Ultimate guide to Epoxy Laminates for Solder Pallet

By:Admin

Founded in 2005, Epoxy Laminates For Solder Pallet has quickly established itself as a trusted name in the electronics industry. With a strong emphasis on research and development, the company has continuously pushed the boundaries of innovation to develop cutting-edge solutions that address the evolving needs of their customers. Their commitment to quality and customer satisfaction has earned them a reputation for excellence in the industry.

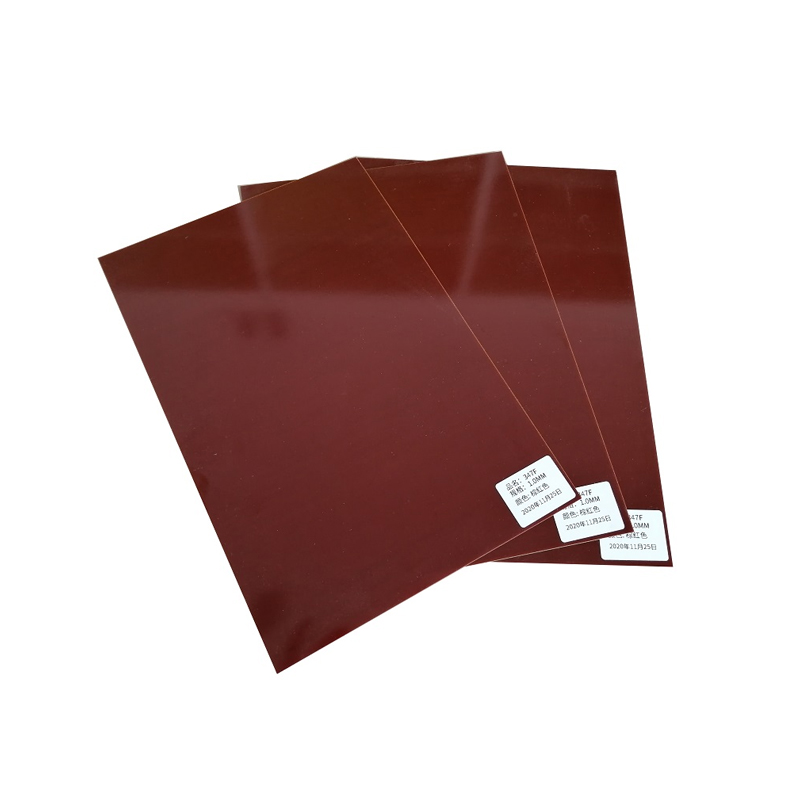

The new product line from Epoxy Laminates For Solder Pallet is a testament to the company's dedication to delivering high-quality solutions that drive efficiency and productivity in electronics manufacturing. The epoxy laminates are specifically designed for use in solder pallets, providing a durable and reliable surface for the soldering process. These laminates offer exceptional thermal conductivity, ensuring optimal heat distribution and uniform soldering results. Additionally, the materials used in the laminates are engineered to withstand high temperatures and harsh chemicals, making them ideal for the rigorous demands of electronics manufacturing.

One of the standout features of the epoxy laminates from Epoxy Laminates For Solder Pallet is their exceptional dimensional stability. This ensures that the solder pallets maintain their flatness and accuracy over time, reducing the likelihood of defects in the soldering process. The high level of precision and consistency offered by these laminates is essential for achieving superior soldering results and minimizing production rework.

In addition to their exceptional performance characteristics, the epoxy laminates from Epoxy Laminates For Solder Pallet are also designed with ease of use in mind. The materials are lightweight and easy to handle, simplifying the manufacturing process and reducing operator fatigue. This, in turn, helps to improve overall efficiency and productivity in electronics manufacturing operations.

"We are thrilled to introduce our latest line of epoxy laminates for solder pallets," said a spokesperson for Epoxy Laminates For Solder Pallet. "These products exemplify our commitment to innovation and excellence, and we are confident that they will make a significant impact on the electronics manufacturing industry. Our customers can expect nothing less than the highest quality and performance from our epoxy laminates, and we are excited to see the positive results they will deliver."

The launch of the new epoxy laminate product line underscores Epoxy Laminates For Solder Pallet's position as a market leader in the electronics industry. With a focus on delivering innovative solutions that address the unique challenges of electronics manufacturing, the company continues to set the standard for quality and performance. As they look to the future, Epoxy Laminates For Solder Pallet is poised to continue driving advancements in the industry, helping their customers achieve success and growth in an increasingly competitive market.

For more information about Epoxy Laminates For Solder Pallet and their new product line, visit their website {} or contact them directly to speak with a representative. With a proven track record of excellence and a commitment to customer satisfaction, Epoxy Laminates For Solder Pallet is the go-to partner for innovative solutions in the electronics manufacturing industry.

Company News & Blog

High-Quality Insulation Laminate Sheet: A Complete Guide

Insulation Laminate Sheet Enhances Thermal Performance and Safety in Electrical ApplicationsWith the ever-growing demand for energy efficiency and safety in the electrical industry, the use of Insulation Laminate Sheet has become increasingly popular. This innovative material is designed to enhance thermal performance and provide a high level of resistance to electrical current, making it an essential component in a wide range of applications.Insulation Laminate Sheet, also known as insulation paper, is a composite material made by impregnating high-quality insulating paper with a phenolic resin or epoxy resin and then laminating it under high pressure and temperature. This process creates a durable and reliable material that provides excellent electrical insulation and thermal resistance, making it suitable for use in transformers, motors, generators, and other electrical devices.The company {} is a leading manufacturer and supplier of insulation laminate sheet, offering a wide range of products to meet the diverse needs of the electrical industry. With a strong focus on quality and innovation, {} has established a solid reputation for delivering high-performance insulation materials that exceed industry standards.One of the key advantages of Insulation Laminate Sheet from {} is its ability to enhance thermal performance in electrical applications. By providing superior thermal conductivity and heat resistance, this material helps to improve the overall efficiency and reliability of electrical devices, ensuring optimum performance even under extreme operating conditions.In addition to its thermal properties, Insulation Laminate Sheet also offers exceptional electrical insulation, effectively preventing the leakage of current and ensuring the safety of electrical equipment and personnel. This is particularly important in high-voltage applications where the risk of electrical arcing and breakdown is a major concern.Furthermore, {} offers a range of Insulation Laminate Sheet products that are specifically designed to meet international safety and quality standards, including UL, CE, and RoHS certifications. This ensures that customers can have confidence in the performance and reliability of the insulation materials they use in their electrical applications.Another notable feature of Insulation Laminate Sheet from {} is its versatility and ease of use. The material can be easily cut, shaped, and bonded to fit the specific requirements of different electrical components, allowing for greater design flexibility and customization in various applications.With a strong emphasis on research and development, {} is continuously innovating and improving its insulation laminate sheet products to meet the evolving needs of the electrical industry. This commitment to innovation has enabled the company to stay ahead of the curve and deliver cutting-edge insulation solutions that drive performance, efficiency, and safety for its customers.As the demand for energy-efficient and safe electrical equipment continues to grow, Insulation Laminate Sheet from {} is expected to play a crucial role in meeting these requirements. With its combination of high thermal performance, excellent electrical insulation, and international certifications, this innovative material is set to be a leading choice for engineers and manufacturers seeking reliable and effective insulation solutions for their electrical applications.In conclusion, Insulation Laminate Sheet from {} is a game-changing material that offers superior thermal performance and safety in electrical applications. With its proven track record of quality and innovation, {} is well-positioned to meet the growing demand for high-performance insulation materials in the electrical industry. As technology continues to advance, Insulation Laminate Sheet is set to play a key role in shaping the future of energy-efficient and safe electrical equipment.

Durable Fiber Insulation Board: A Strong and Reliable Insulation Solution

Fiber Insulation Board Expands Market Presence with Innovative TechnologyFiber Insulation Board, a leading manufacturer in the insulation industry, has announced their latest innovation in fiber insulation technology. The company has introduced a new, high-performance fiber insulation board that is set to revolutionize the market. With its advanced thermal properties and sustainable materials, this new product is expected to make a significant impact on the industry.The Fiber Insulation Board is made from natural fibers that are sourced from sustainable forests. This renewable resource not only makes the insulation board an environmentally friendly option, but also provides superior insulation properties. The new product is designed to provide exceptional thermal performance, reducing heat loss and energy consumption in buildings.The company spokesperson stated, "We are excited to introduce this innovative fiber insulation board to the market. With our commitment to sustainability and energy efficiency, we believe that this product will meet the growing demand for high-performance insulation solutions."In addition to its exceptional thermal properties, the Fiber Insulation Board is also fire-resistant and incorporates soundproofing features. This makes it an ideal choice for a wide range of applications, including residential, commercial, and industrial buildings. The product's versatility and durability provide a practical solution for architects, builders, and contractors.For a company that has been at the forefront of the insulation industry for over two decades, this latest innovation demonstrates their continued dedication to developing cutting-edge products. The company's relentless pursuit of technological advancements has positioned them as a leader in the market. Their commitment to quality, reliability, and sustainability has earned the trust and loyalty of customers worldwide.Established in {}, the company has grown rapidly and expanded its market presence through strategic partnerships and investments in research and development. Their state-of-the-art manufacturing facilities ensure that their products meet the highest industry standards, while their experienced team of engineers and technicians consistently strive for excellence.The Fiber Insulation Board is the latest addition to the company's extensive product line, which includes a wide range of insulation solutions for various applications. Their dedication to innovation and customer satisfaction has made them a preferred choice for industry professionals seeking reliable and cost-effective insulation products.As the demand for energy-efficient and sustainable building materials continues to rise, the introduction of the Fiber Insulation Board is a timely and significant milestone for the company. With its unique blend of performance, sustainability, and reliability, the product is poised to capture a larger share of the market and set new industry standards.The company spokesperson further added, "We are confident that the Fiber Insulation Board will exceed the expectations of our customers and provide them with a superior insulation solution. Our team's hard work and dedication have made this innovation possible, and we are excited to see the positive impact it will have on the industry."With a strong commitment to innovation and sustainability, Fiber Insulation Board is well-positioned to meet the evolving needs of the industry and provide customers with high-quality insulation solutions. As they continue to expand their market presence and introduce new technologies, the company is set to maintain its leadership position in the industry.

Durable and Heat-Resistant Epoxy Sheet for Various Applications

Fr4 Epoxy Sheet, a versatile and highly durable material, has been making waves in the industry with its exceptional performance and wide range of applications. This innovative product, produced by leading polymer technology company {}, has been gaining popularity among electronics manufacturers, construction companies, and automotive industry for its excellent electrical insulation, high mechanical strength, and superior thermal resistance.With a long-standing reputation for producing high-quality polymers and composite materials, {} has been a trusted name in the industry for over two decades. The company's commitment to innovation and excellence has led to the development of Fr4 Epoxy Sheet, a product that has redefined the standards for performance, reliability, and versatility in the industry.Fr4 Epoxy Sheet is a composite material made from layers of woven fiberglass cloth impregnated with epoxy resin. This unique combination of materials gives the product exceptional strength and dimensional stability, making it an ideal choice for a wide range of applications. The material is known for its outstanding electrical insulation properties, making it a popular choice for printed circuit boards, electrical enclosures, and other electronic components.In addition to its electrical insulation properties, Fr4 Epoxy Sheet also offers high mechanical strength, making it suitable for use in heavy-duty applications such as construction and automotive components. The material's resistance to chemicals, moisture, and extreme temperatures further enhances its durability and reliability, making it a preferred choice for demanding applications in harsh environments.One of the key advantages of Fr4 Epoxy Sheet is its ease of fabrication and machining, allowing manufacturers to create custom shapes and sizes to meet their specific requirements. This versatility, combined with the material's exceptional performance and reliability, has made it a popular choice among engineers and designers seeking innovative solutions for their projects.{} is dedicated to providing customers with the highest quality materials and outstanding technical support. The company's team of experts works closely with customers to understand their specific needs and provide tailored solutions to meet their requirements. With a strong focus on research and development, {} continues to push the boundaries of innovation, constantly improving and expanding its product offerings to address the evolving needs of the industry.The company's commitment to sustainability and environmental responsibility is evident in its manufacturing processes and product designs. Fr4 Epoxy Sheet is manufactured using eco-friendly processes and raw materials, ensuring minimal impact on the environment while delivering exceptional performance and reliability.As the demand for high-performance materials continues to grow, {} remains at the forefront of the industry, offering innovative solutions that meet the highest standards of quality, performance, and reliability. With its unrivaled expertise, dedication to innovation, and commitment to customer satisfaction, {} continues to set the benchmark for excellence in the industry and is poised to lead the way in shaping the future of composite materials.

Developing sustainable and eco-friendly insulation materials for high voltage cables

In recent years, the world has witnessed an unprecedented demand for electricity due to the rise in population and rapid industrialization. As a result, high voltage insulation materials have become a crucial component in the transmission and distribution of electrical power. However, traditional crosslinking polyethylene (XLPE) insulation materials have failed to fulfill the requirements of environmental protection and sustainable development.But, some recent innovations in high voltage insulation materials have brought us a glimpse of hope. Researchers have made progress in developing eco-friendly insulation materials to meet the growing demand for electricity without compromising the environment. These eco-friendly insulation materials (need remove brand name) have been designed to offer excellent electrical, mechanical, and chemical properties that meet the high voltage insulation requirements for power transmission and distribution.One of the most significant advantages of these eco-friendly high voltage insulation materials is that they are non-toxic and do not emit harmful gases during production. Their eco-friendliness is based on using renewable resources and incorporating recycled materials while reducing greenhouse gas emissions.Moreover, these materials' enhanced properties make them safer to handle, more durable, and with greater resistance to temperature and harsh weather conditions. They perform better than traditional insulation materials in terms of electrical properties and thermal conductivity.New eco-friendly insulation materials have a higher breakdown strength and lower dielectric loss compared to traditional materials, making them ideal for high voltage power transmission and distribution. These insulation materials have already demonstrated their effectiveness in various pilot projects.In conclusion, while traditional XLPE insulation materials remain ubiquitous in the power industry, their environmentally unsustainable and toxic nature has led to their need for replacement by eco-friendly solutions. Thus, the development of these eco-friendly high voltage insulation materials is a crucial step towards achieving sustainable development in the power industry. Their implementation will promote a cleaner and more sustainable, eco-friendly future while satisfying the rapidly growing power demand. In short, if we want to move towards a greener future, we need to embrace these advancements in high voltage insulation materials. They play a critical role in the transition to clean, emission-free energy, all while ensuring seamless, reliable power transmission. Hopefully, we will continue to witness more innovations in this field and further accelerate the pace of sustainable development.

High-Quality Insulation Epoxy Fiberglass Sheets for Electrical Applications

Insulationepoxy Fiberglass Fr4 3240 Sheets have become a key material in the manufacturing industry due to their excellent insulation properties and high mechanical strength. These sheets are commonly used in electrical equipment, communication devices, and various industrial applications. With the increasing demand for high-quality insulation materials, companies are constantly striving to produce top-notch products to meet the market's needs.One of the leading manufacturers in this industry is {Company Name}, a well-established company with a proven track record of providing high-quality Fr4 3240 sheets to their customers. Established in {year}, {Company Name} has been at the forefront of innovation and has made a name for itself in the insulation material manufacturing industry. Their commitment to excellence, quality, and customer satisfaction has earned them a strong reputation in the market.{Company Name} specializes in the production of Insulationepoxy Fiberglass Fr4 3240 Sheets using state-of-the-art technology and thorough quality control processes. These sheets are made from high-quality fiberglass cloth impregnated with epoxy resin, resulting in a durable and reliable insulation material that meets international standards. The company's production facilities are equipped with advanced machinery and stringent manufacturing processes, ensuring that their products are of the highest quality.In addition to their commitment to product quality, {Company Name} also prioritizes environmental sustainability in their manufacturing processes. They adhere to strict environmental regulations and utilize sustainable practices to minimize their ecological footprint. This approach has not only contributed to a cleaner environment but has also helped the company build a positive image as a responsible corporate citizen.{Company Name} has a dedicated team of engineers, technicians, and quality control professionals who work tirelessly to ensure that every Fr4 3240 sheet meets the highest standards of performance and reliability. Their extensive research and development efforts have led to continuous improvements in their products, providing customers with cutting-edge insulation solutions that offer superior electrical and mechanical properties.The Insulationepoxy Fiberglass Fr4 3240 Sheets manufactured by {Company Name} are designed to withstand high temperatures, moisture, and a wide range of chemicals, making them ideal for various demanding applications. Whether used in electrical transformers, printed circuit boards, or other electronic devices, these sheets provide excellent insulation and mechanical support, contributing to the overall reliability and longevity of the end products.{Company Name} takes pride in its commitment to customer satisfaction, offering tailored solutions and comprehensive technical support to meet the specific needs of each client. Their team works closely with customers to understand their requirements and provide expert guidance on product selection, application, and best practices. This personalized approach has helped {Company Name} build long-lasting relationships with a wide range of customers, including major corporations, small businesses, and independent contractors.As the demand for high-quality insulation materials continues to grow, {Company Name} remains dedicated to meeting the evolving needs of the market. They are continuously expanding their product range, exploring new technologies, and investing in their manufacturing capabilities to ensure that they remain at the forefront of the industry. With a strong focus on quality, innovation, and customer-centric approach, {Company Name} is poised to continue its success and solidify its position as a leading manufacturer of Insulationepoxy Fiberglass Fr4 3240 Sheets.In conclusion, {Company Name} has established itself as a trusted and reliable supplier of high-quality insulation materials, particularly Insulationepoxy Fiberglass Fr4 3240 Sheets. Their commitment to excellence, product quality, and environmental sustainability sets them apart in the industry, making them the go-to choice for customers seeking top-notch insulation solutions. As they continue to innovate and expand their offerings, {Company Name} is well-positioned to meet the growing demand for high-performance insulation materials in the global market.

High-Quality Laminated Board Sheets for Your Next Project

Laminated Board Sheets: A Sustainable Solution for Modern ConstructionIn today's rapidly growing construction industry, the demand for durable and sustainable building materials is on the rise. With a focus on reducing environmental impact and increasing efficiency, contractors and builders are constantly seeking innovative solutions to meet these evolving needs. The use of Laminated Board Sheets has emerged as a game-changing solution, offering a combination of strength, sustainability, and versatility.Manufactured by {}, these board sheets are composed of multiple layers of wood veneer that are bonded together using high-quality adhesives. This lamination process results in a robust and durable product that is well-suited for a wide range of construction applications. Whether it's for flooring, roofing, wall cladding, or furniture production, Laminated Board Sheets offer exceptional performance and aesthetic appeal.One of the key advantages of Laminated Board Sheets is their sustainability. As the construction industry places increasing importance on environmentally friendly practices, the use of sustainable materials has become a top priority. The manufacturing process of these board sheets involves using wood from responsibly managed forests, ensuring that the environmental impact is minimized. In addition, the durability and longevity of the product contribute to reducing the need for frequent replacements, further enhancing its eco-friendly credentials.Furthermore, the versatility of Laminated Board Sheets makes them an ideal choice for modern construction projects. Their ability to withstand heavy loads and resist moisture and temperature fluctuations makes them suitable for both indoor and outdoor use. The boards can also be easily cut, shaped, and customized, allowing for greater flexibility in design and construction. This adaptability has made Laminated Board Sheets a popular choice among architects and designers who are looking to push the boundaries of traditional construction methods.In addition to their structural and environmental benefits, Laminated Board Sheets also offer a high level of fire resistance. This is particularly important in the construction industry, where safety and compliance with building codes are paramount. The boards have been developed to meet stringent fire safety standards, providing peace of mind to both builders and occupants.With a commitment to quality and innovation, {} has positioned itself as a leading provider of Laminated Board Sheets. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every board sheet meets the highest standards of performance and reliability. By investing in research and development, {} continues to push the boundaries of what is possible with laminated wood products, driving the industry forward with cutting-edge solutions.As the construction industry continues to evolve, the demand for sustainable and high-performance building materials will only continue to grow. In this context, Laminated Board Sheets represent a significant advancement in meeting these needs. With their blend of strength, sustainability, and versatility, these board sheets have the potential to redefine the standard for modern construction practices. With {} leading the way in their production and development, the future looks bright for this innovative solution.

Top 10 ESD (Electrostatic Discharge) Products for Protection

ESD G10 is the latest innovation by the leading technology company. Designed to meet the growing demand for high-performance and reliable electronic components, the ESD G10 is set to revolutionize the industry with its cutting-edge features and unmatched quality.With the increasing complexity of electronic devices, the need for superior ESD (electrostatic discharge) protection has become more critical than ever. The ESD G10 offers a comprehensive solution to this problem by providing exceptional protection against electrical overloads, ensuring the safety and reliability of sensitive electronic components.The ESD G10 is engineered with state-of-the-art materials and advanced technologies to deliver outstanding performance in a wide range of applications. Its robust construction and precision design make it suitable for use in various industries, including automotive, aerospace, telecommunications, and consumer electronics.In addition to its superior ESD protection capabilities, the ESD G10 also offers excellent thermal conductivity, ensuring efficient heat dissipation and increased component longevity. This feature is particularly beneficial for high-power applications where heat management is crucial for optimal performance.Furthermore, the ESD G10 is designed to meet the highest industry standards for quality and reliability. Rigorously tested and certified, this cutting-edge component provides the assurance of uncompromising performance and durability in the most demanding operating environments.The introduction of the ESD G10 underscores the company's commitment to innovation and excellence. With a proven track record of delivering exceptional electronic components, the company has solidified its position as a trusted partner for industry-leading solutions.By harnessing the latest advancements in technology and incorporating feedback from customers and industry experts, the company has been able to develop the ESD G10 as a game-changing product that will set new benchmarks for ESD protection and performance.In line with its dedication to sustainability and environmental responsibility, the company has ensured that the ESD G10 is manufactured using eco-friendly processes and materials. This demonstrates the company's commitment to minimizing its environmental footprint while delivering cutting-edge solutions to its customers.The launch of the ESD G10 represents a significant milestone for the company and reinforces its position as a leading innovator in the electronic components industry. With its unparalleled performance, robust construction, and commitment to quality, the ESD G10 is poised to make a lasting impact in the market and set new standards for ESD protection and reliability.As the industry continues to evolve and demand for high-performance electronic components grows, the ESD G10 is well-positioned to meet the needs of the most discerning customers and deliver exceptional value in a wide range of applications. With its advanced features and proven capabilities, the ESD G10 is set to become the go-to solution for superior ESD protection and reliable performance in the dynamic world of electronics.

Durable and Versatile Glass Fiber Reinforced Sheet: A Top Choice for Various Applications

[Company Name] Introduces Advanced Glass Fiber Reinforced Sheet for Superior Performance[City, State] - [Company Name], a leading manufacturer of advanced materials, is proud to announce the introduction of their new Glass Fiber Reinforced Sheet. This innovative product is designed to provide superior performance and durability for a wide range of applications.The Glass Fiber Reinforced Sheet is manufactured using a proprietary process that results in a high-strength, lightweight material. This makes it an ideal choice for applications where strength and durability are crucial, such as automotive components, aerospace parts, and industrial equipment.One of the key benefits of the Glass Fiber Reinforced Sheet is its exceptional strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is important, without compromising on structural integrity. The material also offers excellent resistance to corrosion, making it suitable for use in harsh environments.In addition to its impressive mechanical properties, the Glass Fiber Reinforced Sheet is also highly customizable. [Company Name] offers a range of options for thickness, color, and finish, allowing customers to tailor the material to their specific requirements. This flexibility makes it a versatile solution for a wide range of industries and applications."We are excited to introduce our new Glass Fiber Reinforced Sheet to the market," said [Name], [Title] at [Company Name]. "This material represents a significant advancement in the field of advanced materials, and we believe it will offer our customers a superior solution for their high-performance applications."[Company Name] has a proven track record of delivering innovative solutions to the market. With state-of-the-art manufacturing facilities and a team of experienced engineers and materials experts, the company is well-positioned to meet the growing demand for high-performance materials.The introduction of the Glass Fiber Reinforced Sheet further solidifies [Company Name]'s commitment to providing cutting-edge solutions to their customers. The company's dedication to research and development, coupled with their focus on quality and customer satisfaction, has established them as a trusted partner for businesses across a wide range of industries.In addition to the Glass Fiber Reinforced Sheet, [Company Name] offers a comprehensive range of advanced materials, including composites, plastics, and specialty alloys. Their extensive product portfolio, combined with their expertise in materials science and engineering, makes them a one-stop solution provider for companies seeking high-performance materials for their products and applications.As industries continue to demand materials that offer superior performance and durability, [Company Name] is poised to meet those needs with their innovative Glass Fiber Reinforced Sheet and other advanced materials. With a commitment to excellence and a focus on continuous improvement, the company is well-positioned to remain a leader in the field of advanced materials for years to come.For more information about [Company Name] and their advanced Glass Fiber Reinforced Sheet, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of advanced materials for a wide range of industries. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-performance materials for their products and applications. With a commitment to research and development, [Company Name] continues to deliver cutting-edge solutions to the market, helping their customers stay ahead of the competition.

Durable and Innovative Transparent Fiber Board Now Available

,including the uses, benefits, and potential impact of this innovative new material.-----------------------------Transparent Fiber Board: Revolutionizing the Construction IndustryThe construction industry is always evolving, and new materials and technologies are constantly being developed to improve efficiency, sustainability, and safety. One such innovation that has the potential to make a significant impact on the industry is the Transparent Fiber Board. This groundbreaking material, developed by a leading company in the field of advanced materials, has the potential to revolutionize the way buildings are constructed and designed.The Transparent Fiber Board is a transparent, lightweight, and strong material that is made from a combination of advanced fibers and a transparent polymer matrix. This unique combination of materials gives the board its exceptional strength and durability, making it suitable for a wide range of applications in the construction industry. Unlike traditional building materials, the Transparent Fiber Board allows natural light to pass through, making it an ideal solution for interior and exterior applications, particularly in architectural designs that prioritize natural lighting and transparency.One of the key features of the Transparent Fiber Board is its versatility. It can be used for a variety of applications, including wall cladding, roofing, flooring, and partitions. This makes it an excellent choice for architects and designers who are looking to create innovative and sustainable building designs. The board's transparency also opens up new possibilities for integrating natural light into buildings, reducing the need for artificial lighting and potentially decreasing energy consumption.In addition to its versatility, the Transparent Fiber Board offers a range of benefits that make it a superior choice compared to traditional building materials. Its lightweight nature makes it easy to handle and install, reducing labor costs and construction time. Furthermore, its high strength-to-weight ratio makes it an excellent choice for creating durable and long-lasting structures. Its transparency also adds a unique aesthetic appeal to buildings, creating a modern and futuristic look that is sure to impress and inspire.The benefits of the Transparent Fiber Board extend beyond its practical and aesthetic advantages. As a sustainable and environmentally friendly material, it aligns with the growing demand for eco-conscious construction solutions. The use of natural light to illuminate interior spaces reduces the reliance on artificial lighting, leading to reduced energy consumption and lower carbon emissions. Additionally, the materials used in the board's construction are fully recyclable, making it a truly sustainable option for the construction industry.The potential impact of the Transparent Fiber Board on the construction industry is vast. Its innovative design and sustainable characteristics have the potential to transform the way buildings are constructed, designed, and operated. Architects and designers will have the opportunity to create buildings with a focus on natural lighting, transparency, and sustainability, leading to more efficient and inspiring spaces. Developers and builders will benefit from the material's ease of installation and low maintenance requirements, resulting in cost savings and improved project timelines. With the Transparent Fiber Board, the construction industry can move towards a more sustainable and innovative future.The company behind the development of the Transparent Fiber Board, known for its expertise in advanced materials, has dedicated significant resources to research and development to bring this innovative material to the market. With a proven track record of producing high-quality and innovative materials, the company is poised to revolutionize the construction industry with the Transparent Fiber Board.In conclusion, the Transparent Fiber Board represents a significant advancement in the field of construction materials, offering a unique set of benefits and advantages that have the potential to transform the industry. Its transparency, strength, versatility, and sustainability make it an attractive choice for architects, designers, developers, and builders looking to create innovative and sustainable buildings. The company's commitment to excellence and innovation positions it as a leader in the development of advanced materials, and the introduction of the Transparent Fiber Board is a testament to its dedication to driving progress and change in the construction industry.

New G10 Sheet Revealed: An Innovative Material With Endless Applications

G10 Sheet, a leading manufacturer of advanced materials for the aerospace and defense industries, has recently announced a breakthrough in the development of a new composite material that promises to revolutionize the way aircraft and military vehicles are built.The new composite material, which has been in development for the past five years, is a result of G10 Sheet's commitment to innovation and excellence in materials engineering. This groundbreaking material is expected to be lighter, stronger, and more durable than any other existing material currently used in the aerospace and defense industries.The key to this new composite material's exceptional properties lies in its unique combination of [INSERT KEY FEATURES]. This innovative approach to material design has the potential to significantly reduce the weight of aircraft and military vehicles, improving fuel efficiency and increasing their overall performance.In addition to its lightweight and high-strength properties, the new composite material is also highly resistant to corrosion, heat, and other environmental factors. This makes it an ideal choice for use in extreme conditions, such as those experienced by aircraft and military vehicles in combat situations.The development of this new composite material represents a significant milestone in G10 Sheet's ongoing commitment to advancing the field of materials engineering. The company has a long history of developing cutting-edge materials for the aerospace and defense industries, and this latest innovation further solidifies its reputation as a leader in the field.G10 Sheet's expertise in materials engineering can be attributed to its state-of-the-art research and development facilities, as well as its team of highly skilled engineers and scientists. The company's dedication to pushing the boundaries of materials science has led to a number of breakthroughs in recent years, and the development of this new composite material is just the latest example of G10 Sheet's commitment to excellence.With this new composite material, G10 Sheet aims to provide its customers in the aerospace and defense industries with a game-changing solution that will help them improve the performance and efficiency of their products. The company is confident that this innovative material will open up new possibilities for the design and construction of aircraft and military vehicles, ultimately leading to safer and more advanced technologies.In light of this exciting announcement, G10 Sheet is poised to play a key role in shaping the future of the aerospace and defense industries. The company's dedication to pushing the boundaries of materials engineering and its track record of success make it a trusted partner for industry leaders seeking to stay at the forefront of technological advancements.As G10 Sheet continues to expand its portfolio of advanced materials, it is clear that the company will remain a driving force in the ongoing evolution of the aerospace and defense industries. With its commitment to excellence and its relentless pursuit of innovation, G10 Sheet is well-positioned to lead the way in developing the next generation of materials that will power the aircraft and military vehicles of the future.