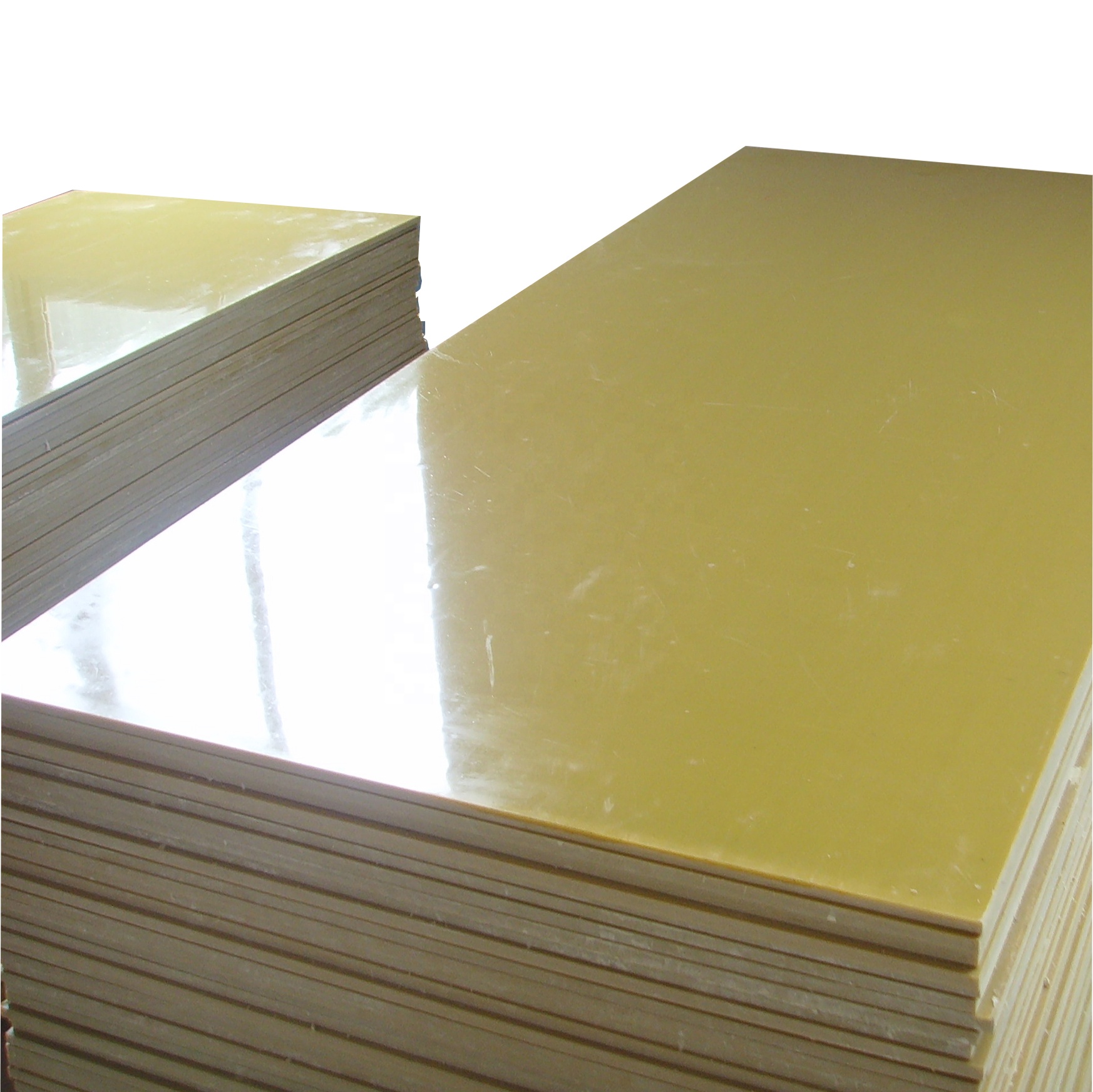

High-Quality Fr4/G11/3240 and Laminate Sheet in China

By:Admin

One company that has made a significant impact in this sector is [Company Name]. With a strong reputation for providing high-quality Fr4/G11/3240 and Laminate Sheet, the company has become a trusted supplier for many prominent manufacturers in China and abroad.

The Fr4/G11/3240 materials offered by [Company Name] are known for their exceptional strength, durability, and electrical insulation properties. These materials are widely used in the production of printed circuit boards (PCBs), as well as in various electrical and mechanical applications. With a focus on stringent quality control and product testing, [Company Name] ensures that its Fr4/G11/3240 materials meet the highest industry standards, providing customers with reliable and consistent performance.

In addition to Fr4/G11/3240, [Company Name] also specializes in the production of laminate sheets, which are commonly used in the construction of high-pressure laminate (HPL) surfaces. These laminate sheets are valued for their versatility, aesthetic appeal, and resistance to wear and tear. Whether used in residential, commercial, or industrial settings, [Company Name] laminate sheets offer a durable and stylish solution for a wide range of applications.

[Company Name] has positioned itself as a leader in the industry by continually investing in research and development, as well as in cutting-edge manufacturing processes. The company's state-of-the-art facilities are equipped with advanced technology and machinery, allowing for efficient production and customization of Fr4/G11/3240 and laminate sheet materials to meet the specific needs of its customers.

Moreover, [Company Name] holds a strong commitment to environmental sustainability and responsible production practices. The company adheres to strict environmental standards and regulations, ensuring that its manufacturing processes have minimal impact on the environment. By prioritizing sustainability, [Company Name] is able to provide its customers with eco-friendly materials that align with their own corporate social responsibility initiatives.

As a testament to its excellence and reliability, [Company Name] has established long-standing relationships with a diverse range of clients across various industries, including electronics, telecommunications, automotive, and construction. By consistently delivering superior quality products and exceptional customer service, the company has earned the trust and loyalty of its customers, solidifying its position as a preferred supplier in the market.

Looking ahead, [Company Name] is committed to furthering its presence and impact in the industry by continuing to expand its product offerings, improving its manufacturing capabilities, and exploring new opportunities for growth and innovation. With a focus on quality, sustainability, and customer satisfaction, [Company Name] is well-positioned to remain a leading force in the production of Fr4/G11/3240 and laminate sheet materials for years to come.

In summary, [Company Name] is a reputable and reliable supplier of Fr4/G11/3240 and laminate sheet materials, serving the needs of various industries with a focus on quality, sustainability, and customer satisfaction. With a strong track record and a commitment to excellence, the company is poised for continued success and leadership in the market.

Company News & Blog

Semiconductor Sheet Market in China: Latest Trends and Insights

China Semiconductor Sheet is a leading company in the semiconductor industry, specializing in the development and production of high-quality semiconductor materials. The company has made significant contributions to the advancement of technology through its innovative products and solutions. With a strong focus on research and development, China Semiconductor Sheet has established itself as a key player in the global semiconductor market.The company's semiconductor sheet is a critical component in the manufacturing of various electronic devices, including smartphones, computers, and automotive systems. Its high-performance materials are known for their durability, reliability, and efficiency, making them essential for the production of advanced semiconductor devices.China Semiconductor Sheet's commitment to quality and technological advancement has led to the development of a wide range of semiconductor materials that meet the diverse needs of its customers. Its products are widely used in the automotive, consumer electronics, and industrial sectors, contributing to the growth and development of various industries.In recent years, China Semiconductor Sheet has expanded its production capacity and invested in cutting-edge manufacturing technologies to meet the growing demand for semiconductor materials. The company's state-of-the-art facilities and stringent quality control processes ensure that its products meet the highest industry standards.Furthermore, China Semiconductor Sheet has established strong partnerships with leading technology companies and research institutions to drive innovation and continuous improvement. By collaborating with industry experts, the company stays at the forefront of technological advancements and secures its position as a market leader in the semiconductor industry.The company's commitment to sustainability and environmental responsibility is evident in its efforts to develop eco-friendly semiconductor materials. China Semiconductor Sheet continues to invest in research and development to create products that minimize environmental impact while delivering superior performance.As a global leader in the semiconductor industry, China Semiconductor Sheet has a strong presence in international markets, serving customers across the globe. Its dedication to customer satisfaction and product excellence has earned the company a reputation for reliability and industry expertise.With a focus on continuous improvement and innovation, China Semiconductor Sheet remains dedicated to driving the advancement of semiconductor technology. The company's ongoing investments in research and development, manufacturing capabilities, and strategic partnerships position it for continued success and leadership in the global semiconductor market.In conclusion, China Semiconductor Sheet is a leading force in the semiconductor industry, with a strong commitment to innovation, quality, and sustainability. The company's dedication to technological advancement and customer satisfaction solidifies its position as a key player in the global semiconductor market. With a focus on growth and development, China Semiconductor Sheet is poised to continue its success and make significant contributions to the advancement of technology in the years to come.

Strong and durable glass epoxy sheet for various applications

Epgc 308 Glass Epoxy Sheet is a high-quality product that has gained a strong reputation in the market for its durability and reliability. This glass epoxy sheet is manufactured by a renowned company{} that has been a leader in the industry for many years.The Epgc 308 Glass Epoxy Sheet is known for its outstanding mechanical and electrical properties. It is made from a combination of glass fabric and epoxy resin, which gives it exceptional strength and resistance to heat, moisture, and chemicals. This makes it an ideal material for a wide range of applications in industries such as electrical and electronics, aerospace, automotive, and construction.One of the key features of the Epgc 308 Glass Epoxy Sheet is its high mechanical strength. It has a strong resistance to impact and flexural stresses, which makes it suitable for use in applications where the material may be subject to heavy loads or constant movement. This makes it a popular choice for use in electrical insulation, structural components, and machine parts.In addition to its mechanical properties, the Epgc 308 Glass Epoxy Sheet also boasts excellent electrical insulation properties. It has high dielectric strength and low water absorption, making it suitable for use in electrical and electronic applications where insulation and protection against moisture are crucial. This makes it a valuable material for use in switchgear, transformers, and other electrical equipment.The Epgc 308 Glass Epoxy Sheet is also highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it a versatile material for use in demanding environments where exposure to harsh chemicals is a concern. Its resistance to chemical attack also makes it suitable for use in marine and offshore applications, where the material may be exposed to saltwater and other corrosive substances.As a company{}, we take pride in our commitment to quality and innovation. Our extensive experience and expertise in the industry have enabled us to develop the Epgc 308 Glass Epoxy Sheet to meet the highest standards of performance and reliability. We utilize advanced manufacturing processes and stringent quality control measures to ensure that each sheet meets the strictest specifications and requirements.Our dedication to customer satisfaction is reflected in the superior performance and durability of the Epgc 308 Glass Epoxy Sheet. We understand the diverse needs of our customers and strive to deliver products that exceed their expectations. Whether it's for electrical insulation, structural reinforcement, or chemical resistance, our glass epoxy sheet is designed to deliver exceptional performance in the most demanding applications.In conclusion, the Epgc 308 Glass Epoxy Sheet is a high-quality material that offers exceptional mechanical, electrical, and chemical properties. It is manufactured by {} a company with a proven track record of excellence and innovation. Whether it's for industrial, commercial, or residential applications, this glass epoxy sheet is a reliable and cost-effective solution for a wide range of needs.

Essential Guide to Transformer Insulation Pressboard

Transformer Insulation Pressboard is a critical component in the construction of transformers, playing a key role in insulating the electrical components and ensuring the safe and efficient operation of these essential devices. In recent years, the demand for high-quality transformer insulation pressboard has been on the rise, driven by the increasing reliance on electrical power systems and the need for reliable and sustainable energy infrastructure. One company that has been at the forefront of this industry is {}. With a long history of expertise and innovation in the field of transformer insulation materials, {} has established itself as a leading supplier of pressboard products for transformer manufacturers and utilities around the world.Established in [year], {} has grown to become a trusted name in the global electrical insulation industry, known for its commitment to quality, reliability, and customer satisfaction. The company's pressboard products are manufactured using state-of-the-art processes and technologies, ensuring that they meet the highest standards for performance and durability. With a focus on sustainability and environmental responsibility, {} has also developed a range of eco-friendly pressboard materials that are designed to minimize the environmental impact of transformer insulation production and use.In addition to its dedication to product excellence, {} has also built a reputation for its technical expertise and customer support. The company's team of engineers and technical specialists are available to provide guidance and support to transformer manufacturers and end-users, helping them to select the right pressboard products for their specific applications and requirements. With a strong emphasis on collaboration and partnership, {} works closely with its customers to develop customized solutions that meet their unique needs and challenges.One of the key strengths of {} is its global presence and distribution network. With manufacturing facilities and sales offices in multiple countries, the company is able to serve customers around the world with efficiency and flexibility. This global reach also enables {} to stay at the forefront of industry trends and developments, ensuring that its products and services remain at the cutting edge of transformer insulation technology.Looking to the future, {} remains committed to driving innovation and advancement in the field of transformer insulation pressboard. The company continues to invest in research and development, exploring new materials, technologies, and processes that will further enhance the performance, reliability, and sustainability of its products. At the same time, {} is dedicated to fostering strong relationships with its customers and partners, working together to address the evolving needs and challenges of the electrical power industry.As the demand for electrical power continues to grow, the role of transformer insulation pressboard in ensuring the reliable and safe operation of electrical infrastructure will only become more critical. With its proven track record of excellence, innovation, and customer focus, {} is well-positioned to continue leading the way in this important sector, providing the high-quality pressboard products and support that the industry relies on.

High Quality Laminate Slot Wedge for Industrial Applications

9334 Laminate Slot Wedge: Improving Efficiency and Reliability in Electrical MachinesIn the world of electrical machines, efficiency and reliability are two of the most important factors to consider. Whether it's a motor, generator, or transformer, these machines play a critical role in countless industries and applications around the globe. One key component that helps improve the efficiency and reliability of these machines is the 9334 Laminate Slot Wedge, a product that has been designed and manufactured by a leading company in the field of electrical insulation materials.The 9334 Laminate Slot Wedge is a crucial component in electrical machines, as it helps to optimize the performance and durability of the machines by providing insulation and support to the winding components. This product is made of high-quality laminate materials, and its unique design allows for easy installation and excellent thermal and mechanical properties. As a result, electrical machines equipped with the 9334 Laminate Slot Wedge are able to operate more efficiently and reliably, ultimately leading to cost savings and improved productivity for the end users.{The company} is a renowned manufacturer of electrical insulation materials, with a strong focus on innovation and quality. With decades of experience in the industry, {the company} has established itself as a trusted partner for countless OEMs and end users around the world. The company's commitment to excellence and customer satisfaction has driven them to continuously develop new and improved products, such as the 9334 Laminate Slot Wedge, in order to meet the evolving needs of the market and exceed the expectations of their customers.One of the key advantages of the 9334 Laminate Slot Wedge is its ability to enhance the thermal performance of electrical machines. With its superior thermal conductivity and heat dissipation properties, this product helps to reduce the risk of overheating and insulation degradation, which are common causes of failure in electrical machines. By using the 9334 Laminate Slot Wedge, OEMs and end users can expect their machines to operate at lower temperatures and achieve a longer service life, ultimately resulting in lower maintenance costs and higher uptime.In addition to its thermal benefits, the 9334 Laminate Slot Wedge also offers excellent mechanical strength and insulation properties. This product is designed to provide robust support and protection to the winding components of electrical machines, which are often subjected to high levels of mechanical stress and electrical voltage. By using the 9334 Laminate Slot Wedge, OEMs and end users can ensure that their machines are well-protected against potential damage and breakdowns, thus minimizing the risk of downtime and costly repairs.Furthermore, the 9334 Laminate Slot Wedge is easy to install and highly adaptable to different machine designs. Whether it's a small motor or a large generator, this product can be customized to fit various slot geometries and dimensions, allowing for seamless integration into different types of electrical machines. As a result, OEMs and end users can enjoy greater flexibility and convenience when incorporating the 9334 Laminate Slot Wedge into their products, without compromising on performance or reliability.Overall, the 9334 Laminate Slot Wedge is a key enabler for improving the efficiency and reliability of electrical machines. With its superior thermal and mechanical properties, as well as its ease of installation and adaptability, this product offers tangible benefits for OEMs and end users across a wide range of industries and applications. As {the company} continues to innovate and expand its product offerings, the 9334 Laminate Slot Wedge stands out as a prime example of their commitment to driving positive change in the field of electrical insulation materials, and ultimately, in the performance of electrical machines around the world.

Latest Update on G11 Fr5: Check out the Latest News Content

G11 Fr5 is making waves in the tech industry with its groundbreaking advancements in the field of artificial intelligence and machine learning. The company, founded in 2010, has quickly risen to become a leader in the development of cutting-edge technologies that are revolutionizing the way we live and work.G11 Fr5's mission is to make AI accessible to everyone, and they are achieving this through their innovative products and services. Their team of experts is constantly pushing the boundaries of what is possible with AI, and their dedication to excellence has led to a number of breakthroughs in the industry.One of G11 Fr5's flagship products is a state-of-the-art AI platform that is capable of processing and analyzing massive amounts of data in real time. This platform is being used by companies across a wide range of industries to gain valuable insights and make better-informed decisions. G11 Fr5's AI platform has been praised for its accuracy, speed, and scalability, making it a game-changer for businesses looking to stay ahead of the curve.In addition to their AI platform, G11 Fr5 has also developed a number of other innovative products that are having a significant impact on the tech industry. From advanced machine learning algorithms to powerful data analytics tools, G11 Fr5 is constantly developing new and exciting ways to harness the power of AI.But G11 Fr5's influence extends beyond just their products and services. The company is also committed to fostering a thriving AI community through their educational initiatives and research and development efforts. They regularly host workshops, seminars, and other events aimed at bringing together experts and enthusiasts from around the world to collaborate and share knowledge.Moreover, G11 Fr5 is dedicated to ethical and responsible AI development. They recognize the potential risks and challenges that come with the advancement of AI and are actively working to address these issues. By promoting transparency, accountability, and fairness in AI, G11 Fr5 is setting a new standard for responsible AI development.In the midst of all these groundbreaking developments, G11 Fr5 has also managed to earn the trust and respect of some of the biggest names in the tech industry. Companies like Amazon, Google, and Microsoft have all formed strategic partnerships with G11 Fr5 to leverage their AI expertise and incorporate their technologies into their own products and services.With all of these achievements under their belt, it's no wonder that G11 Fr5 is quickly becoming a household name in the tech world. Their commitment to pushing the boundaries of what is possible with AI, while also promoting responsible development and ethical practices, sets them apart as a true leader in the industry.As G11 Fr5 continues to grow and expand their reach, it's clear that they are poised to make an even bigger impact on the tech industry in the years to come. Their innovative products and services, combined with their dedication to ethical and responsible AI development, make them a force to be reckoned with in the world of artificial intelligence.

Strong and durable glass reinforced laminate for various applications

G11 Glass Reinforced Laminate - The Next Generation in Composite MaterialsIn today's fast-paced and constantly evolving world, the demand for high-quality, durable, and innovative materials has never been higher. Industries ranging from aerospace and automotive to defense and sports equipment are constantly seeking new solutions to improve performance, reduce weight, and increase longevity. This is where G11 Glass Reinforced Laminate comes into play, offering a cutting-edge solution that exceeds the expectations of even the most demanding applications.G11 Glass Reinforced Laminate is a composite material that combines the incredible strength and durability of glass fibers with a high-performance epoxy resin. The result is a material that offers the best of both worlds - the rigidity and thermal stability of glass, combined with the flexibility and impact resistance of the epoxy resin. This unique combination of properties makes G11 Glass Reinforced Laminate ideal for a wide range of applications, including aerospace components, electronic insulation, and high-performance sports equipment.One of the key advantages of G11 Glass Reinforced Laminate is its exceptional strength-to-weight ratio. This makes it an attractive option for industries where weight reduction is crucial, such as aerospace and automotive. In addition to its impressive strength, G11 Glass Reinforced Laminate also offers excellent electrical insulation properties, making it a popular choice for electronic and electrical applications. Furthermore, its resistance to chemicals, moisture, and extreme temperatures makes it an excellent choice for demanding environments.The company behind G11 Glass Reinforced Laminate, {} has been at the forefront of composite materials technology for decades. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible with composite materials, and G11 Glass Reinforced Laminate is the latest example of their innovative approach to material science. By leveraging their expertise in materials engineering and advanced manufacturing processes, {} has been able to develop a material that offers unparalleled performance and reliability.With a dedicated team of engineers and researchers, {} continues to explore new ways to enhance the properties of G11 Glass Reinforced Laminate, ensuring that it remains at the forefront of material innovation. By collaborating with industry partners and leveraging the latest technological advancements, {} is committed to delivering solutions that meet the evolving needs of their customers.One of the key strengths of {} is their ability to customize G11 Glass Reinforced Laminate to specific requirements. Whether it's a unique shape, size, or performance characteristic, {} can tailor G11 Glass Reinforced Laminate to meet the precise needs of their customers, ensuring that they get the exact material they need for their specific application. This level of customization sets {} apart from their competitors and allows them to provide tailored solutions that are truly fit-for-purpose.As the demand for high-performance materials continues to grow, the future looks bright for G11 Glass Reinforced Laminate. With its exceptional properties, versatility, and customizability, it's no surprise that G11 Glass Reinforced Laminate is quickly becoming the material of choice for a wide range of industries. Whether it's in the air, on the ground, or in the water, G11 Glass Reinforced Laminate is proving to be a game-changer, offering unparalleled performance and reliability in the most demanding environments. As the world continues to push the boundaries of what is possible, G11 Glass Reinforced Laminate will undoubtedly play a crucial role in shaping the future of materials technology.

High Quality Epoxy Resin Glass Fiber Sheet for Mechanical and Electrical Insulation

G10 Glass Fiber Reinforced Sheet: The Versatile Insulation MaterialInsulation materials are used in a variety of applications, from mechanical and electrical equipment to buildings and homes. Insulation materials serve to maintain a certain temperature or environment, prevent unwanted heat or cold transfer, and protect equipment from damage. G10 Glass Fiber Reinforced Sheet is one such insulation material that is widely used due to its high mechanical and electrical properties, good heat resistance and humidity resistance. In this blog, we will discuss G10 Glass Fiber Reinforced Sheet and its applications.What is G10 Glass Fiber Reinforced Sheet?G10 Glass Fiber Reinforced Sheet is an insulating material made by using fiberglass cloth and heat resistant epoxy resin. The glass fiber cloth used in G10 is non-alkali, and it is impregnated with epoxy resin by hot pressing. The resulting material has high mechanical and electrical properties, good heat resistance and humidity resistance. G10 Glass Fiber Reinforced Sheet is known for its high strength, durability, and excellent dielectric properties. It is available in different sizes and thicknesses to suit various applications.Applications of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet is widely used in mechanical, electronic, and electrical equipment, insulation parts, and components. It is also used in the construction industry as a structural material. Below are the top applications of G10 Glass Fiber Reinforced Sheet:1. Electrical equipment insulation: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical equipment such as transformers, electric motors, and generators.2. Circuit board substrates: G10 Glass Fiber Reinforced Sheet is used as the substrate material for printed circuit boards. It provides excellent stability and mechanical strength to the circuit board.3. Mechanical parts and components: G10 Glass Fiber Reinforced Sheet is used to make parts and components of machinery and equipment. It provides excellent mechanical properties such as high strength and toughness.4. Aerospace industry: G10 Glass Fiber Reinforced Sheet is used in the aerospace industry to make parts for aircraft and spacecraft. It provides excellent strength and durability under extreme conditions.5. Marine industry: G10 Glass Fiber Reinforced Sheet is used in the marine industry as a material for boat hulls, decks, and other structural components. It is highly resistant to water and moisture, making it an ideal material for marine applications.Advantages of G10 Glass Fiber Reinforced SheetG10 Glass Fiber Reinforced Sheet has several advantages over other insulation materials, such as:1. High strength and durability: G10 Glass Fiber Reinforced Sheet has high mechanical properties, making it ideal for use in high-stress applications that require strength and durability.2. Excellent electrical insulation properties: G10 Glass Fiber Reinforced Sheet is an excellent electrical insulator, making it ideal for use in electrical and electronic applications.3. Good heat resistance: G10 Glass Fiber Reinforced Sheet is resistant to high temperatures, which makes it suitable for use in high-temperature applications.4. Resistance to moisture and chemicals: G10 Glass Fiber Reinforced Sheet is highly resistant to moisture and chemicals, making it ideal for use in harsh environments.ConclusionG10 Glass Fiber Reinforced Sheet is a versatile insulation material that has several advantages over other insulation materials. Its high mechanical and electrical properties, good heat resistance, and humidity resistance make it ideal for use in a variety of applications. Its applications include electrical equipment insulation, circuit board substrates, mechanical parts and components, aerospace industry, and marine industry. If you are looking for an insulation material that offers high strength, durability, and excellent dielectric properties, G10 Glass Fiber Reinforced Sheet is an excellent choice.

Epoxy Glass Fiber Sheet Market in China: 3240 Sheet Overview

China 3240 Epoxy Glass Fiber Sheet, a high-quality electrical insulating material, has become one of the key products in the portfolio of a leading manufacturing company in China. With its excellent mechanical and electrical properties, this epoxy glass fiber sheet is an essential material for the electrical and electronic industry.The China 3240 Epoxy Glass Fiber Sheet is manufactured using high-quality glass fiber cloth and epoxy resin, which is then processed through a hot press molding process. This results in a product with outstanding electrical insulation properties, high mechanical strength, and excellent heat resistance. The product is widely used in various electrical equipment, such as insulating supports, switchgear panels, and transformers.The unique combination of glass fiber and epoxy resin gives this material exceptional electrical insulation properties. It can withstand high voltage and prevents electrical leakage, making it suitable for use in electrical equipment that requires high insulation performance. Additionally, the material's high mechanical strength allows it to withstand mechanical stress, making it a durable and reliable choice for electrical insulation applications.In addition to its electrical properties, the China 3240 Epoxy Glass Fiber Sheet also exhibits excellent heat resistance. The material can withstand high temperatures without compromising its insulation performance, making it suitable for use in applications where exposure to heat is a concern. This makes it a versatile material for a wide range of electrical and electronic applications.The manufacturing company behind the China 3240 Epoxy Glass Fiber Sheet has a strong focus on quality and innovation. With state-of-the-art production facilities and a dedicated research and development team, the company is committed to delivering high-quality products that meet the needs of its customers. Their stringent quality control measures ensure that every sheet meets international standards for electrical insulation materials.The company has also made significant investments in modern technology and equipment to improve the efficiency and quality of its manufacturing processes. This has enabled them to produce the China 3240 Epoxy Glass Fiber Sheet in large quantities without compromising on quality, making it readily available to meet the demand of the market.Moreover, the company has a robust distribution network that enables them to supply the China 3240 Epoxy Glass Fiber Sheet to customers both domestically and internationally. This ensures that the product is readily accessible to industries around the world that rely on high-quality electrical insulation materials.In addition to its commitment to quality and innovation, the company also places a strong emphasis on environmental sustainability. They adhere to strict environmental regulations and strive to minimize their environmental impact throughout the manufacturing process. This ensures that the China 3240 Epoxy Glass Fiber Sheet is not only a high-performance material but also an eco-friendly choice for businesses that prioritize sustainability.Overall, the China 3240 Epoxy Glass Fiber Sheet has established itself as a reliable and high-quality electrical insulation material, thanks to its exceptional electrical and mechanical properties. Combined with the company's commitment to quality, innovation, and sustainability, it has become a popular choice for industries that require reliable insulation materials for their electrical and electronic applications.As the demand for high-quality electrical insulation materials continues to grow, the China 3240 Epoxy Glass Fiber Sheet is well-positioned to meet the needs of the market, both domestically and internationally. With its outstanding performance and the company's dedication to excellence, this product is poised to remain a key component in the electrical and electronic industry for years to come.

Durable and Versatile Phenolic Resin Board for Multiple Applications

Phenolic Resin Board: An Innovative Solution for Various IndustriesIn today's fast-paced world, innovation is the key to staying ahead of the competition. Companies are constantly looking for new materials and technologies that can help improve their products and processes. One such innovative solution that has been gaining attention in various industries is the Phenolic Resin Board. This versatile material has been revolutionizing the way companies design and create their products, offering a wide range of benefits and applications.Phenolic resin boards are a type of composite material that is made by combining layers of cellulose fibers with phenolic resin. This combination of materials results in a strong, durable, and versatile product that can be used in a wide variety of applications. The boards are known for their high-temperature resistance, chemical resistance, and low moisture absorption, making them an ideal choice for industries such as aerospace, automotive, construction, and manufacturing.One company that has been at the forefront of developing and producing high-quality phenolic resin boards is {Company Name}. With over 30 years of experience in the composite materials industry, {Company Name} has established itself as a leading supplier of phenolic resin boards, offering a wide range of products that meet the diverse needs of their customers.{Company Name} prides itself on its commitment to innovation and quality, constantly investing in research and development to improve its products and meet the ever-changing demands of the market. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians ensure that their phenolic resin boards are of the highest quality, meeting the strictest industry standards and regulations.The versatility of phenolic resin boards makes them suitable for a wide range of applications. In the aerospace industry, these boards are used in the construction of aircraft interiors, providing lightweight, fire-resistant, and durable materials for cabinetry, flooring, and wall panels. In the automotive industry, phenolic resin boards are used in engine compartments, under the hood, and interior components, offering thermal and chemical resistance as well as enhanced mechanical properties.In the construction industry, phenolic resin boards are used in architectural cladding, exterior wall panels, and balcony flooring, providing a durable and low-maintenance solution for modern buildings. In the manufacturing industry, these boards are used to create molds, patterns, and tooling, offering excellent dimensional stability, high temperature resistance, and low moisture absorption.{Company Name} understands the importance of sustainability and environmental responsibility, and they are committed to producing phenolic resin boards that are eco-friendly and recyclable. Their production processes are designed to minimize waste and reduce the environmental impact, ensuring that their products are not only high-quality but also sustainable.In addition to their commitment to quality and sustainability, {Company Name} also prides itself on its dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, offering customized solutions and technical support to ensure that their phenolic resin boards meet and exceed their expectations.As the demand for innovative and high-performance materials continues to grow, phenolic resin boards are expected to play a key role in driving the future of various industries. With their exceptional properties, versatility, and sustainability, these boards are proving to be a game-changer for companies looking to stay ahead in today's competitive market.In conclusion, phenolic resin boards are an innovative solution that offers a wide range of benefits and applications for industries such as aerospace, automotive, construction, and manufacturing. {Company Name} has been at the forefront of developing and producing high-quality phenolic resin boards, offering a diverse range of products that meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {Company Name} is poised to continue leading the way in the production and supply of phenolic resin boards for years to come.

Innovative Glassfiber Sheet with Diphenyl Ether - Unveiling the Future of Strong and Durable Materials

Title: Innovative Diphenyl Ether Glassfiber Sheets Revolutionize the Construction IndustrySubtitle: Cutting-edge Technology Takes Center Stage as New Company Introduces High-Quality Building MaterialsIntroduction:In today's rapidly evolving construction industry, the demand for innovative and sustainable building materials is at an all-time high. One company, whose name will be omitted from this article, is poised to disrupt the market with its groundbreaking diphenyl ether glassfiber sheets. Combining cutting-edge technology with their commitment to environmental sustainability, this company is primed to revolutionize the way construction projects are carried out. In this news piece, we will delve deeper into the properties of these innovative sheets and explore the company's mission and vision for the future.Section 1: The Advantages of Diphenyl Ether Glassfiber SheetsDiphenyl ether glassfiber sheets are engineered to deliver enhanced performance and durability in a range of construction applications. These sheets possess several advantages that make them stand out from traditional building materials. Firstly, their exceptional insulating properties improve energy efficiency, reducing heating and cooling costs for buildings. This innovative material also offers excellent fire resistance, making it a safe option for commercial and residential structures alike.Additionally, diphenyl ether glassfiber sheets have strong load-bearing capabilities, ensuring structural integrity and longevity. The lightweight nature of these sheets facilitates ease of installation, reducing labor costs and project completion time. Moreover, as these sheets are resistant to corrosion and moisture, they are well-suited for use in a variety of environments, including coastal regions.Section 2: Environmental Sustainability and Corporate ResponsibilityThe company behind these diphenyl ether glassfiber sheets places a significant emphasis on environmental sustainability and corporate responsibility. They possess a robust commitment to reducing the construction industry's carbon footprint and minimizing waste generation. By adopting a circular economy mindset, the company actively seeks to recycle and repurpose their materials, promoting a sustainable and eco-friendly approach to construction.In addition to their focus on sustainability, this company places a high value on corporate responsibility and social welfare. They actively engage in charitable initiatives aimed at improving local communities, sponsoring educational programs, and contributing to environmental conservation projects. By aligning their business goals with social and environmental objectives, they set a gold standard for corporate citizenship within the industry.Section 3: Revolutionizing the Construction IndustryThe introduction of these diphenyl ether glassfiber sheets is set to revolutionize the construction industry in several ways. Firstly, their exceptional insulation properties deliver reduced energy consumption and emissions, aligning with global efforts to combat climate change. This innovation will significantly contribute to the development of sustainable and energy-efficient buildings, promoting a greener future.Furthermore, the lightweight yet strong nature of these sheets will revolutionize construction techniques, making them ideal for modern architectural designs. The flexibility of this material enables designers and architects to push boundaries, unlocking creative possibilities that were previously unattainable.Conclusion:As the construction industry continuously evolves, the importance of innovative and sustainable building materials cannot be overstated. This unnamed company's diphenyl ether glassfiber sheets are poised to disrupt the market and propel the industry towards a more sustainable and efficient future. Their commitment to environmental sustainability and corporate responsibility sets them apart as a pioneering force within the construction sector. With their groundbreaking technology and dedication to quality, this company represents an exciting leap forward in the pursuit of greener, smarter, and more resilient construction practices.