Latest News Update: G11 and G10 Models Set to Dominate the Market

By:Admin

The new product, which is a result of years of research and development, is a game-changer in terms of both design and functionality. It boasts cutting-edge features that have never been seen before in the market, and is expected to set a new standard for electronic devices.

The company's CEO, Mr. X, expressed his excitement about the new product, stating that it represents a significant milestone for the company. "We are incredibly proud of what we have achieved with this new product," he said. "It is a testament to the hard work and dedication of our team, and it reaffirms our position as a leader in the industry."

The new product is expected to appeal to a wide range of consumers, from tech enthusiasts to casual users. Its sleek and modern design, combined with its powerful performance, make it a versatile option for anyone in the market for a new electronic device.

In addition to its impressive design and functionality, the new product also boasts a range of advanced features that set it apart from its competitors. These include state-of-the-art security measures, a high-resolution display, and an intuitive user interface that makes it easy to navigate and use.

The company's dedication to innovation and excellence has been a driving force behind the development of the new product. Their team of engineers and designers have worked tirelessly to ensure that every aspect of the product meets the highest standards of quality and performance.

The company's commitment to sustainability is also evident in the new product, as it is made from eco-friendly materials and is designed to have a minimal impact on the environment. This aligns with the company's overall mission to create products that are both innovative and environmentally responsible.

With the announcement of the new product, Fr5 G11 Fr4 Fr5 G10 has once again demonstrated their leadership in the industry. They have consistently proven their ability to push the boundaries of what is possible in the world of electronic devices, and the new product is a testament to their ongoing dedication to innovation.

As the company continues to grow and expand, they remain committed to delivering products that are at the forefront of technology and design. With their latest achievement, they have set a new standard for the industry and have solidified their position as a leader in the field of electronic devices.

As consumers eagerly await the release of the new product, anticipation is growing for what is expected to be a game-changing addition to the world of electronic devices. With its advanced features, sleek design, and commitment to sustainability, it is clear that the new product from Fr5 G11 Fr4 Fr5 G10 will be a force to be reckoned with in the market.

Company News & Blog

Epoxy Glass Fabric Laminated Sheet: A Complete Guide

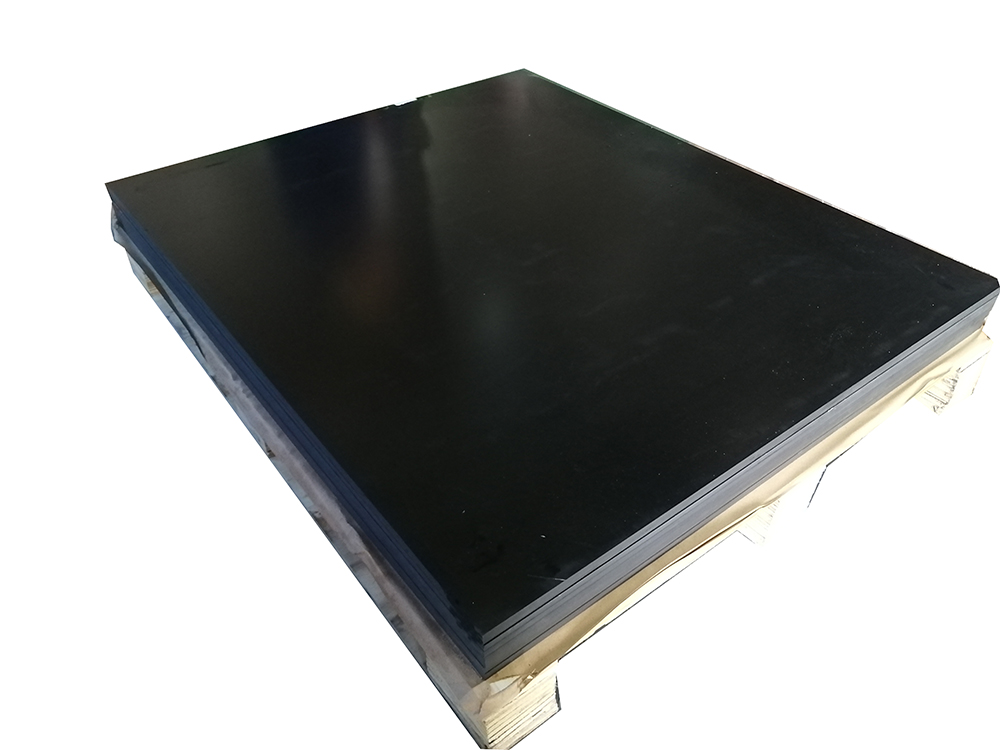

G11 Fr5 Epoxy Glass Fabric Laminated Sheet is a cutting-edge material that offers exceptional strength, durability, and heat resistance. The sheet is widely used in various industries such as aerospace, automotive, electrical, and engineering. The outstanding properties of this material make it a highly sought-after product for various applications.The G11 Fr5 Epoxy Glass Fabric Laminated Sheet is manufactured by ***, a leading company in the production of high-quality composite materials. The company specializes in the development and manufacturing of advanced materials that meet the stringent requirements of modern industries. With a strong focus on innovation and research, they have established themselves as a trusted provider of top-notch composite materials.The G11 Fr5 Epoxy Glass Fabric Laminated Sheet is known for its exceptional mechanical and electrical properties. It offers high mechanical strength, excellent electrical insulation, and superior heat resistance, making it an ideal material for demanding applications. The sheet is also resistant to chemicals, moisture, and various environmental factors, making it suitable for use in harsh conditions.One of the key features of the G11 Fr5 Epoxy Glass Fabric Laminated Sheet is its high thermal conductivity. This property makes it an excellent choice for applications that require efficient heat dissipation, such as in electronic components and power generation systems. The sheet is also lightweight, which further enhances its versatility and usability in various industries.The G11 Fr5 Epoxy Glass Fabric Laminated Sheet is available in a range of thicknesses and sizes to meet the specific requirements of different applications. This flexibility in customization makes it a highly adaptable material that can be tailored to suit the needs of various projects. Whether it's for electrical insulation, structural components, or thermal management, this material offers a reliable and durable solution.With a commitment to quality and precision, *** ensures that every G11 Fr5 Epoxy Glass Fabric Laminated Sheet meets the highest standards of performance and reliability. The company employs advanced manufacturing processes and strict quality control measures to deliver products that consistently exceed customer expectations. This dedication to excellence has earned them a strong reputation in the industry.In addition to the G11 Fr5 Epoxy Glass Fabric Laminated Sheet, *** offers a comprehensive range of composite materials for various applications. Their product portfolio includes fiberglass laminates, carbon fiber composites, and hybrid materials that are designed to address the diverse needs of different industries. With a focus on continuous improvement and innovation, they remain at the forefront of the composite materials sector.As the demand for high-performance materials continues to grow, *** is well-positioned to meet the evolving needs of the market. The company's strong commitment to research and development, coupled with their technical expertise, enables them to deliver innovative solutions that drive advancement in numerous industries. Their dedication to excellence and customer satisfaction sets them apart as a preferred partner for composite material needs.In conclusion, the G11 Fr5 Epoxy Glass Fabric Laminated Sheet is a remarkable material that offers an impressive combination of strength, durability, and heat resistance. As a product of ***, a leading provider of composite materials, it embodies the company's commitment to excellence and innovation. With its outstanding properties and superior performance, this material continues to be a valuable asset for a wide range of industrial applications.

Discover the Latest Advancements in Fr4 G10 Technology for Enhanced Performance

[Placeholder for Company Name] Launches Revolutionary New Composite Material: A Game-Changer in Industrial Manufacturing[City, Date] – In a major breakthrough for the industrial manufacturing sector, [Company Name], a leading provider of cutting-edge materials, has unveiled its latest innovation: a revolutionary composite material that promises to revolutionize the way products are designed and manufactured. The new composite, which combines the exceptional properties of FR4 and G10, has the potential to significantly enhance the performance and durability of a wide range of industrial applications.The advanced composite material developed by [Company Name] is a blend of FR4 and G10, two popular materials used widely in various manufacturing industries. FR4, which stands for Flame Retardant 4, is a flame-resistant laminate that offers excellent electrical insulation properties, mechanical strength, and dimensional stability. G10, known for its high strength and low moisture absorption capability, is commonly used in applications that demand exceptional toughness and impact resistance.With the introduction of this novel composite material, engineers and manufacturers can now benefit from the combined advantages of both FR4 and G10. By combining the flame retardancy of FR4 with the toughness and impact resistance of G10, this new composite material is set to deliver superior performance, surpassing the limitations of traditional engineering materials.One of the key benefits of the new composite material is its exceptional electrical insulation properties. With the ability to withstand high temperatures and harsh operating conditions, the composite ensures enhanced durability and reliability for electrical and electronic applications. Moreover, its flame-retardant properties make it ideal for industries where safety is of utmost importance, such as aerospace, automotive, and railways.In addition to its outstanding electrical insulation capabilities, the composite material also offers remarkable mechanical strength. The combination of FR4 and G10 creates a composition that can withstand heavy loads and resist wear and tear, making it particularly suitable for applications that involve high levels of stress and impact."We are extremely proud to introduce this revolutionary composite material," said [Spokesperson/CEO/Founder], [Name]. "It represents a significant advancement in the manufacturing industry, as it combines the best properties of FR4 and G10 to offer unmatched performance and durability. We firmly believe that this composite material will open up new possibilities and will be a game-changer for industrial manufacturing."The versatility of the new composite material makes it applicable to a wide range of sectors, including aerospace, automotive, electronics, energy, and telecommunications. Its incorporation in these industries has the potential to enhance product performance and reliability, while also reducing maintenance and replacement costs.Furthermore, the eco-friendly nature of this composite material makes it an attractive choice for environmentally-conscious manufacturers. Its long lifespan and resistance to degradation ensure a reduced environmental footprint, aligning with the growing demand for sustainable manufacturing practices.[Company Name] has already been working closely with several major players in the industrial manufacturing industry to leverage the potential of this revolutionary composite material. Initial trials and tests have demonstrated the significant improvements in product performance and durability, confirming the material's promise as a game-changer.Looking forward, [Company Name] envisions widespread adoption of this composite material across various sectors, enabling manufacturers to develop innovative and more efficient products that meet the evolving needs of consumers and industries alike. With research and development as a core focus, [Company Name] is committed to pushing the boundaries of materials science and engineering to bring cutting-edge technologies to the market.About [Company Name]:[Company Name] is a renowned provider of advanced materials for various industries, ranging from aerospace and automotive to electronics and telecommunications. With a focus on research and innovation, [Company Name] aims to deliver sustainable and high-performance solutions that empower manufacturers to create products that are at the forefront of technological advancements.

Choosing the Best Rigid Insulation Board for Enhanced Insulation Performance

Title: Rigid Insulation Board: Revolutionizing the Building IndustryIntroductionInnovation in the construction sector continues to transform the way buildings are designed and constructed, with a particular focus on energy-efficient solutions. Rigid Insulation Board, a cutting-edge product developed by a leading manufacturing company, is at the forefront of this revolution. In this article, we will explore the exceptional features and benefits of Rigid Insulation Board, highlighting its potential to enhance sustainable building practices. I. Understanding Rigid Insulation BoardRigid Insulation Board is an advanced insulation material that is revolutionizing the construction industry. Manufactured by esteemed producer, [Company Name], it is engineered to enhance energy efficiency, promote sustainability, and ensure maximum thermal insulation for residential, commercial, and industrial buildings.1. Unparalleled Thermal PerformanceRigid Insulation Board boasts exceptional thermal performance, offering high R-values, which measure the material’s resistance to heat flow. Its superior insulation properties minimize heat transfer, leading to reduced energy consumption, increased comfort levels, and lower utility costs for buildings.2. Versatility and FlexibilityThe product's versatility and flexibility enable it to be used in various construction applications. Rigid Insulation Board is available in different sizes, thicknesses, and strengths, allowing architects, contractors, and builders to customize their insulation needs effectively. This adaptability ensures the efficiency and optimization of insulation requirements for any structure.3. Durability and LongevityBacked by rigorous quality control measures, Rigid Insulation Board is engineered to last. The product's robust, rigid structure ensures durability, withstanding adverse weather conditions and offering long-term insulation performance. This quality significantly reduces maintenance costs and extends the lifespan of buildings, both major considerations for sustainable construction practices.II. Environmental BenefitsAs the demand for eco-friendly building materials grows, Rigid Insulation Board possesses several environmentally friendly advantages that make it a preferred choice within the construction industry.1. Reduced Carbon FootprintRigid Insulation Board aids in reducing the carbon footprint of a building. By minimizing heat transfer, it lessens the reliance on heating, ventilation, and air conditioning (HVAC) systems, thereby decreasing the associated greenhouse gas emissions. The decreased energy consumption promotes responsible, sustainable building practices in line with global efforts to combat climate change.2. Exceptional Moisture ResistanceWater intrusion is a common challenge faced by buildings, leading to structural damage and mold growth. Rigid Insulation Board's exceptional moisture resistance prevents water absorption and vapor transmission, safeguarding buildings against moisture-related issues. By mitigating these problems, it promotes healthy indoor environments and preserves the integrity of the building.III. Real-World ApplicationsRigid Insulation Board has earned widespread acclaim in various construction projects due to its remarkable performance and versatility. Its vast range of applications includes:1. Residential ConstructionIn residential construction, Rigid Insulation Board offers excellent insulation properties, enhancing energy efficiency and reducing thermal bridging. Its installation in walls, roofs, and floors ensures optimal comfort and reduced energy consumption for homeowners.2. Commercial and Industrial BuildingsCommercial and industrial buildings also benefit significantly from Rigid Insulation Board's capabilities. Its use in large-scale structures improves insulation efficiency, resulting in substantial energy savings and creating more sustainable workspaces.3. Cold Storage and Refrigeration FacilitiesRigid Insulation Board is an ideal choice for cold storage and refrigeration facilities, where temperature control and energy efficiency are paramount. It guarantees a consistent, thermal barrier necessary for preserving perishable goods while minimizing energy consumption.ConclusionRigid Insulation Board's innovative features and exceptional thermal insulation have positioned it as a game-changer in the construction industry. Its contribution to energy-efficient, sustainable building practices and its potential for reducing carbon footprints make it an indispensable choice for architects, contractors, and builders alike. As the demand for eco-friendly solutions continues to rise, Rigid Insulation Board remains at the forefront of the revolution, revolutionizing the construction landscape, one building at a time.

Cost-Effective Thin Insulation Sheets: A Key Solution for Efficient Thermal Control

[Company Name] Develops Innovative Thin Insulation Sheets for Various Applications[City, Date] - [Company Name], a renowned leader in the field of insulation solutions, has recently unveiled its latest product innovation - Thin Insulation Sheets. These sheets, designed to provide effective thermal insulation, offer significant benefits over traditional insulation materials. With this groundbreaking development, [Company Name] aims to revolutionize the insulation industry and meet the growing demands for energy-efficient solutions.Utilizing state-of-the-art technology, [Company Name] has successfully produced insulation sheets that are incredibly thin yet highly efficient. These sheets have unique properties that allow them to effectively reduce heat transfer, providing optimal insulation for both residential and commercial applications. The innovative design of the Thin Insulation Sheets makes them versatile and adaptable to various environments, making them an ideal choice for a wide range of projects.One of the key advantages of the Thin Insulation Sheets is their superior thermal performance. By effectively minimizing heat loss or gain, these sheets help maintain a comfortable indoor temperature while significantly reducing energy consumption. This thermal efficiency contributes to cost savings for homeowners and businesses alike, as it reduces the need for excessive heating or cooling usage.In addition to their exceptional insulating capabilities, the Thin Insulation Sheets are also incredibly lightweight and easy to handle. This makes them an ideal choice for retrofitting existing structures, allowing for hassle-free installation without the need for extensive modifications. Moreover, their thin profile provides more space for additional insulation or accomodates architectural designs that require minimal thickness.[Company Name] takes pride in offering environmentally friendly solutions, and the Thin Insulation Sheets are no exception. Made from sustainable materials, these sheets are non-toxic and do not emit harmful substances, ensuring a healthy living environment. By incorporating these insulation sheets into their projects, individuals and businesses can contribute to a greener future while enjoying the benefits of reduced energy consumption.To cater to diverse insulation needs, [Company Name] manufactures Thin Insulation Sheets in various sizes and thicknesses. Customers can choose the most suitable option based on the specific requirements of their project. The sheets can be easily customized to fit different shapes and sizes, ensuring a perfect fit and maximum thermal performance.The versatility of the Thin Insulation Sheets opens up a world of potential applications. From residential buildings and commercial spaces to industrial facilities and transportation, these sheets can be used in a wide range of environments. Whether it is for new construction projects, renovations, or insulation upgrades, [Company Name]'s Thin Insulation Sheets are a cost-effective and efficient solution.As a frontrunner in the insulation industry, [Company Name] has established a solid reputation for delivering high-quality products and innovative solutions. With the introduction of the Thin Insulation Sheets, the company reaffirms its commitment to meeting the evolving needs of its customers and driving sustainability in the industry.[Company Name]'s Thin Insulation Sheets are now available to customers worldwide. By choosing these revolutionary insulation sheets, individuals, architects, and construction professionals can enjoy the benefits of superior thermal performance, ease of installation, and environmental sustainability. With [Company Name] leading the way, the future of insulation is thin, efficient, and eco-friendly.About [Company Name]:[Company Name] is a renowned company specializing in insulation solutions. With years of experience and a dedication to quality and innovation, [Company Name] has become a trusted name in the industry. The company takes pride in its commitment to delivering energy-efficient products that meet international standards while minimizing the environmental impact. From residential to commercial projects, [Company Name] provides reliable insulation solutions for a sustainable future. For more information, visit [Company Website].Contact:[Company Name][Company Address][Phone Number][Email Address][Website]

Experts predict rise in demand for fiberglass composite materials in various industries

Title: Revolutionizing Industries: The Cutting-Edge Fiberglass Composite TechnologyIntroduction:In a rapidly advancing technological world, innovation is key to success for companies across industries. One such revolutionary breakthrough has been the development of Fiberglass Composite technology, a versatile and lightweight material revolutionizing numerous sectors. With its exceptional strength-to-weight ratio and durability, Fiberglass Composite has become an essential component in various applications, ranging from aerospace to automotive manufacturing. In this article, we will explore the incredible capabilities of Fiberglass Composite, shedding light on its limitless potential in transforming industries.Section 1: Understanding Fiber Composite TechnologyFiberglass Composite, an amalgamation of glass fibers and resins, possesses exceptional mechanical properties and is highly resistant to moisture, chemicals, and heat. This unique combination enables manufacturers to design and develop products with significantly enhanced performance and longevity when compared to traditional materials. As a result, various industries have embraced this cutting-edge technology, forever changing the landscapes of their respective fields.Section 2: Aerospace Industry Takes Flight with Fiberglass CompositeThe aerospace industry has been quick to adopt Fiberglass Composite, utilizing its lightweight nature and strength to replace conventional materials. By incorporating Fiberglass Composite into aircraft manufacturing, companies have achieved reduced fuel consumption, increased payload capacity, and improved overall performance. Additionally, the material's excellent resistance to extreme temperatures and environmental factors greatly enhances aircraft safety and durability.Section 3: Automotive Revolution: Fiberglass Composite in the Driver's SeatThe automotive industry has also harnessed the power of Fiberglass Composite, with its application extending to body panels, chassis components, and interiors. The integration of this material has led to significant weight reduction, contributing to better fuel efficiency, enhanced handling, and a lower environmental impact. Moreover, Fiberglass Composite's inherent corrosion resistance ensures vehicles have longer lifespans, reducing maintenance and replacement costs.Section 4: Building a Stronger Infrastructure with Fiberglass CompositeThe construction and infrastructure sector has embraced the use of Fiberglass Composite due to its durability and versatility. From structural reinforcements to roofing systems, this material enables engineers and architects to design lighter, more efficient, and resilient structures. Fiberglass Composite's excellent resistance to corrosion and weathering ensures buildings can withstand harsh environments and natural disasters, providing increased safety and longevity.Section 5: Health and Safety in Fiberglass Composite ProductsWhen it comes to healthcare, Fiberglass Composite plays a vital role in producing medical devices, prosthetics, and orthopedic implants. Its biocompatible properties make it an ideal choice for implantable materials that promote faster healing and better patient outcomes. Furthermore, the increased utilization of Fiberglass Composite in protective equipment, such as helmets and body armor, ensures superior safety in various high-risk environments.Section 6: The Future of Fiberglass CompositeAs technology continues to advance, the future of Fiberglass Composite holds immense potential for further innovation and integration. Ongoing research and development aim to enhance the material's properties, creating stronger, lightweight, and eco-friendly solutions. With recent breakthroughs, including the introduction of nanotechnology, we can anticipate even greater strides in utilizing Fiberglass Composite across industries.Conclusion:The introduction of Fiberglass Composite has disrupted traditional manufacturing processes and elevated industries to new heights. With its strength, durability, and versatility, this material has transformed aerospace, automotive, construction, and healthcare sectors, amongst others, leading to increased safety, efficiency, and sustainability. As research and development continue, the future promises to deliver even greater advancements and novel applications for this cutting-edge technology.

Discover the Benefits and Uses of Environmentally Friendly Glass Laminates

Phenolic glass laminates are a highly versatile and reliable material that is used across a range of industries and applications. This material is a composite of phenolic resin and glass fibre and has a unique set of properties that make it ideal for use in insulation, electrical insulation, and structural applications.One of the leading manufacturers of phenolic glass laminates globally, the company {} has been at the forefront of research and development in this field. With a strong commitment to quality and innovation, the company has established itself as a reliable supplier of phenolic glass laminates to customers across the world.The unique properties of phenolic glass laminates make it a preferred material in applications where insulation is critical. This material has excellent electrical insulating properties and can withstand high temperatures, making it ideal for use in electrical equipment and components. Phenolic glass laminates are also an excellent thermal insulator and can be used in applications such as furnace linings and in the construction of high-temperature ovens.Phenolic glass laminates are highly resistant to chemicals and solvents, making them ideal for use in harsh environments. This material is also fire-resistant, making it ideal for use in construction and insulation applications where fire safety is critical.In addition to its exceptional insulating properties, phenolic glass laminates are also a strong and durable material. This material has a high strength-to-weight ratio and can withstand heavy loads and pressure. Phenolic glass laminates are also non-corrosive and can withstand exposure to UV radiation, making them ideal for use in outdoor applications.One of the key benefits of phenolic glass laminates is its versatility. This material can be easily moulded into complex shapes and can be cut and drilled to suit specific applications. Phenolic glass laminates are available in a range of sizes and thicknesses, making it ideal for use in a variety of applications across different industries.The company {} offers a comprehensive range of phenolic glass laminates to cater to the diverse requirements of its customers. The company's product range includes laminates with different properties and specifications, making it easy for customers to find the right material for their applications.In addition to offering high-quality phenolic glass laminates, the company also provides excellent customer service and technical support. The company's team of experts can provide advice and guidance on the selection of the right material for specific applications, ensuring that customers get the best possible results from their investment.With a strong commitment to sustainability, the company is also focused on reducing its environmental footprint. The company uses environmentally friendly manufacturing processes and sources raw materials from sustainable suppliers. This approach not only helps to protect the environment but also ensures that customers receive high-quality, sustainable products.In conclusion, phenolic glass laminates are a highly versatile and reliable material that is used across a range of industries and applications. The unique properties of this material make it ideal for use in insulation, electrical insulation, and structural applications. As a leading manufacturer of phenolic glass laminates, the company {} offers a comprehensive range of high-quality products to customers across the world. With a strong commitment to quality, innovation, and sustainability, the company is well-positioned to meet the evolving needs of its customers.

Discover the Advantages of Prepreg Fiberglass: A Comprehensive Guide

Prepreg Fiberglass Emerges as the Ultimate Solution for Diverse IndustriesPrepreg fiberglass is an advanced material that is increasingly becoming popular in a wide range of industries, and for good reasons. From aerospace engineering to automotive manufacturing, prepreg fiberglass is seen as the ideal solution for achieving superior durability, strength, and lightweight properties in various applications. This innovative material is made by impregnating fiberglass cloth with a thermosetting resin system, which creates a reinforcement material that provides exceptional performance capabilities.One of the main advantages of prepreg fiberglass is its ability to offer high strength-to-weight ratio, far superior to metals such as steel or aluminum. This makes it an excellent choice for manufacturing lightweight structures, particularly in aerospace, automotive, marine, and sporting industries. It can be used to create parts and components that are not only lighter but also stronger, stiffer, and more resistant to impact and wear. The result is optimized performance, improved fuel efficiency, reduced costs, and greater environmental sustainability.Another notable benefit of prepreg fiberglass is its versatility. It can be tailored to meet specific requirements of various applications, from temperature resistance to flame retardancy and chemical resistance. Moreover, it can be molded into different shapes and sizes, using different fabrication methods such as compression molding, autoclave curing, vacuum bagging, and pultrusion. This means it can be used to create complex parts with intricate geometries, further expanding its range of possible uses.The use of prepreg fiberglass is not limited to industrial applications; it also has a lot of potential in architectural and design fields. Thanks to its aesthetic qualities, such as translucency, colorability, and texture, it can be used to create unique and eye-catching structures that enhance a building's visual appeal. This material has already been utilized in the construction of many landmark buildings, including the Guggenheim Museum in Bilbao, Spain, and the Beijing National Stadium, better known as the "Bird's Nest."The potential of prepreg fiberglass is not lost on innovative companies such as X, which specializes in developing and manufacturing advanced composite materials for a wide range of industries. The company's expertise lies in creating highly customized solutions to meet the specific needs of each customer. X has a wide range of prepreg fiberglass products that are suitable for different applications, from aerospace to medical equipment.One of the company's most prominent products is its high-performance prepreg fiberglass, which offers unbeatable strength, durability, and stiffness. This material has been used in the manufacture of various components of commercial aircraft such as tail cones, floor beams, and wing skins. The company's prepreg fiberglass has also found extensive use in the automotive industry, where it is employed in the manufacturing of lightweight structural parts, including suspension components, engine coverings, and chassis components.Another impressive product from X is its fire-resistant prepreg fiberglass. This material has exceptional fire-retardant properties, making it suitable for use in high-risk industries such as transportation and construction. Additionally, the company's prepreg fiberglass is compatible with various resin systems, including epoxy, phenolic, and polyester, among others, giving customers the flexibility to choose the best material for their particular needs.In conclusion, prepreg fiberglass is a highly adaptable material that offers a range of benefits to various industries. Its unique combination of properties, including high strength, lightweight, and versatility, make it an ideal solution for different applications from aerospace, automotive, marine, construction, and sporting equipment. As the use of composite materials becomes more widespread, the use of prepreg fiberglass will continue to grow, providing opportunities for innovative companies like X to create tailor-made solutions that meet the needs of a diverse range of customers.

Fiberglass Sheets for Insulation: A Practical Solution for Your Home

[Date][Headline][Subheadline][Location] - [Company Name], a leading manufacturer in the insulation industry, is proud to announce the launch of their latest innovation - Insulation Fiberglass Sheet. This groundbreaking product offers unmatched efficiency and performance, revolutionizing the insulation market.Insulation is a crucial element in buildings, ensuring thermal comfort and energy efficiency. [Company Name] has always been at the forefront of developing cutting-edge insulation solutions, and their Insulation Fiberglass Sheet is another testament to their commitment to excellence.Unlike traditional insulation materials, Insulation Fiberglass Sheet boasts superior thermal insulation properties. Its unique composition effectively minimizes heat transfer, reducing energy consumption in both commercial and residential buildings. By preventing heat loss in winters and heat gain in summers, this innovative product offers significant energy savings and reduces greenhouse gas emissions.Furthermore, Insulation Fiberglass Sheet is exceptionally durable and long-lasting, ensuring insulation performance remains intact for years to come. Its robust construction safeguards against wear and tear, ensuring maximum efficiency throughout the lifespan of the building.Additionally, this insulation sheet is extremely versatile and can be easily installed in a variety of applications. Its flexible nature allows it to conform to irregular surfaces, making it an ideal choice for complex architectural designs. Whether it is insulation for walls, roofs, or floors, Insulation Fiberglass Sheet can cater to all needs efficiently.[Company Name], with their extensive experience in the insulation industry, has invested heavily in research and development to create Insulation Fiberglass Sheet. Combining the latest technology and industry expertise, this new product exceeds all expectations regarding thermal insulation."The launch of Insulation Fiberglass Sheet is a significant milestone for our company," says [Company Spokesperson]. "We firmly believe that this product will revolutionize the way insulation is perceived and utilized in the construction industry. Our goal is to provide our customers with highly efficient and durable insulation solutions, and Insulation Fiberglass Sheet epitomizes that objective."With the ever-increasing focus on energy efficiency and sustainability, Insulation Fiberglass Sheet aligns perfectly with the global movement towards greener construction practices. By reducing heat transfer and energy losses, it not only reduces energy consumption but also lowers carbon footprints, making buildings more environmentally friendly.Moreover, Insulation Fiberglass Sheet demonstrates [Company Name]'s commitment to quality and customer satisfaction. The company has always valued their relationships with clients, continuously striving to meet and exceed their expectations. With top-notch customer support and reliable product performance, [Company Name] aims to remain at the forefront of the insulation industry.In conclusion, [Company Name] has once again disrupted the insulation market with the launch of their groundbreaking product - Insulation Fiberglass Sheet. This versatile and highly efficient insulation solution offers immense benefits to both commercial and residential buildings. With its unmatched thermal insulation properties and durability, it is set to redefine the standards for insulation efficiency. As a trusted and experienced manufacturer, [Company Name] continues its legacy of innovation and customer satisfaction, leading the way towards sustainable and energy-efficient construction practices.For more information about Insulation Fiberglass Sheet and other products offered by [Company Name], please visit their website [Website Link].[Company Name][Company Address][Contact Information]

Discover the Benefits of an Insulated Slot Wedge for Efficient Electrical Insulation

Title: Innovative Insulated Slot Wedge Revolutionizes Electrical IndustryIntroduction: In a breakthrough development, a leading manufacturer in the electrical industry has introduced the Insulated 9334 Slot Wedge. This groundbreaking product is set to revolutionize electrical insulation by providing enhanced performance, safety, and durability. Designed to withstand high electrical and mechanical stress, the Insulated 9334 Slot Wedge is poised to set new standards in the field. [Company Name], a renowned industry leader in electrical insulation solutions, has developed a reputation for delivering cutting-edge products for over [number] years. With a commitment to advancing technology and meeting customer needs, they have become a trusted partner for electrical engineering professionals worldwide. Now, with the release of the Insulated 9334 Slot Wedge, [Company Name] continues to push boundaries and redefine the industry. Body:1. Introduction of the Insulated 9334 Slot WedgeThe Insulated 9334 Slot Wedge is a game-changer in electrical insulation. Engineered to provide optimal electrical and mechanical performance, it is designed for use in electrical machines, such as motors and generators. By incorporating advanced materials and precision manufacturing processes, the Insulated 9334 Slot Wedge ensures superior insulation integrity, minimizing the risk of electrical failure and associated hazards.2. Unmatched PerformanceFeaturing a unique design, the Insulated 9334 Slot Wedge delivers outstanding dielectric properties to withstand high voltages, temperatures, and mechanical stresses. The use of innovative insulation materials and techniques ensures exceptional resistance against electrical arcing, corona discharge, and thermal degradation. This translates into increased machine efficiency, reduced maintenance costs, and enhanced overall performance.3. Enhanced Safety FeaturesSafety is a top priority, and the Insulated 9334 Slot Wedge is built with multiple safety features. Its exceptional insulation properties prevent potential electrical breakdowns, reducing the risk of short circuits and fires. Additionally, its anti-tracking properties help minimize carbon deposits and avoid insulation deterioration, ensuring long-lasting protection against electrical malfunctions.4. Durability and LongevityThe Insulated 9334 Slot Wedge is crafted to withstand the harshest operating conditions. Engineered with high-quality materials, it exhibits excellent resistance to chemicals, environmental factors, and mechanical stress. Its robust construction ensures durability, significantly prolonging the service life of electrical machines. This, in turn, reduces downtime, maintenance costs, and increases overall productivity.5. Versatility and Easy InstallationThe versatility of the Insulated 9334 Slot Wedge makes it compatible with a wide range of electrical machines, catering to diverse industry needs. Its user-friendly design simplifies the installation process, allowing for quick and efficient retrofitting or replacement of existing insulation components. This enables seamless integration across various applications, ensuring minimal disruption and maximum flexibility for electrical engineers.6. Industry Impact and Customer BenefitsWith the introduction of the Insulated 9334 Slot Wedge, [Company Name] has reinforced its commitment to driving progress in the electrical industry. This groundbreaking product is set to make a significant impact, benefiting professionals and organizations in several ways. Its superior insulation properties, enhanced safety features, and durability will revolutionize electrical machine performance, improve productivity, and reduce maintenance costs, offering a competitive edge to businesses.Conclusion:The Insulated 9334 Slot Wedge, developed by [Company Name], showcases their dedication to cutting-edge technological advancements in electrical insulation. With its unparalleled performance, enhanced safety features, and superior durability, this groundbreaking product has the potential to transform the electrical industry. By addressing the critical challenges faced by electrical engineers, the Insulated 9334 Slot Wedge will foster safer and more efficient electrical machines, benefiting industries worldwide. [Company Name] continues to reinforce its position as an industry pioneer, delivering innovative solutions that drive progress and set new standards in electrical insulation.