Guide to Understanding Electrical Insulation Pressboard for Industrial Use

By:Admin

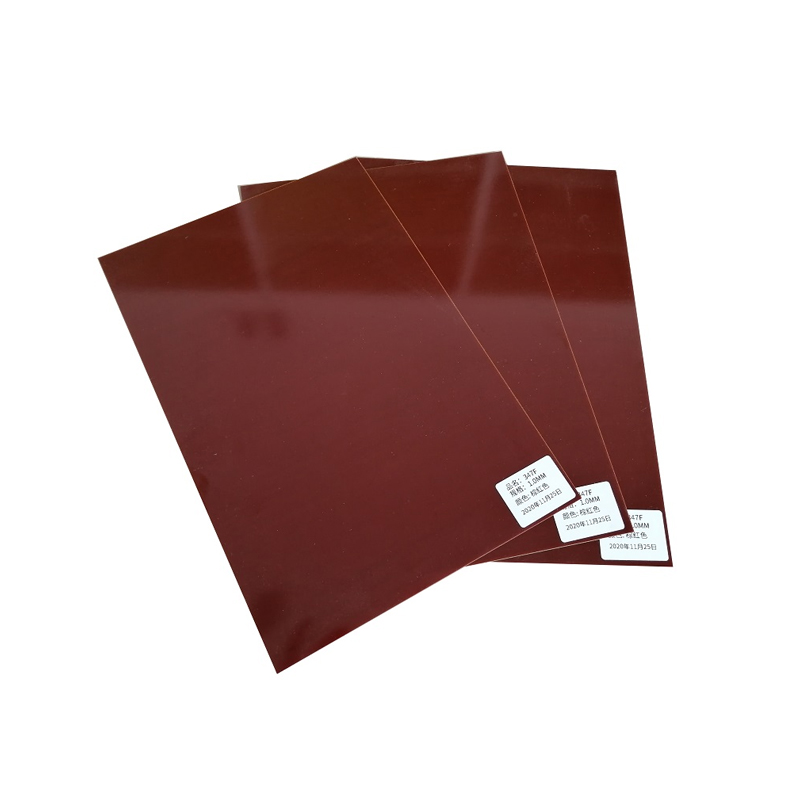

In recent years, the demand for high-quality Electrical Insulation Pressboard has risen significantly, driven by the growing need for reliable and efficient electrical infrastructure to support the increasing demands of modern society. As a result, the market for Electrical Insulation Pressboard has become increasingly competitive, with companies striving to innovate and develop superior products to meet the evolving needs of the industry.

One company that has made significant strides in the development of advanced Electrical Insulation Pressboard is {Company}. With a strong focus on research and development, {Company} has become a leading provider of high-quality Electrical Insulation Pressboard, recognized for its superior performance, durability, and reliability. The company's commitment to innovation and excellence has earned it a reputation as a trusted partner for electrical equipment manufacturers and utilities worldwide.

Established in {Year}, {Company} has a proven track record of delivering innovative solutions for the electrical industry. The company's state-of-the-art manufacturing facilities are equipped with advanced technology and processes, allowing for the production of top-of-the-line Electrical Insulation Pressboard that meets the highest industry standards. In addition, {Company}'s team of experienced engineers and technical experts are dedicated to continuously improving and optimizing their products, ensuring that they remain at the forefront of technological advancements in the field of electrical insulation.

One of {Company}'s core strengths lies in its commitment to sustainability and environmental responsibility. The company places great emphasis on using ecologically friendly materials and processes in its manufacturing operations, ensuring that its products have minimal impact on the environment. Furthermore, {Company} is dedicated to reducing waste and energy consumption, further contributing to its sustainable and ethical business practices.

{Company}'s dedication to excellence and innovation has not gone unnoticed in the industry. The company has received numerous accolades and certifications for its outstanding products and contributions to the field of electrical insulation. With a strong global presence, {Company} has established itself as a reliable and trusted partner for companies and organizations in need of high-quality Electrical Insulation Pressboard.

Looking ahead, {Company} remains committed to pushing the boundaries of what is possible in electrical insulation technology. The company continues to invest in research and development, exploring new materials and manufacturing processes to further enhance the performance and capabilities of its Electrical Insulation Pressboard. Additionally, {Company} is focused on expanding its global reach, forging new partnerships and collaborations to bring its innovative solutions to new markets and customers.

In conclusion, {Company} stands as a shining example of excellence and innovation in the field of electrical insulation. With its unwavering commitment to quality, sustainability, and technological advancement, the company has solidified its position as a leader in the industry, trusted and revered by customers and partners alike. As the demand for superior Electrical Insulation Pressboard continues to grow, {Company} is well-positioned to meet and exceed the evolving needs of the market, driving the industry forward with its cutting-edge solutions.

Company News & Blog

Simple Methods for Measuring FR-4 Foil Thickness in PCB Manufacturing

When it comes to working with FR-4, one of the most crucial parameters to consider is the thickness of the copper foil on the PCB. However, it is not always easy to determine this parameter, especially if the manufacturer does not readily share this information.Thankfully, there are a few methods that engineers and technicians can use to measure the thickness of the foil on FR-4. Here are some of the most popular options:1. Micrometer: A micrometer is a precision tool used to measure small distances or thicknesses. When measuring the foil thickness on FR-4, a micrometer with a range of 0-1 inch and a resolution of 0.0001 inch can be used to achieve accurate results.2. Cross-Sectioning: Cross-sectioning involves cutting a small slice of the PCB and examining it under a microscope to determine the thickness of the copper layer. Although this technique is more time-consuming and invasive than others, it is also one of the most accurate options available.3. X-ray Fluorescence: X-ray fluorescence (XRF) is a non-destructive method used to analyze the elemental composition of a material. This technique can be used to determine the thickness of copper foil on FR-4 by analyzing the XRF signals from the material. However, XRF equipment can be expensive and may not be accessible to everyone.In addition to these methods, it is important to note that different brands of FR-4 may have slightly different foil thicknesses. Therefore, it is always a good idea to consult the manufacturer's specifications or contact them directly to get accurate information.Overall, while determining the foil thickness on FR-4 may require some effort, the results are well worth it. Knowing this parameter can help ensure the proper functionality and reliability of PCBs in various applications. Keywords: FR-5 sheet, copper foil, thickness, micrometer, cross-sectioning, X-ray fluorescence.

Top 5 Best Insulation Panels for Your Home

Insulation Panel Company Announces Breakthrough TechnologyInsulation Panels is a leading provider of insulation products to the construction and building industry. The company has recently announced the launch of its new, breakthrough insulation panel technology that can help to improve energy efficiency in buildings while reducing costs.According to a spokesperson for the company, "Our new insulation panel technology is a game-changer for the industry. It offers superior thermal resistance, making it the perfect solution for colder climates. Additionally, our insulation panels have excellent air and moisture barriers, which results in a much more energy-efficient building."The insulation panels are made from a combination of high-density foam and a reflective layer that helps to reflect radiant heat back into the building. This design helps to maintain a comfortable temperature in all seasons, making it perfect for use in residential and commercial buildings alike.One of the key features of this innovative insulation panel technology is its exceptional fire resistance. It can stop the spread of flames for up to two hours, making it the ideal choice for structures that require increased fire protection.Insulation Panels are available in a range of sizes, making them suitable for a variety of applications. They are also incredibly easy to install, helping to reduce installation times and labor costs.The company's insulation panels are also environmentally friendly, boasting low VOC (volatile organic compound) emissions. This means that they are a safer choice for the environment and for the people who will be using these buildings.One of the key advantages of Insulation Panels' products is that they can help reduce energy costs for homeowners and businesses alike. By reducing the amount of energy required to heat or cool a building, this new technology can help to reduce energy bills significantly. This has the added benefit of reducing a building's carbon footprint, making it a more sustainable choice."A lot of people are looking to reduce their energy consumption and carbon footprint," says the company spokesperson. "Our insulation panels are the perfect solution for this. They use the latest technology to keep buildings comfortable and energy-efficient while remaining incredibly cost-effective."In addition to its new insulation panel technology, the company also offers a range of other insulation products and services. These include traditional batt insulation, as well as spray foam, rigid board insulation, and even custom insulation solutions.Insulation Panels have been serving the construction and building industry for over 20 years. They have a strong reputation for providing high-quality insulation products at extremely competitive prices. The company's experienced staff can also help customers choose the best insulation solution for their needs and answer any questions they may have.With its new breakthrough technology, Insulation Panels is set to continue leading the way in the insulation industry, providing its customers with the latest and most advanced insulation products and technologies on the market.

Durable Fiberglass FR5: A Strong and Reliable Material for Various Applications

The use of fiberglass FR5 as a key material in the manufacturing industry has been steadily increasing due to its exceptional properties and versatility. [Company name], a leading manufacturer of fiberglass FR5, has been at the forefront of this development, providing high-quality fiberglass products to meet the growing demands of various industries.[Company name] is a renowned company with a strong reputation in the fiberglass industry. With a focus on innovation and quality, the company has established itself as a trusted provider of fiberglass FR5 and other related products. Their commitment to excellence and customer satisfaction has enabled them to build long-lasting relationships with clients worldwide.The use of fiberglass FR5 has become essential in many industrial applications due to its exceptional strength, electrical insulation, and resistance to heat and chemicals. This makes it an ideal material for manufacturing electrical and electronic components, as well as in the construction of industrial equipment and infrastructure. The demand for high-performance materials like fiberglass FR5 is expected to continue to grow as industries strive for more efficient and durable solutions.One of the key advantages of fiberglass FR5 is its excellent resistance to high temperatures and fire, making it a preferred choice for applications where safety is paramount. The material's low thermal conductivity and high mechanical strength make it ideal for use in high-temperature environments, such as in the aerospace and automotive industries. Additionally, fiberglass FR5 is also an excellent electrical insulator, making it suitable for various electrical and electronic applications.[Company name] has been at the forefront of developing advanced fiberglass FR5 materials that meet the evolving needs of the industry. Their state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their products consistently meet the highest industry standards. The company's commitment to research and development has led to the introduction of innovative fiberglass FR5 materials that offer superior performance and reliability.In addition to offering standard fiberglass FR5 products, [Company name] also specializes in customizing solutions to meet the specific requirements of their clients. This flexibility has made them a preferred partner for many companies in various industries, as they can rely on [Company name] to provide tailored solutions that meet their unique needs.The growing demand for fiberglass FR5 has led [Company name] to expand its production capacity and streamline its operations to meet the increasing market demand. The company's investments in technology and infrastructure have enabled them to enhance their manufacturing capabilities and develop new and improved fiberglass FR5 products that offer even greater performance and durability.As the global economy continues to recover and industries ramp up their production, the demand for high-performance materials like fiberglass FR5 is expected to soar. [Company name] is well-positioned to capitalize on this trend, with its extensive experience and expertise in fiberglass manufacturing. Their commitment to quality and innovation makes them a trusted partner for companies seeking reliable and high-quality fiberglass FR5 products.In conclusion, the use of fiberglass FR5 has become increasingly prevalent in various industries due to its exceptional properties and versatility. [Company name] has been a key player in this development, providing high-quality fiberglass FR5 products and customized solutions to meet the growing demands of the industry. With their commitment to excellence and innovation, [Company name] is poised to continue leading the way in the fiberglass manufacturing industry.

How Electrical Laminated Sheet is Revolutionizing the Industry

[News Content]Electrical Laminated Sheet Revolutionizes Power Distribution EfficiencyIn today's rapidly advancing world, technological advancements play a crucial role in shaping the landscape of various industries. Power distribution is one such sector that consistently necessitates innovation to meet growing demands and improve efficiency. Enter Electrical Laminated Sheet, a groundbreaking development designed to transform the way electricity is distributed.Electrical Laminated Sheet, developed by cutting-edge materials engineering company {}, boasts an array of features that make it an ideal choice for power distribution applications. With its superior electrical insulation properties, excellent mechanical strength, and high temperature resistance, this innovative solution ensures optimal performance in even the most demanding environments.The electrical laminated sheet category has traditionally been dominated by outdated materials, resulting in limited efficiency and effectiveness. However, with this latest offering from {}, the industry will witness a paradigm shift. The unique composition of the Electrical Laminated Sheet facilitates reduced energy losses during power transmission, thereby enhancing overall system efficiency.Furthermore, the material's remarkable mechanical strength provides exceptional protection against mechanical stress, vibration, and thermal expansion, ensuring long-term reliability. This enhanced durability translates to reduced maintenance costs and increased operational lifespan, making it an economically viable choice for power distribution systems worldwide.A significant advantage of Electrical Laminated Sheet is its ability to withstand high temperatures. Traditionally, extreme heat adversely affects the performance of electrical insulation materials, leading to compromised safety and reliability. The innovative design of this new solution equips it with the capability to operate flawlessly at elevated temperatures, thereby ensuring uninterrupted power distribution even in harsh conditions.Beyond its exceptional technical specifications, the Electrical Laminated Sheet also satisfies industry demands for sustainable solutions. The materials used in its manufacturing prioritize environmental safety and adhere to strict regulatory standards. With the growing focus on environmental consciousness, this product aligns perfectly with the shift towards sustainable practices in the power distribution sector.The advent of Electrical Laminated Sheet marks an exciting milestone in the power distribution industry. Its ability to revolutionize efficiency, reliability, and sustainability in electrical systems positions it as the trailblazer in the market. Companies around the world are eagerly embracing this groundbreaking solution to enhance the performance and longevity of their power distribution networks.Leading businesses have already recognized the benefits of Electrical Laminated Sheet and incorporated it into their operations. Testimonials from satisfied customers highlight the significant improvement in system efficiency and reduced maintenance costs achieved after implementing this innovative solution. As demand continues to rise, industry experts predict a bright future for Electrical Laminated Sheet, forecasting its rapid adoption worldwide.In conclusion, Electrical Laminated Sheet, introduced by {}, is a game-changing development in the power distribution industry. Its exceptional electrical insulation properties, mechanical strength, and high-temperature resistance contribute to enhanced efficiency, reliability, and sustainability. With its eco-friendly manufacturing process and adherence to rigorous standards, it aligns perfectly with the growing focus on sustainable practices. As more companies recognize its unparalleled performance, Electrical Laminated Sheet is set to transform power distribution systems across the globe.

Durable and Versatile Phenolic Resin Board for Multiple Applications

Phenolic Resin Board: An Innovative Solution for Various IndustriesIn today's fast-paced world, innovation is the key to staying ahead of the competition. Companies are constantly looking for new materials and technologies that can help improve their products and processes. One such innovative solution that has been gaining attention in various industries is the Phenolic Resin Board. This versatile material has been revolutionizing the way companies design and create their products, offering a wide range of benefits and applications.Phenolic resin boards are a type of composite material that is made by combining layers of cellulose fibers with phenolic resin. This combination of materials results in a strong, durable, and versatile product that can be used in a wide variety of applications. The boards are known for their high-temperature resistance, chemical resistance, and low moisture absorption, making them an ideal choice for industries such as aerospace, automotive, construction, and manufacturing.One company that has been at the forefront of developing and producing high-quality phenolic resin boards is {Company Name}. With over 30 years of experience in the composite materials industry, {Company Name} has established itself as a leading supplier of phenolic resin boards, offering a wide range of products that meet the diverse needs of their customers.{Company Name} prides itself on its commitment to innovation and quality, constantly investing in research and development to improve its products and meet the ever-changing demands of the market. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians ensure that their phenolic resin boards are of the highest quality, meeting the strictest industry standards and regulations.The versatility of phenolic resin boards makes them suitable for a wide range of applications. In the aerospace industry, these boards are used in the construction of aircraft interiors, providing lightweight, fire-resistant, and durable materials for cabinetry, flooring, and wall panels. In the automotive industry, phenolic resin boards are used in engine compartments, under the hood, and interior components, offering thermal and chemical resistance as well as enhanced mechanical properties.In the construction industry, phenolic resin boards are used in architectural cladding, exterior wall panels, and balcony flooring, providing a durable and low-maintenance solution for modern buildings. In the manufacturing industry, these boards are used to create molds, patterns, and tooling, offering excellent dimensional stability, high temperature resistance, and low moisture absorption.{Company Name} understands the importance of sustainability and environmental responsibility, and they are committed to producing phenolic resin boards that are eco-friendly and recyclable. Their production processes are designed to minimize waste and reduce the environmental impact, ensuring that their products are not only high-quality but also sustainable.In addition to their commitment to quality and sustainability, {Company Name} also prides itself on its dedication to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, offering customized solutions and technical support to ensure that their phenolic resin boards meet and exceed their expectations.As the demand for innovative and high-performance materials continues to grow, phenolic resin boards are expected to play a key role in driving the future of various industries. With their exceptional properties, versatility, and sustainability, these boards are proving to be a game-changer for companies looking to stay ahead in today's competitive market.In conclusion, phenolic resin boards are an innovative solution that offers a wide range of benefits and applications for industries such as aerospace, automotive, construction, and manufacturing. {Company Name} has been at the forefront of developing and producing high-quality phenolic resin boards, offering a diverse range of products that meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {Company Name} is poised to continue leading the way in the production and supply of phenolic resin boards for years to come.

Discover the Benefits of Epoxy Fiberglass Sheet for Industrial Use

Title: Introducing High-Quality Epoxy Fiberglass Sheets for Various Industrial ApplicationsIntroduction:In recent news, industry-leading manufacturer {} is proud to announce the launch of their latest product, the 3240 Epoxy Fiberglass Sheet. Designed with cutting-edge technology and superior materials, this new addition to their extensive product range is set to revolutionize various industrial applications. With its exceptional properties and versatile nature, the 3240 Epoxy Fiberglass Sheet promises to be a game-changer in the field.1. Overview of the 3240 Epoxy Fiberglass Sheet:The 3240 Epoxy Fiberglass Sheet is a high-performance composite material crafted using epoxy resin and fine fiberglass cloth. This combination results in a sturdy and resilient sheet that exhibits excellent mechanical, thermal, and electrical insulation properties. Its exceptional dielectric strength, along with resistance to heat, chemicals, and moisture, makes it a reliable choice for a wide range of industries.2. Applications in Electrical Engineering:The electrical engineering industry requires materials that can withstand high temperatures and offer superior electrical insulation. The 3240 Epoxy Fiberglass Sheet meets these requirements flawlessly. It can be seamlessly incorporated into electrical insulation systems, such as slot insulations, transformer barriers, and liner insulation for motors and generators.3. Utilization in the Automotive Sector:In the automotive industry, where temperature variations, vibrations, and exposure to harsh fluids are common, the 3240 Epoxy Fiberglass Sheet excels. It can be applied in various automobile components, including engine gaskets, electrical connectors, and spark plug insulators, ensuring durability and reliability under extreme conditions.4. Role in the Aerospace Industry:With its exceptional reliability and strength, the 3240 Epoxy Fiberglass Sheet finds numerous applications in the aerospace sector. From aircraft insulation to circuit boards and radomes, this sheet exhibits outstanding mechanical strength, temperature resistance, and electrical insulation properties, ensuring optimal performance in the most demanding environments.5. Benefits in Manufacturing and Engineering:Manufacturing and engineering sectors often require materials that can endure heavy mechanical stress and extreme temperatures. The 3240 Epoxy Fiberglass Sheet proves to be an ideal solution, offering exceptional resistance to both tension and compression. It can be used for manufacturing molded parts, panels, and laminates, contributing to robust and long-lasting structures.6. Ensuring Quality and Compliance:{Company Name} takes immense pride in the quality and compliance of its products. The 3240 Epoxy Fiberglass Sheet meets rigorous industry standards, including the electrical insulation requirements of the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Customers can have confidence in the superior performance and safety of this product.7. Commitment to Sustainability:{Company Name} places significant importance on sustainability, and the 3240 Epoxy Fiberglass Sheet follows suit. The material is manufactured using eco-friendly processes that minimize waste and energy consumption. Additionally, its long lifespan and resistance to degradation contribute to reduced material waste and overall environmental impact.Conclusion:The launch of the 3240 Epoxy Fiberglass Sheet by {} represents a significant breakthrough in composite material technology. Its remarkable insulation, thermal resistance, and mechanical strength make it a versatile and reliable choice for various industries. With its commitment to quality, compliance, and sustainability, {} continues to redefine excellence in the field of composite materials.

Epoxy Glass Fiber Sheet Market in China: 3240 Sheet Overview

China 3240 Epoxy Glass Fiber Sheet, a high-quality electrical insulating material, has become one of the key products in the portfolio of a leading manufacturing company in China. With its excellent mechanical and electrical properties, this epoxy glass fiber sheet is an essential material for the electrical and electronic industry.The China 3240 Epoxy Glass Fiber Sheet is manufactured using high-quality glass fiber cloth and epoxy resin, which is then processed through a hot press molding process. This results in a product with outstanding electrical insulation properties, high mechanical strength, and excellent heat resistance. The product is widely used in various electrical equipment, such as insulating supports, switchgear panels, and transformers.The unique combination of glass fiber and epoxy resin gives this material exceptional electrical insulation properties. It can withstand high voltage and prevents electrical leakage, making it suitable for use in electrical equipment that requires high insulation performance. Additionally, the material's high mechanical strength allows it to withstand mechanical stress, making it a durable and reliable choice for electrical insulation applications.In addition to its electrical properties, the China 3240 Epoxy Glass Fiber Sheet also exhibits excellent heat resistance. The material can withstand high temperatures without compromising its insulation performance, making it suitable for use in applications where exposure to heat is a concern. This makes it a versatile material for a wide range of electrical and electronic applications.The manufacturing company behind the China 3240 Epoxy Glass Fiber Sheet has a strong focus on quality and innovation. With state-of-the-art production facilities and a dedicated research and development team, the company is committed to delivering high-quality products that meet the needs of its customers. Their stringent quality control measures ensure that every sheet meets international standards for electrical insulation materials.The company has also made significant investments in modern technology and equipment to improve the efficiency and quality of its manufacturing processes. This has enabled them to produce the China 3240 Epoxy Glass Fiber Sheet in large quantities without compromising on quality, making it readily available to meet the demand of the market.Moreover, the company has a robust distribution network that enables them to supply the China 3240 Epoxy Glass Fiber Sheet to customers both domestically and internationally. This ensures that the product is readily accessible to industries around the world that rely on high-quality electrical insulation materials.In addition to its commitment to quality and innovation, the company also places a strong emphasis on environmental sustainability. They adhere to strict environmental regulations and strive to minimize their environmental impact throughout the manufacturing process. This ensures that the China 3240 Epoxy Glass Fiber Sheet is not only a high-performance material but also an eco-friendly choice for businesses that prioritize sustainability.Overall, the China 3240 Epoxy Glass Fiber Sheet has established itself as a reliable and high-quality electrical insulation material, thanks to its exceptional electrical and mechanical properties. Combined with the company's commitment to quality, innovation, and sustainability, it has become a popular choice for industries that require reliable insulation materials for their electrical and electronic applications.As the demand for high-quality electrical insulation materials continues to grow, the China 3240 Epoxy Glass Fiber Sheet is well-positioned to meet the needs of the market, both domestically and internationally. With its outstanding performance and the company's dedication to excellence, this product is poised to remain a key component in the electrical and electronic industry for years to come.

Durable and Versatile Glass Fiber Reinforced Sheet: A Top Choice for Various Applications

[Company Name] Introduces Advanced Glass Fiber Reinforced Sheet for Superior Performance[City, State] - [Company Name], a leading manufacturer of advanced materials, is proud to announce the introduction of their new Glass Fiber Reinforced Sheet. This innovative product is designed to provide superior performance and durability for a wide range of applications.The Glass Fiber Reinforced Sheet is manufactured using a proprietary process that results in a high-strength, lightweight material. This makes it an ideal choice for applications where strength and durability are crucial, such as automotive components, aerospace parts, and industrial equipment.One of the key benefits of the Glass Fiber Reinforced Sheet is its exceptional strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is important, without compromising on structural integrity. The material also offers excellent resistance to corrosion, making it suitable for use in harsh environments.In addition to its impressive mechanical properties, the Glass Fiber Reinforced Sheet is also highly customizable. [Company Name] offers a range of options for thickness, color, and finish, allowing customers to tailor the material to their specific requirements. This flexibility makes it a versatile solution for a wide range of industries and applications."We are excited to introduce our new Glass Fiber Reinforced Sheet to the market," said [Name], [Title] at [Company Name]. "This material represents a significant advancement in the field of advanced materials, and we believe it will offer our customers a superior solution for their high-performance applications."[Company Name] has a proven track record of delivering innovative solutions to the market. With state-of-the-art manufacturing facilities and a team of experienced engineers and materials experts, the company is well-positioned to meet the growing demand for high-performance materials.The introduction of the Glass Fiber Reinforced Sheet further solidifies [Company Name]'s commitment to providing cutting-edge solutions to their customers. The company's dedication to research and development, coupled with their focus on quality and customer satisfaction, has established them as a trusted partner for businesses across a wide range of industries.In addition to the Glass Fiber Reinforced Sheet, [Company Name] offers a comprehensive range of advanced materials, including composites, plastics, and specialty alloys. Their extensive product portfolio, combined with their expertise in materials science and engineering, makes them a one-stop solution provider for companies seeking high-performance materials for their products and applications.As industries continue to demand materials that offer superior performance and durability, [Company Name] is poised to meet those needs with their innovative Glass Fiber Reinforced Sheet and other advanced materials. With a commitment to excellence and a focus on continuous improvement, the company is well-positioned to remain a leader in the field of advanced materials for years to come.For more information about [Company Name] and their advanced Glass Fiber Reinforced Sheet, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of advanced materials for a wide range of industries. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-performance materials for their products and applications. With a commitment to research and development, [Company Name] continues to deliver cutting-edge solutions to the market, helping their customers stay ahead of the competition.

High Temperature Resistant Epoxy Resin Fiberglass Cloth Laminate Sheet for Transformers and Motors

Title: Groundbreaking High Temperature Resistant G11/Fr4 Epoxy Resin Fiberglass Cloth Laminate Sheet for Transformers and MotorsIntroduction:In a move that promises to revolutionize the electrical industry, a leading composite materials manufacturer has unveiled their latest innovation - a groundbreaking G11/Fr4 epoxy resin fiberglass cloth laminate sheet. Engineered to withstand extreme temperatures, this innovative material is set to enhance the performance and reliability of transformers and motors in various industries.Company Background:{'Company name}' is a renowned industry leader in the manufacture of composite materials. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation in the electrical sector. Their vast expertise and commitment to delivering high-quality products have earned them a stellar reputation among their global clientele.News:The recently launched G11/Fr4 epoxy resin fiberglass cloth laminate sheet marks a significant milestone in the company's continued pursuit of excellence. This advanced material promises to address the growing demand for high temperature resistant components in transformers and motors, particularly in industries such as manufacturing, energy, and automotive.Being able to withstand extreme temperature variations is crucial for the efficient functioning of transformers and motors. Traditionally, these components faced limitations due to the lack of suitable materials capable of withstanding prolonged exposure to high temperatures. However, the new G11/Fr4 epoxy resin fiberglass laminate sheet offers an unparalleled solution to this long-standing issue.What sets this material apart is its exceptional thermal stability, which allows it to maintain its structural integrity even under extreme heat conditions. With a high glass transition temperature, this laminate sheet can endure continuous exposure to temperatures above 180°C, ensuring enhanced performance and reliability in demanding environments.Additionally, the G11/Fr4 epoxy resin fiberglass cloth laminate sheet exhibits superior electrical insulation properties. By effectively preventing electrical leakage and short circuits, this material eliminates the risk of equipment malfunctions and ensures safe and efficient operation. Its excellent dielectric strength makes it an ideal choice for applications where electrical insulation is critical.Moreover, this laminate sheet boasts remarkable mechanical strength and resistance to impact and vibrations. It maintains its durability even in harsh conditions, thereby guaranteeing the longevity and reliability of transformers and motors. As a result, manufacturers can minimize downtime and maintenance costs while maximizing productivity.The G11/Fr4 epoxy resin fiberglass cloth laminate sheet also offers excellent chemical resistance, ensuring that it remains unaffected by corrosive agents and solvents commonly encountered in industrial settings. This feature further enhances its longevity and versatility, making it suitable for a wide range of applications beyond transformers and motors.To cater to diverse industry requirements, the company offers customization options for the G11/Fr4 laminate sheet, including size, thickness, and specific composition variations. This flexibility allows manufacturers to tailor the material to their unique needs, further expanding its potential applications across multiple sectors.Looking ahead, {Company name} aims to continue its research and development efforts to further improve the performance and capabilities of the G11/Fr4 epoxy resin fiberglass cloth laminate sheet. With an unwavering commitment to innovation and customer satisfaction, the company strives to solidify its position as a leading provider of composite materials for the electrical industry.In conclusion, the introduction of the high temperature resistant G11/Fr4 epoxy resin fiberglass cloth laminate sheet marks a major breakthrough in the electrical sector. This transformative material offers outstanding thermal stability, superior electrical insulation properties, exceptional mechanical strength, and chemical resistance. As a result, transformers and motors incorporating this advanced laminate sheet can operate reliably in challenging environments, minimizing downtime and maximizing productivity for industries worldwide.