Efficient Energy Saving Sheet for Sustainable Living

By:Admin

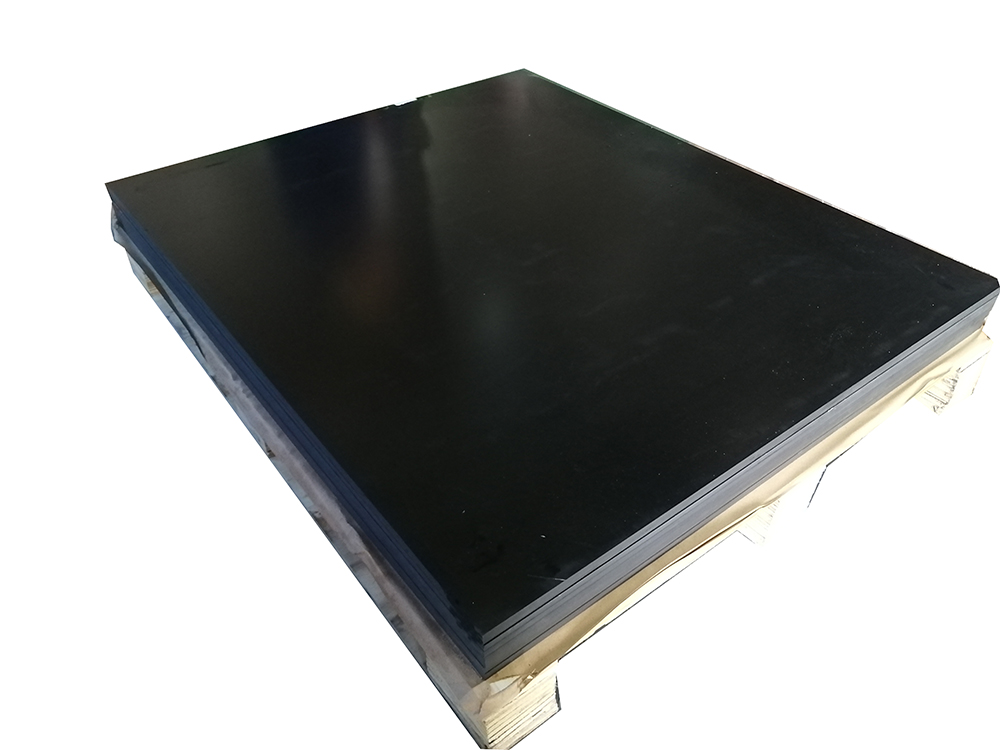

The China Energy Saving Sheet is made from high-quality materials that are designed to effectively insulate and regulate temperature in different environments. This innovative product is capable of reducing heat loss and improving energy efficiency in buildings, industrial equipment, and other applications. Its versatile nature makes it suitable for use in a wide range of scenarios, providing a convenient and effective solution for energy conservation.

The company behind this groundbreaking product, {}, has a strong reputation for delivering high-quality and reliable energy-saving solutions. With years of experience in the industry, they have established themselves as a trusted provider of sustainable products that meet the highest standards of performance and durability. Their commitment to innovation and continuous improvement has enabled them to stay ahead of the competition and consistently deliver products that offer long-term value to their customers.

The China Energy Saving Sheet is the latest addition to the company’s extensive portfolio of energy-saving products. It is the result of extensive research and development, aimed at addressing the growing demand for sustainable solutions that help reduce energy consumption and minimize environmental impact. By providing an effective and affordable way to improve energy efficiency, this product is expected to be well-received by businesses and homeowners alike.

One of the key advantages of the China Energy Saving Sheet is its ability to provide significant cost savings. By reducing heat loss and improving insulation, this product can help lower energy bills and minimize the need for constant heating and cooling. This can make a significant impact on the overall energy consumption of a building or a production facility, ultimately leading to lower operating costs and a more sustainable operation.

Furthermore, the China Energy Saving Sheet is easy to install and maintain, making it a practical and convenient solution for various applications. Its durable construction and long-lasting performance ensure that it will continue to deliver energy-saving benefits for years to come, making it a wise investment for businesses and homeowners looking to improve their energy efficiency.

With the launch of the China Energy Saving Sheet, {} continues to demonstrate their commitment to driving positive change in the industry. By offering innovative and sustainable products that deliver real value to their customers, they are contributing to a more sustainable and efficient future. As the global focus on environmental responsibility and energy efficiency continues to grow, this new product is poised to make a significant impact in the market and help pave the way for a more sustainable world.

In conclusion, the introduction of the China Energy Saving Sheet represents a significant milestone for {}. With its proven track record of delivering high-quality and reliable energy-saving solutions, they are well-positioned to make a meaningful impact with this innovative new product. As businesses and homeowners continue to prioritize energy efficiency and sustainability, the China Energy Saving Sheet offers a practical and cost-effective solution that can help reduce energy consumption and drive positive change. This product is a testament to the company’s ongoing commitment to innovation and environmental responsibility, and it is poised to make a significant impact in the market for years to come.

Company News & Blog

Discover the Benefits of Rigid Insulation Sheets for Enhanced Insulation Efficiency

[Title]: Innovative Rigid Insulation Sheets Revolutionize Construction Industry[Subtitle]: Company X Pioneers High-performance Rigid Insulation Sheets for Enhanced Thermal Efficiency[Date][City, State] - The construction industry is set to witness a game-changing innovation with the introduction of advanced rigid insulation sheets developed by Company X. These cutting-edge insulation panels are poised to revolutionize the way buildings maintain thermal efficiency, providing significant benefits in energy conservation and reducing carbon footprints.Rigid insulation sheets have long been a vital component in construction projects, acting as a barrier that prevents heat transfer between inside and outside environments. However, traditional insulation materials have not always met the demands of modern construction practices. Recognizing the need for a high-performance solution, Company X has innovated a range of insulation sheets that address key challenges faced by builders and architects.Company X's rigid insulation sheets are the result of years of research and development, combining advanced material science and engineering expertise. The result is a product that not only enhances thermal efficiency but also offers superior durability, versatility, and ease of installation.One of the key advantages of Company X's insulation panels is their remarkable thermal performance. The sheets feature an innovative closed-cell structure that minimizes thermal bridging, ensuring optimal energy conservation. With fluctuating temperatures and increasing energy costs worldwide, these rigid insulation sheets provide an effective solution for creating energy-efficient and comfortable living and working environments.Moreover, Company X's advanced insulation materials come in a variety of thicknesses, enabling builders and architects to optimize thermal resistance according to specific project requirements. From residential buildings to large-scale commercial projects, the versatility of these insulation sheets caters to a wide variety of applications, ensuring superior thermal performance across the board.In addition to thermal performance, Company X's rigid insulation sheets offer exceptional durability, delivering long-lasting insulation capabilities. The robust composition of the panels ensures they can withstand the rigors of construction, resisting moisture, mold, and pests. This durability ensures that buildings insulated with Company X's sheets maintain their performance characteristics over extended periods, reducing the need for frequent renovations or replacements.Beyond their functional attributes, these insulation sheets contribute significantly to environmental sustainability. Company X is committed to eco-friendly practices, and their insulation panels are no exception. Produced using recycled and eco-friendly materials, they help reduce waste and minimize environmental impact. By integrating Company X's insulation sheets into construction projects, the industry can make substantial strides towards reducing carbon emissions and energy consumption.To complement the innovative product line, Company X also offers comprehensive technical support to architects, builders, and contractors. This support includes detailed installation guidelines, performance data, and customized solutions for unique project needs. Company X's technical team is readily available to assist in ensuring the seamless incorporation of their insulation sheets into construction plans.With the construction industry increasingly prioritizing sustainable practices and energy efficiency, Company X's rigid insulation sheets are well-positioned to become a fixture in the market. The company's commitment to innovation, combined with exceptional thermal performance, durability, and eco-friendliness, establishes a new standard for sustainable building materials.As the demand for energy-efficient buildings and low-impact construction solutions continues to grow, Company X's rigid insulation sheets provide an invaluable tool for architects and builders alike. By investing in these cutting-edge materials, the industry can contribute to a greener future while also enjoying the benefits of enhanced thermal efficiency and cost savings.In conclusion, Company X's groundbreaking rigid insulation sheets stand as a testament to the immense potential of innovation in the construction industry. With their advanced thermal performance, durability, and commitment to sustainability, these insulation panels are set to reshape the way buildings are constructed and pave the way for a more sustainable future.---Word count: 578 words

Discover the Benefits of Epoxy Fiberglass Sheet for Industrial Use

Title: Introducing High-Quality Epoxy Fiberglass Sheets for Various Industrial ApplicationsIntroduction:In recent news, industry-leading manufacturer {} is proud to announce the launch of their latest product, the 3240 Epoxy Fiberglass Sheet. Designed with cutting-edge technology and superior materials, this new addition to their extensive product range is set to revolutionize various industrial applications. With its exceptional properties and versatile nature, the 3240 Epoxy Fiberglass Sheet promises to be a game-changer in the field.1. Overview of the 3240 Epoxy Fiberglass Sheet:The 3240 Epoxy Fiberglass Sheet is a high-performance composite material crafted using epoxy resin and fine fiberglass cloth. This combination results in a sturdy and resilient sheet that exhibits excellent mechanical, thermal, and electrical insulation properties. Its exceptional dielectric strength, along with resistance to heat, chemicals, and moisture, makes it a reliable choice for a wide range of industries.2. Applications in Electrical Engineering:The electrical engineering industry requires materials that can withstand high temperatures and offer superior electrical insulation. The 3240 Epoxy Fiberglass Sheet meets these requirements flawlessly. It can be seamlessly incorporated into electrical insulation systems, such as slot insulations, transformer barriers, and liner insulation for motors and generators.3. Utilization in the Automotive Sector:In the automotive industry, where temperature variations, vibrations, and exposure to harsh fluids are common, the 3240 Epoxy Fiberglass Sheet excels. It can be applied in various automobile components, including engine gaskets, electrical connectors, and spark plug insulators, ensuring durability and reliability under extreme conditions.4. Role in the Aerospace Industry:With its exceptional reliability and strength, the 3240 Epoxy Fiberglass Sheet finds numerous applications in the aerospace sector. From aircraft insulation to circuit boards and radomes, this sheet exhibits outstanding mechanical strength, temperature resistance, and electrical insulation properties, ensuring optimal performance in the most demanding environments.5. Benefits in Manufacturing and Engineering:Manufacturing and engineering sectors often require materials that can endure heavy mechanical stress and extreme temperatures. The 3240 Epoxy Fiberglass Sheet proves to be an ideal solution, offering exceptional resistance to both tension and compression. It can be used for manufacturing molded parts, panels, and laminates, contributing to robust and long-lasting structures.6. Ensuring Quality and Compliance:{Company Name} takes immense pride in the quality and compliance of its products. The 3240 Epoxy Fiberglass Sheet meets rigorous industry standards, including the electrical insulation requirements of the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Customers can have confidence in the superior performance and safety of this product.7. Commitment to Sustainability:{Company Name} places significant importance on sustainability, and the 3240 Epoxy Fiberglass Sheet follows suit. The material is manufactured using eco-friendly processes that minimize waste and energy consumption. Additionally, its long lifespan and resistance to degradation contribute to reduced material waste and overall environmental impact.Conclusion:The launch of the 3240 Epoxy Fiberglass Sheet by {} represents a significant breakthrough in composite material technology. Its remarkable insulation, thermal resistance, and mechanical strength make it a versatile and reliable choice for various industries. With its commitment to quality, compliance, and sustainability, {} continues to redefine excellence in the field of composite materials.

ESD Epoxy Fiberglass Black G10 Laminate Sheet: A Durable and Versatile Material

The company {} is proud to announce the launch of their latest product, the ESD Epoxy Fiberglass Black G10 Laminate Sheet. This innovative new product is set to revolutionize the industry with its advanced technology and exceptional performance.The ESD Epoxy Fiberglass Black G10 Laminate Sheet is a high-quality material that is designed for use in a variety of applications. It is known for its excellent electrical properties, making it an ideal choice for electronic and electrical insulation. In addition, it offers superior mechanical strength and high temperature resistance, making it a reliable and durable option for a wide range of industrial uses.The ESD Epoxy Fiberglass Black G10 Laminate Sheet is constructed from layers of fiberglass cloth impregnated with epoxy resin, which is then compressed and heated to form a solid laminate. This process results in a material that is highly resistant to heat, chemicals, and moisture, making it a versatile and long-lasting solution for demanding applications.One of the key features of the ESD Epoxy Fiberglass Black G10 Laminate Sheet is its electrostatic discharge (ESD) properties. This means that it is able to dissipate static electricity, making it suitable for use in environments where electronic components are sensitive to static build-up. This makes it an ideal choice for use in the manufacture of electronic devices, as well as in the construction of clean rooms and other controlled environments.In addition to its ESD properties, the ESD Epoxy Fiberglass Black G10 Laminate Sheet offers excellent dimensional stability and low water absorption, making it a reliable choice for use in humid or wet environments. Its high mechanical strength and resistance to impact and abrasion also make it a suitable choice for use in a wide range of industrial applications.The launch of the ESD Epoxy Fiberglass Black G10 Laminate Sheet further solidifies {}'s position as a leading provider of high-quality industrial materials. With their dedication to innovation and excellence, they continue to push the boundaries of what is possible in the industry, offering their customers the latest and most advanced products to meet their needs.{}'s commitment to quality and customer satisfaction is evident in the development of the ESD Epoxy Fiberglass Black G10 Laminate Sheet. This new product is the result of extensive research and development, and it has undergone rigorous testing to ensure its performance and reliability. As a result, customers can have full confidence in the quality and durability of this new product.In conclusion, the launch of the ESD Epoxy Fiberglass Black G10 Laminate Sheet represents a significant milestone for {}. With its exceptional electrical and mechanical properties, as well as its ESD capabilities, this innovative new product is set to make a lasting impact in the industry. As {} continues to lead the way in innovation and quality, customers can look forward to more groundbreaking products that meet their evolving needs.

High-Quality Flexible Fiberglass Sheets for Versatile Applications

Flexible Fiberglass Sheets: A Versatile Solution for Various ApplicationsFiberglass is a versatile and durable material that has been widely used in the construction and manufacturing industries. It is valued for its strength, flexibility, and resistance to corrosion, making it an ideal choice for a wide range of applications.{Company name} is a leading manufacturer of flexible fiberglass sheets, offering high-quality products that meet the needs of diverse industries. With a strong focus on innovation and product development, the company has established a reputation for delivering reliable and cost-effective solutions to its customers.Flexible fiberglass sheets, also known as FRP (Fiberglass Reinforced Plastic), are made by combining fine glass fibers with polymer resins. This results in a material that is lightweight, yet incredibly strong and durable. The flexibility of fiberglass sheets makes them suitable for a wide range of applications, from construction and automotive to marine and aerospace.One of the key advantages of flexible fiberglass sheets is their resistance to corrosion and weathering. This makes them an ideal choice for outdoor and marine applications, where exposure to moisture and harsh environments can cause traditional materials to deteriorate over time. Additionally, fiberglass sheets are non-conductive and have excellent thermal insulation properties, making them a popular choice for electrical and HVAC applications.{Company name}'s flexible fiberglass sheets are available in a wide range of sizes, thicknesses, and surface finishes to meet the specific requirements of different projects. Whether it's a small-scale DIY project or a large-scale industrial application, the company offers customizable solutions to fit the unique needs of its customers.In addition to their durability and flexibility, fiberglass sheets are also easy to install and maintain. Unlike traditional materials such as steel or wood, fiberglass does not require painting or sealing to protect it from the elements. This reduces the long-term maintenance costs and ensures that the material retains its strength and appearance over time.{Company name}'s commitment to quality and innovation is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. The company invests in the latest technology and equipment to ensure that its products meet the highest industry standards and exceed customer expectations.As the demand for sustainable and eco-friendly materials continues to grow, fiberglass has emerged as a popular choice for architects, engineers, and designers looking to reduce the environmental impact of their projects. Fiberglass is fully recyclable and can be repurposed at the end of its lifespan, making it a more sustainable alternative to traditional building materials.In conclusion, flexible fiberglass sheets are a versatile and cost-effective solution for a wide range of applications, and {company name} is a trusted provider of high-quality fiberglass products. With its commitment to innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry and drive the adoption of fiberglass as a preferred material choice. Whether it's for construction, transportation, or industrial applications, flexible fiberglass sheets offer a durable and sustainable solution for today's most demanding projects.

Fiberglass Reinforced Wall Panels for Durable and Stylish Interiors

title: Fiberglass Reinforced Panels Wall Panels Revolutionize the Construction IndustryIntroduction:The construction industry is constantly evolving, and innovative materials are key to its advancement. One such material gaining popularity is Fiberglass Reinforced Panels (FRP) wall panels. These durable and versatile panels are revolutionizing the way we build structures. With their properties of strength, flexibility, and ease of installation, FRP wall panels are becoming a go-to choice for architects, builders, and designers alike.Understanding Fiberglass Reinforced Panels:Fiberglass Reinforced Panels consist of a polymer matrix reinforced with fiberglass strands. This combination creates a lightweight yet robust material that can withstand high impact, moisture, chemicals, and UV exposure. The panels come in various sizes and textures, making them suitable for both interior and exterior applications.Applications and Benefits:1. Versatile and Appealing: FRP wall panels can be used in a wide range of applications. From commercial buildings to hospitals, schools, restaurants, and residential spaces, these panels offer a visually appealing alternative to traditional wall finishes. The panels come in various finishes, including wood grain, marble, mosaic, and metallic effects, enabling architects to unleash their creative ideas.2. Durability: FRP wall panels are incredibly durable, making them ideal for high-traffic areas. They are resistant to scratches, dents, and stains, ensuring a long-lasting finish that requires minimal maintenance. Moreover, their resistance to moisture and humidity makes them suitable for areas such as bathrooms or kitchens where traditional materials may deteriorate.3. Easy Installation: FRP wall panels are lightweight and easy to install, reducing construction time and labor costs. Their interlocking system allows for quick assembly, and their flexible nature enables them to be easily cut to fit any specific dimensions or odd angles.4. Safety and Hygiene: In environments where sanitation is crucial, FRP wall panels shine. The smooth surface of these panels resists the growth of mold, mildew, and bacteria, making them ideal for healthcare facilities and food processing environments. Their non-porous nature also ensures easy cleaning and maintenance.5. Sustainability: FRP wall panels contribute to sustainability efforts as they can be recycled and have a significantly longer lifespan than traditional wall materials. Their light weight also reduces transportation costs and energy consumption during installation.Market Expansion:As awareness of the benefits of FRP wall panels grows, their demand is increasing. Companies such as {Glass Fiber Reinforced Plastic Panels} have emerged as leading suppliers in the market, catering to the growing needs of the construction industry. These companies provide a wide range of FRP wall panels, satisfying the requirements of different projects.Conclusion:Fiberglass Reinforced Panels (FRP) wall panels are transforming the construction industry with their durability, versatility, and ease of installation. With their aesthetically pleasing finishes, they are replacing traditional wall materials, offering a cost-effective, sustainable, and hygienic solution. As the demand for FRP wall panels continues to rise, the future of construction looks brighter and more efficient.

High-Quality 8mm Fiberglass Sheet for Various Applications

8mm Fiberglass Sheet is a versatile and durable construction material that has become increasingly popular in the industry due to its strength and versatility. It is widely used in various applications such as roofing, wall cladding, and insulation. The sheets are made of high-quality fiberglass material, which ensures durability and longevity.The company, with over 20 years of experience in the industry, has established itself as a leading manufacturer and supplier of fiberglass products. They have a strong commitment to providing high-quality products and excellent customer service. Their 8mm Fiberglass Sheets are manufactured with state-of-the-art technology and are designed to meet the highest industry standards.The 8mm Fiberglass Sheets offered by the company are suitable for a wide range of applications in construction and industrial settings. The sheets are lightweight, making them easy to handle and install. They are also resistant to fire, chemicals, and corrosion, making them an ideal choice for areas that require high-performance materials.One of the key features of the 8mm Fiberglass Sheets is their excellent thermal and acoustic insulation properties. This makes them an ideal choice for building construction, where energy efficiency and noise control are important factors. The sheets also provide superior protection against weather elements, making them suitable for outdoor applications.The company takes pride in its ability to customize the 8mm Fiberglass Sheets according to the specific requirements of their customers. They offer a wide range of colors, sizes, and finishes to suit different applications. Whether it’s a residential, commercial, or industrial project, the company can provide tailored solutions to meet the needs of their clients.In addition to their high-quality products, the company also places a strong emphasis on sustainability and environmental responsibility. The 8mm Fiberglass Sheets are manufactured using eco-friendly processes and materials, making them a green choice for construction projects. The company is committed to reducing its carbon footprint and promoting sustainable practices in the industry.With a comprehensive understanding of the construction and industrial markets, the company has established a strong distribution network to ensure timely delivery of their products. Their dedicated team of professionals is always ready to provide expert advice and support to their customers, ensuring that they get the right products for their specific needs.In conclusion, the 8mm Fiberglass Sheets offered by the company are a premium choice for construction and industrial applications. With their exceptional strength, durability, and flexibility, these sheets are a cost-effective solution for a wide range of projects. Customers can rely on the company’s expertise and commitment to quality to deliver the best fiberglass products for their needs.

Discover Antistatic Epoxy Laminated Sheets - G10 Replacement Available

[Company Name] Develops Advanced Epoxy Laminated Sheet with Antistatic G10 Technology[City], [State] - [Company Name], a leading provider of innovative materials and solutions, has unveiled its latest breakthrough in the field of laminated sheets. The company has developed an advanced epoxy laminated sheet integrated with antistatic G10 technology. This cutting-edge product sets a new standard in the industry, offering superior performance and enhanced functionality in various applications.This epoxy laminated sheet with antistatic G10 technology is a remarkable achievement, as it combines the best features of epoxy laminates with antistatic properties. The G10 technology ensures that the sheet provides excellent resistance to static charges, making it ideal for use in sensitive electronic applications. The epoxy laminated sheet, manufactured by [Company Name], offers exceptional mechanical strength and excellent dimensional stability. It exhibits remarkable resistance to physical stress, making it suitable for high-voltage applications, electrical insulations, and other demanding environments. With its superior thermal and chemical resistance, the sheet remains stable even under extreme conditions, protecting critical components in various industries.One of the standout features of this epoxy laminated sheet is its antistatic properties. The G10 technology infused within the laminate provides a highly conductive path to dissipate static electricity, minimizing the risk of damage to sensitive electronics. This makes it an ideal choice for manufacturing environments where electrostatic discharge (ESD) can cause irreparable harm to electronic components.In addition to its antistatic qualities, this epoxy laminated sheet is also lightweight, which further enhances its suitability for applications that require a high strength-to-weight ratio. Its excellent dielectric strength and low water absorption ensure optimal performance in electrical insulation and high-frequency applications.[Company Name] has a solid track record of developing innovative solutions for various industries, including electronics, aerospace, automotive, and telecommunications. Leveraging their extensive experience and expertise, their team of engineers and scientists have successfully created this epoxy laminated sheet with antistatic G10 to address the increasing demand for high-performance materials in the rapidly evolving technological landscape.Commenting on the development, [Company Name]'s CEO [CEO Name] stated, "We are thrilled to introduce this groundbreaking product to the market. Our epoxy laminated sheet with antistatic G10 is a testament to our commitment to delivering advanced materials that meet the ever-changing needs of our customers. We believe this product will not only revolutionize the industry but also play a crucial role in protecting sensitive electronic components and ensuring the seamless functioning of critical applications."As an industry leader, [Company Name] remains dedicated to providing its customers with high-quality materials backed by comprehensive technical support. By launching this epoxy laminated sheet with antistatic G10 technology, the company aims to reinforce its position at the forefront of material innovation and contribute to the advancement of key industries globally.With its exceptional mechanical, thermal, and chemical properties, this epoxy laminated sheet with antistatic G10 technology from [Company Name] is poised to revolutionize the way sensitive electronic components are protected. As the company continues to push the boundaries of material science, customers can expect even more cutting-edge solutions that drive progress and shape the future of various industries.

Latest Report on Global G11 Market Trends and Analysis

The high-performance technology company, {Company Name}, is making waves in the industry with its latest innovation in the aerospace industry. The company, known for its expertise in designing and manufacturing advanced aerospace systems, has recently announced a groundbreaking development that is set to redefine the future of aviation. The innovative technology, which has been in development for several years, promises to revolutionize the way airplanes are designed and operated, ushering in a new era of efficiency, safety, and sustainability in air travel.{Company Name} has a long history of pushing the boundaries of what is possible in the aerospace industry. With a team of dedicated engineers, scientists, and researchers, the company has consistently delivered cutting-edge solutions that have set new standards for performance, reliability, and safety. The latest development from {Company Name} is no exception, as it promises to deliver significant advancements in all of these areas.The new technology, which has been named {Project Name}, is a result of years of research and development by {Company Name}’s team of experts. {Project Name} is a high-efficiency propulsion system that offers unprecedented levels of fuel efficiency, reduced emissions, and enhanced performance. By harnessing the latest advancements in aerospace engineering and materials science, {Company Name} has been able to create a propulsion system that is lighter, more efficient, and more reliable than any other system currently available on the market.One of the most exciting aspects of {Project Name} is its potential to revolutionize the environmental impact of air travel. With a strong focus on sustainability and environmental stewardship, {Company Name} has designed {Project Name} to minimize the carbon footprint of airplanes, making air travel more environmentally friendly than ever before. By significantly reducing fuel consumption and emissions, {Project Name} has the potential to make a significant contribution to the global effort to combat climate change and reduce the environmental impact of air travel.In addition to its environmental benefits, {Project Name} also promises to deliver significant improvements in aircraft performance and operational efficiency. By providing more power with less fuel, the technology will enable airplanes to fly farther, faster, and more efficiently than ever before. This will not only benefit airlines and their passengers, but also have a positive impact on the industry as a whole by reducing operating costs and increasing the overall efficiency of air travel.{Company Name}’s innovative approach to aerospace technology has garnered the attention of industry leaders and experts around the world. The company’s commitment to pushing the boundaries of what is possible in aerospace engineering has established it as a leading innovator in the industry, and {Project Name} is further evidence of its dedication to driving progress and advancement in aviation.With the announcement of {Project Name}, {Company Name} has once again demonstrated its leadership in the aerospace industry and its commitment to delivering game-changing solutions that have the potential to transform air travel as we know it. As the world looks towards a future of sustainable and efficient air travel, {Project Name} stands out as a shining example of innovative technology that has the power to shape the future of aviation for years to come. With its unrivaled performance, environmental benefits, and potential to revolutionize the industry, {Project Name} is a testament to {Company Name}’s ongoing commitment to innovation and excellence in aerospace engineering.

Top Quality Epoxy Glassfiber Sheet Insulating Sheet: Titanium White/Black EPGC201/EPGC204

Our company is pleased to announce the launch of a new product, Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet insulating sheet, designed to meet the needs of the modern electrical and engineering industries. This innovative product is set to revolutionize the market with its high-quality materials and superior performance.The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a state-of-the-art insulating sheet that offers excellent electrical insulation properties, high dimensional stability, and mechanical strength. It is widely used in electrical equipment, electric motors, PCB drilling pads, and many other industrial applications. The product is available in both white and black colors, offering customers flexibility and choice to suit their specific requirements.Our company has a long-standing reputation for delivering reliable and high-quality products to our customers. With a commitment to innovation and excellence, we are constantly striving to offer the latest advancements in technology and materials. The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a testament to our dedication to meeting the evolving needs of the industry.One of the key features of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is its exceptional thermal and chemical resistance. This makes it suitable for use in harsh and demanding environments, where it can withstand extreme temperatures and exposure to chemicals. The product is also resistant to moisture, making it an ideal choice for outdoor and marine applications.In addition, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet offers outstanding electrical insulation properties, ensuring the safety and reliability of electrical equipment. It has high dielectric strength and low water absorption, providing excellent insulation in a variety of electrical and electronic applications.The mechanical strength of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is another standout feature. It has high flexural and impact strength, as well as excellent dimensional stability, ensuring long-term performance and durability. This makes it a preferred choice for structural and mechanical applications in the engineering and construction industries.Our company is proud to offer the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet in a range of thicknesses and dimensions, catering to the diverse needs of our customers. We understand the importance of providing versatile and customizable solutions, and we are committed to delivering products that meet the specific requirements of each project.With the launch of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet, our company is poised to further solidify its position as a leading provider of high-performance materials for the electrical and engineering industries. We are confident that this product will set a new standard for excellence in insulation and engineering materials, and we look forward to seeing the positive impact it will have on our customers' projects.In conclusion, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a cutting-edge product that offers superior electrical insulation, thermal and chemical resistance, and mechanical strength. Backed by our company's commitment to quality and innovation, this product is set to make a significant impact in the market and provide our customers with a reliable and high-performance solution for their insulation and engineering needs.

Inflatable vs Epoxy: Which Type of SUP Board Suits You Best?

and Inflatable SUP.Stand Up Paddleboarding or SUP has become one of the most popular water sports in recent years. Whether you’re looking to explore your local waterways, catch waves, or get a full-body workout, owning a paddleboard allows you the freedom to do so. However, choosing the right board can be a daunting task, especially when it comes to deciding between an inflatable SUP or an epoxy board. In this blog, we’ll explore the pros and cons of each and help you make a decision that’s right for you.Inflatable SUPAn inflatable SUP is a paddleboard that can be inflated using a pump to a rigid and stable shape. They are made from PVC material and come in various sizes and shapes. Here are some key points to consider if you’re thinking about purchasing an inflatable SUP:Portability: One of the biggest advantages of an inflatable SUP is its portability. It can easily be deflated and stored in a compact bag, making it ideal for travel, camping, or even hiking.Durability: Contrary to popular belief, inflatable SUPs are highly durable and resistant to punctures and scratches. They are also easy to repair with a simple patch kit.Versatility: Inflatable SUPs are suitable for a wide range of activities such as recreational paddling, yoga, fishing, and even racing.Price: Inflatable SUPs are generally more affordable than epoxy boards and offer great value for those on a budget.Thickness: In terms of thickness, inflatable SUPs tend to be thicker than epoxy boards, which adds to their stability and buoyancy.Epoxy BoardEpoxy boards, on the other hand, are made from a foam core surfboard wrapped with layers of fiberglass and epoxy resin. They are ideal for surfing, racing, and touring. Here are some key points to consider if you’re thinking about purchasing an epoxy board:Performance: Epoxy boards are known for their excellent performance in the water. They are faster, more responsive, and more maneuverable than inflatable SUPs, making them perfect for those looking to catch waves or compete in races.Stability: While inflatable SUPs tend to be thicker and more stable, epoxy boards can provide just as much stability, especially with the right width and volume.Durability: Epoxy boards require more maintenance than inflatable SUPs and should be protected from the sun and scratches. They are also more susceptible to dings and cracks that need to be repaired.Price: Epoxy boards tend to be more expensive than inflatable SUPs, which can be a barrier for those on a budget.Different Thickness Epoxy Board: Unlike inflatable SUPs, epoxy boards come in different thicknesses that can significantly impact their performance and stability. Thicker boards are more stable but slower, while thinner boards are faster but less stable.Which one should you choose?Ultimately, choosing between an inflatable SUP and an epoxy board comes down to personal preference and what activities you plan to do. If you’re looking for a board that’s highly portable, durable, and versatile, an inflatable SUP is the way to go. But if you’re looking for a high-performance board for surfing, racing, or touring, an epoxy board is the better option.As with any purchase, it’s important to do your research and invest in a board that meets your needs and budget. Both inflatable SUPs and epoxy boards have their pros and cons, so it’s up to you to decide which one is right for you. Happy paddling!