High-Quality Rigid Insulation Sheets for Effective Temperature Control

By:Admin

In recent years, the demand for high-quality rigid insulation sheets has been on the rise, leading to a greater focus on product innovation and performance. One company that has been at the forefront of this movement is {Company Name}. With a commitment to excellence and a dedication to meeting the needs of their customers, {Company Name} has become a trusted name in the insulation industry.

{Company Name} was founded in [year] and has since grown to become a leading manufacturer of rigid insulation sheets. The company's products are known for their exceptional quality and performance, making them a popular choice among builders and homeowners. With a state-of-the-art manufacturing facility and a team of experienced professionals, {Company Name} is able to deliver reliable and cost-effective solutions to their customers.

One of the key advantages of {Company Name}'s rigid insulation sheets is their versatility. These sheets can be used in a wide range of applications, including walls, roofs, and floors. They are also available in a variety of sizes and thicknesses, making them suitable for both residential and commercial projects. Whether it's a new construction or a renovation, {Company Name} has the right insulation solution to meet the specific needs of their customers.

In addition to their superior performance, {Company Name}'s rigid insulation sheets are also environmentally friendly. The company is committed to sustainability and has implemented measures to reduce their environmental impact. By choosing {Company Name}'s products, customers can not only benefit from energy savings but also contribute to a greener future.

Furthermore, {Company Name} takes pride in their customer service. The company's team of experts is dedicated to providing comprehensive support and guidance to their customers. From product selection to installation, {Company Name} is committed to ensuring a smooth and successful experience for their customers.

As the demand for energy-efficient building materials continues to grow, {Company Name} remains dedicated to staying at the forefront of innovation. The company's research and development team is constantly working to improve their products and develop new solutions to meet the evolving needs of the market.

In conclusion, {Company Name} has established itself as a leading provider of high-quality rigid insulation sheets. With a focus on performance, sustainability, and customer satisfaction, the company has earned a reputation for excellence in the industry. Whether it's a residential or commercial project, builders and homeowners can rely on {Company Name} to provide reliable and cost-effective insulation solutions. With a commitment to innovation and a dedication to meeting the needs of their customers, {Company Name} is poised to continue leading the way in the insulation industry.

Company News & Blog

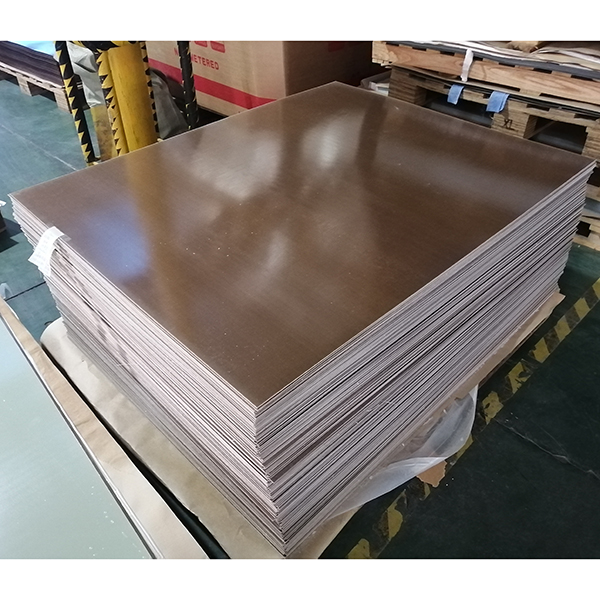

Top Quality Laminate Sheet and Fr4/Fr5/G10 Available in China

Title: China Emerges as Prominent Producer of High-Quality Laminate Sheets and Fr4/Fr5/G10 Insulation MaterialsIntroduction: In recent years, China has witnessed a significant surge in the production of high-quality laminate sheets and insulation materials, namely Fr4/Fr5/G10. With an ever-expanding list of manufacturers dedicated to delivering top-notch products, China has solidified its position as a global leader in the industry. This article explores the growth of China's laminate sheet and insulation material market, highlighting the key players and their contributions to the industry.Market Expansion and Industry Overview: China's laminate sheet and insulation material market has experienced remarkable growth in recent years. This growth can be attributed to a multitude of factors, including advancements in manufacturing technology, increased investment in research and development, and a focus on producing innovative and high-performance products. The market has witnessed a surge in demand from various sectors, such as electronics, automotive, aerospace, and telecommunications, all of which rely heavily on laminate sheets and insulation materials for their operations.Leading Manufacturers: One prominent player in the market is [Company Name], a leading manufacturer of laminate sheets and insulation materials. Their diverse product range includes a wide variety of laminate sheets, including copper-clad laminates (CCL), aluminum-based laminates, and phenolic paper laminates. The company's emphasis on quality control and adherence to international standards has earned them a solid reputation among their global clientele.Another key player in the market is [Company Name], known for their expertise in Fr4/Fr5/G10 insulation materials. With advanced manufacturing facilities and a highly skilled workforce, they consistently deliver high-performance products to meet the diverse needs of industries such as electronics, energy, and transportation. By leveraging their deep understanding of customer requirements and market trends, they have established themselves as a reliable and trusted source for insulation materials.Innovation and Technological Advancements: China's laminate sheet and insulation material manufacturers have been at the forefront of innovation, developing new materials and manufacturing processes to meet the evolving needs of their customers. Continuous investment in research and development has led to the introduction of environmentally friendly and cost-effective materials that offer superior performance characteristics. These innovative products not only improve efficiency but also contribute to the overall sustainability goals of businesses across different industries.Quality Assurance and International Certification: To ensure the consistent quality of their products, leading Chinese manufacturers comply with international certification standards such as ISO 9001, ISO 14001, and UL. Rigorous quality control measures are implemented at every stage of the manufacturing process, from raw material inspection to final product testing. By adhering to these strict quality standards, Chinese manufacturers have garnered trust and credibility from clients worldwide.Global Market Reach:China's laminate sheet and insulation material manufacturers have successfully expanded their market reach beyond national boundaries. By tapping into the global supply chain and establishing strategic partnerships with distributors, these companies have created a robust distribution network. As a result, their high-quality products have gained recognition and acceptance in markets around the world, further solidifying China's position as a major player in the global laminate sheet and insulation material industry.Conclusion:China's emergence as a prominent producer of high-quality laminate sheets and Fr4/Fr5/G10 insulation materials has reshaped the global market. With a focus on innovation, adherence to international standards, and a commitment to delivering superior products, Chinese manufacturers have become trusted partners to industries that rely on laminate sheets and insulation materials for their operations. As the industry continues to grow, China is poised to play a pivotal role in shaping its future, meeting the evolving demands of a wide range of sectors on a global scale.

Lightweight Insulation Board: A suitable choice for construction projects

Thin Insulation Board Emerges as a Game-Changer in Energy-Saving Solutions The importance of energy-saving solutions has been a topic of discussion across the world for some time now. Several industries work towards incorporating energy-efficient technologies into their operations, to promote sustainability and reduce environmental pollution. Air conditioning systems are known to consume a significant amount of electrical energy in homes, buildings, and offices. However, with the introduction of Thin Insulation Board, users can significantly reduce energy consumption by up to 60%. Thin Insulation Board is an innovative solution that provides thermal insulation to air conditioning systems in homes, offices, and other buildings. This product is manufactured by a company that has been in the market for several years and is known for producing high-quality and durable materials. Their state-of-the-art production facility ensures that their products meet international standards and comply with regulations that govern the manufacturing of insulation materials. The company behind Thin Insulation Board uses cutting-edge technology and high-quality materials in producing their products. They have worked tirelessly to develop a product that is both durable and efficient in energy consumption. Thin Insulation Board is made of a special thermal insulating material that guarantees maximum heat retention. Additionally, the material is lightweight, which makes it ideal for installation in any air conditioning system. Thanks to its slim design, it is easy to fit into air conditioning units without taking up too much space. Thin Insulation Board has several features that set it apart from traditional insulation materials. Firstly, it is highly resistant to fire, meaning that it does not pose a danger in case of accidental fires. Secondly, it is waterproof, which makes it resistant to moisture, a factor that typically reduces the efficiency of traditional insulation materials. Thirdly, it is soundproof, which helps reduce noise pollution from air conditioning units. The impact of Thin Insulation Board on energy consumption cannot be overstated. When installed in an air conditioning system, it reduces the amount of energy consumed by up to 60%, a significant reduction that translates to lower energy costs for homeowners and businesses. Moreover, it increases the lifespan of air conditioning units by up to 50%, as well as reducing the frequency of repairs needed. One of the advantages of Thin Insulation Board is that it is affordable and easily accessible. The company has developed a range of sizes and quantities to cater to the needs of its customers. They offer products that are suitable for various air conditioning systems, whether in residential or commercial settings. What's more, the insulation board is easy to install, and customers can do it themselves without professional help. As energy consumption continues to be an area of concern, various initiatives have been developed to encourage energy-saving practices. Thin Insulation Board aligns with these initiatives, and its production process takes into account the need for environmentally friendly materials. The material used in the insulation board is recyclable and poses no harm to the environment. In conclusion, Thin Insulation Board is a game-changer in energy-saving solutions. It is durable, efficient, and reduces energy consumption by up to 60%. Its soundproof and fire-resistant features make it a practical and safe choice for use in air conditioning units. Moreover, it is easily accessible, affordable, and environmentally friendly. It offers a long-lasting solution for individuals and businesses looking to reduce energy consumption and promote sustainable practices.

Durable Epoxy Fiber Glass Laminate Sheet: A Reliable Choice for Various Applications

3240 Epoxy Fiber Glass Laminate Sheet: The Ultimate Choice for Electrical Insulation SolutionsWhen it comes to electrical insulation solutions, one name stands out above the rest - 3240 Epoxy Fiber Glass Laminate Sheet. This high-quality, versatile material has become the go-to choice for professionals across a wide range of industries, and for good reason. With its exceptional electrical insulation properties, durability, and ease of use, it's no wonder that 3240 Epoxy Fiber Glass Laminate Sheet has become the top choice for businesses worldwide.But what exactly sets 3240 Epoxy Fiber Glass Laminate Sheet apart from other materials on the market? To answer that question, we need to take a closer look at what makes this product so special.First and foremost, 3240 Epoxy Fiber Glass Laminate Sheet is known for its outstanding electrical insulation properties. With a high dielectric strength and excellent resistance to electric current, this material provides reliable insulation for a wide range of electrical applications. Whether it's being used to insulate transformers, motors, or electrical panels, 3240 Epoxy Fiber Glass Laminate Sheet delivers the performance and reliability that professionals demand.In addition to its exceptional electrical insulation properties, 3240 Epoxy Fiber Glass Laminate Sheet is also prized for its durability. Made from high-quality materials, this laminate sheet is designed to withstand the rigors of daily use in industrial and commercial settings. It is resistant to heat, moisture, and various chemicals, making it a long-lasting solution for even the most demanding applications.Furthermore, 3240 Epoxy Fiber Glass Laminate Sheet is incredibly versatile. It can be easily cut, drilled, and machined to meet the specific requirements of a given project. This flexibility makes it a popular choice for custom applications, where precise dimensions and shapes are necessary.Another key advantage of 3240 Epoxy Fiber Glass Laminate Sheet is its ease of use. Whether it's being used in a small-scale project or a large industrial application, this material is easy to handle and install. This saves valuable time and labor costs, making it a cost-effective choice for businesses of all sizes.But perhaps the most impressive aspect of 3240 Epoxy Fiber Glass Laminate Sheet is its reliability. With a proven track record of performance in a wide range of applications, this material has earned the trust of professionals worldwide. Businesses can rely on 3240 Epoxy Fiber Glass Laminate Sheet to deliver consistent, long-lasting insulation solutions, time and time again.All of these qualities have made 3240 Epoxy Fiber Glass Laminate Sheet the ultimate choice for electrical insulation solutions. Whether it's being used in the manufacturing of electrical equipment, the construction of industrial machinery, or the maintenance of commercial infrastructure, this material has proven itself to be an indispensable part of modern industry.In conclusion, 3240 Epoxy Fiber Glass Laminate Sheet is the go-to choice for professionals who demand the best in electrical insulation solutions. With its exceptional electrical insulation properties, durability, versatility, ease of use, and reliability, it's no wonder that this material has become the top choice for businesses around the world. For all of these reasons and more, 3240 Epoxy Fiber Glass Laminate Sheet is the clear leader in its field, and the ultimate choice for any project that demands top-quality electrical insulation.

High-quality Epoxy Glass Insulation Board for Electrical Applications

Fr4 Epoxy Glass Insulation Board is considered to be one of the most reliable and high-quality insulation materials in the industry. It is manufactured using a combination of woven glass fabric and epoxy resin, which results in a durable and versatile material that is widely used in various electrical and electronic applications. The Fr4 Epoxy Glass Insulation Board is known for its excellent electrical insulation properties, high mechanical strength, and resistance to heat and chemicals. These characteristics make it an ideal choice for applications that require reliable insulation and protection, such as in electrical panels, circuit boards, transformers, and power distribution systems.With a proven track record of performance and reliability, the Fr4 Epoxy Glass Insulation Board has become a popular choice among engineers, designers, and manufacturers in the electrical and electronics industry. Its ability to withstand high temperatures and harsh operating conditions makes it a preferred choice for critical applications where safety and reliability are paramount.The company {} is a leading manufacturer and supplier of Fr4 Epoxy Glass Insulation Board. With years of experience and expertise in the field, the company has established itself as a trusted provider of high-quality insulation materials for a wide range of industrial applications. Their commitment to quality and innovation has made them a preferred partner for many leading companies in the electrical and electronics industry.The Fr4 Epoxy Glass Insulation Board offered by {} is manufactured to the highest standards, using the latest technology and advanced production processes. This ensures that the material meets the most demanding requirements for performance, reliability, and safety. The company's dedication to quality control and product testing also ensures that their Fr4 Epoxy Glass Insulation Board consistently meets or exceeds industry standards for electrical insulation materials.In addition to providing high-quality insulation materials, {} also offers technical support and customization services to meet the specific needs of their customers. Their team of experienced engineers and technical experts work closely with clients to develop customized solutions that address their unique requirements and challenges.The company's commitment to customer satisfaction and continuous improvement has earned them a reputation for excellence in the industry. They are known for their reliability, responsiveness, and ability to deliver quality products on time and within budget. As a result, {} has become a trusted partner for many companies seeking high-quality insulation solutions for their electrical and electronic applications.As the demand for reliable and high-performance insulation materials continues to grow, {}. The company is dedicated to maintaining its position as a leading provider of Fr4 Epoxy Glass Insulation Board and other innovative insulation solutions. By staying at the forefront of technological advancements and industry trends, the company is well-positioned to meet the evolving needs of its customers and the market.Overall, with a proven track record of performance and a commitment to excellence, {} continues to be a preferred choice for companies seeking high-quality Fr4 Epoxy Glass Insulation Board and other advanced insulation materials. The company's dedication to quality, innovation, and customer satisfaction sets them apart as a leader in the industry, and their continued success is a testament to their exceptional products and services.

High performing G11 H class - everything you need to know

G11 H Class is a groundbreaking new product that has just been introduced by a leading technology company. This new product is set to revolutionize the way we use technology in our daily lives. With its innovative features and cutting-edge technology, the G11 H Class is sure to make a big impact in the market.The G11 H Class is a sleek and stylish device that is packed full of impressive features. It boasts a powerful processor, a high-definition display, and a long-lasting battery. This means that users can enjoy a smooth and seamless experience, whether they are playing games, streaming videos, or working on important projects.One of the most exciting features of the G11 H Class is its advanced camera system. This device is equipped with a high-quality camera that can capture stunning, professional-quality photos and videos. This means that users can document their lives with crystal-clear images, whether they are on vacation, at a special event, or simply spending time with friends and family.In addition to its impressive hardware, the G11 H Class also comes with a range of innovative software features. The device runs on the latest version of the company's operating system, which is known for its user-friendly interface and smooth performance. The G11 H Class also comes with a range of pre-installed apps and services, making it easy for users to get started as soon as they take it out of the box.The company behind the G11 H Class has a long history of producing high-quality technology products. With a focus on innovation and customer satisfaction, this company has established itself as a leader in the technology industry. The G11 H Class is just the latest example of the company's commitment to pushing the boundaries of what is possible with technology."We are thrilled to introduce the G11 H Class to the market," said a spokesperson for the company. "This device represents the very best of what we have to offer, and we are confident that it will exceed the expectations of our customers. Whether you are a seasoned tech enthusiast or a casual user, the G11 H Class has something to offer everyone."The G11 H Class is set to be available in stores and online in the coming months. With its impressive features and stylish design, this device is sure to be a hit with consumers. Whether you are looking for a new smartphone for yourself or as a gift for a loved one, the G11 H Class is definitely worth considering.In conclusion, the G11 H Class is an exciting new product that is set to make a big impact in the technology market. With its powerful hardware, innovative software, and stylish design, this device is sure to be a hit with consumers. Keep an eye out for the G11 H Class in the coming months, and get ready to experience the future of technology.

Ultimate Guide to Fiberglass Insulation: Benefits, Installation Tips and Uses Revealed

Title: Driven by Innovation and Quality, Transforming the Insulation Industry: Fiberglass InsulationIntroduction:In today's rapidly evolving world, energy efficiency has become a top priority for individuals, businesses, and governments. As the demand for sustainable solutions continues to grow, companies are focusing on developing innovative products that not only reduce energy consumption but also enhance overall comfort. One such company at the forefront of this revolution is Fiberglass Insulation.Company Overview:Fiberglass Insulation, a leading provider in the insulation industry, has built a solid reputation for its commitment to quality, innovation, and sustainability. With a rich history spanning over 50 years, the company has continuously transformed the industry landscape through its cutting-edge products and techniques.A pioneer in fiberglass insulation, the company has garnered substantial recognition for its remarkable breakthroughs, ensuring that thermal efficiency and environmental consciousness go hand in hand. By leveraging advanced manufacturing processes and state-of-the-art technology, Fiberglass Insulation has successfully contributed to improving energy efficiency and reducing the carbon footprint of countless homes and commercial buildings.Key Products and Technology:Fiberglass Insulation offers a comprehensive range of insulation products, tailored to meet the specific needs of residential, commercial, and industrial sectors. With a focus on maximizing thermal performance, while minimizing environmental impact, their product line showcases a remarkable blend of innovation, sustainability, and functionality.1. Fiberglass Batts and Rolls:Engineered for optimal heat retention and acoustic control, fiberglass batts and rolls are designed to fit seamlessly between stud frames, floor joists, and ceilings. These highly flexible and easy-to-install insulation solutions provide a superior thermal barrier, reducing energy consumption and enhancing comfort.2. Blown-in Fiberglass:Blown-in fiberglass insulation offers a cost-effective solution for attics, walls, and hard-to-reach spaces. Utilizing a specially formulated adhesive, this product adheres to the substrate, ensuring uniform coverage and eliminating voids. With its remarkable heat resistance and sound absorption capabilities, blown-in fiberglass insulation guarantees long-lasting energy efficiency.3. Spray-Foam Hybrid Insulation:Fiberglass Insulation's innovative spray-foam hybrid insulation combines the benefits of traditional fiberglass insulation with the superior air sealing properties of spray foam. This revolutionary product not only provides exceptional thermal performance but also acts as a barrier against moisture, allergens, and pollutants, ensuring a healthier and more sustainable living environment.Sustainability Initiatives:Fiberglass Insulation is committed to sustainable manufacturing practices and reducing its environmental impact throughout the product life cycle. The company employs an extensive recycling program, ensuring that waste materials are transformed into usable products, significantly reducing landfill waste.With an emphasis on energy efficiency, their manufacturing processes utilize renewable energy sources, further minimizing carbon emissions. With its LEED-certified products, the company actively supports green building initiatives to create a more environmentally conscious future.Conclusion:Fiberglass Insulation's unwavering dedication to innovation, quality, and sustainability has cemented its position as an industry leader. By continuously developing cutting-edge insulation solutions, the company has successfully contributed to reducing energy consumption, providing optimal comfort, and minimizing the environmental impact of buildings.As the demand for sustainable solutions continues to rise, Fiberglass Insulation remains committed to its mission of transforming the insulation industry. With advanced technology, a focus on energy efficiency, and an unwavering commitment to quality, the company is well-positioned to shape a greener, more sustainable future.

Top Quality PCB Boards Manufactured in China: Find out more here

China PCB Board Company Expands Its Presence in the Global MarketChina PCB Board (CPB), a leading manufacturer of high-quality printed circuit boards, has been making significant strides in the global market, providing innovative solutions to meet the growing demand for advanced electronic components. With a strong emphasis on research and development, CPB has been successful in catering to the needs of diverse industries, including telecommunications, automotive, medical, and consumer electronics.Established in 2005, CPB has quickly grown to become a trusted name in the electronics industry, known for its commitment to quality, reliability, and customer satisfaction. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for the production of a wide range of PCBs, including single-sided, double-sided, and multilayer boards.CPB's dedication to innovation and continuous improvement has enabled it to stay at the forefront of technological advancements in the PCB industry. With a team of experienced engineers and technicians, the company has the expertise to design and develop custom PCBs to meet the specific requirements of its clients. This flexibility has been a key factor in CPB's ability to serve a diverse customer base and adapt to the evolving needs of the global market.In recent years, CPB has been focusing on expanding its reach beyond the domestic market, with a strategic vision to become a global leader in the PCB industry. To achieve this goal, the company has been actively participating in international trade fairs and exhibitions, showcasing its products and capabilities to potential customers from around the world. This proactive approach has helped CPB to establish a strong presence in key international markets and build valuable partnerships with leading companies in various sectors.Furthermore, CPB has been investing in research and development to enhance its product offerings and stay ahead of the competition. The company's R&D team is constantly working on developing new materials, manufacturing processes, and technologies to improve the performance and reliability of its PCBs. This commitment to innovation has allowed CPB to introduce advanced products that meet the stringent requirements of modern electronic applications.Moreover, CPB is dedicated to maintaining the highest standards of quality and environmental sustainability in its operations. The company has implemented strict quality control measures at every stage of the manufacturing process, ensuring that its products meet international standards and regulations. Additionally, CPB has been investing in green initiatives to minimize its environmental footprint, with a focus on energy efficiency, waste reduction, and recycling.As a result of these efforts, CPB has gained a reputation for delivering superior quality PCBs that offer exceptional performance and durability. This has led to an increase in demand for CPB's products in the global market, with the company securing partnerships with renowned multinational corporations and OEMs.Looking ahead, CPB remains committed to its vision of becoming a global leader in the PCB industry, driven by a combination of innovation, quality, and customer satisfaction. The company will continue to invest in advanced technology and talent to further enhance its capabilities and expand its market presence. With a strong focus on meeting the evolving needs of the electronics industry, CPB is poised for continued success in the global market.

High-Quality Insulation Laminate Sheet: A Complete Guide

Insulation Laminate Sheet Enhances Thermal Performance and Safety in Electrical ApplicationsWith the ever-growing demand for energy efficiency and safety in the electrical industry, the use of Insulation Laminate Sheet has become increasingly popular. This innovative material is designed to enhance thermal performance and provide a high level of resistance to electrical current, making it an essential component in a wide range of applications.Insulation Laminate Sheet, also known as insulation paper, is a composite material made by impregnating high-quality insulating paper with a phenolic resin or epoxy resin and then laminating it under high pressure and temperature. This process creates a durable and reliable material that provides excellent electrical insulation and thermal resistance, making it suitable for use in transformers, motors, generators, and other electrical devices.The company {} is a leading manufacturer and supplier of insulation laminate sheet, offering a wide range of products to meet the diverse needs of the electrical industry. With a strong focus on quality and innovation, {} has established a solid reputation for delivering high-performance insulation materials that exceed industry standards.One of the key advantages of Insulation Laminate Sheet from {} is its ability to enhance thermal performance in electrical applications. By providing superior thermal conductivity and heat resistance, this material helps to improve the overall efficiency and reliability of electrical devices, ensuring optimum performance even under extreme operating conditions.In addition to its thermal properties, Insulation Laminate Sheet also offers exceptional electrical insulation, effectively preventing the leakage of current and ensuring the safety of electrical equipment and personnel. This is particularly important in high-voltage applications where the risk of electrical arcing and breakdown is a major concern.Furthermore, {} offers a range of Insulation Laminate Sheet products that are specifically designed to meet international safety and quality standards, including UL, CE, and RoHS certifications. This ensures that customers can have confidence in the performance and reliability of the insulation materials they use in their electrical applications.Another notable feature of Insulation Laminate Sheet from {} is its versatility and ease of use. The material can be easily cut, shaped, and bonded to fit the specific requirements of different electrical components, allowing for greater design flexibility and customization in various applications.With a strong emphasis on research and development, {} is continuously innovating and improving its insulation laminate sheet products to meet the evolving needs of the electrical industry. This commitment to innovation has enabled the company to stay ahead of the curve and deliver cutting-edge insulation solutions that drive performance, efficiency, and safety for its customers.As the demand for energy-efficient and safe electrical equipment continues to grow, Insulation Laminate Sheet from {} is expected to play a crucial role in meeting these requirements. With its combination of high thermal performance, excellent electrical insulation, and international certifications, this innovative material is set to be a leading choice for engineers and manufacturers seeking reliable and effective insulation solutions for their electrical applications.In conclusion, Insulation Laminate Sheet from {} is a game-changing material that offers superior thermal performance and safety in electrical applications. With its proven track record of quality and innovation, {} is well-positioned to meet the growing demand for high-performance insulation materials in the electrical industry. As technology continues to advance, Insulation Laminate Sheet is set to play a key role in shaping the future of energy-efficient and safe electrical equipment.

Durable and Heat-Resistant Phenolic Sheet Gaining Popularity in Multiple Industries

Title: Highly Durable G10 Phenolic Sheet Finds Application in Numerous IndustriesIntroduction:Throughout various industries, the need for durable and reliable materials is paramount. One such material garnering attention is the G10 Phenolic Sheet. This high-performance laminate is gaining recognition for its exceptional mechanical strength, excellent electrical properties, and chemical resistance. It has become a sought-after choice for professionals across sectors, ranging from aerospace and automotive to electronics and construction.Company Introduction:{Insert company name} is a leading provider of advanced materials, specializing in manufacturing and distributing high-quality G10 Phenolic Sheets. With years of expertise in the field, our company has established a strong reputation for delivering top-notch solutions that meet and exceed industry standards. We prioritize innovation and sustainability, ensuring our products align with the evolving needs of modern industries.Article:The versatility of G10 Phenolic Sheet has made it an indispensable material in a wide range of applications. With its exceptional durability and resistance to extreme conditions, it has proven itself as a valuable asset in demanding environments. Let us explore the key characteristics and applications of this remarkable material.1. Mechanical Strength: G10 Phenolic Sheet offers impressive mechanical properties, including high tensile strength, impact resistance, and dimensional stability. These features make it an ideal choice for applications requiring structural integrity, such as load-bearing components, gears, and bushings. Its resilience to wear and tear ensures a prolonged lifespan, reducing replacement costs.2. Electrical Properties:The G10 Phenolic Sheet possesses outstanding electrical insulation properties, making it an excellent choice for applications in the electronics industry. With superior dielectric strength, this material provides a reliable barrier against electrical current flow. It is commonly used as insulating supports, terminal boards, and electrical housings in various electronic devices.3. Chemical Resistance:G10 Phenolic Sheet exhibits excellent resistance to various chemicals, making it suitable for applications exposed to corrosive environments. It can withstand exposure to oils, solvents, acids, and alkalis, ensuring durability in demanding industries such as chemical processing, oil and gas, and marine sectors. This resistance prevents degradation and ensures the long-term reliability of equipment and structures.4. Thermal Stability:The G10 Phenolic Sheet offers exceptional thermal stability, enabling it to withstand elevated temperatures without significant degradation. This characteristic makes it suitable for applications where heat resistance is crucial, such as high-temperature insulation, electrical and electronics equipment, and automotive components.5. Aerospace and Defense:The aerospace and defense industries heavily rely on the superior properties of the G10 Phenolic Sheet. Its lightweight yet robust nature makes it ideal for manufacturing aircraft interior panels, structural components, as well as missile and weapon systems. The material's flame-retardant qualities also ensure compliance with safety regulations.6. Automotive Industry:G10 Phenolic Sheet has become a preferred choice in the automotive sector due to its excellent mechanical strength, durability, and resistance to high temperatures. It finds application in engine gaskets, electrical insulation components, friction materials, and composite structures, enhancing overall performance and extending the lifespan of vehicles.7. Construction and Electrical Engineering:The construction industry benefits from G10 Phenolic Sheet's ability to withstand extreme weather conditions, chemical exposure, and mechanical stress. It is commonly used in wall panels, flooring, insulation, and electrical insulation systems. Its resistance to fire and electrical conductivity ensures the safety and performance of infrastructure.Conclusion:The G10 Phenolic Sheet has emerged as a versatile and highly durable material, finding applications across multiple industries. Its mechanical strength, excellent electrical properties, chemical resistance, and thermal stability make it an invaluable asset for aerospace, automotive, electronics, construction, and other sectors. As technological advancements continue, the demand for reliable and resilient materials like the G10 Phenolic Sheet is expected to rise, fueling further innovation in the industry.

Cost-Effective Thin Insulation Sheets: A Key Solution for Efficient Thermal Control

[Company Name] Develops Innovative Thin Insulation Sheets for Various Applications[City, Date] - [Company Name], a renowned leader in the field of insulation solutions, has recently unveiled its latest product innovation - Thin Insulation Sheets. These sheets, designed to provide effective thermal insulation, offer significant benefits over traditional insulation materials. With this groundbreaking development, [Company Name] aims to revolutionize the insulation industry and meet the growing demands for energy-efficient solutions.Utilizing state-of-the-art technology, [Company Name] has successfully produced insulation sheets that are incredibly thin yet highly efficient. These sheets have unique properties that allow them to effectively reduce heat transfer, providing optimal insulation for both residential and commercial applications. The innovative design of the Thin Insulation Sheets makes them versatile and adaptable to various environments, making them an ideal choice for a wide range of projects.One of the key advantages of the Thin Insulation Sheets is their superior thermal performance. By effectively minimizing heat loss or gain, these sheets help maintain a comfortable indoor temperature while significantly reducing energy consumption. This thermal efficiency contributes to cost savings for homeowners and businesses alike, as it reduces the need for excessive heating or cooling usage.In addition to their exceptional insulating capabilities, the Thin Insulation Sheets are also incredibly lightweight and easy to handle. This makes them an ideal choice for retrofitting existing structures, allowing for hassle-free installation without the need for extensive modifications. Moreover, their thin profile provides more space for additional insulation or accomodates architectural designs that require minimal thickness.[Company Name] takes pride in offering environmentally friendly solutions, and the Thin Insulation Sheets are no exception. Made from sustainable materials, these sheets are non-toxic and do not emit harmful substances, ensuring a healthy living environment. By incorporating these insulation sheets into their projects, individuals and businesses can contribute to a greener future while enjoying the benefits of reduced energy consumption.To cater to diverse insulation needs, [Company Name] manufactures Thin Insulation Sheets in various sizes and thicknesses. Customers can choose the most suitable option based on the specific requirements of their project. The sheets can be easily customized to fit different shapes and sizes, ensuring a perfect fit and maximum thermal performance.The versatility of the Thin Insulation Sheets opens up a world of potential applications. From residential buildings and commercial spaces to industrial facilities and transportation, these sheets can be used in a wide range of environments. Whether it is for new construction projects, renovations, or insulation upgrades, [Company Name]'s Thin Insulation Sheets are a cost-effective and efficient solution.As a frontrunner in the insulation industry, [Company Name] has established a solid reputation for delivering high-quality products and innovative solutions. With the introduction of the Thin Insulation Sheets, the company reaffirms its commitment to meeting the evolving needs of its customers and driving sustainability in the industry.[Company Name]'s Thin Insulation Sheets are now available to customers worldwide. By choosing these revolutionary insulation sheets, individuals, architects, and construction professionals can enjoy the benefits of superior thermal performance, ease of installation, and environmental sustainability. With [Company Name] leading the way, the future of insulation is thin, efficient, and eco-friendly.About [Company Name]:[Company Name] is a renowned company specializing in insulation solutions. With years of experience and a dedication to quality and innovation, [Company Name] has become a trusted name in the industry. The company takes pride in its commitment to delivering energy-efficient products that meet international standards while minimizing the environmental impact. From residential to commercial projects, [Company Name] provides reliable insulation solutions for a sustainable future. For more information, visit [Company Website].Contact:[Company Name][Company Address][Phone Number][Email Address][Website]