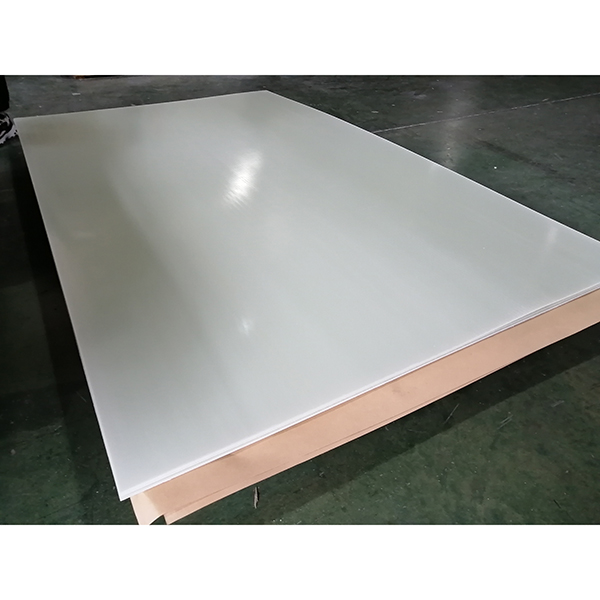

High-Quality FRP Panels: Durable and Versatile Solutions for various Applications

By:Admin

The FRP panels are lightweight, yet incredibly strong and resistant to corrosion, making them an ideal choice for a variety of applications in different industries. They are also known for their high-impact strength, making them ideal for use in areas where impact and abrasion resistance are crucial.

One of the leading companies in the FRP panel industry is {company name}. With over 20 years of experience in the industry, {company name} has been at the forefront of manufacturing high-quality FRP panels that meet the highest standards of quality and performance. They have the expertise and capabilities to provide customized solutions to meet the specific needs of their clients, making them a trusted partner for many businesses across different industries.

{Company name} offers a wide range of FRP panels that are designed for various applications, including wall and ceiling panels, corrosion-resistant panels, and structural panels. Their panels are made using advanced manufacturing processes and high-quality materials, ensuring durability and performance in the harshest environments.

The company's commitment to innovation and quality has led to the development of FRP panels that are not only highly functional but also aesthetically pleasing. With a variety of colors, textures, and finishes available, their panels can be customized to meet the design requirements of any project.

In addition to their extensive product range, {company name} also offers comprehensive technical support and assistance to their clients. Their team of experts can provide guidance on panel selection, installation, and maintenance, ensuring that their clients get the most out of their products.

The versatility of FRP panels makes them suitable for a wide range of applications, including industrial, commercial, and residential projects. From chemical processing plants and food processing facilities to hospitals and commercial kitchens, FRP panels can be used in various environments where hygiene, durability, and aesthetics are essential.

One of the key advantages of using FRP panels is their low maintenance requirements. Unlike traditional building materials, FRP panels are resistant to mold, mildew, and bacteria, making them easy to clean and maintain. This not only helps in reducing maintenance costs but also ensures a healthier and safer environment for the occupants.

Furthermore, the lightweight nature of FRP panels makes them easy to handle and install, reducing labor costs and installation time. This is particularly beneficial for projects with tight timelines and budget constraints.

With a strong focus on quality, innovation, and customer satisfaction, {company name} has established itself as a leader in the FRP panel industry. Their commitment to providing high-quality products and exceptional service has earned them a solid reputation and the trust of their clients.

In conclusion, the use of FRP panels has revolutionized the construction and manufacturing industry, offering a durable, versatile, and cost-effective solution for a wide range of applications. With companies like {company name} leading the way in innovation and quality, the future of FRP panels looks promising, and their use is expected to continue to grow across various industries.

Company News & Blog

How Electrical Laminated Sheet is Revolutionizing the Industry

[News Content]Electrical Laminated Sheet Revolutionizes Power Distribution EfficiencyIn today's rapidly advancing world, technological advancements play a crucial role in shaping the landscape of various industries. Power distribution is one such sector that consistently necessitates innovation to meet growing demands and improve efficiency. Enter Electrical Laminated Sheet, a groundbreaking development designed to transform the way electricity is distributed.Electrical Laminated Sheet, developed by cutting-edge materials engineering company {}, boasts an array of features that make it an ideal choice for power distribution applications. With its superior electrical insulation properties, excellent mechanical strength, and high temperature resistance, this innovative solution ensures optimal performance in even the most demanding environments.The electrical laminated sheet category has traditionally been dominated by outdated materials, resulting in limited efficiency and effectiveness. However, with this latest offering from {}, the industry will witness a paradigm shift. The unique composition of the Electrical Laminated Sheet facilitates reduced energy losses during power transmission, thereby enhancing overall system efficiency.Furthermore, the material's remarkable mechanical strength provides exceptional protection against mechanical stress, vibration, and thermal expansion, ensuring long-term reliability. This enhanced durability translates to reduced maintenance costs and increased operational lifespan, making it an economically viable choice for power distribution systems worldwide.A significant advantage of Electrical Laminated Sheet is its ability to withstand high temperatures. Traditionally, extreme heat adversely affects the performance of electrical insulation materials, leading to compromised safety and reliability. The innovative design of this new solution equips it with the capability to operate flawlessly at elevated temperatures, thereby ensuring uninterrupted power distribution even in harsh conditions.Beyond its exceptional technical specifications, the Electrical Laminated Sheet also satisfies industry demands for sustainable solutions. The materials used in its manufacturing prioritize environmental safety and adhere to strict regulatory standards. With the growing focus on environmental consciousness, this product aligns perfectly with the shift towards sustainable practices in the power distribution sector.The advent of Electrical Laminated Sheet marks an exciting milestone in the power distribution industry. Its ability to revolutionize efficiency, reliability, and sustainability in electrical systems positions it as the trailblazer in the market. Companies around the world are eagerly embracing this groundbreaking solution to enhance the performance and longevity of their power distribution networks.Leading businesses have already recognized the benefits of Electrical Laminated Sheet and incorporated it into their operations. Testimonials from satisfied customers highlight the significant improvement in system efficiency and reduced maintenance costs achieved after implementing this innovative solution. As demand continues to rise, industry experts predict a bright future for Electrical Laminated Sheet, forecasting its rapid adoption worldwide.In conclusion, Electrical Laminated Sheet, introduced by {}, is a game-changing development in the power distribution industry. Its exceptional electrical insulation properties, mechanical strength, and high-temperature resistance contribute to enhanced efficiency, reliability, and sustainability. With its eco-friendly manufacturing process and adherence to rigorous standards, it aligns perfectly with the growing focus on sustainable practices. As more companies recognize its unparalleled performance, Electrical Laminated Sheet is set to transform power distribution systems across the globe.

Epoxy Glass Laminate Sheet: A Comprehensive Field Visit by Pakistani Customers

Title: Unveiling the Versatility and Reliability of 3240 Epoxy Fiber Glass Laminate SheetsIntroduction:In the fast-paced world of electrical insulation materials, 3240 epoxy fiber glass laminate sheets hold a prominent position. As an industry leader and pioneer in the manufacturing of quality insulation products, ZTelec Group recently welcomed two Pakistani customers for a field visit. The purpose of their visit was to explore the unparalleled attributes and applications of 3240 epoxy fiber glass laminate sheets, popularly known as G10 FR4 laminate sheets. In this blog post, we will delve deeper into the properties of these composite materials that make them a preferred choice for various industries, providing you with an insightful understanding of their significance in the market.Overview of 3240 Epoxy Fiber Glass Laminate Sheets:3240 epoxy fiber glass laminate sheets are composite materials constructed by impregnating glass fiber fabric with an epoxy resin binder. These sheets offer a wide range of outstanding features, such as excellent electrical insulation properties, high mechanical strength, fire resistance, and exceptional temperature resistance. The high-quality manufacturing of a 3240 epoxy laminate sheet ensures its longevity and contribution to robust insulation systems.Key Properties:1. Electrical Insulation: With a dielectric strength of up to 16kV/mm, these sheets possess exceptional electrical insulation capabilities. They are resistant to high voltage, thereby ensuring safety and reliability in various electrical applications.2. Mechanical Strength: 3240 epoxy fiber glass laminate sheets exhibit excellent mechanical stability due to their high tensile and flexural strength. This makes them ideal for use in components that require resistant and durable insulation against deformation.3. Fire Resistance: Thanks to their incombustible nature, these laminate sheets are self-extinguishing and offer excellent fire resistance properties. They do not propagate flames or generate excessive smoke, ensuring enhanced safety in case of fire accidents.4. Temperature Resistance: One of the most distinctive features of these sheets is their ability to withstand high temperatures. With a heat resistance of up to 180°C, they retain their mechanical strength, electrical properties, and dimensional stability even in extreme environments.Applications:3240 epoxy fiber glass laminate sheets find extensive use in a wide range of industries. Some common applications include:1. Electrical Industry: These sheets are commonly used as insulation components in transformers, switchgear, circuit breakers, and various electrical devices that require reliable and durable insulation against electrical current.2. Automotive Industry: G10 FR4 laminate sheets are used in automotive applications such as ignition systems, electrical connectors, and motor insulation due to their exceptional electrical and thermal properties.3. Aerospace Industry: The aerospace sector utilizes these sheets for electrical insulation in aircraft components, including cockpit equipment, engine control panels, and avionics insulation.4. Electronics Industry: These laminate sheets serve as an ideal material for printed circuit boards (PCBs) due to their low moisture absorption, dimensional stability, and excellent electrical properties.Conclusion:The field visit by the Pakistani customers to ZTelec Group unveiled the remarkable versatility, performance, and reliability of 3240 epoxy fiber glass laminate sheets. These composite materials have become an essential choice across multiple industries due to their exceptional electrical insulation, high mechanical strength, fire resistance, and outstanding temperature stability. From electrical and automotive sectors to aerospace and electronics industries, the applications of these sheets are diverse and critical. The continued advancements in manufacturing technologies ensure that 3240 epoxy laminate sheets will remain at the forefront of the insulation material market, supporting efficient and safe electrical systems around the world.Keywords: 3240 epoxy fiber glass laminate sheet, G10 FR4 laminate sheet, electrical insulation, mechanical strength, fire resistance, temperature resistance, electrical industry, automotive industry, aerospace industry, electronics industry.

Exploring the Benefits and Applications of Epoxy Fiberglass G10

Title: Epoxy Fiberglass G10 Revolutionizes Industrial ApplicationsIntroduction:Innovation and technological advancements continue to shape our world of manufacturing and industrial applications. Among the various groundbreaking materials, Epoxy Fiberglass G10 stands out as a game-changer in its ability to enhance durability, strength, and versatility across numerous industries. This article aims to delve into the key features and applications of Epoxy Fiberglass G10, highlighting its potential to revolutionize traditional manufacturing processes.Unearthing the Potential:Epoxy Fiberglass G10 is a composite material that combines layers of epoxy resin impregnated with woven fiberglass cloth. The resulting material possesses exceptional strength, rigidity, and electrical insulation properties. These attributes make it an ideal choice for applications requiring exceptional mechanical strength, dimensional stability, and reliability.Industrial Applications:1. Electronics and Electrical Components:Epoxy Fiberglass G10 finds significant application in the electronics industry, where it is used extensively in the production of PCBs (Printed Circuit Boards). Its excellent dielectric properties make it an ideal insulator for high-voltage applications. The dimensional stability and exceptional stiffness of Epoxy Fiberglass G10 also contribute towards enhancing the lifespan and performance of electrical components.2. Aerospace and Defense:The aerospace and defense sector relies on materials that can withstand extreme conditions, including high temperatures, impacts, and vibrations. Epoxy Fiberglass G10's remarkable mechanical strength coupled with its resistance to chemical and environmental degradation make it indispensable in the production of structural reinforcements, radomes, antenna assemblies, and advanced insulation systems.3. Automotive Industry:Epoxy Fiberglass G10 contributes significantly to the automotive industry, particularly in the manufacturing of lightweight components. By employing this material in areas such as chassis panels, brackets, and engine components, manufacturers can reduce the overall weight of vehicles without compromising on durability. This, in turn, contributes to improved fuel efficiency and reduced emissions.4. Marine and Offshore Applications:The marine and offshore industries benefit immensely from the exceptional corrosion resistance of Epoxy Fiberglass G10. Its ability to withstand harsh saltwater environments, coupled with its inherent insulation properties, makes it an ideal material for boat hulls, marine electronics, and offshore equipment. Additionally, its excellent moisture resistance ensures prolonged service life in marine applications.Advantages of Epoxy Fiberglass G10:1. High Mechanical Strength: Epoxy Fiberglass G10 exhibits exceptional tensile and flexural strength, making it suitable for various load-bearing applications.2. Dimensional Stability: The material demonstrates minimal expansion or contraction under thermal or mechanical stress, ensuring its longevity.3. Electrical Insulation: Epoxy Fiberglass G10 possesses excellent dielectric properties, making it an effective insulator in electrical and electronic applications.4. Chemical Resistance: The material resists the effects of many chemicals and solvents, making it suitable for versatile applications across different industries.5. Fire Resistance: Epoxy Fiberglass G10 exhibits excellent fire-retardant properties, adding an extra layer of safety to its applications.Company Introduction:At our company, we have capitalized on our expertise and cutting-edge technology to manufacture high-quality Epoxy Fiberglass G10 composites. With a commitment to delivering reliable and durable materials, we have established ourselves as a leading provider in the industry. Our state-of-the-art manufacturing processes ensure stringent quality control, resulting in products that meet the highest industry standards.Conclusion:Epoxy Fiberglass G10 represents a significant leap forward in the world of industrial materials. Its exceptional mechanical strength, electrical insulation, and resistance to various environmental factors make it a material of choice in a plethora of industries. As technology continues to evolve, Epoxy Fiberglass G10 will likely push the boundaries of manufacturing and revolutionize traditional applications, opening doors to new possibilities and innovations.

Long-lasting and Stylish Toilet Partitions with Phenolic Material - Request a Quote Now!

- Durability - Partition Systems - Bathroom PartitionsWhen it comes to public restrooms, bathroom partitions are a crucial component. Not only do they provide privacy for users, but they also offer a level of comfort and safety. However, traditional bathroom partitions made of materials like metal or plastic have certain limitations in terms of durability and aesthetic appeal. This is where Phenolic Laminate Sheet bathroom partitions come into play.Phenolic Laminate Sheet bathroom partitions are a popular partition system due to their durability, strength, and versatility. Produced by using layers of cellulose fibers that are impregnated with phenolic resin and bonded together under high pressure and temperature, Phenolic Laminate Sheet partitions offer unparalleled strength and durability. They are resistant to fire, moisture, impact, and vandalism.One of the key advantages of Phenolic Laminate Sheet bathroom partitions is their resistance to moisture and humidity. This makes them ideal for installations in public restrooms and shower rooms where moisture levels are typically high. Additionally, these partitions offer superior hygiene, are easy to clean, and require minimal maintenance, making them a top choice for healthcare facilities, schools, and restaurants.Apart from the practical benefits of Phenolic Laminate Sheet partitions, they are also an aesthetically pleasing option. They are available in a range of colors, finishes and decorative patterns, making them a versatile option for any restroom design scheme. This not only enhances the visual appeal of a restroom but also creates an inviting and calming atmosphere for users.In conclusion, Phenolic Laminate Sheet bathroom partitions are a top-performing partition system that offers a long lifespan, low maintenance, and high durability. They offer a range of design possibilities and are known for their exceptional strength and resistance to moisture. Whether you are outfitting a new restroom or replacing existing partitions, Phenolic Laminate Sheet partitions are a smart investment that delivers a fast return and guarantees user satisfaction. At [company name] we offer Phenolic Toilet Partitions that are durable, attractive and customizable. Get in touch with us today for a free quote and installation!

High Quality Heat Resistance Epoxy Sheet - Perfect for Industrial Applications

The 200 Heat Resistance Epoxy Sheet, a new product being offered by {}, is set to revolutionize the construction and manufacturing industries. With its impressive heat resistance and durability, this epoxy sheet is sure to become a staple in a variety of applications.With the increasing demand for materials that can withstand high temperatures, the 200 Heat Resistance Epoxy Sheet is a game-changer. Whether it's used in building construction, electronics manufacturing, or aerospace engineering, this product is designed to meet the toughest challenges. Its ability to withstand temperatures of up to 200 degrees Celsius makes it an ideal choice for use in environments where extreme heat is a concern.The company {} is a leading manufacturer of high-quality industrial materials, including epoxy sheets, laminates, and insulation products. With a focus on innovation and quality, the company has earned a reputation for delivering reliable solutions to the market. The introduction of the 200 Heat Resistance Epoxy Sheet is a testament to the company's commitment to meeting the evolving needs of its customers.The 200 Heat Resistance Epoxy Sheet is designed to provide excellent thermal insulation and electrical insulation properties. This makes it an ideal choice for use in electrical equipment, such as transformers, motors, and generators. The sheet's ability to withstand high temperatures without compromising its mechanical strength makes it a valuable asset in critical applications where reliability is paramount.In addition to its heat resistance, the 200 Heat Resistance Epoxy Sheet offers exceptional chemical resistance, making it suitable for use in harsh industrial environments. This versatility makes it a valuable investment for businesses looking for a durable and reliable material for their operations.The company {} has invested significant resources into research and development to ensure that the 200 Heat Resistance Epoxy Sheet meets the highest standards of quality and performance. As a result, customers can trust that they are getting a product that is not only reliable but also backed by the expertise and experience of a reputable manufacturer.One of the key advantages of the 200 Heat Resistance Epoxy Sheet is its ease of installation and maintenance. Its lightweight and flexible nature make it easy to work with, saving time and labor costs during the installation process. Once in place, the sheet requires minimal maintenance, reducing ongoing operational expenses for businesses.Moreover, the 200 Heat Resistance Epoxy Sheet is environmentally friendly, as it is manufactured using sustainable and recyclable materials. This further enhances its appeal to businesses looking to minimize their environmental footprint and adhere to sustainable practices.With the introduction of the 200 Heat Resistance Epoxy Sheet, {} continues to demonstrate its commitment to providing innovative, reliable, and sustainable solutions to its customers. As industries continue to evolve and demand for high-performance materials grows, the company's dedication to meeting these challenges ensures that it will remain a leader in the market.In conclusion, the 200 Heat Resistance Epoxy Sheet from {} is poised to become a valuable asset for businesses across various industries. Its impressive heat resistance, durability, and versatility make it a practical choice for a wide range of applications. Backed by the expertise and reputation of {}, this product is set to make a significant impact on the market and provide long-term value to its users.

High-Quality Fiberglass Sheets - 4x8 in Size - Ideal for Various Applications

Title: Versatile and Durable Fiberglass Sheets: The go-to Solution for all Construction NeedsIntroduction:In the world of construction materials, fiberglass sheets have emerged as a versatile and durable option for a wide range of applications. These sheets, measuring 4x8 feet, are widely used due to their exceptional strength, flexible solutions, and resistance to various environmental factors. Renowned for their ability to withstand extreme weather conditions and offer immense structural support, fiberglass sheets have become the go-to solution for many industries. This article aims to shed light on the benefits and applications of these fiberglass sheets while omitting any specific brand name to maintain unbiased information.1. The Unmatched Strength of Fiberglass Sheets:Fiberglass sheets, made from reinforced glass fibers embedded in a polymer matrix, offer unmatched strength and durability. With a tensile strength several times higher than steel, fiberglass sheets are capable of withstanding heavy loads, making them ideal for various construction projects, such as roofing, flooring, and cladding. These sheets are also resistant to corrosion, which ensures a longer lifespan compared to traditional materials.2. Versatility and Application Areas:The versatility of fiberglass sheets cannot be understated, as they find widespread use across multiple industry sectors. In the construction industry, these sheets are used for wall panels, partitions, insulation, and concrete formwork. Additionally, their lightweight nature allows for easy transportation and installation, making them a highly sought-after material for commercial buildings, warehouses, and residential projects. Fiberglass sheets are also utilized in the transportation sector, specifically for manufacturing automotive parts, boats, and aircraft due to their excellent corrosion resistance and durability.3. Superior Resistance to Environmental Factors:Fiberglass sheets possess exceptional resistance to environmental factors, including moisture, chemicals, and UV radiation. This resistance makes them an optimal choice for outdoor applications. Their non-conductive nature is particularly advantageous in electrical installations, ensuring safety and preventing electrical accidents. Moreover, fiberglass sheets are fire-resistant and do not release toxic gases, enhancing the overall safety of any structure they are incorporated into.4. Cost-Effectiveness and Low Maintenance:The cost-effectiveness of fiberglass sheets is an added benefit for builders and construction companies. Despite their outstanding properties, these sheets are relatively affordable compared to alternative materials. Furthermore, fiberglass sheets require minimal maintenance due to their resistance to rot, termites, and warping commonly associated with wood or metal. This low-maintenance feature helps reduce long-term costs, making them an economically sound choice for construction projects.5. Eco-Friendly Material:With increasing global environmental concerns, the demand for eco-friendly construction materials is on the rise. Fiberglass sheets meet this requirement as they are manufactured with minimal impact on the environment. They are 100% recyclable and can be reused in various applications, reducing the carbon footprint associated with traditional construction materials.Conclusion:Fiberglass sheets, sized at 4x8 feet, have revolutionized the construction industry due to their unmatched strength, versatility, and resistance to environmental factors. As a superior alternative to traditional construction materials, fiberglass sheets provide durability, cost-effectiveness, and ease of installation. With their ability to withstand extreme weather conditions and resistance to corrosion and fire, these sheets are the go-to solution for builders, architects, and engineers alike. As the construction industry continues to evolve, fiberglass sheets are expected to play an increasingly crucial role in shaping the buildings and structures of the future.

Fiberglass Reinforced Wall Panels for Durable and Stylish Interiors

title: Fiberglass Reinforced Panels Wall Panels Revolutionize the Construction IndustryIntroduction:The construction industry is constantly evolving, and innovative materials are key to its advancement. One such material gaining popularity is Fiberglass Reinforced Panels (FRP) wall panels. These durable and versatile panels are revolutionizing the way we build structures. With their properties of strength, flexibility, and ease of installation, FRP wall panels are becoming a go-to choice for architects, builders, and designers alike.Understanding Fiberglass Reinforced Panels:Fiberglass Reinforced Panels consist of a polymer matrix reinforced with fiberglass strands. This combination creates a lightweight yet robust material that can withstand high impact, moisture, chemicals, and UV exposure. The panels come in various sizes and textures, making them suitable for both interior and exterior applications.Applications and Benefits:1. Versatile and Appealing: FRP wall panels can be used in a wide range of applications. From commercial buildings to hospitals, schools, restaurants, and residential spaces, these panels offer a visually appealing alternative to traditional wall finishes. The panels come in various finishes, including wood grain, marble, mosaic, and metallic effects, enabling architects to unleash their creative ideas.2. Durability: FRP wall panels are incredibly durable, making them ideal for high-traffic areas. They are resistant to scratches, dents, and stains, ensuring a long-lasting finish that requires minimal maintenance. Moreover, their resistance to moisture and humidity makes them suitable for areas such as bathrooms or kitchens where traditional materials may deteriorate.3. Easy Installation: FRP wall panels are lightweight and easy to install, reducing construction time and labor costs. Their interlocking system allows for quick assembly, and their flexible nature enables them to be easily cut to fit any specific dimensions or odd angles.4. Safety and Hygiene: In environments where sanitation is crucial, FRP wall panels shine. The smooth surface of these panels resists the growth of mold, mildew, and bacteria, making them ideal for healthcare facilities and food processing environments. Their non-porous nature also ensures easy cleaning and maintenance.5. Sustainability: FRP wall panels contribute to sustainability efforts as they can be recycled and have a significantly longer lifespan than traditional wall materials. Their light weight also reduces transportation costs and energy consumption during installation.Market Expansion:As awareness of the benefits of FRP wall panels grows, their demand is increasing. Companies such as {Glass Fiber Reinforced Plastic Panels} have emerged as leading suppliers in the market, catering to the growing needs of the construction industry. These companies provide a wide range of FRP wall panels, satisfying the requirements of different projects.Conclusion:Fiberglass Reinforced Panels (FRP) wall panels are transforming the construction industry with their durability, versatility, and ease of installation. With their aesthetically pleasing finishes, they are replacing traditional wall materials, offering a cost-effective, sustainable, and hygienic solution. As the demand for FRP wall panels continues to rise, the future of construction looks brighter and more efficient.

Durable and Versatile Glass Fiber Reinforced Sheet: A Top Choice for Various Applications

[Company Name] Introduces Advanced Glass Fiber Reinforced Sheet for Superior Performance[City, State] - [Company Name], a leading manufacturer of advanced materials, is proud to announce the introduction of their new Glass Fiber Reinforced Sheet. This innovative product is designed to provide superior performance and durability for a wide range of applications.The Glass Fiber Reinforced Sheet is manufactured using a proprietary process that results in a high-strength, lightweight material. This makes it an ideal choice for applications where strength and durability are crucial, such as automotive components, aerospace parts, and industrial equipment.One of the key benefits of the Glass Fiber Reinforced Sheet is its exceptional strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is important, without compromising on structural integrity. The material also offers excellent resistance to corrosion, making it suitable for use in harsh environments.In addition to its impressive mechanical properties, the Glass Fiber Reinforced Sheet is also highly customizable. [Company Name] offers a range of options for thickness, color, and finish, allowing customers to tailor the material to their specific requirements. This flexibility makes it a versatile solution for a wide range of industries and applications."We are excited to introduce our new Glass Fiber Reinforced Sheet to the market," said [Name], [Title] at [Company Name]. "This material represents a significant advancement in the field of advanced materials, and we believe it will offer our customers a superior solution for their high-performance applications."[Company Name] has a proven track record of delivering innovative solutions to the market. With state-of-the-art manufacturing facilities and a team of experienced engineers and materials experts, the company is well-positioned to meet the growing demand for high-performance materials.The introduction of the Glass Fiber Reinforced Sheet further solidifies [Company Name]'s commitment to providing cutting-edge solutions to their customers. The company's dedication to research and development, coupled with their focus on quality and customer satisfaction, has established them as a trusted partner for businesses across a wide range of industries.In addition to the Glass Fiber Reinforced Sheet, [Company Name] offers a comprehensive range of advanced materials, including composites, plastics, and specialty alloys. Their extensive product portfolio, combined with their expertise in materials science and engineering, makes them a one-stop solution provider for companies seeking high-performance materials for their products and applications.As industries continue to demand materials that offer superior performance and durability, [Company Name] is poised to meet those needs with their innovative Glass Fiber Reinforced Sheet and other advanced materials. With a commitment to excellence and a focus on continuous improvement, the company is well-positioned to remain a leader in the field of advanced materials for years to come.For more information about [Company Name] and their advanced Glass Fiber Reinforced Sheet, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of advanced materials for a wide range of industries. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-performance materials for their products and applications. With a commitment to research and development, [Company Name] continues to deliver cutting-edge solutions to the market, helping their customers stay ahead of the competition.

Latest Updates on Sheet 3240 News: Read the Latest Updates Here

{Company introduction} is a leading provider of innovative solutions in the field of technology and consumer electronics. With a strong focus on research and development, the company has consistently delivered cutting-edge products that have redefined the way people live and work. From mobile devices to home appliances, {Company} has established itself as a global leader in the industry, with a strong presence in markets around the world.In a recent news update, {Company} has announced a significant milestone with the production of its 3240th sheet of advanced technology. This achievement highlights the company's commitment to pushing the boundaries of innovation and delivering products that exceed the expectations of consumers.The 3240th sheet produced by {Company} represents a culmination of years of research and development in the field of technology. The sheet is a vital component in a range of {Company}'s products, including mobile devices, computers, and home appliances. Its production showcases the company's dedication to creating high-quality, reliable, and cutting-edge technology that enhances the lives of its customers.{Company}'s 3240th sheet is a testament to its relentless pursuit of excellence in the field of technology. It embodies the company's commitment to staying ahead of the curve and continually raising the bar for innovation in the industry. By producing this significant milestone, {Company} is reinforcing its position as a leader in the global market for consumer electronics.In addition to the production of the 3240th sheet, {Company} has also continued to invest in research and development to pave the way for future advancements in technology. The company's state-of-the-art facilities and a team of dedicated experts are at the forefront of creating the next generation of products that will shape the future of technology.{Company}'s 3240th sheet is a representation of the company's dedication to sustainability and eco-friendly practices. As part of its commitment to corporate social responsibility, {Company} has implemented environmentally friendly processes in the production of its technology, ensuring that its products have a minimal impact on the environment.Furthermore, {Company} is actively engaged in initiatives to give back to the community and support initiatives that promote education and innovation. The company's commitment to making a positive impact extends beyond its products and technology, reflecting a strong sense of corporate citizenship.The production of the 3240th sheet is a significant milestone for {Company}, symbolizing its position as a leader in the technology and consumer electronics industry. As the company continues to push the boundaries of innovation, it is poised to deliver even more groundbreaking products that will shape the future of technology and enhance the lives of consumers around the world. With a strong foundation built on research, development, and a commitment to excellence, {Company} is well-positioned to lead the way in the ever-evolving landscape of technology.