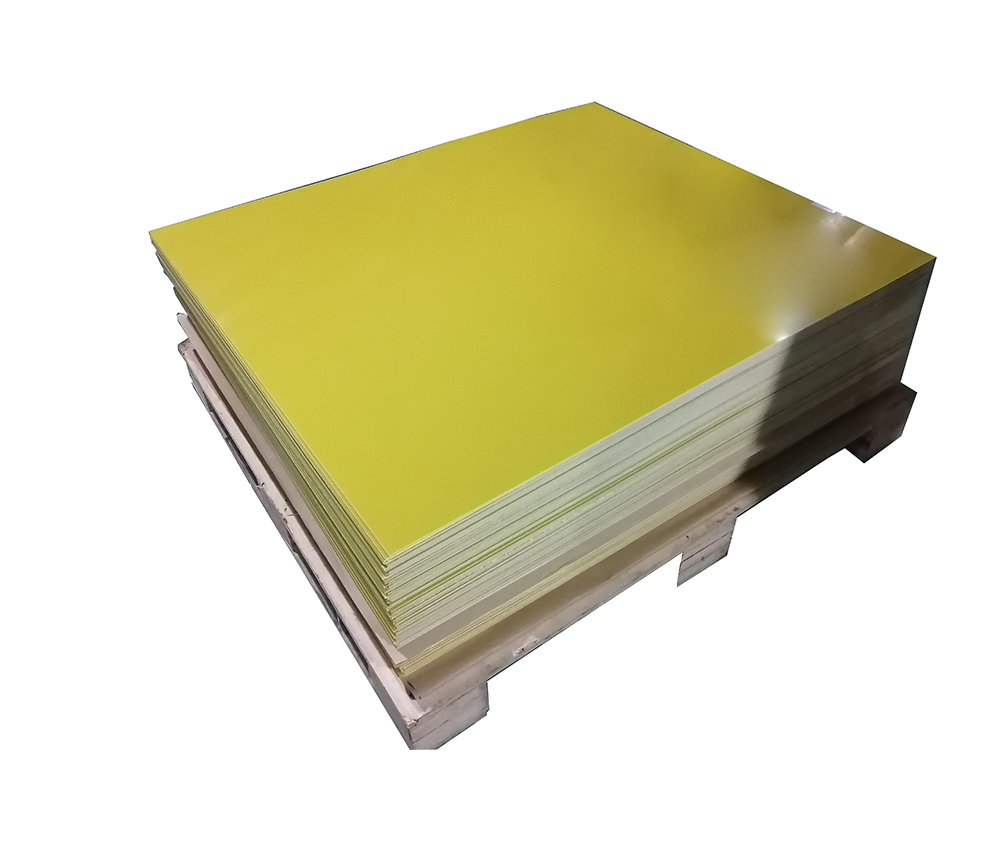

High-quality Fiberglass Composite Sheets for Various Applications

By:Admin

One prominent company leading the way in the production of Fiberglass Composite Sheets is [Company Name]. Specializing in the manufacturing of advanced composites, [Company Name] has established itself as a trusted provider of high-quality fiberglass materials that meet the stringent requirements of the industry.

Established [X] years ago, [Company Name] has continually invested in cutting-edge technology and research to develop innovative composite solutions. With a state-of-the-art manufacturing facility and a team of experienced engineers and scientists, the company has been able to stay ahead of the curve in the rapidly evolving composites industry.

One of the key offerings of [Company Name] is its range of Fiberglass Composite Sheets, which are designed to deliver exceptional performance in demanding environments. These sheets are manufactured using a combination of high-quality fiberglass reinforcement and a specialized resin matrix, resulting in a material that offers superior mechanical properties and resistance to harsh conditions.

The Fiberglass Composite Sheets offered by [Company Name] are widely used in the construction industry for applications such as roofing, cladding, and wall panels. Their high strength and lightweight nature make them an ideal choice for building materials, providing durability and longevity to structures.

In the automotive and aerospace sectors, [Company Name]'s Fiberglass Composite Sheets are utilized in the production of various components, including interior panels, exterior body parts, and structural reinforcements. The excellent impact resistance and structural integrity of these sheets make them crucial for ensuring the safety and performance of vehicles and aircraft.

Moreover, the marine industry relies on Fiberglass Composite Sheets for applications such as boat hulls, decks, and components due to their unparalleled resistance to water, chemicals, and environmental factors. [Company Name] has been a trusted supplier to boat manufacturers, offering composite solutions that withstand the rigors of marine environments.

With a commitment to quality and innovation, [Company Name] ensures that its Fiberglass Composite Sheets meet the highest industry standards and certifications. The company's dedication to research and development enables it to continually improve the performance and capabilities of its composites, staying at the forefront of technological advancements.

In addition to its primary product offerings, [Company Name] provides custom solutions for specific needs, working closely with clients to develop tailored composite materials that meet their unique requirements. This flexibility and customer-centric approach have set [Company Name] apart as a preferred partner for businesses seeking reliable composite solutions.

As the demand for lightweight, high-performance materials continues to rise across various industries, Fiberglass Composite Sheets have emerged as a vital asset for manufacturers and builders. With [Company Name] leading the way in the production of advanced composites, the future looks promising for the widespread adoption of these versatile materials in diverse applications.

In conclusion, Fiberglass Composite Sheets have demonstrated their value in delivering exceptional performance and durability across multiple industries, and [Company Name] has played a crucial role in advancing the capabilities of these materials. With a strong focus on research, innovation, and customer satisfaction, [Company Name] is poised to remain a key player in the composites industry, providing high-quality solutions that meet the evolving needs of the market.

Company News & Blog

Top 5 Best Insulation Panels for Your Home

Insulation Panel Company Announces Breakthrough TechnologyInsulation Panels is a leading provider of insulation products to the construction and building industry. The company has recently announced the launch of its new, breakthrough insulation panel technology that can help to improve energy efficiency in buildings while reducing costs.According to a spokesperson for the company, "Our new insulation panel technology is a game-changer for the industry. It offers superior thermal resistance, making it the perfect solution for colder climates. Additionally, our insulation panels have excellent air and moisture barriers, which results in a much more energy-efficient building."The insulation panels are made from a combination of high-density foam and a reflective layer that helps to reflect radiant heat back into the building. This design helps to maintain a comfortable temperature in all seasons, making it perfect for use in residential and commercial buildings alike.One of the key features of this innovative insulation panel technology is its exceptional fire resistance. It can stop the spread of flames for up to two hours, making it the ideal choice for structures that require increased fire protection.Insulation Panels are available in a range of sizes, making them suitable for a variety of applications. They are also incredibly easy to install, helping to reduce installation times and labor costs.The company's insulation panels are also environmentally friendly, boasting low VOC (volatile organic compound) emissions. This means that they are a safer choice for the environment and for the people who will be using these buildings.One of the key advantages of Insulation Panels' products is that they can help reduce energy costs for homeowners and businesses alike. By reducing the amount of energy required to heat or cool a building, this new technology can help to reduce energy bills significantly. This has the added benefit of reducing a building's carbon footprint, making it a more sustainable choice."A lot of people are looking to reduce their energy consumption and carbon footprint," says the company spokesperson. "Our insulation panels are the perfect solution for this. They use the latest technology to keep buildings comfortable and energy-efficient while remaining incredibly cost-effective."In addition to its new insulation panel technology, the company also offers a range of other insulation products and services. These include traditional batt insulation, as well as spray foam, rigid board insulation, and even custom insulation solutions.Insulation Panels have been serving the construction and building industry for over 20 years. They have a strong reputation for providing high-quality insulation products at extremely competitive prices. The company's experienced staff can also help customers choose the best insulation solution for their needs and answer any questions they may have.With its new breakthrough technology, Insulation Panels is set to continue leading the way in the insulation industry, providing its customers with the latest and most advanced insulation products and technologies on the market.

Essential Guide to Transformer Insulation Pressboard

Transformer Insulation Pressboard is a critical component in the construction of transformers, playing a key role in insulating the electrical components and ensuring the safe and efficient operation of these essential devices. In recent years, the demand for high-quality transformer insulation pressboard has been on the rise, driven by the increasing reliance on electrical power systems and the need for reliable and sustainable energy infrastructure. One company that has been at the forefront of this industry is {}. With a long history of expertise and innovation in the field of transformer insulation materials, {} has established itself as a leading supplier of pressboard products for transformer manufacturers and utilities around the world.Established in [year], {} has grown to become a trusted name in the global electrical insulation industry, known for its commitment to quality, reliability, and customer satisfaction. The company's pressboard products are manufactured using state-of-the-art processes and technologies, ensuring that they meet the highest standards for performance and durability. With a focus on sustainability and environmental responsibility, {} has also developed a range of eco-friendly pressboard materials that are designed to minimize the environmental impact of transformer insulation production and use.In addition to its dedication to product excellence, {} has also built a reputation for its technical expertise and customer support. The company's team of engineers and technical specialists are available to provide guidance and support to transformer manufacturers and end-users, helping them to select the right pressboard products for their specific applications and requirements. With a strong emphasis on collaboration and partnership, {} works closely with its customers to develop customized solutions that meet their unique needs and challenges.One of the key strengths of {} is its global presence and distribution network. With manufacturing facilities and sales offices in multiple countries, the company is able to serve customers around the world with efficiency and flexibility. This global reach also enables {} to stay at the forefront of industry trends and developments, ensuring that its products and services remain at the cutting edge of transformer insulation technology.Looking to the future, {} remains committed to driving innovation and advancement in the field of transformer insulation pressboard. The company continues to invest in research and development, exploring new materials, technologies, and processes that will further enhance the performance, reliability, and sustainability of its products. At the same time, {} is dedicated to fostering strong relationships with its customers and partners, working together to address the evolving needs and challenges of the electrical power industry.As the demand for electrical power continues to grow, the role of transformer insulation pressboard in ensuring the reliable and safe operation of electrical infrastructure will only become more critical. With its proven track record of excellence, innovation, and customer focus, {} is well-positioned to continue leading the way in this important sector, providing the high-quality pressboard products and support that the industry relies on.

High-Quality Grade B Epoxy Fiberglass Laminate Sheet: What You Need to Know

Grade B Epoxy Fiberglass Laminate Sheet (brand name removed), is a high-quality and reliable material that is widely used across various industries for its excellent insulation and mechanical properties. Manufactured by {} - a leading provider of advanced materials and solutions for the electrical, electronics, and thermal management industries - this epoxy fiberglass laminate sheet has garnered a reputation for its superior performance and durability.The Grade B Epoxy Fiberglass Laminate Sheet is a thermosetting material that is made by impregnating layers of fiberglass with an epoxy resin and then compressing them under high pressure. This results in a material that is highly resistant to heat, moisture, and chemicals, making it an ideal choice for applications that require high-performance insulation and protection.The sheet is available in a variety of thicknesses and sizes, making it suitable for a wide range of applications, including electrical insulation, structural components, and printed circuit boards. Its excellent dielectric properties and high mechanical strength make it a preferred choice for use in transformers, switchgear, motors, and generators, where reliable insulation is essential for the safety and performance of the equipment.In addition to its exceptional electrical and mechanical properties, the Grade B Epoxy Fiberglass Laminate Sheet also offers good dimensional stability and resistance to flame, making it a versatile material that can withstand harsh operating conditions. The material is also easy to machine and fabricate, allowing for customized designs and precise manufacturing of components.The Grade B Epoxy Fiberglass Laminate Sheet is manufactured by {} using advanced production techniques and quality control processes to ensure consistent and reliable performance. The company is committed to delivering high-quality materials that meet the stringent requirements of its customers and exceed industry standards.With a global presence and a strong reputation for innovation and excellence, {} has established itself as a trusted partner for companies seeking advanced materials and solutions for their applications. The company's extensive experience and expertise in the field of advanced materials enable it to offer comprehensive support and technical assistance to its customers, helping them to optimize their designs and achieve the best performance from the Grade B Epoxy Fiberglass Laminate Sheet.As industries continue to demand high-performance materials that can withstand extreme conditions and deliver reliable performance, the Grade B Epoxy Fiberglass Laminate Sheet from {} has proven to be a top choice for engineers and designers looking for a durable and versatile material for their applications. With its superior insulation and mechanical properties, this material is poised to continue making significant contributions to the advancement of various industries, including electrical, electronics, and thermal management.In conclusion, the Grade B Epoxy Fiberglass Laminate Sheet from {} stands as a testament to the company's commitment to providing high-quality materials and solutions that meet the evolving needs of its customers. With its exceptional performance and reliability, this material is set to remain a preferred choice for a wide range of applications, helping companies to achieve superior insulation and protection for their critical components and systems.

Discover the Benefits of an Epoxy Fiberglass Cutting Board for your Kitchen

Epoxy Fiberglass Cutting Board: An Innovative Kitchen AccessoryIn today's fast-paced world, people have become increasingly conscious about the quality of food they consume. They are seeking innovative ways to ensure that they are eating healthy and nutritious food, and cooking their meals using the best quality ingredients. This has led to a spurt in demand for high-quality kitchen accessories that can help them prepare food in a hygienic and safe manner. One such innovative kitchen accessory is the Epoxy Fiberglass Cutting Board, which has gained tremendous popularity among health-conscious consumers.Epoxy Fiberglass Cutting Board is a kitchen accessory that is specifically designed to meet the needs of professional chefs and home cooks. It is made from a unique blend of epoxy and fiberglass that makes it highly durable, resistant to scratches and cuts, and easy to clean. The cutting board is also hygienic and safe to use, as it is non-porous and does not absorb bacteria, dirt, or moisture. These features make it an ideal product for people looking for a durable and hygienic kitchen accessory.The Epoxy Fiberglass Cutting Board is a versatile accessory that can be used for cutting a variety of food items, including vegetables, fruits, meat, and bread. It is available in different sizes and shapes, allowing users to choose the one that fits their specific needs. The cutting board is also available in different colors and patterns, allowing users to pick the one that matches their kitchen's decor.One of the key highlights of the Epoxy Fiberglass Cutting Board is its durability. Unlike wooden cutting boards that tend to warp and crack over time, this cutting board is designed to last for years. It is also resistant to stains, so users can be assured that their board will always look as good as new. The cutting board is also easy to maintain, as it can be washed with soap and water and dried with a towel.Another advantage of the Epoxy Fiberglass Cutting Board is its safety. As it is non-porous, it does not absorb bacteria or other harmful germs that can contaminate food. This makes it an ideal accessory for people who are health-conscious and want to ensure that they are consuming safe and hygienic food.In addition to its durability and safety, the Epoxy Fiberglass Cutting Board is also a stylish kitchen accessory. It comes in a variety of colors and patterns, allowing users to choose the one that matches their kitchen's decor. This makes it not just a functional accessory but also an aesthetic one that can enhance the look of any kitchen.The company behind the Epoxy Fiberglass Cutting Board is a leading manufacturer of innovative kitchen accessories in China. It has been in the industry for several years and is committed to creating high-quality products that meet the needs and expectations of its customers. The company's mission is to provide innovative and functional products that make cooking easy, safe, and enjoyable.The company's Epoxy Fiberglass Cutting Board is manufactured using the latest technology and the highest quality materials. The manufacturing process is environmentally friendly, and the company's products are free of harmful chemicals and toxins. The company also has a strict quality control process in place, ensuring that every product meets its high standards.In conclusion, the Epoxy Fiberglass Cutting Board is an innovative kitchen accessory that offers a perfect blend of functionality, safety, durability, and style. It is an ideal product for both professional chefs and home cooks who are looking for a reliable and hygienic product to prepare their food. The cutting board is manufactured by a leading company in China that is committed to producing high-quality products that meet the needs of its customers. Overall, the Epoxy Fiberglass Cutting Board is a must-have accessory for any kitchen, and it is sure to become a favorite among health-conscious consumers.

High Quality Insulation Materials Meet CTI 600V Standards in China's G11/Epgc203 Line

China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V: Leveraging Superior Performance in Electrical ApplicationsFor electrical engineers and manufacturers, sourcing reliable insulation materials is vital. Poor quality insulation can cause short circuits, fires, and other hazards, harming people and equipment. Among the many materials available, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V stand out for their superior performance in electrical applications.The CTI (Comparative Tracking Index) is a measure of the electrical breakdown resistance of insulating materials under severe conditions. China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V have a CTI rating of 600V, which means they can withstand high voltage and extreme temperatures without breaking down. This makes them ideal for use in transformers, motors, generators, and other electrical equipment.China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are made of epoxy resin and glass fiber cloth, which gives them exceptional mechanical strength, heat resistance, and flame retardancy. They can withstand temperatures up to 180°C continuously and up to 300°C for short periods without losing their properties. They are also self-extinguishing when exposed to flames, which prevents fires from spreading.Another advantage of China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V is their low dielectric constant and dissipation factor, which means they have low losses and high insulation resistance. This translates into more efficient and reliable electrical systems with reduced energy consumption and maintenance costs.Moreover, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are easy to process and shape into various forms, including sheets, rods, tubes, and molded parts. They can be machined, drilled, and tapped into precise dimensions and tolerances. They can also be laminated with metals and other materials to form composites with enhanced properties.China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are widely used in industries such as aerospace, marine, automotive, and electronics, where high-performance insulation is critical for safety and performance. They are also exported to many countries, including the United States, Europe, and Southeast Asia, where they have earned a reputation for quality and reliability.One of the leading manufacturers of China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V is {Company X}, a Chinese company that specializes in the production and distribution of advanced composite materials. Founded in 2008, {Company X} has grown into a global player in the composite industry, with a wide range of products and services that cater to the needs of various markets and customers.{Company X} is committed to providing high-quality products that meet or exceed international standards and customer expectations. They have a state-of-the-art production facility that is equipped with the latest technology and machinery for mixing, impregnating, curing, and testing composite materials. They also have a team of experienced engineers and technicians who work closely with customers to develop customized solutions for their specific applications.{Company X} has achieved several certifications, such as ISO 9001, ISO 14001, and OHSAS 18001, that demonstrate their commitment to quality, environmental protection, and occupational health and safety. They have also invested in research and development to improve their products and processes and stay ahead of the competition.{Company X} is determined to expand its market share and reputation by combining innovation, quality, and service excellence. They welcome inquiries from customers worldwide and are ready to provide technical support, samples, and quotations upon request.In conclusion, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are high-performance insulation materials that offer superior properties for electrical applications. They are made of epoxy resin and glass fiber cloth, which give them mechanical strength, heat resistance, and flame retardancy. They have a CTI rating of 600V, which makes them suitable for high voltage and extreme temperature environments. They are also easy to process and shape into various forms and can be customized to meet specific requirements. {Company X} is one of the leading manufacturers of these materials and offers a range of products and services that meet or exceed international standards.

How to Use Anti-Static Sheets: A Complete Guide for Static Control

[Company Name] Introduces Cutting-Edge Anti-Static Sheet for Industries[City, State] - [Company Name], a leading provider of innovative solutions for industrial applications, has introduced a new and advanced anti-static sheet designed to address the growing concerns of static electricity in various industries. The anti-static sheet, which will be available for purchase from [Company Name], aims to provide a reliable and cost-effective solution for businesses looking to mitigate the adverse effects of static electricity in their operations.Static electricity is a common issue in many industries, particularly in environments where friction and movement of materials can generate high levels of electrostatic charge. This can create a range of problems, from damaging sensitive electronic components to posing a safety hazard for workers. The new anti-static sheet from [Company Name] offers a practical and efficient way to control and neutralize static electricity, helping businesses to maintain a stable and safe working environment.The innovative technology behind the anti-static sheet enables it to effectively dissipate static charges, preventing the build-up of electrostatic discharge and reducing the risk of damage to sensitive equipment. This makes it an ideal solution for industries such as electronics manufacturing, cleanroom environments, pharmaceutical production, and other settings where static control is a critical concern.Moreover, the anti-static sheet is designed to be highly durable and long-lasting, providing businesses with a cost-effective solution for managing static electricity over an extended period. Its robust construction ensures that it can withstand the rigors of industrial operations, making it a practical choice for businesses seeking a reliable static control solution.[Company Name] has a strong track record of delivering high-quality industrial solutions, and the introduction of the new anti-static sheet further demonstrates its commitment to addressing the evolving needs of its customers. With a focus on innovation and practicality, the company continues to develop products that offer tangible benefits for businesses across a range of industries.In addition to offering the new anti-static sheet, [Company Name] provides a comprehensive range of industrial products and solutions, including anti-static mats, ionizing blowers, and static control devices. Its dedication to providing effective static control solutions has established [Company Name] as a trusted partner for businesses looking to enhance the safety and efficiency of their operations.As businesses strive to optimize their manufacturing processes and maintain high standards of product quality, the need for effective static control measures has become increasingly important. The introduction of the new anti-static sheet from [Company Name] reflects the company's commitment to supporting the continued success of its customers by offering practical and reliable solutions to address industry challenges.With its innovative approach to static control and its proven track record of delivering quality industrial solutions, [Company Name] is well-positioned to meet the growing demands of businesses seeking effective anti-static products. The new anti-static sheet is poised to make a significant impact in the industry by providing businesses with a dependable and efficient solution for managing static electricity in their operations.For more information about [Company Name] and its range of industrial solutions, including the new anti-static sheet, please visit [Company Website].About [Company Name]:[Company Name] is a leading provider of industrial solutions, offering a comprehensive range of products and services to support the diverse needs of businesses across various industries. With a focus on innovation, quality, and practicality, the company has established itself as a trusted partner for businesses seeking reliable and effective solutions for their operations.

Discover the Advantages of Prepreg Fiberglass: A Comprehensive Guide

Prepreg Fiberglass Emerges as the Ultimate Solution for Diverse IndustriesPrepreg fiberglass is an advanced material that is increasingly becoming popular in a wide range of industries, and for good reasons. From aerospace engineering to automotive manufacturing, prepreg fiberglass is seen as the ideal solution for achieving superior durability, strength, and lightweight properties in various applications. This innovative material is made by impregnating fiberglass cloth with a thermosetting resin system, which creates a reinforcement material that provides exceptional performance capabilities.One of the main advantages of prepreg fiberglass is its ability to offer high strength-to-weight ratio, far superior to metals such as steel or aluminum. This makes it an excellent choice for manufacturing lightweight structures, particularly in aerospace, automotive, marine, and sporting industries. It can be used to create parts and components that are not only lighter but also stronger, stiffer, and more resistant to impact and wear. The result is optimized performance, improved fuel efficiency, reduced costs, and greater environmental sustainability.Another notable benefit of prepreg fiberglass is its versatility. It can be tailored to meet specific requirements of various applications, from temperature resistance to flame retardancy and chemical resistance. Moreover, it can be molded into different shapes and sizes, using different fabrication methods such as compression molding, autoclave curing, vacuum bagging, and pultrusion. This means it can be used to create complex parts with intricate geometries, further expanding its range of possible uses.The use of prepreg fiberglass is not limited to industrial applications; it also has a lot of potential in architectural and design fields. Thanks to its aesthetic qualities, such as translucency, colorability, and texture, it can be used to create unique and eye-catching structures that enhance a building's visual appeal. This material has already been utilized in the construction of many landmark buildings, including the Guggenheim Museum in Bilbao, Spain, and the Beijing National Stadium, better known as the "Bird's Nest."The potential of prepreg fiberglass is not lost on innovative companies such as X, which specializes in developing and manufacturing advanced composite materials for a wide range of industries. The company's expertise lies in creating highly customized solutions to meet the specific needs of each customer. X has a wide range of prepreg fiberglass products that are suitable for different applications, from aerospace to medical equipment.One of the company's most prominent products is its high-performance prepreg fiberglass, which offers unbeatable strength, durability, and stiffness. This material has been used in the manufacture of various components of commercial aircraft such as tail cones, floor beams, and wing skins. The company's prepreg fiberglass has also found extensive use in the automotive industry, where it is employed in the manufacturing of lightweight structural parts, including suspension components, engine coverings, and chassis components.Another impressive product from X is its fire-resistant prepreg fiberglass. This material has exceptional fire-retardant properties, making it suitable for use in high-risk industries such as transportation and construction. Additionally, the company's prepreg fiberglass is compatible with various resin systems, including epoxy, phenolic, and polyester, among others, giving customers the flexibility to choose the best material for their particular needs.In conclusion, prepreg fiberglass is a highly adaptable material that offers a range of benefits to various industries. Its unique combination of properties, including high strength, lightweight, and versatility, make it an ideal solution for different applications from aerospace, automotive, marine, construction, and sporting equipment. As the use of composite materials becomes more widespread, the use of prepreg fiberglass will continue to grow, providing opportunities for innovative companies like X to create tailor-made solutions that meet the needs of a diverse range of customers.

Latest Updates on Sheet 3240 News: Read the Latest Updates Here

{Company introduction} is a leading provider of innovative solutions in the field of technology and consumer electronics. With a strong focus on research and development, the company has consistently delivered cutting-edge products that have redefined the way people live and work. From mobile devices to home appliances, {Company} has established itself as a global leader in the industry, with a strong presence in markets around the world.In a recent news update, {Company} has announced a significant milestone with the production of its 3240th sheet of advanced technology. This achievement highlights the company's commitment to pushing the boundaries of innovation and delivering products that exceed the expectations of consumers.The 3240th sheet produced by {Company} represents a culmination of years of research and development in the field of technology. The sheet is a vital component in a range of {Company}'s products, including mobile devices, computers, and home appliances. Its production showcases the company's dedication to creating high-quality, reliable, and cutting-edge technology that enhances the lives of its customers.{Company}'s 3240th sheet is a testament to its relentless pursuit of excellence in the field of technology. It embodies the company's commitment to staying ahead of the curve and continually raising the bar for innovation in the industry. By producing this significant milestone, {Company} is reinforcing its position as a leader in the global market for consumer electronics.In addition to the production of the 3240th sheet, {Company} has also continued to invest in research and development to pave the way for future advancements in technology. The company's state-of-the-art facilities and a team of dedicated experts are at the forefront of creating the next generation of products that will shape the future of technology.{Company}'s 3240th sheet is a representation of the company's dedication to sustainability and eco-friendly practices. As part of its commitment to corporate social responsibility, {Company} has implemented environmentally friendly processes in the production of its technology, ensuring that its products have a minimal impact on the environment.Furthermore, {Company} is actively engaged in initiatives to give back to the community and support initiatives that promote education and innovation. The company's commitment to making a positive impact extends beyond its products and technology, reflecting a strong sense of corporate citizenship.The production of the 3240th sheet is a significant milestone for {Company}, symbolizing its position as a leader in the technology and consumer electronics industry. As the company continues to push the boundaries of innovation, it is poised to deliver even more groundbreaking products that will shape the future of technology and enhance the lives of consumers around the world. With a strong foundation built on research, development, and a commitment to excellence, {Company} is well-positioned to lead the way in the ever-evolving landscape of technology.

Durable and Heat-Resistant Phenolic Sheet Gaining Popularity in Multiple Industries

Title: Highly Durable G10 Phenolic Sheet Finds Application in Numerous IndustriesIntroduction:Throughout various industries, the need for durable and reliable materials is paramount. One such material garnering attention is the G10 Phenolic Sheet. This high-performance laminate is gaining recognition for its exceptional mechanical strength, excellent electrical properties, and chemical resistance. It has become a sought-after choice for professionals across sectors, ranging from aerospace and automotive to electronics and construction.Company Introduction:{Insert company name} is a leading provider of advanced materials, specializing in manufacturing and distributing high-quality G10 Phenolic Sheets. With years of expertise in the field, our company has established a strong reputation for delivering top-notch solutions that meet and exceed industry standards. We prioritize innovation and sustainability, ensuring our products align with the evolving needs of modern industries.Article:The versatility of G10 Phenolic Sheet has made it an indispensable material in a wide range of applications. With its exceptional durability and resistance to extreme conditions, it has proven itself as a valuable asset in demanding environments. Let us explore the key characteristics and applications of this remarkable material.1. Mechanical Strength: G10 Phenolic Sheet offers impressive mechanical properties, including high tensile strength, impact resistance, and dimensional stability. These features make it an ideal choice for applications requiring structural integrity, such as load-bearing components, gears, and bushings. Its resilience to wear and tear ensures a prolonged lifespan, reducing replacement costs.2. Electrical Properties:The G10 Phenolic Sheet possesses outstanding electrical insulation properties, making it an excellent choice for applications in the electronics industry. With superior dielectric strength, this material provides a reliable barrier against electrical current flow. It is commonly used as insulating supports, terminal boards, and electrical housings in various electronic devices.3. Chemical Resistance:G10 Phenolic Sheet exhibits excellent resistance to various chemicals, making it suitable for applications exposed to corrosive environments. It can withstand exposure to oils, solvents, acids, and alkalis, ensuring durability in demanding industries such as chemical processing, oil and gas, and marine sectors. This resistance prevents degradation and ensures the long-term reliability of equipment and structures.4. Thermal Stability:The G10 Phenolic Sheet offers exceptional thermal stability, enabling it to withstand elevated temperatures without significant degradation. This characteristic makes it suitable for applications where heat resistance is crucial, such as high-temperature insulation, electrical and electronics equipment, and automotive components.5. Aerospace and Defense:The aerospace and defense industries heavily rely on the superior properties of the G10 Phenolic Sheet. Its lightweight yet robust nature makes it ideal for manufacturing aircraft interior panels, structural components, as well as missile and weapon systems. The material's flame-retardant qualities also ensure compliance with safety regulations.6. Automotive Industry:G10 Phenolic Sheet has become a preferred choice in the automotive sector due to its excellent mechanical strength, durability, and resistance to high temperatures. It finds application in engine gaskets, electrical insulation components, friction materials, and composite structures, enhancing overall performance and extending the lifespan of vehicles.7. Construction and Electrical Engineering:The construction industry benefits from G10 Phenolic Sheet's ability to withstand extreme weather conditions, chemical exposure, and mechanical stress. It is commonly used in wall panels, flooring, insulation, and electrical insulation systems. Its resistance to fire and electrical conductivity ensures the safety and performance of infrastructure.Conclusion:The G10 Phenolic Sheet has emerged as a versatile and highly durable material, finding applications across multiple industries. Its mechanical strength, excellent electrical properties, chemical resistance, and thermal stability make it an invaluable asset for aerospace, automotive, electronics, construction, and other sectors. As technological advancements continue, the demand for reliable and resilient materials like the G10 Phenolic Sheet is expected to rise, fueling further innovation in the industry.