Durable and Lightweight Fiberglass Composite Materials in the News

By:Admin

Established in [year], Fiberglass Composite has been at the forefront of creating advanced composite materials that are used in a variety of industries, including aerospace, automotive, marine, and construction. The company’s products are known for their durability, strength, and versatility, making them an ideal choice for a wide range of applications.

One of Fiberglass Composite’s most recent developments is its [product name], which has been garnering attention for its exceptional performance and reliability. The [product name] is a fiberglass composite that is engineered to meet the demanding requirements of modern applications. With its high strength-to-weight ratio and resistance to corrosion, the [product name] is a game-changer in the industry.

The [product name] is highly versatile and can be customized to meet specific requirements, making it an ideal choice for various applications. Whether it is used in aerospace components, automotive parts, marine equipment, or structural elements in construction, the [product name] delivers unmatched performance and durability.

Furthermore, Fiberglass Composite’s commitment to innovation and excellence sets it apart from its competitors. The company’s team of skilled engineers and researchers are constantly pushing the boundaries of composite materials, ensuring that their products are always at the forefront of technological advancements.

In addition to its commitment to product development, Fiberglass Composite also places a strong emphasis on sustainability and environmental responsibility. The company’s manufacturing processes are designed to minimize waste and energy consumption, and its products are designed to have a minimal impact on the environment. By prioritizing sustainability, Fiberglass Composite is not only meeting the needs of its customers but also contributing to a cleaner and healthier planet.

Another key factor that sets Fiberglass Composite apart is its dedication to customer satisfaction. The company works closely with its clients to understand their specific needs and provide tailored solutions that meet and exceed expectations. With a focus on building long-lasting partnerships, Fiberglass Composite ensures that its customers receive the support and expertise they need to succeed.

Fiberglass Composite’s [product name] is just one example of the company’s commitment to excellence and innovation. With a track record of delivering high-quality products and a dedication to serving its customers, Fiberglass Composite continues to be a driving force in the industry, leading the way in composite material technology.

As Fiberglass Composite continues to expand its product offerings and push the boundaries of composite materials, the company remains focused on its core values of innovation, quality, and customer satisfaction. With a solid foundation built on expertise and excellence, Fiberglass Composite is poised to remain a leader in the industry for years to come.

Company News & Blog

Discover the Benefits and Applications of Insulation Sheets for Effective Temperature Control

[Company Name] Introduces Innovative Insulation Sheet for Enhanced Energy Efficiency[date]In today's rapidly evolving world, energy conservation and environmental sustainability have become paramount concerns. As people increasingly recognize the importance of reducing carbon footprints and conserving energy, industries have responded by developing innovative solutions to enhance energy efficiency. In this regard, [Company Name], a leading provider of cutting-edge insulation products, has recently introduced an exceptional insulation sheet that promises to revolutionize the market.Derived from years of extensive research and development, [Company Name]'s newly launched insulation sheet is designed to address the growing demand for energy-efficient solutions across various sectors. By leveraging advanced materials and cutting-edge technologies, the company strives to provide its customers with a product that not only meets their insulation needs but surpasses expectations.At the core of [Company Name]'s insulation sheet is its exceptional design, incorporating state-of-the-art materials that enable improved thermal performance and energy conservation. Crafted with precision and attention to detail, the insulation sheet offers an unparalleled level of insulation. Its innovative composition allows for enhanced heat resistance, preventing unnecessary energy loss and minimizing energy consumption.The insulation sheet, which is available in various sizes and thicknesses, is incredibly versatile and can be adapted to meet a wide range of insulation requirements. Whether it is residential, commercial, or industrial applications, the sheet seamlessly integrates with diverse structures, ensuring effective thermal insulation and promoting energy efficiency.One of the key highlights of [Company Name]'s insulation sheet is its remarkable resistance to moisture and condensation. This crucial feature ensures that the insulation remains intact over prolonged periods, maintaining its optimum performance. By preventing the formation of moisture on the surface, the insulation sheet not only prolongs its lifespan significantly but also prevents the growth of mold and mildew, creating a healthier and safer environment.In an era characterized by increased awareness of sustainability, the insulation sheet offered by [Company Name] stands out for its commitment to environmental responsibility. The innovative composition of the sheet is free from harmful chemicals, making it an eco-friendly choice for architects, engineers, contractors, and homeowners aiming for sustainable building practices. By embracing this insulation solution, consumers can effectively reduce their energy demands and make a positive impact on the environment.As [Company Name] continues to make strides in the insulation industry, its commitment to quality and customer satisfaction remains unwavering. The company boasts a highly experienced team of professionals dedicated to providing exceptional service and support. With a comprehensive understanding of diverse market requirements, the team collaborates closely with clients to customize insulation solutions and ensure optimal results.Furthermore, [Company Name] has established a robust distribution network to ensure the availability of its insulation sheet nationwide. By strategically partnering with distributors and suppliers, the company aims to make its product easily accessible to customers across different regions.The launch of this innovative insulation sheet by [Company Name] presents an exciting opportunity for companies and individuals seeking to enhance their energy efficiency practices. With its superior thermal performance, resistance to moisture, and commitment to sustainability, this product is set to redefine insulation standards in various industries.As the world continues to grapple with climate change and energy conservation, innovative solutions like [Company Name]'s insulation sheet hold the promise of a more sustainable future. By choosing this groundbreaking product, individuals and organizations can actively contribute to the global effort of reducing energy consumption and mitigating the adverse effects of climate change.About [Company Name]:[Company Name] has been a leading manufacturer and provider of insulation products for over [number] years. With a strong commitment to research and development, the company consistently pushes the boundaries of energy efficiency and sustainability. Offering a wide range of insulation solutions, [Company Name] has earned a reputation for excellence, reliability, and customer satisfaction. For further information, please visit [Company Name]'s official website at [website] or contact their customer service team at [phone number].

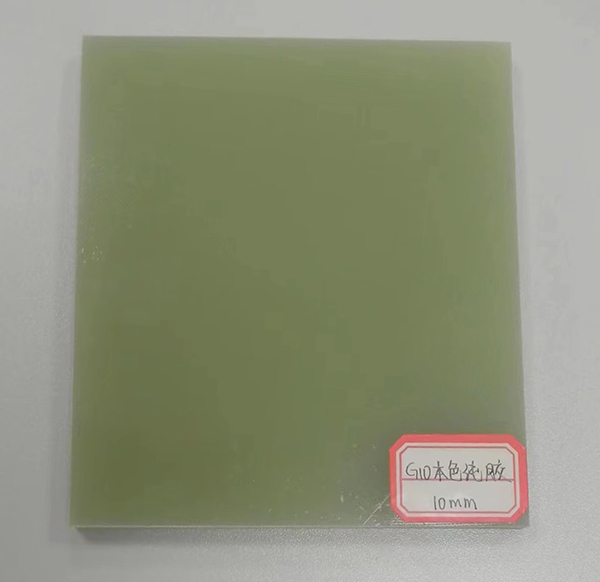

High-quality Epoxy Fiberglass Laminate Sheet: A Grade B Option for Enhanced Performance

The Grade B Epoxy Fiberglass Laminate Sheet, a high-quality industrial material, has gained widespread attention for its exceptional performance and reliability in a variety of applications. This versatile material has been acclaimed for its durability, electrical insulation properties, and resistance to heat and chemical corrosion, making it a popular choice in the manufacturing and electrical industries.The Grade B Epoxy Fiberglass Laminate Sheet is a composite material composed of a woven fiberglass cloth impregnated with an epoxy resin, which is then cured under high pressure and temperature. This process results in a strong and stable material that can withstand extreme conditions while maintaining its structural integrity. The laminate sheet is available in a variety of thicknesses and can be customized to meet specific requirements, making it suitable for a wide range of applications.One company that has been at the forefront of producing Grade B Epoxy Fiberglass Laminate Sheet is {}. With a strong focus on research and development, the company has continuously innovated to improve the quality and performance of its products. Utilizing advanced manufacturing techniques and quality control processes, {} has been able to consistently deliver high-quality Grade B Epoxy Fiberglass Laminate Sheet to its customers.In addition to its superior technical capabilities, {} has also distinguished itself through its dedication to environmental sustainability. The company has implemented eco-friendly practices in its production processes, ensuring that its products have minimal impact on the environment. This commitment to sustainability has been well-received by customers and industry partners, further solidifying {}'s reputation as a responsible and forward-thinking manufacturer.The Grade B Epoxy Fiberglass Laminate Sheet produced by {} has found applications in numerous industries, including electrical equipment, aerospace, automotive, and construction. Its excellent electrical insulation properties and heat resistance make it an ideal material for electrical insulation boards, transformer components, and circuit breakers. In the aerospace and automotive sectors, the material is utilized in the manufacturing of components that require high strength and durability. Additionally, in the construction industry, it is used for architectural and structural applications, thanks to its robustness and weather resistance.{}. has also developed advanced bonding techniques for Grade B Epoxy Fiberglass Laminate Sheet, allowing for seamless integration into complex manufacturing processes. This capability has enabled customers to leverage the material's unique properties in innovative ways, leading to the development of cutting-edge products that meet the highest industry standards.Furthermore, {}. offers comprehensive technical support and consultancy services, assisting customers in selecting the most suitable Grade B Epoxy Fiberglass Laminate Sheet for their specific needs. The company's dedicated team of experts provides valuable insights and guidance, ensuring that customers are equipped with the knowledge and resources to maximize the performance of the material in their applications.Looking ahead, {}. is committed to continuing its research and development efforts to further enhance the performance and versatility of Grade B Epoxy Fiberglass Laminate Sheet. By staying at the forefront of technological advancements, the company aims to address the evolving needs of its customers and contribute to the advancement of various industries.In conclusion, the Grade B Epoxy Fiberglass Laminate Sheet has emerged as a highly sought-after material for its exceptional properties and reliability. Thanks to the innovative manufacturing capabilities and environmental consciousness demonstrated by {}, the material has been able to make a significant impact across diverse industries. With a strong commitment to quality, innovation, and sustainability, the company is well-positioned to continue leading the way in the production of Grade B Epoxy Fiberglass Laminate Sheet and drive progress across multiple sectors.

High Quality Insulation Materials Meet CTI 600V Standards in China's G11/Epgc203 Line

China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V: Leveraging Superior Performance in Electrical ApplicationsFor electrical engineers and manufacturers, sourcing reliable insulation materials is vital. Poor quality insulation can cause short circuits, fires, and other hazards, harming people and equipment. Among the many materials available, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V stand out for their superior performance in electrical applications.The CTI (Comparative Tracking Index) is a measure of the electrical breakdown resistance of insulating materials under severe conditions. China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V have a CTI rating of 600V, which means they can withstand high voltage and extreme temperatures without breaking down. This makes them ideal for use in transformers, motors, generators, and other electrical equipment.China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are made of epoxy resin and glass fiber cloth, which gives them exceptional mechanical strength, heat resistance, and flame retardancy. They can withstand temperatures up to 180°C continuously and up to 300°C for short periods without losing their properties. They are also self-extinguishing when exposed to flames, which prevents fires from spreading.Another advantage of China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V is their low dielectric constant and dissipation factor, which means they have low losses and high insulation resistance. This translates into more efficient and reliable electrical systems with reduced energy consumption and maintenance costs.Moreover, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are easy to process and shape into various forms, including sheets, rods, tubes, and molded parts. They can be machined, drilled, and tapped into precise dimensions and tolerances. They can also be laminated with metals and other materials to form composites with enhanced properties.China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are widely used in industries such as aerospace, marine, automotive, and electronics, where high-performance insulation is critical for safety and performance. They are also exported to many countries, including the United States, Europe, and Southeast Asia, where they have earned a reputation for quality and reliability.One of the leading manufacturers of China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V is {Company X}, a Chinese company that specializes in the production and distribution of advanced composite materials. Founded in 2008, {Company X} has grown into a global player in the composite industry, with a wide range of products and services that cater to the needs of various markets and customers.{Company X} is committed to providing high-quality products that meet or exceed international standards and customer expectations. They have a state-of-the-art production facility that is equipped with the latest technology and machinery for mixing, impregnating, curing, and testing composite materials. They also have a team of experienced engineers and technicians who work closely with customers to develop customized solutions for their specific applications.{Company X} has achieved several certifications, such as ISO 9001, ISO 14001, and OHSAS 18001, that demonstrate their commitment to quality, environmental protection, and occupational health and safety. They have also invested in research and development to improve their products and processes and stay ahead of the competition.{Company X} is determined to expand its market share and reputation by combining innovation, quality, and service excellence. They welcome inquiries from customers worldwide and are ready to provide technical support, samples, and quotations upon request.In conclusion, China G11/Epgc203 Insulation Materials CTI 600V and CTI 600V are high-performance insulation materials that offer superior properties for electrical applications. They are made of epoxy resin and glass fiber cloth, which give them mechanical strength, heat resistance, and flame retardancy. They have a CTI rating of 600V, which makes them suitable for high voltage and extreme temperature environments. They are also easy to process and shape into various forms and can be customized to meet specific requirements. {Company X} is one of the leading manufacturers of these materials and offers a range of products and services that meet or exceed international standards.

Choosing the Best Rigid Insulation Board for Enhanced Insulation Performance

Title: Rigid Insulation Board: Revolutionizing the Building IndustryIntroductionInnovation in the construction sector continues to transform the way buildings are designed and constructed, with a particular focus on energy-efficient solutions. Rigid Insulation Board, a cutting-edge product developed by a leading manufacturing company, is at the forefront of this revolution. In this article, we will explore the exceptional features and benefits of Rigid Insulation Board, highlighting its potential to enhance sustainable building practices. I. Understanding Rigid Insulation BoardRigid Insulation Board is an advanced insulation material that is revolutionizing the construction industry. Manufactured by esteemed producer, [Company Name], it is engineered to enhance energy efficiency, promote sustainability, and ensure maximum thermal insulation for residential, commercial, and industrial buildings.1. Unparalleled Thermal PerformanceRigid Insulation Board boasts exceptional thermal performance, offering high R-values, which measure the material’s resistance to heat flow. Its superior insulation properties minimize heat transfer, leading to reduced energy consumption, increased comfort levels, and lower utility costs for buildings.2. Versatility and FlexibilityThe product's versatility and flexibility enable it to be used in various construction applications. Rigid Insulation Board is available in different sizes, thicknesses, and strengths, allowing architects, contractors, and builders to customize their insulation needs effectively. This adaptability ensures the efficiency and optimization of insulation requirements for any structure.3. Durability and LongevityBacked by rigorous quality control measures, Rigid Insulation Board is engineered to last. The product's robust, rigid structure ensures durability, withstanding adverse weather conditions and offering long-term insulation performance. This quality significantly reduces maintenance costs and extends the lifespan of buildings, both major considerations for sustainable construction practices.II. Environmental BenefitsAs the demand for eco-friendly building materials grows, Rigid Insulation Board possesses several environmentally friendly advantages that make it a preferred choice within the construction industry.1. Reduced Carbon FootprintRigid Insulation Board aids in reducing the carbon footprint of a building. By minimizing heat transfer, it lessens the reliance on heating, ventilation, and air conditioning (HVAC) systems, thereby decreasing the associated greenhouse gas emissions. The decreased energy consumption promotes responsible, sustainable building practices in line with global efforts to combat climate change.2. Exceptional Moisture ResistanceWater intrusion is a common challenge faced by buildings, leading to structural damage and mold growth. Rigid Insulation Board's exceptional moisture resistance prevents water absorption and vapor transmission, safeguarding buildings against moisture-related issues. By mitigating these problems, it promotes healthy indoor environments and preserves the integrity of the building.III. Real-World ApplicationsRigid Insulation Board has earned widespread acclaim in various construction projects due to its remarkable performance and versatility. Its vast range of applications includes:1. Residential ConstructionIn residential construction, Rigid Insulation Board offers excellent insulation properties, enhancing energy efficiency and reducing thermal bridging. Its installation in walls, roofs, and floors ensures optimal comfort and reduced energy consumption for homeowners.2. Commercial and Industrial BuildingsCommercial and industrial buildings also benefit significantly from Rigid Insulation Board's capabilities. Its use in large-scale structures improves insulation efficiency, resulting in substantial energy savings and creating more sustainable workspaces.3. Cold Storage and Refrigeration FacilitiesRigid Insulation Board is an ideal choice for cold storage and refrigeration facilities, where temperature control and energy efficiency are paramount. It guarantees a consistent, thermal barrier necessary for preserving perishable goods while minimizing energy consumption.ConclusionRigid Insulation Board's innovative features and exceptional thermal insulation have positioned it as a game-changer in the construction industry. Its contribution to energy-efficient, sustainable building practices and its potential for reducing carbon footprints make it an indispensable choice for architects, contractors, and builders alike. As the demand for eco-friendly solutions continues to rise, Rigid Insulation Board remains at the forefront of the revolution, revolutionizing the construction landscape, one building at a time.

High-Quality Fiberglass Sheets - 4x8 in Size - Ideal for Various Applications

Title: Versatile and Durable Fiberglass Sheets: The go-to Solution for all Construction NeedsIntroduction:In the world of construction materials, fiberglass sheets have emerged as a versatile and durable option for a wide range of applications. These sheets, measuring 4x8 feet, are widely used due to their exceptional strength, flexible solutions, and resistance to various environmental factors. Renowned for their ability to withstand extreme weather conditions and offer immense structural support, fiberglass sheets have become the go-to solution for many industries. This article aims to shed light on the benefits and applications of these fiberglass sheets while omitting any specific brand name to maintain unbiased information.1. The Unmatched Strength of Fiberglass Sheets:Fiberglass sheets, made from reinforced glass fibers embedded in a polymer matrix, offer unmatched strength and durability. With a tensile strength several times higher than steel, fiberglass sheets are capable of withstanding heavy loads, making them ideal for various construction projects, such as roofing, flooring, and cladding. These sheets are also resistant to corrosion, which ensures a longer lifespan compared to traditional materials.2. Versatility and Application Areas:The versatility of fiberglass sheets cannot be understated, as they find widespread use across multiple industry sectors. In the construction industry, these sheets are used for wall panels, partitions, insulation, and concrete formwork. Additionally, their lightweight nature allows for easy transportation and installation, making them a highly sought-after material for commercial buildings, warehouses, and residential projects. Fiberglass sheets are also utilized in the transportation sector, specifically for manufacturing automotive parts, boats, and aircraft due to their excellent corrosion resistance and durability.3. Superior Resistance to Environmental Factors:Fiberglass sheets possess exceptional resistance to environmental factors, including moisture, chemicals, and UV radiation. This resistance makes them an optimal choice for outdoor applications. Their non-conductive nature is particularly advantageous in electrical installations, ensuring safety and preventing electrical accidents. Moreover, fiberglass sheets are fire-resistant and do not release toxic gases, enhancing the overall safety of any structure they are incorporated into.4. Cost-Effectiveness and Low Maintenance:The cost-effectiveness of fiberglass sheets is an added benefit for builders and construction companies. Despite their outstanding properties, these sheets are relatively affordable compared to alternative materials. Furthermore, fiberglass sheets require minimal maintenance due to their resistance to rot, termites, and warping commonly associated with wood or metal. This low-maintenance feature helps reduce long-term costs, making them an economically sound choice for construction projects.5. Eco-Friendly Material:With increasing global environmental concerns, the demand for eco-friendly construction materials is on the rise. Fiberglass sheets meet this requirement as they are manufactured with minimal impact on the environment. They are 100% recyclable and can be reused in various applications, reducing the carbon footprint associated with traditional construction materials.Conclusion:Fiberglass sheets, sized at 4x8 feet, have revolutionized the construction industry due to their unmatched strength, versatility, and resistance to environmental factors. As a superior alternative to traditional construction materials, fiberglass sheets provide durability, cost-effectiveness, and ease of installation. With their ability to withstand extreme weather conditions and resistance to corrosion and fire, these sheets are the go-to solution for builders, architects, and engineers alike. As the construction industry continues to evolve, fiberglass sheets are expected to play an increasingly crucial role in shaping the buildings and structures of the future.

High-Quality Grade B Epoxy Fiberglass Laminate Sheet: What You Need to Know

Grade B Epoxy Fiberglass Laminate Sheet (brand name removed), is a high-quality and reliable material that is widely used across various industries for its excellent insulation and mechanical properties. Manufactured by {} - a leading provider of advanced materials and solutions for the electrical, electronics, and thermal management industries - this epoxy fiberglass laminate sheet has garnered a reputation for its superior performance and durability.The Grade B Epoxy Fiberglass Laminate Sheet is a thermosetting material that is made by impregnating layers of fiberglass with an epoxy resin and then compressing them under high pressure. This results in a material that is highly resistant to heat, moisture, and chemicals, making it an ideal choice for applications that require high-performance insulation and protection.The sheet is available in a variety of thicknesses and sizes, making it suitable for a wide range of applications, including electrical insulation, structural components, and printed circuit boards. Its excellent dielectric properties and high mechanical strength make it a preferred choice for use in transformers, switchgear, motors, and generators, where reliable insulation is essential for the safety and performance of the equipment.In addition to its exceptional electrical and mechanical properties, the Grade B Epoxy Fiberglass Laminate Sheet also offers good dimensional stability and resistance to flame, making it a versatile material that can withstand harsh operating conditions. The material is also easy to machine and fabricate, allowing for customized designs and precise manufacturing of components.The Grade B Epoxy Fiberglass Laminate Sheet is manufactured by {} using advanced production techniques and quality control processes to ensure consistent and reliable performance. The company is committed to delivering high-quality materials that meet the stringent requirements of its customers and exceed industry standards.With a global presence and a strong reputation for innovation and excellence, {} has established itself as a trusted partner for companies seeking advanced materials and solutions for their applications. The company's extensive experience and expertise in the field of advanced materials enable it to offer comprehensive support and technical assistance to its customers, helping them to optimize their designs and achieve the best performance from the Grade B Epoxy Fiberglass Laminate Sheet.As industries continue to demand high-performance materials that can withstand extreme conditions and deliver reliable performance, the Grade B Epoxy Fiberglass Laminate Sheet from {} has proven to be a top choice for engineers and designers looking for a durable and versatile material for their applications. With its superior insulation and mechanical properties, this material is poised to continue making significant contributions to the advancement of various industries, including electrical, electronics, and thermal management.In conclusion, the Grade B Epoxy Fiberglass Laminate Sheet from {} stands as a testament to the company's commitment to providing high-quality materials and solutions that meet the evolving needs of its customers. With its exceptional performance and reliability, this material is set to remain a preferred choice for a wide range of applications, helping companies to achieve superior insulation and protection for their critical components and systems.

New Resistance Sheet: The Latest in Resistance Training Technology

Resistance Sheet, a leading provider of innovative technology solutions, has recently announced the launch of their newest product, the Resistance Sheet Pro. This cutting-edge product is designed to revolutionize the way individuals and businesses approach fitness and training.The Resistance Sheet Pro is a high-quality, durable resistance band that can be used for a wide range of exercises, including strength training, flexibility exercises, and physical therapy. Its unique design and construction make it the perfect choice for individuals of all fitness levels, from beginners to fitness enthusiasts.One of the key features of the Resistance Sheet Pro is its versatility. The band can be easily adjusted to provide different levels of resistance, making it suitable for a variety of exercises and training routines. Its compact and portable design also makes it ideal for use at home, in the gym, or while traveling.In addition to its practical design, the Resistance Sheet Pro is also equipped with a range of features that set it apart from traditional resistance bands. These include built-in sensors that can track performance and provide real-time feedback, as well as a companion app that offers a wide range of guided workouts and training programs."We are thrilled to introduce the Resistance Sheet Pro to the market," said [Company CEO]. "This product represents the culmination of years of research and development, and we believe it has the potential to revolutionize the way people approach their fitness and training goals."In addition to its innovative features, the Resistance Sheet Pro is also backed by [Company]'s commitment to quality and customer satisfaction. The company is known for its exceptional customer service and dedication to producing high-quality products that stand the test of time.As part of the launch of the Resistance Sheet Pro, [Company] is offering a range of special promotions and discounts to customers. This includes the opportunity to pre-order the product at a discounted rate, as well as special bundles that include additional accessories and training materials.With the launch of the Resistance Sheet Pro, [Company] continues to solidify its position as a leader in the fitness and technology industries. The company's dedication to innovation and quality has earned it a strong reputation among customers and industry professionals alike.As the fitness and wellness industries continue to evolve, [Company] remains at the forefront of new developments, consistently striving to provide cutting-edge solutions that help individuals and businesses achieve their health and fitness goals.For more information about the Resistance Sheet Pro and other products offered by [Company], please visit their website or contact their customer service team.

Durable and Heat-Resistant Epoxy Sheet for Various Applications

Fr4 Epoxy Sheet, a versatile and highly durable material, has been making waves in the industry with its exceptional performance and wide range of applications. This innovative product, produced by leading polymer technology company {}, has been gaining popularity among electronics manufacturers, construction companies, and automotive industry for its excellent electrical insulation, high mechanical strength, and superior thermal resistance.With a long-standing reputation for producing high-quality polymers and composite materials, {} has been a trusted name in the industry for over two decades. The company's commitment to innovation and excellence has led to the development of Fr4 Epoxy Sheet, a product that has redefined the standards for performance, reliability, and versatility in the industry.Fr4 Epoxy Sheet is a composite material made from layers of woven fiberglass cloth impregnated with epoxy resin. This unique combination of materials gives the product exceptional strength and dimensional stability, making it an ideal choice for a wide range of applications. The material is known for its outstanding electrical insulation properties, making it a popular choice for printed circuit boards, electrical enclosures, and other electronic components.In addition to its electrical insulation properties, Fr4 Epoxy Sheet also offers high mechanical strength, making it suitable for use in heavy-duty applications such as construction and automotive components. The material's resistance to chemicals, moisture, and extreme temperatures further enhances its durability and reliability, making it a preferred choice for demanding applications in harsh environments.One of the key advantages of Fr4 Epoxy Sheet is its ease of fabrication and machining, allowing manufacturers to create custom shapes and sizes to meet their specific requirements. This versatility, combined with the material's exceptional performance and reliability, has made it a popular choice among engineers and designers seeking innovative solutions for their projects.{} is dedicated to providing customers with the highest quality materials and outstanding technical support. The company's team of experts works closely with customers to understand their specific needs and provide tailored solutions to meet their requirements. With a strong focus on research and development, {} continues to push the boundaries of innovation, constantly improving and expanding its product offerings to address the evolving needs of the industry.The company's commitment to sustainability and environmental responsibility is evident in its manufacturing processes and product designs. Fr4 Epoxy Sheet is manufactured using eco-friendly processes and raw materials, ensuring minimal impact on the environment while delivering exceptional performance and reliability.As the demand for high-performance materials continues to grow, {} remains at the forefront of the industry, offering innovative solutions that meet the highest standards of quality, performance, and reliability. With its unrivaled expertise, dedication to innovation, and commitment to customer satisfaction, {} continues to set the benchmark for excellence in the industry and is poised to lead the way in shaping the future of composite materials.

Discover the Benefits of Electrical Insulation Fiber Board for Optimal Safety

Title: Groundbreaking Electrical Insulation Fiber Board Innovates Safety and EfficiencyIntroduction:In today's rapidly advancing technological landscape, the demand for efficient and safe electrical insulation solutions is higher than ever. A recent breakthrough by [Company Name], a leading pioneer in the field, has introduced a game-changing product—a cutting-edge Electrical Insulation Fiber Board. This revolutionary board promises to transform the way we insulate electrical systems, offering enhanced safety, reliability, and efficiency across various industries. 1. Importance of Electrical Insulation:Effective electrical insulation is crucial for safeguarding electrical systems against potential failures, disruptions, and accidents. Traditional insulation materials often face limitations in terms of resistance, durability, and cost-effectiveness. As a result, the search for innovative solutions that address these challenges persistently continues.2. The Birth of [Company Name]:[Company Name], a renowned manufacturer in the electrical insulation industry, has been a trailblazer in developing advanced products that meet the evolving needs of the market. Their extensive research and development efforts have solidified their reputation as a trusted provider of cutting-edge insulation solutions.3. The Revolutionary Electrical Insulation Fiber Board:[Company Name]'s latest innovation, the Electrical Insulation Fiber Board, is an outcome of their relentless pursuit of excellence. This groundbreaking product represents a significant leap forward in insulation technology, offering unparalleled benefits across multiple applications.4. Advanced Features and Benefits:The Electrical Insulation Fiber Board boasts a myriad of impressive qualities that set it apart from traditional insulation materials. Photovoltaic modules, electric vehicles, transformers, and generators are among the many applications that stand to benefit from this innovative solution. Some key features of the Electrical Insulation Fiber Board include: a) Thermal Stability: With exceptional heat resistance, the board significantly reduces the risk of electrical system malfunctions caused by elevated temperatures. b) Superior Dielectric Strength: The board's exceptional dielectric properties ensure optimal electrical insulation, preventing short circuits and resulting in increased safety. c) Mechanical Strength: The Electrical Insulation Fiber Board is sturdy and durable, capable of withstanding mechanical stress and vibrations, thereby guaranteeing long-lasting performance. d) Chemical Resistance: Its resistance to chemicals, including acids and alkalis, makes the board suitable for a wide range of industrial environments. e) Lightweight Construction: The board's lightweight nature makes it easier to handle and install, while also contributing to cost-savings in terms of transportation and support structures. f) Environmental Sustainability: [Company Name] remains committed to environmental conservation, and the Electrical Insulation Fiber Board reflects this ethos by being eco-friendly and recyclable.5. Versatile Applications:The Electrical Insulation Fiber Board finds applications in a multitude of industries, including renewable energy, transportation, power generation, and more. Its adaptability enables it to be utilized in high-voltage transformers, solar inverters, electric vehicle chargers, and other critical electrical equipment.6. Advancing Safety Standards:By investing in [Company Name]'s Electrical Insulation Fiber Board, organizations can significantly enhance the safety standards of their electrical infrastructure. This leads to reduced downtime, improved system reliability, and increased peace of mind for operators.7. Collaborations and Future Enhancements:[Company Name] continues to collaborate with industry leaders, research institutions, and customers to further enhance the Electrical Insulation Fiber Board's capabilities. Ongoing research and development efforts aim to meet the evolving industry requirements and pave the way for even more efficient and reliable electrical insulation solutions.Conclusion:As the demand for reliable and efficient electrical insulation solutions continues to grow, [Company Name]'s breakthrough Electrical Insulation Fiber Board emerges as a game-changer. With its advanced features, versatility, and commitment to environmental sustainability, this innovative product sets new benchmarks in the field of electrical insulation. By investing in this groundbreaking solution, industries can enhance safety levels, boost operational efficiency, and ensure seamless performance across their electrical systems.