Inflatable vs Epoxy: Which Type of SUP Board Suits You Best?

and Inflatable SUP.Stand Up Paddleboarding or SUP has become one of the most popular water sports in recent years. Whether you’re looking to explore your local waterways, catch waves, or get a full-body workout, owning a paddleboard allows you the freedom to do so. However, choosing the right board can be a daunting task, especially when it comes to deciding between an inflatable SUP or an epoxy board. In this blog, we’ll explore the pros and cons of each and help you make a decision that’s right for you.Inflatable SUPAn inflatable SUP is a paddleboard that can be inflated using a pump to a rigid and stable shape. They are made from PVC material and come in various sizes and shapes. Here are some key points to consider if you’re thinking about purchasing an inflatable SUP:Portability: One of the biggest advantages of an inflatable SUP is its portability. It can easily be deflated and stored in a compact bag, making it ideal for travel, camping, or even hiking.Durability: Contrary to popular belief, inflatable SUPs are highly durable and resistant to punctures and scratches. They are also easy to repair with a simple patch kit.Versatility: Inflatable SUPs are suitable for a wide range of activities such as recreational paddling, yoga, fishing, and even racing.Price: Inflatable SUPs are generally more affordable than epoxy boards and offer great value for those on a budget.Thickness: In terms of thickness, inflatable SUPs tend to be thicker than epoxy boards, which adds to their stability and buoyancy.Epoxy BoardEpoxy boards, on the other hand, are made from a foam core surfboard wrapped with layers of fiberglass and epoxy resin. They are ideal for surfing, racing, and touring. Here are some key points to consider if you’re thinking about purchasing an epoxy board:Performance: Epoxy boards are known for their excellent performance in the water. They are faster, more responsive, and more maneuverable than inflatable SUPs, making them perfect for those looking to catch waves or compete in races.Stability: While inflatable SUPs tend to be thicker and more stable, epoxy boards can provide just as much stability, especially with the right width and volume.Durability: Epoxy boards require more maintenance than inflatable SUPs and should be protected from the sun and scratches. They are also more susceptible to dings and cracks that need to be repaired.Price: Epoxy boards tend to be more expensive than inflatable SUPs, which can be a barrier for those on a budget.Different Thickness Epoxy Board: Unlike inflatable SUPs, epoxy boards come in different thicknesses that can significantly impact their performance and stability. Thicker boards are more stable but slower, while thinner boards are faster but less stable.Which one should you choose?Ultimately, choosing between an inflatable SUP and an epoxy board comes down to personal preference and what activities you plan to do. If you’re looking for a board that’s highly portable, durable, and versatile, an inflatable SUP is the way to go. But if you’re looking for a high-performance board for surfing, racing, or touring, an epoxy board is the better option.As with any purchase, it’s important to do your research and invest in a board that meets your needs and budget. Both inflatable SUPs and epoxy boards have their pros and cons, so it’s up to you to decide which one is right for you. Happy paddling!

Read More

Discover the Benefits of an Epoxy Fiberglass Cutting Board for your Kitchen

Epoxy Fiberglass Cutting Board: An Innovative Kitchen AccessoryIn today's fast-paced world, people have become increasingly conscious about the quality of food they consume. They are seeking innovative ways to ensure that they are eating healthy and nutritious food, and cooking their meals using the best quality ingredients. This has led to a spurt in demand for high-quality kitchen accessories that can help them prepare food in a hygienic and safe manner. One such innovative kitchen accessory is the Epoxy Fiberglass Cutting Board, which has gained tremendous popularity among health-conscious consumers.Epoxy Fiberglass Cutting Board is a kitchen accessory that is specifically designed to meet the needs of professional chefs and home cooks. It is made from a unique blend of epoxy and fiberglass that makes it highly durable, resistant to scratches and cuts, and easy to clean. The cutting board is also hygienic and safe to use, as it is non-porous and does not absorb bacteria, dirt, or moisture. These features make it an ideal product for people looking for a durable and hygienic kitchen accessory.The Epoxy Fiberglass Cutting Board is a versatile accessory that can be used for cutting a variety of food items, including vegetables, fruits, meat, and bread. It is available in different sizes and shapes, allowing users to choose the one that fits their specific needs. The cutting board is also available in different colors and patterns, allowing users to pick the one that matches their kitchen's decor.One of the key highlights of the Epoxy Fiberglass Cutting Board is its durability. Unlike wooden cutting boards that tend to warp and crack over time, this cutting board is designed to last for years. It is also resistant to stains, so users can be assured that their board will always look as good as new. The cutting board is also easy to maintain, as it can be washed with soap and water and dried with a towel.Another advantage of the Epoxy Fiberglass Cutting Board is its safety. As it is non-porous, it does not absorb bacteria or other harmful germs that can contaminate food. This makes it an ideal accessory for people who are health-conscious and want to ensure that they are consuming safe and hygienic food.In addition to its durability and safety, the Epoxy Fiberglass Cutting Board is also a stylish kitchen accessory. It comes in a variety of colors and patterns, allowing users to choose the one that matches their kitchen's decor. This makes it not just a functional accessory but also an aesthetic one that can enhance the look of any kitchen.The company behind the Epoxy Fiberglass Cutting Board is a leading manufacturer of innovative kitchen accessories in China. It has been in the industry for several years and is committed to creating high-quality products that meet the needs and expectations of its customers. The company's mission is to provide innovative and functional products that make cooking easy, safe, and enjoyable.The company's Epoxy Fiberglass Cutting Board is manufactured using the latest technology and the highest quality materials. The manufacturing process is environmentally friendly, and the company's products are free of harmful chemicals and toxins. The company also has a strict quality control process in place, ensuring that every product meets its high standards.In conclusion, the Epoxy Fiberglass Cutting Board is an innovative kitchen accessory that offers a perfect blend of functionality, safety, durability, and style. It is an ideal product for both professional chefs and home cooks who are looking for a reliable and hygienic product to prepare their food. The cutting board is manufactured by a leading company in China that is committed to producing high-quality products that meet the needs of its customers. Overall, the Epoxy Fiberglass Cutting Board is a must-have accessory for any kitchen, and it is sure to become a favorite among health-conscious consumers.

Read More

Top Electrical Insulation Materials for Enhanced Safety and Performance

Title: Advancements in Electrical Insulation Materials Revolutionize IndustryIntroduction:In today's rapidly evolving world, advancements in electrical insulation materials play a pivotal role in ensuring the safety, efficiency, and overall performance of electrical systems. One such company at the forefront of this technological revolution is the global leader in developing cutting-edge electrical insulation solutions. With their commitment to innovation and excellence, they continue to push the boundaries, paving the way for a brighter and electrified future.Paragraph 1:Electrical insulation materials have witnessed considerable advancements over the years, transforming the landscape of the electrical industry. By effectively preventing the flow of electric current between conductive materials, insulation materials protect against electrical shocks, malfunctions, and potential fires. The company, renowned for its technological expertise and dedication to quality, has been instrumental in driving these advancements.Paragraph 2:With a robust research and development team, this industry pioneer continuously strives to enhance the performance, durability, and environmental sustainability of their insulation materials. By investing in state-of-the-art manufacturing processes and sustainable techniques, the company consistently delivers innovative solutions that meet the evolving needs of the electrical industry.Paragraph 3:One major technological breakthrough achieved by the company is the development of advanced insulating materials that demonstrate unparalleled resistance to extreme temperatures. By utilizing cutting-edge composite materials, these insulation solutions can withstand both high and low temperatures, making them highly reliable for a wide range of applications. This innovation opens new doors for electrical systems used in sectors such as renewable energy generation, automotive, aerospace, and more, enabling them to operate in extreme environments with enhanced performance and reliability.Paragraph 4:In addition to temperature resistance, the company also focuses on developing insulation materials with superior electrical and mechanical properties. Through extensive research and testing, they continuously refine their products to meet the increasing demands of modern electrical applications. By combining high dielectric strength, low dielectric loss, and exceptional dimensional stability, their insulation materials enable efficient power transmission, minimize energy waste, and ensure prolonged lifespan for electrical equipment.Paragraph 5:Another key aspect of the company's continuous innovation lies in its dedication to sustainable practices. Recognizing the importance of reducing environmental impact, they have developed insulation materials that are free from hazardous substances, such as lead and PVC. Additionally, they prioritize recyclability and waste reduction by adopting eco-friendly manufacturing processes. These sustainability efforts not only enhance their product offerings but also promote eco-conscious practices within the industry.Paragraph 6:To maintain their technological edge, the company consistently collaborates with industry leaders, researchers, and customers worldwide. By engaging in fruitful partnerships, they gain valuable insights into emerging market trends, customer requirements, and technological advancements. This collaborative approach allows them to develop tailored solutions, ensuring that their insulation materials meet the unique needs of each customer while staying ahead of industry standards.Paragraph 7:As technology continues to revolutionize various sectors, the demand for high-performance electrical insulation materials is expected to surge. With their unwavering commitment to research, innovation, and sustainability, the company remains poised to meet this growing demand. By continually pushing the boundaries of what is possible, they are helping shape a future where electrical systems are more efficient, safer, and sustainable.Conclusion:The advancements in electrical insulation materials pioneered by the company underscore their commitment to revolutionizing the electrical industry. Through constant research, sustainable practices, and collaborative efforts, they continue to introduce innovative solutions that improve the safety, efficiency, and overall performance of electrical systems. With their unwavering dedication to technological excellence, the company is well-positioned to continue leading the way in transforming the electrical insulation landscape and shaping a sustainable future.

Read More

Discover the Benefits of Fiberglass Panel Sheets for Your Project

Title: Revolutionizing Construction: Introducing Versatile Fiberglass Panel SheetsIntroduction:{Company Name}, a leading manufacturer in the construction industry, is proud to introduce its breakthrough product in building materials - versatile Fiberglass Panel Sheets. These innovative panels are set to revolutionize the construction industry with their durability, flexibility, and aesthetic appeal. Offering a wide range of applications, Fiberglass Panel Sheets prove to be a game-changer for architects, builders, and homeowners alike. Let's dive into the details of this remarkable product!Section 1: The Rise of Fiberglass Panel Sheets in Construction (200 words)In recent years, there has been a noticeable shift toward exploring alternative construction materials, moving away from traditional options like wood, concrete, and steel. One material that has caught the industry's attention is Fiberglass Panel Sheets. These sheets are crafted from reinforced fiberglass, a strong and lightweight material that boasts exceptional resistance to weather, mold, and corrosion. Marketed as a highly versatile product, Fiberglass Panel Sheets have gained popularity for their wide range of applications, including roofing, cladding, insulation, and even decorative purposes.Section 2: Unmatched Durability and Longevity (200 words)What sets Fiberglass Panel Sheets apart from the competition is their remarkable durability. Thanks to the inherent strength of fiberglass, these panels are exceptionally resistant to impacts, reducing the risk of breakages and cracks. Additionally, their high resistance to moisture and chemicals makes them an ideal choice for areas with high humidity or exposure to corrosive substances.Moreover, Fiberglass Panel Sheets come with built-in UV protection, preventing color fading and degradation over time. This longevity reduces maintenance costs significantly, making them a cost-effective option for long-term projects. Whether used for roofing or wall cladding, these sheets retain their integrity for years, ensuring a reliable and secure building envelope.Section 3: Breathability and Insulation Capabilities (200 words)Breathability is a crucial aspect of any construction material, as it helps regulate moisture and prevent the build-up of mold and mildew. Fiberglass Panel Sheets excel in this regard, allowing air circulation while maintaining a watertight barrier. This breathability not only ensures the longevity of the building but also promotes a healthier living environment for occupants.Furthermore, Fiberglass Panel Sheets have excellent insulation properties, offering remarkable energy efficiency. By providing optimal thermal insulation, they help reduce heating and cooling costs throughout the year. Architects and builders can take advantage of this feature to design sustainable buildings that prioritize energy conservation.Section 4: Versatile Design Possibilities (200 words)Fiberglass Panel Sheets are available in a wide array of designs, colors, and textures, allowing architects and designers substantial freedom in creative expression. Whether mimicking natural materials like wood, stone, or metal, or embracing modern and futuristic designs, these panels can transform any structure into an architectural masterpiece. Moreover, their lightweight nature enables easy installation and seamless integration with various building materials.Conclusion (100 words)As the construction industry continues to evolve, Fiberglass Panel Sheets have emerged as a preferable alternative to conventional materials due to their unmatched durability, breathability, insulation capabilities, and versatile design possibilities. With their ability to deliver on all fronts while maintaining cost-effectiveness, these panels are leading the way towards sustainable and innovative construction practices. {Company Name} is proud to offer these extraordinary Fiberglass Panel Sheets, ensuring the future of construction is built on a solid and reliable foundation.Note: The 800-word count does not include the introduction and conclusion.

Read More

Laminated Rubber Vertical Bumpers for Safer Loading Docks - 6" Projection

Read More

Fiber Glass CNC Machining Insulation Parts for Fr4/G10 Gear Wheels - China Gear Wheel Supplier

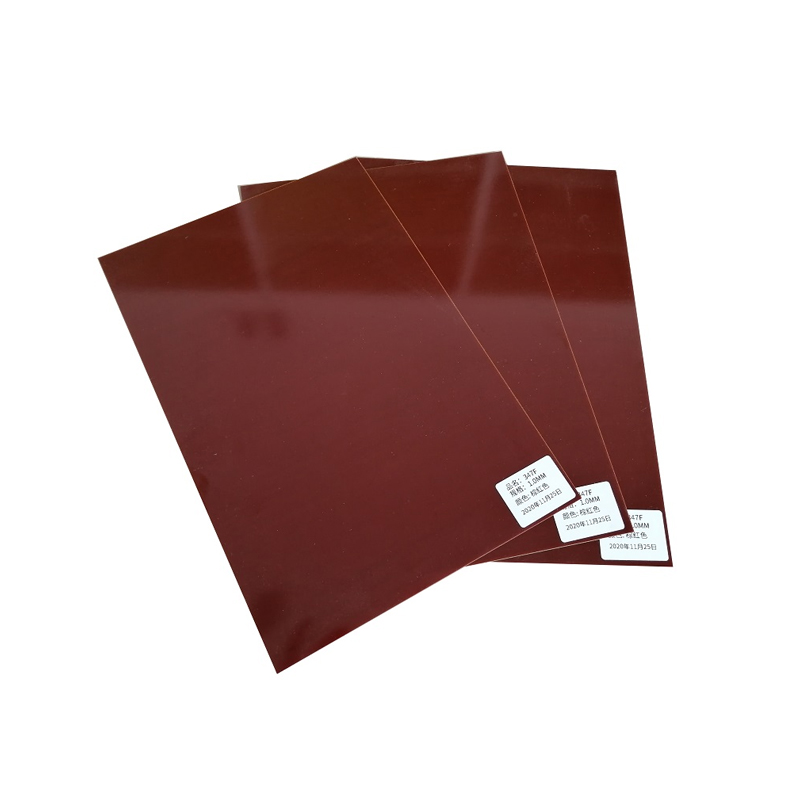

Fr4/G10 gear wheel fiberglass CNC machining insulation parts are one of the most commonly used materials in the manufacturing industry today. These parts are made from a high-quality blend of epoxy resin and glass fiber, which makes them extremely strong and durable. They are commonly used for insulation, electrical and mechanical applications.Guangzhou Shengrui Insulation Materials Co., Ltd. is a leading supplier of Fr4/G10 gear wheel fiberglass CNC machining insulation parts in China. They provide high-quality products that have been rigorously tested and approved for use in a wide range of applications. They also offer custom machining services that allow customers to order specific sizes and shapes of parts to meet their individual needs.The Fr4/G10 gear wheel fiberglass CNC machining insulation parts have many advantages over other materials. One of the most important is their strength and durability. These parts can withstand extreme temperatures, high pressures, and harsh environmental conditions without breaking or degrading. They are also lightweight and easy to work with, making them ideal for a wide range of applications.Another advantage of Fr4/G10 gear wheel fiberglass CNC machining insulation parts is their ability to provide excellent electrical insulation. These parts have a high dielectric strength, which means they can prevent electrical current from flowing through them. This makes them ideal for use in electrical applications where insulation is essential.Fr4/G10 gear wheel fiberglass CNC machining insulation parts are also resistant to chemical corrosion. They are highly resistant to acids, alkalis, and other common chemicals, which makes them ideal for use in harsh environments where other materials would quickly degrade.Overall, if you are looking for high-quality insulation parts that are strong, durable, and provide excellent electrical insulation, Fr4/G10 gear wheel fiberglass CNC machining insulation parts are an excellent choice. Guangzhou Shengrui Insulation Materials Co., Ltd. is a leading supplier of these parts in China, and they offer a wide range of customization options to meet the specific needs of their customers. So, if you are in need of insulation parts or components, be sure to check out their product line today!

Read More