with its application extending to body panels, chassis components, and interiors. The integration of this material has led to significant weight reduction, contributing to better fuel efficiency, enhanced handling, and a lower environmental impact. Moreover, Fiberglass Composite's inherent corrosion resistance ensures vehicles have longer lifespans, reducing maintenance and replacement costs.Section 4: Building a Stronger Infrastructure with Fiberglass CompositeThe construction and infrastructure sector has embraced the use of Fiberglass Composite due to its durability and versatility. From structural reinforcements to roofing systems, this material enables engineers and architects to design lighter, more efficient, and resilient structures. Fiberglass Composite's excellent resistance to corrosion and weathering ensures buildings can withstand harsh environments and natural disasters, providing increased safety and longevity.Section 5: Health and Safety in Fiberglass Composite ProductsWhen it comes to healthcare, Fiberglass Composite plays a vital role in producing medical devices, prosthetics, and orthopedic implants. Its biocompatible properties make it an ideal choice for implantable materials that promote faster healing and better patient outcomes. Furthermore, the increased utilization of Fiberglass Composite in protective equipment, such as helmets and body armor, ensures superior safety in various high-risk environments.Section 6: The Future of Fiberglass CompositeAs technology continues to advance, the future of Fiberglass Composite holds immense potential for further innovation and integration. Ongoing research and development aim to enhance the material's properties, creating stronger, lightweight, and eco-friendly solutions. With recent breakthroughs, including the introduction of nanotechnology, we can anticipate even greater strides in utilizing Fiberglass Composite across industries.Conclusion:The introduction of Fiberglass Composite has disrupted traditional manufacturing processes and elevated industries to new heights. With its strength, durability, and versatility, this material has transformed aerospace, automotive, construction, and healthcare sectors, amongst others, leading to increased safety, efficiency, and sustainability. As research and development continue, the future promises to deliver even greater advancements and novel applications for this cutting-edge technology.

High Quality Epoxy Resin Glass Fiber Sheet for Mechanical and Electrical Insulation

G10 Glass Fiber Reinforced Sheet: The Versatile Insulation MaterialInsulation materials are used in a variety of applications, from mechanical and electrical equipment to buildings and homes. Insulation materials serve to maintain a certain temperature or environment, prevent unwanted heat or cold transfer, and protect equipment from damage. G10 Glass Fiber Reinforced Sheet is one such insulation material that is widely used due to its high mechanical and electrical properties, good heat resistance and humidity resistance. In this blog, we will discuss G10 Glass Fiber Reinforced Sheet and its applications.What is G10 Glass Fiber Reinforced Sheet?G10 Glass Fiber Reinforced Sheet is an insulating material made by using fiberglass cloth and heat resistant epoxy resin. The glass fiber cloth used in G10 is non-alkali, and it is impregnated with epoxy resin by hot pressing. The resulting material has high mechanical and electrical properties, good heat resistance and humidity resistance. G10 Glass Fiber Reinforced Sheet is known for its high strength, durability, and excellent dielectric properties. It is available in different sizes and thicknesses to suit various applications.Applications of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet is widely used in mechanical, electronic, and electrical equipment, insulation parts, and components. It is also used in the construction industry as a structural material. Below are the top applications of G10 Glass Fiber Reinforced Sheet:1. Electrical equipment insulation: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical equipment such as transformers, electric motors, and generators.2. Circuit board substrates: G10 Glass Fiber Reinforced Sheet is used as the substrate material for printed circuit boards. It provides excellent stability and mechanical strength to the circuit board.3. Mechanical parts and components: G10 Glass Fiber Reinforced Sheet is used to make parts and components of machinery and equipment. It provides excellent mechanical properties such as high strength and toughness.4. Aerospace industry: G10 Glass Fiber Reinforced Sheet is used in the aerospace industry to make parts for aircraft and spacecraft. It provides excellent strength and durability under extreme conditions.5. Marine industry: G10 Glass Fiber Reinforced Sheet is used in the marine industry as a material for boat hulls, decks, and other structural components. It is highly resistant to water and moisture, making it an ideal material for marine applications.Advantages of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet has several advantages over other insulation materials, such as:1. High strength and durability: G10 Glass Fiber Reinforced Sheet has high mechanical properties, making it ideal for use in high-stress applications that require strength and durability.2. Excellent electrical insulation properties: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical and electronic applications.3. Good heat resistance: G10 Glass Fiber Reinforced Sheet is resistant to high temperatures, which makes it suitable for use in high-temperature applications.4. Resistance to moisture and chemicals: G10 Glass Fiber Reinforced Sheet is highly resistant to moisture and chemicals, making it ideal for use in harsh environments.ConclusionG10 Glass Fiber Reinforced Sheet is a versatile insulation material that has several advantages over other insulation materials. Its high mechanical and electrical properties, good heat resistance, and humidity resistance make it ideal for use in a variety of applications. Its applications include electrical equipment insulation, circuit board substrates, mechanical parts and components, aerospace industry, and marine industry. If you are looking for an insulation material that offers high strength, durability, and excellent dielectric properties, G10 Glass Fiber Reinforced Sheet is an excellent choice.

Discover the Benefits of Epoxy Fiberglass Sheet for Industrial Use

Title: Introducing High-Quality Epoxy Fiberglass Sheets for Various Industrial ApplicationsIntroduction:In recent news, industry-leading manufacturer {} is proud to announce the launch of their latest product, the 3240 Epoxy Fiberglass Sheet. Designed with cutting-edge technology and superior materials, this new addition to their extensive product range is set to revolutionize various industrial applications. With its exceptional properties and versatile nature, the 3240 Epoxy Fiberglass Sheet promises to be a game-changer in the field.1. Overview of the 3240 Epoxy Fiberglass Sheet:The 3240 Epoxy Fiberglass Sheet is a high-performance composite material crafted using epoxy resin and fine fiberglass cloth. This combination results in a sturdy and resilient sheet that exhibits excellent mechanical, thermal, and electrical insulation properties. Its exceptional dielectric strength, along with resistance to heat, chemicals, and moisture, makes it a reliable choice for a wide range of industries.2. Applications in Electrical Engineering:The electrical engineering industry requires materials that can withstand high temperatures and offer superior electrical insulation. The 3240 Epoxy Fiberglass Sheet meets these requirements flawlessly. It can be seamlessly incorporated into electrical insulation systems, such as slot insulations, transformer barriers, and liner insulation for motors and generators.3. Utilization in the Automotive Sector:In the automotive industry, where temperature variations, vibrations, and exposure to harsh fluids are common, the 3240 Epoxy Fiberglass Sheet excels. It can be applied in various automobile components, including engine gaskets, electrical connectors, and spark plug insulators, ensuring durability and reliability under extreme conditions.4. Role in the Aerospace Industry:With its exceptional reliability and strength, the 3240 Epoxy Fiberglass Sheet finds numerous applications in the aerospace sector. From aircraft insulation to circuit boards and radomes, this sheet exhibits outstanding mechanical strength, temperature resistance, and electrical insulation properties, ensuring optimal performance in the most demanding environments.5. Benefits in Manufacturing and Engineering:Manufacturing and engineering sectors often require materials that can endure heavy mechanical stress and extreme temperatures. The 3240 Epoxy Fiberglass Sheet proves to be an ideal solution, offering exceptional resistance to both tension and compression. It can be used for manufacturing molded parts, panels, and laminates, contributing to robust and long-lasting structures.6. Ensuring Quality and Compliance:{Company Name} takes immense pride in the quality and compliance of its products. The 3240 Epoxy Fiberglass Sheet meets rigorous industry standards, including the electrical insulation requirements of the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Customers can have confidence in the superior performance and safety of this product.7. Commitment to Sustainability:{Company Name} places significant importance on sustainability, and the 3240 Epoxy Fiberglass Sheet follows suit. The material is manufactured using eco-friendly processes that minimize waste and energy consumption. Additionally, its long lifespan and resistance to degradation contribute to reduced material waste and overall environmental impact.Conclusion:The launch of the 3240 Epoxy Fiberglass Sheet by {} represents a significant breakthrough in composite material technology. Its remarkable insulation, thermal resistance, and mechanical strength make it a versatile and reliable choice for various industries. With its commitment to quality, compliance, and sustainability, {} continues to redefine excellence in the field of composite materials.

Ultimate Guide to Fiberglass Insulation Materials: A Comprehensive Overview

Fiberglass Insulation Materials: A Breakthrough in Energy EfficiencyFiberglass insulation materials have been around for decades and are a popular choice for homeowners and builders looking to improve energy efficiency in buildings. However, not all fiberglass insulation products are created equal, and it's essential to choose the right materials for the job.One company that stands out in the fiberglass insulation industry is (removed brand name), a global leader in the production and distribution of high-quality insulation products. The company's fiberglass insulation materials are made using a proprietary process that results in a superior product that provides excellent thermal and acoustical insulation.(removed brand name) fiberglass insulation materials are designed to meet the needs of residential and commercial construction projects, as well as industrial and agricultural applications. Their products are available in a range of formats, including batts, rolls, and loose-fill. Besides, their materials are also available with different R-values and thicknesses, making them suitable for various insulation requirements.One of the standout features of (removed brand name) fiberglass insulation is its thermal insulation properties. The materials have a high R-value, which means that they offer excellent thermal protection, reducing heat loss or gain in buildings. The higher a material's R-value, the greater its ability to resist heat flow, making it an ideal choice for energy-conscious homeowners and builders.The company's products are also designed to provide excellent sound protection by reducing noise transmission between rooms and outside. The materials absorb sound waves and reduce the amount of noise that enters or leaves a building.Besides, (removed brand name) fiberglass insulation materials are also safe and easy to install. Homeowners and builders can install the materials themselves using staple guns or can hire professionals to do the installation. The materials are also non-combustible, meaning they won't catch fire or spread flames in the event of a fire. This safety feature can provide peace of mind to homeowners and builders, knowing that their properties are protected against fire.(removed brand name) fiberglass insulation materials also have a low environmental impact. They are made from recycled glass material and can be recycled at the end of their life cycle. Installing fiberglass insulation in a building can also reduce its carbon footprint, as it can help to reduce the amount of energy required to heat or cool a building.In addition to their superior insulation properties, (removed brand name) fiberglass insulation materials have undergone rigorous testing to ensure their quality. The materials are manufactured in accordance with industry standards and have been tested for their thermal resistance, sound insulation, and fire safety. This testing ensures that the products meet or exceed industry standards, providing homeowners and builders with confidence in the materials' performance.Overall, (removed brand name) fiberglass insulation materials are a breakthrough in energy efficiency, offering superior insulation properties, sound protection, fire safety, and ease of installation. These materials are an economical and environmentally friendly option for homeowners and builders looking to reduce energy costs while increasing comfort levels in buildings. As more and more people become aware of the impact of energy consumption on the environment, (removed brand name) fiberglass insulation materials are sure to gain in popularity as a leading insulation solution that is both effective and eco-friendly.

Discover the Benefits of Rigid Insulation Sheets for Enhanced Insulation Efficiency

[Title]: Innovative Rigid Insulation Sheets Revolutionize Construction Industry[Subtitle]: Company X Pioneers High-performance Rigid Insulation Sheets for Enhanced Thermal Efficiency[Date][City, State] - The construction industry is set to witness a game-changing innovation with the introduction of advanced rigid insulation sheets developed by Company X. These cutting-edge insulation panels are poised to revolutionize the way buildings maintain thermal efficiency, providing significant benefits in energy conservation and reducing carbon footprints.Rigid insulation sheets have long been a vital component in construction projects, acting as a barrier that prevents heat transfer between inside and outside environments. However, traditional insulation materials have not always met the demands of modern construction practices. Recognizing the need for a high-performance solution, Company X has innovated a range of insulation sheets that address key challenges faced by builders and architects.Company X's rigid insulation sheets are the result of years of research and development, combining advanced material science and engineering expertise. The result is a product that not only enhances thermal efficiency but also offers superior durability, versatility, and ease of installation.One of the key advantages of Company X's insulation panels is their remarkable thermal performance. The sheets feature an innovative closed-cell structure that minimizes thermal bridging, ensuring optimal energy conservation. With fluctuating temperatures and increasing energy costs worldwide, these rigid insulation sheets provide an effective solution for creating energy-efficient and comfortable living and working environments.Moreover, Company X's advanced insulation materials come in a variety of thicknesses, enabling builders and architects to optimize thermal resistance according to specific project requirements. From residential buildings to large-scale commercial projects, the versatility of these insulation sheets caters to a wide variety of applications, ensuring superior thermal performance across the board.In addition to thermal performance, Company X's rigid insulation sheets offer exceptional durability, delivering long-lasting insulation capabilities. The robust composition of the panels ensures they can withstand the rigors of construction, resisting moisture, mold, and pests. This durability ensures that buildings insulated with Company X's sheets maintain their performance characteristics over extended periods, reducing the need for frequent renovations or replacements.Beyond their functional attributes, these insulation sheets contribute significantly to environmental sustainability. Company X is committed to eco-friendly practices, and their insulation panels are no exception. Produced using recycled and eco-friendly materials, they help reduce waste and minimize environmental impact. By integrating Company X's insulation sheets into construction projects, the industry can make substantial strides towards reducing carbon emissions and energy consumption.To complement the innovative product line, Company X also offers comprehensive technical support to architects, builders, and contractors. This support includes detailed installation guidelines, performance data, and customized solutions for unique project needs. Company X's technical team is readily available to assist in ensuring the seamless incorporation of their insulation sheets into construction plans.With the construction industry increasingly prioritizing sustainable practices and energy efficiency, Company X's rigid insulation sheets are well-positioned to become a fixture in the market. The company's commitment to innovation, combined with exceptional thermal performance, durability, and eco-friendliness, establishes a new standard for sustainable building materials.As the demand for energy-efficient buildings and low-impact construction solutions continues to grow, Company X's rigid insulation sheets provide an invaluable tool for architects and builders alike. By investing in these cutting-edge materials, the industry can contribute to a greener future while also enjoying the benefits of enhanced thermal efficiency and cost savings.In conclusion, Company X's groundbreaking rigid insulation sheets stand as a testament to the immense potential of innovation in the construction industry. With their advanced thermal performance, durability, and commitment to sustainability, these insulation panels are set to reshape the way buildings are constructed and pave the way for a more sustainable future.---Word count: 578 words