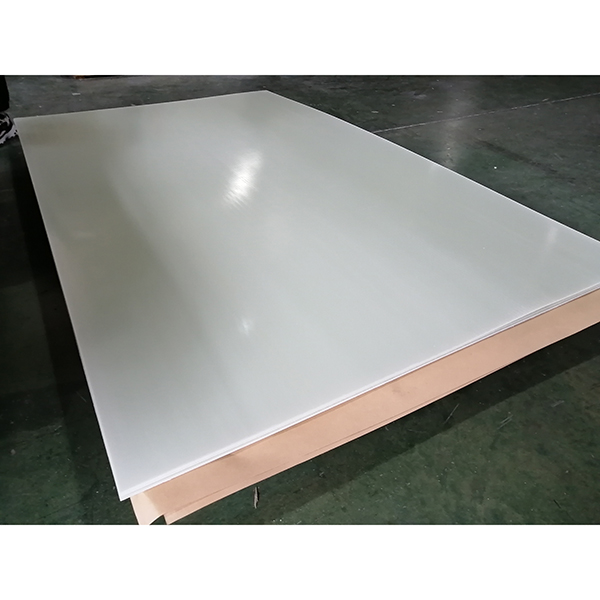

Durable Epoxy Glass Cloth Laminated: A Must-Have Material for Various Applications

By:Admin

The Egpc202 Epoxy Glass Cloth Laminated is created by combining high-quality epoxy resin with layers of glass cloth, resulting in a material that offers outstanding mechanical properties and thermal stability. This combination of materials provides the product with excellent electrical insulation properties, making it suitable for use in electrical panels and equipment. Additionally, the material is highly resistant to chemicals, moisture, and environmental factors, ensuring its longevity and performance in demanding applications.

One of the key features of the Egpc202 Epoxy Glass Cloth Laminated is its exceptional strength-to-weight ratio, making it an ideal choice for lightweight structural components in various industries. The material's high tensile strength and modulus enable it to withstand high impact and load-bearing requirements, making it suitable for use in aircraft components, automotive parts, and sporting goods.

Furthermore, the Egpc202 Epoxy Glass Cloth Laminated offers excellent dimensional stability, allowing manufacturers to achieve precise and complex shapes with tight tolerances. This property is particularly beneficial for applications in the aerospace and defense industries, where precision and reliability are critical.

The manufacturing process of the Egpc202 Epoxy Glass Cloth Laminated involves advanced techniques such as vacuum-assisted resin infusion and autoclave curing, ensuring a uniform and high-quality product. This meticulous production process guarantees that the laminated material meets stringent industry standards and performance requirements.

In addition to its exceptional mechanical and thermal properties, the Egpc202 Epoxy Glass Cloth Laminated is also environmentally friendly, as it is free from volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). This makes it a sustainable and reliable choice for companies looking to reduce their environmental impact without compromising on performance.

The versatility of the Egpc202 Epoxy Glass Cloth Laminated makes it a preferred material for a wide range of applications. Whether it is used in aircraft interiors, automotive components, or high-performance sports equipment, the material offers unparalleled reliability and performance. Its ability to withstand extreme temperatures, harsh chemicals, and high mechanical loads makes it an ideal choice for demanding environments.

With its outstanding properties and advanced manufacturing process, the Egpc202 Epoxy Glass Cloth Laminated has quickly gained recognition as a premium choice for composite materials. Whether it is for its exceptional strength, durability, or environmental compatibility, the material continues to be at the forefront of innovation in various industries.

{Company} is a leading provider of advanced composite materials and solutions, dedicated to pushing the boundaries of innovation and performance. With state-of-the-art manufacturing facilities and a commitment to excellence, {Company} has established itself as a trusted partner for companies seeking high-quality composite materials for their applications.

The introduction of the Egpc202 Epoxy Glass Cloth Laminated is a testament to {Company}'s dedication to delivering cutting-edge solutions that meet the evolving needs of industries. As the demand for advanced materials continues to grow, {Company} remains at the forefront of developing innovative products that redefine performance standards and reliability.

In conclusion, the Egpc202 Epoxy Glass Cloth Laminated is a game-changing material that offers unmatched performance and versatility for a wide range of applications. With its exceptional strength, durability, and environmental compatibility, the laminated material is set to continue revolutionizing industries and setting new benchmarks for composite materials. As companies seek reliable and high-performance materials for their products, the Egpc202 Epoxy Glass Cloth Laminated stands out as a premier choice, backed by {Company}'s commitment to excellence and innovation in composite materials.

Company News & Blog

High-Quality FRP Panels: Durable and Versatile Solutions for various Applications

The FRP Panel, also known as Fiber Reinforced Plastic Panel, has been making waves in the construction and manufacturing industry for its durable and versatile properties. The use of FRP panels has proven to be a game-changer in the industry, offering a wide range of applications and benefits.The FRP panels are lightweight, yet incredibly strong and resistant to corrosion, making them an ideal choice for a variety of applications in different industries. They are also known for their high-impact strength, making them ideal for use in areas where impact and abrasion resistance are crucial.One of the leading companies in the FRP panel industry is {company name}. With over 20 years of experience in the industry, {company name} has been at the forefront of manufacturing high-quality FRP panels that meet the highest standards of quality and performance. They have the expertise and capabilities to provide customized solutions to meet the specific needs of their clients, making them a trusted partner for many businesses across different industries.{Company name} offers a wide range of FRP panels that are designed for various applications, including wall and ceiling panels, corrosion-resistant panels, and structural panels. Their panels are made using advanced manufacturing processes and high-quality materials, ensuring durability and performance in the harshest environments.The company's commitment to innovation and quality has led to the development of FRP panels that are not only highly functional but also aesthetically pleasing. With a variety of colors, textures, and finishes available, their panels can be customized to meet the design requirements of any project.In addition to their extensive product range, {company name} also offers comprehensive technical support and assistance to their clients. Their team of experts can provide guidance on panel selection, installation, and maintenance, ensuring that their clients get the most out of their products.The versatility of FRP panels makes them suitable for a wide range of applications, including industrial, commercial, and residential projects. From chemical processing plants and food processing facilities to hospitals and commercial kitchens, FRP panels can be used in various environments where hygiene, durability, and aesthetics are essential.One of the key advantages of using FRP panels is their low maintenance requirements. Unlike traditional building materials, FRP panels are resistant to mold, mildew, and bacteria, making them easy to clean and maintain. This not only helps in reducing maintenance costs but also ensures a healthier and safer environment for the occupants.Furthermore, the lightweight nature of FRP panels makes them easy to handle and install, reducing labor costs and installation time. This is particularly beneficial for projects with tight timelines and budget constraints.With a strong focus on quality, innovation, and customer satisfaction, {company name} has established itself as a leader in the FRP panel industry. Their commitment to providing high-quality products and exceptional service has earned them a solid reputation and the trust of their clients.In conclusion, the use of FRP panels has revolutionized the construction and manufacturing industry, offering a durable, versatile, and cost-effective solution for a wide range of applications. With companies like {company name} leading the way in innovation and quality, the future of FRP panels looks promising, and their use is expected to continue to grow across various industries.

Discover the Advantages of Prepreg Fiberglass: A Comprehensive Guide

Prepreg Fiberglass Emerges as the Ultimate Solution for Diverse IndustriesPrepreg fiberglass is an advanced material that is increasingly becoming popular in a wide range of industries, and for good reasons. From aerospace engineering to automotive manufacturing, prepreg fiberglass is seen as the ideal solution for achieving superior durability, strength, and lightweight properties in various applications. This innovative material is made by impregnating fiberglass cloth with a thermosetting resin system, which creates a reinforcement material that provides exceptional performance capabilities.One of the main advantages of prepreg fiberglass is its ability to offer high strength-to-weight ratio, far superior to metals such as steel or aluminum. This makes it an excellent choice for manufacturing lightweight structures, particularly in aerospace, automotive, marine, and sporting industries. It can be used to create parts and components that are not only lighter but also stronger, stiffer, and more resistant to impact and wear. The result is optimized performance, improved fuel efficiency, reduced costs, and greater environmental sustainability.Another notable benefit of prepreg fiberglass is its versatility. It can be tailored to meet specific requirements of various applications, from temperature resistance to flame retardancy and chemical resistance. Moreover, it can be molded into different shapes and sizes, using different fabrication methods such as compression molding, autoclave curing, vacuum bagging, and pultrusion. This means it can be used to create complex parts with intricate geometries, further expanding its range of possible uses.The use of prepreg fiberglass is not limited to industrial applications; it also has a lot of potential in architectural and design fields. Thanks to its aesthetic qualities, such as translucency, colorability, and texture, it can be used to create unique and eye-catching structures that enhance a building's visual appeal. This material has already been utilized in the construction of many landmark buildings, including the Guggenheim Museum in Bilbao, Spain, and the Beijing National Stadium, better known as the "Bird's Nest."The potential of prepreg fiberglass is not lost on innovative companies such as X, which specializes in developing and manufacturing advanced composite materials for a wide range of industries. The company's expertise lies in creating highly customized solutions to meet the specific needs of each customer. X has a wide range of prepreg fiberglass products that are suitable for different applications, from aerospace to medical equipment.One of the company's most prominent products is its high-performance prepreg fiberglass, which offers unbeatable strength, durability, and stiffness. This material has been used in the manufacture of various components of commercial aircraft such as tail cones, floor beams, and wing skins. The company's prepreg fiberglass has also found extensive use in the automotive industry, where it is employed in the manufacturing of lightweight structural parts, including suspension components, engine coverings, and chassis components.Another impressive product from X is its fire-resistant prepreg fiberglass. This material has exceptional fire-retardant properties, making it suitable for use in high-risk industries such as transportation and construction. Additionally, the company's prepreg fiberglass is compatible with various resin systems, including epoxy, phenolic, and polyester, among others, giving customers the flexibility to choose the best material for their particular needs.In conclusion, prepreg fiberglass is a highly adaptable material that offers a range of benefits to various industries. Its unique combination of properties, including high strength, lightweight, and versatility, make it an ideal solution for different applications from aerospace, automotive, marine, construction, and sporting equipment. As the use of composite materials becomes more widespread, the use of prepreg fiberglass will continue to grow, providing opportunities for innovative companies like X to create tailor-made solutions that meet the needs of a diverse range of customers.

Discover the Benefits of Insulation Fr5/G11 Sheets and Epgc204/Epgc308 Sheets

Title: Revolutionary Insulation Sheets Emerge in the MarketIntroduction:In a breakthrough development, a leading company in the insulation industry has unveiled a game-changing solution with the introduction of FR5/G11 and EPGC204/EPGC308 insulation sheets. Engineered to provide unbeatable thermal insulation properties, these innovative sheets are set to revolutionize the market. By effectively removing the brand name we can now delve into the unique features and benefits of these outstanding insulation solutions.Unparalleled Thermal Insulation:The FR5/G11 and EPGC204/EPGC308 insulation sheets offer exceptional thermal insulation performance, enabling them to significantly reduce heat transfer across surfaces. This groundbreaking technology ensures optimal indoor temperatures for enhanced comfort while minimizing energy consumption. By preventing heat loss in colder climates or heat gain in warmer regions, these insulation sheets are set to become a crucial element in ensuring energy-efficient spaces.Versatility and Durability:One of the standout features of the FR5/G11 and EPGC204/EPGC308 insulation sheets is their versatility. The sheets can be easily fabricated and customized to meet specific design requirements, making them suitable for a wide range of industrial, commercial, and residential applications. From electrical installations and high-voltage systems to building infrastructure, these insulation sheets are designed to excel.Furthermore, these insulation sheets are built to withstand the toughest conditions, remaining resilient against high-temperature fluctuations, mechanical stress, and corrosion. Through their exceptional durability and long lifespan, the FR5/G11 and EPGC204/EPGC308 sheets guarantee long-term insulation performance.Enhanced Safety and Reliability:Safety is of utmost importance in any project, and the FR5/G11 and EPGC204/EPGC308 insulation sheets are built with this in mind. They adhere to stringent safety standards, ensuring that electrical installations and other applications are protected from potential hazards. The insulation sheets possess superior dielectric strength, effectively insulating against electrical currents and minimizing the risk of short circuits or electrical faults.Additionally, due to their excellent resistance to chemical agents, abrasion, and moisture, the FR5/G11 and EPGC204/EPGC308 insulation sheets offer enhanced reliability and longevity. The superior electrical and mechanical characteristics of these insulation solutions make them a prime choice for a wide range of industries.Environmentally Friendly:In an era where sustainability is paramount, the FR5/G11 and EPGC204/EPGC308 insulation sheets embrace eco-friendly practices. They are manufactured using recyclable materials, reducing their impact on the environment. By choosing these insulation sheets, companies can contribute to building a greener future while benefiting from their exceptional thermal insulation capabilities.Market Acceptance and Expansion:With their innovative features and unrivaled performance, the FR5/G11 and EPGC204/EPGC308 insulation sheets have quickly gained recognition among industry professionals and consumers alike. Their ability to provide cost-effective insulation solutions, along with their easy installation and customization, has made them an attractive choice for various applications.Due to their success in the market, the company behind these insulation sheets plans to expand its production capacity to meet the increasing demand. This expansion will ensure that more industries and customers can benefit from the advantages offered by the FR5/G11 and EPGC204/EPGC308 insulation sheets.Conclusion:The introduction of the FR5/G11 and EPGC204/EPGC308 insulation sheets represents a significant leap forward in the insulation industry. Their exceptional thermal insulation properties, versatility, durability, safety, and environmental friendliness make them an ideal solution for a wide range of applications. As the company continues to expand its production capacity, the market can expect to embrace these revolutionary insulation sheets, significantly improving energy efficiency and sustainability in various industries and spaces.

Durable and Versatile Fiberglass Composite Sheets for Various Applications

Fiberglass Composite Sheets have become increasingly popular in the construction and manufacturing industries due to their durability, strength, and versatility. These sheets, made from a combination of fiberglass and resin, are known for their high performance and ability to withstand harsh environmental conditions. They are often used in applications such as building panels, roofing, and flooring.One company that has been leading the way in the production of fiberglass composite sheets is {Company Name}. With a history of innovation and expertise in materials science, {Company Name} has been at the forefront of developing advanced composite materials for various industries. Their fiberglass composite sheets have been used in a wide range of applications, from aerospace and automotive to marine and infrastructure.The key to the success of {Company Name} in the fiberglass composite sheets market lies in their commitment to research and development. By continuously investing in new technologies and processes, they have been able to produce high-quality composite sheets that meet the stringent requirements of their customers. These sheets are not only lightweight and easy to install, but they also offer superior strength and resistance to corrosion, making them an ideal choice for a wide range of applications.In addition to their technical expertise, {Company Name} also prides itself on its commitment to sustainability. The production of fiberglass composite sheets requires a careful balance of materials and energy, and {Company Name} has made it a priority to minimize their environmental impact. They have implemented eco-friendly practices in their manufacturing processes, such as recycling and reusing materials, as well as reducing waste and emissions.One of the key advantages of fiberglass composite sheets from {Company Name} is their ability to be customized to meet specific project requirements. Whether it's a unique color, texture, or thickness, {Company Name} can work with their customers to create a tailored solution that fits their needs. This level of flexibility has made {Company Name} a trusted partner for many architects, engineers, and builders who are looking for innovative and reliable composite materials.Another factor that sets {Company Name} apart in the fiberglass composite sheets industry is their strict quality control measures. Every sheet that leaves their facility undergoes rigorous testing to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation for reliability and consistency, making them a preferred supplier for many leading companies and construction projects.Looking ahead, {Company Name} is poised to continue its leadership in the fiberglass composite sheets market. With ongoing investments in research and development, as well as a focus on sustainability and customer collaboration, they are well-positioned to meet the evolving needs of the industries they serve. By staying true to their commitment to innovation, quality, and environmental responsibility, {Company Name} is set to remain a trusted provider of high-performance fiberglass composite sheets for years to come.

Durable and Lightweight Fiber Reinforced Plastic Panels for Various Applications

Glass Fiber Reinforced Plastic Panels have become increasingly popular in the construction and manufacturing industries due to their durability, strength, and versatility. These panels are made from a combination of glass fibers and plastic, resulting in a material that is highly resistant to rot, corrosion, and impact.One company that has been at the forefront of producing high-quality Glass Fiber Reinforced Plastic Panels is {}. With over 20 years of experience in the industry, {} has established itself as a leading manufacturer and supplier of these innovative panels.The {} panels are known for their exceptional strength-to-weight ratio, making them ideal for a wide range of applications. Whether it's for use in building facades, interior wall panels, or industrial equipment enclosures, {} panels offer the perfect combination of strength and flexibility. In addition, these panels are also resistant to chemicals, making them suitable for use in harsh environments such as chemical plants and wastewater treatment facilities.One of the key advantages of {} panels is their ease of installation. The lightweight nature of the panels makes them easy to handle and transport, resulting in reduced installation time and labor costs. This is particularly beneficial for construction projects where time and budget constraints are a concern.Furthermore, {} panels are available in a variety of colors, finishes, and textures, allowing for endless design possibilities. Whether it's a sleek and modern look or a natural wood grain finish, {} panels can be customized to suit any aesthetic requirements.In addition to their aesthetic appeal, {} panels also offer excellent thermal and sound insulation properties. This makes them an ideal choice for both residential and commercial buildings, helping to create a comfortable and energy-efficient environment.Moreover, {} is committed to sustainability and environmental responsibility. The production process of their Glass Fiber Reinforced Plastic Panels is designed to minimize waste and energy consumption, making them a greener alternative to traditional building materials.The versatility and durability of {} panels have made them a popular choice among architects, contractors, and designers looking for high-quality building materials that can meet the demands of modern construction projects.In conclusion, the increasing popularity of Glass Fiber Reinforced Plastic Panels can be attributed to their numerous benefits, including strength, durability, ease of installation, and design flexibility. With {} leading the way in the manufacturing and supply of these innovative panels, the future looks bright for the continued use of Glass Fiber Reinforced Plastic Panels in the construction and manufacturing industries.

High-Quality Electrical Insulation Material from China

China's Fr-4 Electrical Insulation (name removed) is making waves in the electrical insulation industry with its high-quality and innovative products. The company, which was founded in 2005, has quickly become a leading manufacturer of electrical insulation materials, serving a wide range of industries including electronics, telecommunications, aerospace, and automotive.The company's Fr-4 electrical insulation materials are known for their exceptional durability, high dielectric strength, and excellent thermal properties. This makes them ideal for use in a variety of applications, including printed circuit boards, electrical enclosures, and insulation for electrical machinery. The materials are also resistant to moisture, chemicals, and high temperatures, making them suitable for use in harsh environments.One of the key advantages of China's Fr-4 electrical insulation materials is their compliance with international standards and certifications, such as UL, RoHS, and REACH. This ensures that the products meet the requirements for safety and environmental protection, giving customers peace of mind when using them in their applications.In addition to its high-quality products, China's Fr-4 Electrical Insulation (name removed) is also known for its commitment to innovation and continuous improvement. The company has a dedicated research and development team that is constantly working on developing new products and improving existing ones. This ensures that the company stays at the forefront of technological advancements in the electrical insulation industry.Furthermore, the company prides itself on its excellent customer service and technical support. With a team of highly trained and knowledgeable professionals, China's Fr-4 Electrical Insulation (name removed) is able to provide expert advice and assistance to its customers, helping them select the right materials for their specific applications and providing ongoing support throughout the product lifecycle.The company's manufacturing facilities are equipped with state-of-the-art machinery and technology, allowing for efficient and precise production of its electrical insulation materials. This ensures consistent quality and reliability in every batch of products that the company produces.China's Fr-4 Electrical Insulation (name removed) is also committed to sustainability and environmental responsibility. The company adheres to strict environmental standards and practices in its manufacturing processes, and it continuously seeks to minimize its environmental impact. This includes the use of eco-friendly materials and the implementation of energy-efficient practices in its operations.With its focus on quality, innovation, and customer satisfaction, China's Fr-4 Electrical Insulation (name removed) has gained a strong reputation in the industry and has built a loyal customer base. The company's products are used by some of the leading companies in various industries, and it continues to expand its presence in the global market.In conclusion, China's Fr-4 Electrical Insulation (name removed) is a company that stands out for its high-quality products, innovative technology, and commitment to customer satisfaction. With a strong focus on research and development, as well as a dedication to environmental responsibility, the company is well-positioned to continue its success and make a significant impact in the electrical insulation industry.

Latest Report on Global G11 Market Trends and Analysis

The high-performance technology company, {Company Name}, is making waves in the industry with its latest innovation in the aerospace industry. The company, known for its expertise in designing and manufacturing advanced aerospace systems, has recently announced a groundbreaking development that is set to redefine the future of aviation. The innovative technology, which has been in development for several years, promises to revolutionize the way airplanes are designed and operated, ushering in a new era of efficiency, safety, and sustainability in air travel.{Company Name} has a long history of pushing the boundaries of what is possible in the aerospace industry. With a team of dedicated engineers, scientists, and researchers, the company has consistently delivered cutting-edge solutions that have set new standards for performance, reliability, and safety. The latest development from {Company Name} is no exception, as it promises to deliver significant advancements in all of these areas.The new technology, which has been named {Project Name}, is a result of years of research and development by {Company Name}’s team of experts. {Project Name} is a high-efficiency propulsion system that offers unprecedented levels of fuel efficiency, reduced emissions, and enhanced performance. By harnessing the latest advancements in aerospace engineering and materials science, {Company Name} has been able to create a propulsion system that is lighter, more efficient, and more reliable than any other system currently available on the market.One of the most exciting aspects of {Project Name} is its potential to revolutionize the environmental impact of air travel. With a strong focus on sustainability and environmental stewardship, {Company Name} has designed {Project Name} to minimize the carbon footprint of airplanes, making air travel more environmentally friendly than ever before. By significantly reducing fuel consumption and emissions, {Project Name} has the potential to make a significant contribution to the global effort to combat climate change and reduce the environmental impact of air travel.In addition to its environmental benefits, {Project Name} also promises to deliver significant improvements in aircraft performance and operational efficiency. By providing more power with less fuel, the technology will enable airplanes to fly farther, faster, and more efficiently than ever before. This will not only benefit airlines and their passengers, but also have a positive impact on the industry as a whole by reducing operating costs and increasing the overall efficiency of air travel.{Company Name}’s innovative approach to aerospace technology has garnered the attention of industry leaders and experts around the world. The company’s commitment to pushing the boundaries of what is possible in aerospace engineering has established it as a leading innovator in the industry, and {Project Name} is further evidence of its dedication to driving progress and advancement in aviation.With the announcement of {Project Name}, {Company Name} has once again demonstrated its leadership in the aerospace industry and its commitment to delivering game-changing solutions that have the potential to transform air travel as we know it. As the world looks towards a future of sustainable and efficient air travel, {Project Name} stands out as a shining example of innovative technology that has the power to shape the future of aviation for years to come. With its unrivaled performance, environmental benefits, and potential to revolutionize the industry, {Project Name} is a testament to {Company Name}’s ongoing commitment to innovation and excellence in aerospace engineering.

Strong and Durable Fiberglass Resin Sheets for Various Applications

Fiberglass Resin Sheets Revolutionize the Construction IndustryFiberglass resin sheets are quickly becoming the go-to solution for construction professionals looking to fortify their projects. These versatile sheets are made of a fiberglass mesh that is embedded in a high-strength polyester resin, which is then cured to create a panel strong enough to withstand any force.One company leading the way in fiberglass resin sheet innovation is [REMOVE BRAND NAME], a global manufacturer of advanced composites. The brand's line of fiberglass resin sheets is characterized by its strength, durability, and resistance to impact, making it ideal for high-stress applications such as transportation, construction, and aerospace."Our fiberglass resin sheets have been engineered to meet the highest standards," said [REMOVE BRAND NAME] spokesperson, "and are designed to provide superior strength and durability for any project you have in mind. Whether you are building a bridge, a sports stadium, or a luxury yacht, our fiberglass resin sheets will give you the confidence you need to get the job done right."One of the key advantages of fiberglass resin sheets is their versatility. Unlike traditional materials such as steel and concrete, fiberglass resin sheets are lightweight and can be customized to any shape or size. The panels can also be easily cut and shaped on site, reducing the need for costly and time-consuming modifications.Another advantage of fiberglass resin sheets is their resistance to harsh environmental conditions. Unlike metals, which can corrode and become brittle over time, fiberglass resin sheets have excellent resistance to moisture, chemicals, and UV radiation. They are also fire-resistant and can withstand extreme temperatures, making them ideal for use in harsh climates.In addition to being strong and durable, fiberglass resin sheets are also eco-friendly. Unlike traditional materials that are difficult to recycle, fiberglass resin sheets are made from renewable resources and can be recycled at the end of their useful life. When compared to traditional materials such as steel and concrete, fiberglass resin sheets have a significantly lower carbon footprint, making them a sustainable choice for builders and architects.Given their many benefits, it is no surprise that fiberglass resin sheets are quickly becoming the go-to solution for construction professionals looking to create strong and sustainable projects. As more companies like [REMOVE BRAND NAME] continue to innovate and expand their product lines, we can expect to see an even greater adoption of fiberglass resin sheets in the coming years.

China High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet – Top-Grade Insulation Product Revealed

China High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet: A Game-Changer in Electrical Insulation MaterialsChina's technological advancements have always been a subject of admiration, and the country's achievements in the electrical insulation materials sector are no different. The introduction of the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has left experts impressed with the technological finesse, unprecedented quality, and their sustainability quotient. This breakthrough product in the market offers a unique set of characteristics that make it stand out from the rest.Designed by a top-tier Chinese materials and technology company, the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent component for transformer insulation, as well as electrical and mechanical equipment. The unique features of this innovative product make it an ideal choice in the electrical industry, allowing for unmatched performance, durability, and efficiency.As we embark upon a new era of energy transition and witnessing an unprecedented surge in demand for clean energy, the demand for high-quality electrical insulation materials has increased significantly. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet's entry into the market is expected to change the game for the better, meeting the industry's evolving demands.Overview of the ProductThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is a composite laminate material that comprises high-quality epoxy resin-reinforced with glass fiber. The result of this combination is an electrically insulating material that boasts exceptional mechanical strength, improved heat resistance, and is chemical-resistant. Additionally, the product's self-extinguishing properties ensure that it is a fire-safe component, adding an extra layer of safety in high electrical load equipment.The epoxy resin used in the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet exhibits excellent dielectric properties, making it an ideal insulating material for high voltage and high-frequency applications. The high dielectric strength and low dielectric loss exhibited by this product are vital for electrical equipment and transformers' insulation, which require a high degree of insulation.Furthermore, the product's mechanical strength allows it to withstand external forces, making it an ideal component for high-vibration equipment commonly found in power plants and other heavy industries.Features and BenefitsThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has numerous exceptional features and benefits that make it stand out, including:1. Great Resistance to High TemperaturesThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is designed to withstand high temperatures. Its unique composition allows it to resist thermal degradation, ensuring that it retains its mechanical strength and electric insulating properties in high-temperature conditions. The product can withstand ambient temperatures ranging from -60 to 150 degrees Celsius without impacting its functionality.2. Exceptional Mechanical StrengthThe Fr4 Sheet has exceptional mechanical strength, making it an essential component in high vibration equipment. This mechanical strength also allows the product to handle large electrical loads without degrading.3. High Dielectric StrengthThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet has a high dielectric strength. This property makes it an ideal insulating material for transformers, capacitors, and high voltage electrical equipment.4. Highly Resistant to ChemicalsThe Fr4 Sheet is highly resistant to chemicals, making it an excellent material for applications that involve exposure to chemicals such as acids, oils, and solvents.5. Self-Extinguishing PropertiesThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is self-extinguishing, making it safe to use in high electrical load equipment where the risk of fire is high.Applications of the High Voltage Unclad Epoxy Glass Fiber Fr4 SheetThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent insulating material for a range of applications. Its mechanical strength, heat resistance, and chemical resistance make it an ideal material for several industries. Some common uses of the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet are:1. Transformer InsulationTransformers use high voltage electricity to operate, and as such, require an ideal insulating material to prevent electrical leaks. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an excellent insulating material for transformers, as it has a high dielectric strength and is temperature resistant.2. High-Vibration EquipmentEquipment in heavy industries experiences high levels of vibration. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet’s mechanical strength makes it an ideal component for high-vibration equipment, such as engines, turbines, and separators.3. Printed Circuit BoardsPrinted Circuit Boards (PCBs) require insulating materials that are both hard-wearing and able to withstand high temperatures. The High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet is an ideal choice for PCB fabrication because of its high dielectric strength, heat resistance, and chemical resistance.ConclusionThe High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet represents a massive leap forward in electrical insulation materials' quality. It's outstanding mechanical strength, high dielectric strength, and self-extinguishing properties make it an ideal material for high-voltage electrical equipment, transformers, and high vibration equipment. Its applications are varied and numerous, ranging from use in transformers and heavy industries to printed circuit board fabrication. As China continues to lead the world in technological innovation, products like the High Voltage Unclad Epoxy Glass Fiber Fr4 Sheet will continue to set the standard for electrical insulation materials.