Latest Update on G11 Fr5: Check out the Latest News Content

By:Admin

G11 Fr5's mission is to make AI accessible to everyone, and they are achieving this through their innovative products and services. Their team of experts is constantly pushing the boundaries of what is possible with AI, and their dedication to excellence has led to a number of breakthroughs in the industry.

One of G11 Fr5's flagship products is a state-of-the-art AI platform that is capable of processing and analyzing massive amounts of data in real time. This platform is being used by companies across a wide range of industries to gain valuable insights and make better-informed decisions. G11 Fr5's AI platform has been praised for its accuracy, speed, and scalability, making it a game-changer for businesses looking to stay ahead of the curve.

In addition to their AI platform, G11 Fr5 has also developed a number of other innovative products that are having a significant impact on the tech industry. From advanced machine learning algorithms to powerful data analytics tools, G11 Fr5 is constantly developing new and exciting ways to harness the power of AI.

But G11 Fr5's influence extends beyond just their products and services. The company is also committed to fostering a thriving AI community through their educational initiatives and research and development efforts. They regularly host workshops, seminars, and other events aimed at bringing together experts and enthusiasts from around the world to collaborate and share knowledge.

Moreover, G11 Fr5 is dedicated to ethical and responsible AI development. They recognize the potential risks and challenges that come with the advancement of AI and are actively working to address these issues. By promoting transparency, accountability, and fairness in AI, G11 Fr5 is setting a new standard for responsible AI development.

In the midst of all these groundbreaking developments, G11 Fr5 has also managed to earn the trust and respect of some of the biggest names in the tech industry. Companies like Amazon, Google, and Microsoft have all formed strategic partnerships with G11 Fr5 to leverage their AI expertise and incorporate their technologies into their own products and services.

With all of these achievements under their belt, it's no wonder that G11 Fr5 is quickly becoming a household name in the tech world. Their commitment to pushing the boundaries of what is possible with AI, while also promoting responsible development and ethical practices, sets them apart as a true leader in the industry.

As G11 Fr5 continues to grow and expand their reach, it's clear that they are poised to make an even bigger impact on the tech industry in the years to come. Their innovative products and services, combined with their dedication to ethical and responsible AI development, make them a force to be reckoned with in the world of artificial intelligence.

Company News & Blog

Durable and Lightweight Fiber Sheet for Various Applications

Friction-stir processing (FSP) is a solid-state joining process that creates a solid bond by combining frictional heat and deformation. It has been widely used in the aerospace and automotive industries for joining lightweight materials such as aluminum and titanium. In recent years, FSP has also been adopted for processing fiber-reinforced polymer (FRP) composites, leading to the development of FRP fiber sheets that offer enhanced mechanical properties and design flexibility.One company at the forefront of this innovation is {Company Name}, a leading manufacturer of FRP materials and solutions. With a strong focus on research and development, the company has been at the forefront of developing advanced FRP fiber sheets using friction-stir processing technology. These sheets have quickly gained recognition for their exceptional structural performance, high strength-to-weight ratio, and corrosion resistance. Furthermore, they offer a cost-effective alternative to traditional materials like steel and concrete, making them highly desirable for a wide range of applications.The unique manufacturing process employed by {Company Name} involves the use of advanced machinery and proprietary techniques to ensure the highest quality and consistency in their FRP fiber sheets. By carefully controlling the parameters of friction-stir processing, the company is able to tailor the microstructure and mechanical properties of the sheets to meet the specific requirements of different industries and applications. This level of customization has set {Company Name} apart in the market, allowing them to cater to a diverse range of clients with varying needs and specifications.One of the key advantages of FRP fiber sheets produced by {Company Name} is their outstanding durability and long-term performance. These sheets are capable of withstanding harsh environmental conditions, including exposure to corrosive chemicals, extreme temperatures, and high-impact forces. As a result, they are well-suited for use in marine, infrastructure, and transportation applications, where traditional materials may fail to provide adequate protection and reliability. Additionally, the lightweight nature of FRP fiber sheets makes them easy to handle and install, reducing labor costs and construction time for various projects.In terms of structural capabilities, {Company Name} offers a range of FRP fiber sheets with different reinforcement patterns and resin formulations to meet specific load-bearing requirements. This level of customization allows engineers and architects to design and construct a wide variety of structures, such as bridges, building facades, and sporting facilities, with confidence in the performance and longevity of the materials. The company also provides technical support and expertise to assist clients in the selection and implementation of the most suitable FRP fiber sheets for their projects, ensuring optimal results and customer satisfaction.Looking ahead, {Company Name} continues to invest in research and development to advance the capabilities of their FRP fiber sheets further. The company is exploring new fiber reinforcements, resin systems, and processing techniques to expand the application range and performance envelope of their products. Additionally, they are collaborating with academic institutions and industry partners to explore innovative uses of FRP materials in emerging fields, such as renewable energy, aerospace, and medical technology.In conclusion, the development of FRP fiber sheets using friction-stir processing by {Company Name} has opened up new possibilities for the use of advanced composite materials in various industries. With their exceptional mechanical properties, durability, and design flexibility, these sheets are proving to be a game-changer for structural and architectural applications. As the company continues to push the boundaries of innovation, we can expect to see even more groundbreaking uses of FRP fiber sheets in the years to come.

Durable Epoxy Boards for Various Applications: Available in Different Thicknesses

Introducing the Latest Innovation in Epoxy Board ManufacturingIn the world of electronics and circuitry, the demand for high-quality materials and components is constantly on the rise. As technology continues to advance, manufacturers are continuously seeking new and innovative materials to meet the needs of their customers. This is where the latest innovation in epoxy board manufacturing comes into play.One company that is leading the charge in this area is {}. With over 20 years of experience in the industry, they have built a reputation for delivering cutting-edge solutions to their customers. Their latest offering, the Different Thickness Epoxy Board, is set to revolutionize the market by providing a superior level of performance and reliability.The Different Thickness Epoxy Board is a testament to the company's commitment to innovation and excellence. It comes in various thickness options, ranging from ultra-thin to standard thickness, catering to the diverse needs of their customers. This versatility makes it an ideal choice for a wide range of applications, from consumer electronics to industrial equipment.One of the key features of the Different Thickness Epoxy Board is its exceptional electrical properties. It offers low dielectric loss and high insulation resistance, ensuring the smooth and efficient flow of electric currents. This makes it an ideal choice for use in high-frequency circuits, where signal integrity is of utmost importance.In addition to its superior electrical properties, the Different Thickness Epoxy Board also boasts excellent mechanical strength. It is highly resistant to impact and has a high flexural strength, making it a reliable choice for applications that require durability and resilience.Furthermore, the Different Thickness Epoxy Board is designed to withstand harsh environmental conditions. It is resistant to moisture, chemicals, and extreme temperatures, ensuring that it remains stable and reliable in any setting. This level of durability and resilience makes it an ideal choice for use in challenging environments, such as automotive and aerospace applications.The company's innovative manufacturing process ensures that the Different Thickness Epoxy Board meets the highest standards of quality and consistency. Each board undergoes rigorous testing and inspection to ensure that it meets the exact specifications and requirements of the customer. This commitment to quality has earned the company a reputation for delivering products that exceed expectations.With the introduction of the Different Thickness Epoxy Board, the company is set to further solidify its position as a leading provider of high-quality materials for the electronics industry. Their dedication to innovation and excellence is evident in every aspect of the product, from its performance to its reliability.In conclusion, the Different Thickness Epoxy Board is a game-changer in the world of epoxy board manufacturing. Its exceptional electrical properties, mechanical strength, and environmental resilience make it a top choice for a wide range of applications. With its introduction, the company {} has once again demonstrated its commitment to delivering innovative and high-quality solutions to its customers. As technology continues to advance, the Different Thickness Epoxy Board is poised to play a pivotal role in shaping the future of electronics and circuitry.

Durable and Heat-Resistant Phenolic Sheet Gaining Popularity in Multiple Industries

Title: Highly Durable G10 Phenolic Sheet Finds Application in Numerous IndustriesIntroduction:Throughout various industries, the need for durable and reliable materials is paramount. One such material garnering attention is the G10 Phenolic Sheet. This high-performance laminate is gaining recognition for its exceptional mechanical strength, excellent electrical properties, and chemical resistance. It has become a sought-after choice for professionals across sectors, ranging from aerospace and automotive to electronics and construction.Company Introduction:{Insert company name} is a leading provider of advanced materials, specializing in manufacturing and distributing high-quality G10 Phenolic Sheets. With years of expertise in the field, our company has established a strong reputation for delivering top-notch solutions that meet and exceed industry standards. We prioritize innovation and sustainability, ensuring our products align with the evolving needs of modern industries.Article:The versatility of G10 Phenolic Sheet has made it an indispensable material in a wide range of applications. With its exceptional durability and resistance to extreme conditions, it has proven itself as a valuable asset in demanding environments. Let us explore the key characteristics and applications of this remarkable material.1. Mechanical Strength: G10 Phenolic Sheet offers impressive mechanical properties, including high tensile strength, impact resistance, and dimensional stability. These features make it an ideal choice for applications requiring structural integrity, such as load-bearing components, gears, and bushings. Its resilience to wear and tear ensures a prolonged lifespan, reducing replacement costs.2. Electrical Properties:The G10 Phenolic Sheet possesses outstanding electrical insulation properties, making it an excellent choice for applications in the electronics industry. With superior dielectric strength, this material provides a reliable barrier against electrical current flow. It is commonly used as insulating supports, terminal boards, and electrical housings in various electronic devices.3. Chemical Resistance:G10 Phenolic Sheet exhibits excellent resistance to various chemicals, making it suitable for applications exposed to corrosive environments. It can withstand exposure to oils, solvents, acids, and alkalis, ensuring durability in demanding industries such as chemical processing, oil and gas, and marine sectors. This resistance prevents degradation and ensures the long-term reliability of equipment and structures.4. Thermal Stability:The G10 Phenolic Sheet offers exceptional thermal stability, enabling it to withstand elevated temperatures without significant degradation. This characteristic makes it suitable for applications where heat resistance is crucial, such as high-temperature insulation, electrical and electronics equipment, and automotive components.5. Aerospace and Defense:The aerospace and defense industries heavily rely on the superior properties of the G10 Phenolic Sheet. Its lightweight yet robust nature makes it ideal for manufacturing aircraft interior panels, structural components, as well as missile and weapon systems. The material's flame-retardant qualities also ensure compliance with safety regulations.6. Automotive Industry:G10 Phenolic Sheet has become a preferred choice in the automotive sector due to its excellent mechanical strength, durability, and resistance to high temperatures. It finds application in engine gaskets, electrical insulation components, friction materials, and composite structures, enhancing overall performance and extending the lifespan of vehicles.7. Construction and Electrical Engineering:The construction industry benefits from G10 Phenolic Sheet's ability to withstand extreme weather conditions, chemical exposure, and mechanical stress. It is commonly used in wall panels, flooring, insulation, and electrical insulation systems. Its resistance to fire and electrical conductivity ensures the safety and performance of infrastructure.Conclusion:The G10 Phenolic Sheet has emerged as a versatile and highly durable material, finding applications across multiple industries. Its mechanical strength, excellent electrical properties, chemical resistance, and thermal stability make it an invaluable asset for aerospace, automotive, electronics, construction, and other sectors. As technological advancements continue, the demand for reliable and resilient materials like the G10 Phenolic Sheet is expected to rise, fueling further innovation in the industry.

Affordable Epoxy Sheet Prices in China - A Cost-Effective Solution

A leading manufacturer in the electrical insulation industry, {Company Name} has recently announced the launch of their new China Cheap Price Epoxy Sheet. This new product is expected to cater to the growing demand for cost-effective and high-quality insulation materials in the market.The China Cheap Price Epoxy Sheet is a versatile and durable insulation material that is widely used in various electrical applications. It is known for its excellent electrical and mechanical properties, making it an ideal choice for insulating and protecting electrical equipment and components.The company's decision to introduce this new product is in line with their commitment to providing innovative and affordable solutions to their customers. With the rising cost of raw materials and production, {Company Name} recognizes the need for cost-effective insulation materials without compromising on quality and performance.The China Cheap Price Epoxy Sheet is designed to meet the stringent industry standards and specifications, ensuring reliable and long-lasting performance in various electrical applications. Its low price point makes it an attractive choice for customers who are looking to reduce their overall production costs without sacrificing the quality of their end products.In addition to its cost-effectiveness, the China Cheap Price Epoxy Sheet also offers other benefits such as excellent thermal and chemical resistance, high mechanical strength, and resistance to moisture and humidity. These properties make it suitable for use in demanding electrical environments where reliability and safety are paramount.{Company Name} has leveraged its extensive experience and expertise in the insulation industry to develop this new product, ensuring that it meets the specific needs and requirements of their customers. The company's state-of-the-art manufacturing facilities and stringent quality control processes further guarantee the reliability and performance of the China Cheap Price Epoxy Sheet.As part of their commitment to customer satisfaction, {Company Name} also offers technical support and customization options for the China Cheap Price Epoxy Sheet. This allows customers to tailor the insulation material to their specific requirements, further enhancing its suitability for their unique applications.The launch of the China Cheap Price Epoxy Sheet represents a significant milestone for {Company Name} as they continue to expand their product portfolio and meet the evolving needs of the electrical insulation industry. By offering a cost-effective and high-quality insulation solution, the company aims to strengthen its position as a leading provider of electrical insulation materials in the global market.As the demand for reliable and affordable insulation materials continues to grow, {Company Name} remains at the forefront of innovation and excellence, delivering solutions that empower their customers to achieve their business objectives efficiently and cost-effectively.The China Cheap Price Epoxy Sheet is now available for purchase, and interested customers are encouraged to contact {Company Name} for more information or to place their orders. With its competitive pricing and exceptional performance, this new product is set to make a significant impact in the electrical insulation industry, catering to the diverse needs of customers across various sectors.

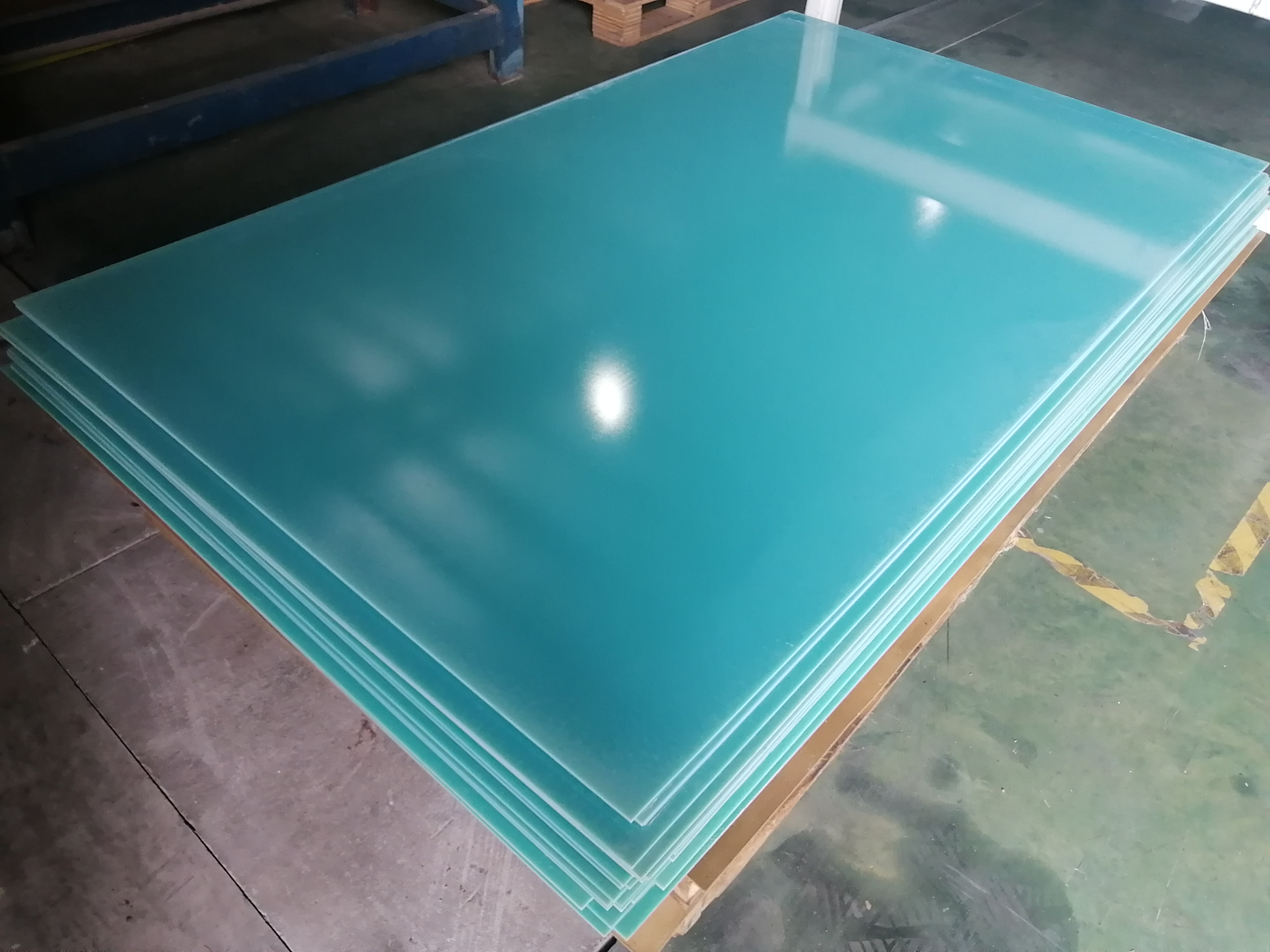

High-quality White Laminates for Your Next Home Improvement Project

White Laminate Sheets now available for purchase from the leading manufacturer of high-quality construction materials, {company name}. Offering durability, versatility, and a sleek, modern look, these laminate sheets are the perfect solution for a wide range of applications in the residential, commercial, and industrial sectors.{Company name} has been a trusted name in the construction industry for over two decades, providing top-notch products to builders, designers, and homeowners alike. Their commitment to quality and innovation has made them a go-to source for construction materials, and the introduction of their new White Laminate Sheets is no exception.The new White Laminate Sheets from {company name} are designed to meet the needs of modern construction projects. Whether it's for kitchen countertops, bathroom vanities, office furniture, or retail displays, these laminate sheets offer a clean and contemporary aesthetic that is sure to elevate any space. The sheets are available in a variety of thicknesses and sizes, making them suitable for a wide range of applications.One of the key benefits of {company name}'s White Laminate Sheets is their durability. Made from high-quality materials, these laminate sheets are resistant to scratches, stains, and heat, making them an ideal choice for high-traffic areas. They are also easy to clean and maintain, making them a practical and long-lasting solution for any project.In addition to their durability, these laminate sheets are also highly versatile. They can be easily cut and shaped to fit any surface, allowing for endless design possibilities. Whether it's a sleek, minimalist look or a bold, statement-making design, {company name}'s White Laminate Sheets provide the flexibility to bring any vision to life.{Company name} takes pride in its commitment to sustainability, and their White Laminate Sheets are no exception. Made from environmentally friendly materials, these sheets are a responsible choice for environmentally conscious builders and designers. They are also manufactured using energy-efficient processes, further reducing their environmental impact.As with all of their products, {company name} is dedicated to providing exceptional customer service and support. Their team of experts is available to provide guidance and assistance throughout every step of the purchasing and installation process. Whether it's choosing the right size and thickness for a project or troubleshooting any challenges that may arise, customers can rely on {company name} to deliver top-notch support.With the introduction of their new White Laminate Sheets, {company name} continues to demonstrate their commitment to providing innovative, high-quality construction materials. Whether for residential, commercial, or industrial projects, these laminate sheets offer a durable, versatile, and stylish solution that is sure to exceed expectations. Builders, designers, and homeowners looking for a reliable source for construction materials need look no further than {company name} for their White Laminate Sheet needs.

Durable and Fire-Resistant Epoxy Sheet for Various Applications

Epoxy Sheet Fr-4 has quickly become a leading material in the electronics and industrial sectors due to its high strength, durability, and heat resistance. This versatile material has revolutionized the way electronic components are manufactured and is a key player in the development of cutting-edge technologies.{Company Name}, a prominent leader in the production of Epoxy Sheet Fr-4, has solidified its position as a top supplier in the industry. With state-of-the-art manufacturing facilities and a commitment to quality, {Company Name} has been able to meet the growing demand for Epoxy Sheet Fr-4 in various applications, from printed circuit boards to aerospace components.One of the key factors that set {Company Name} apart from its competitors is its dedication to research and development. The company continuously invests in new technologies and processes to improve the performance and capabilities of Epoxy Sheet Fr-4. This commitment to innovation has allowed {Company Name} to stay ahead of the curve and provide customers with the most advanced and reliable products on the market.In addition to its focus on innovation, {Company Name} is also dedicated to sustainability and environmental responsibility. The company has implemented strict measures to minimize its environmental impact and ensure that its manufacturing processes are as eco-friendly as possible. This commitment to sustainability has earned {Company Name} a reputation as a responsible and ethical supplier in the industry.The versatility of Epoxy Sheet Fr-4 has made it an essential material in countless applications, from consumer electronics to automotive components. Its ability to withstand extreme temperatures and harsh environments makes it an ideal choice for use in a wide range of industries. As the demand for high-quality Epoxy Sheet Fr-4 continues to grow, {Company Name} is well-positioned to meet the needs of its customers and provide them with reliable and durable products.{Company Name} has also established a strong and reliable distribution network, allowing it to reach customers all around the world. This global presence has helped the company solidify its position as a leading supplier of Epoxy Sheet Fr-4 and has enabled it to build strong and lasting relationships with its clients.Despite the challenges posed by the global pandemic, {Company Name} has remained resilient and adaptable, continuing to meet the needs of its customers while ensuring the safety and well-being of its employees. The company's ability to navigate through difficult times and maintain its high standards of quality and service is a testament to its dedication and professionalism.Looking to the future, {Company Name} is poised to continue its growth and success in the industry. With a strong focus on innovation, sustainability, and customer satisfaction, the company is well-equipped to meet the evolving demands of the market and provide its customers with the best Epoxy Sheet Fr-4 products available.In conclusion, {Company Name} has established itself as a key player in the production and supply of Epoxy Sheet Fr-4, providing customers with high-quality, reliable, and sustainable products. With a commitment to innovation and a dedication to customer satisfaction, the company is well-positioned to continue leading the industry and meeting the growing demand for Epoxy Sheet Fr-4 in various sectors.

Durable Fiberglass Laminate Sheet for Various Applications

Fiberglass Laminate Sheet Revolutionizes the IndustryFiberglass laminate sheets have been around for years, but the latest innovation in this field is taking the industry by storm. Companies such as {} are leading the way in producing high-quality, durable fiberglass laminate sheets that are revolutionizing the market.{} is a leading manufacturer of fiberglass laminate sheets, with a long history of delivering top-notch products to a wide range of industries. With a strong commitment to innovation and customer satisfaction, the company has quickly become a trusted name in the industry.The latest fiberglass laminate sheets from {} are designed to offer unmatched durability and versatility. These sheets are made from high-quality fiberglass material, which is known for its strength and resilience. This makes them ideal for a wide range of applications, from construction and automotive to marine and aerospace.One of the key advantages of {}'s fiberglass laminate sheets is their exceptional resistance to corrosion and extreme temperatures. This makes them ideal for use in harsh environments where other materials may fail. In addition, the sheets are also lightweight and easy to work with, making them a preferred choice for many manufacturers and builders.Another standout feature of {}'s fiberglass laminate sheets is their ability to provide excellent electrical insulation. This makes them suitable for use in electrical and electronic applications, where safety and reliability are paramount. With their high dielectric strength and low electrical conductivity, these sheets offer peace of mind to users in these industries.In addition to their superior performance, {}'s fiberglass laminate sheets are also available in a wide range of sizes, thicknesses, and finishes to suit different customer needs. This customization is a testament to the company's dedication to meeting the diverse requirements of its clients.Furthermore, {} is committed to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to the highest environmental standards, and it continues to explore ways to reduce its carbon footprint. By choosing {}'s fiberglass laminate sheets, customers can be confident that they are supporting a company that prioritizes environmental stewardship.With a strong focus on research and development, {} continues to push the boundaries of what is possible with fiberglass laminate sheets. The company's team of experts is constantly working on new formulations and manufacturing techniques to further improve the performance and capabilities of its products.Customers who have used {}'s fiberglass laminate sheets have been highly impressed with their quality and reliability. Many have reported significant cost savings and improved product performance after switching to these innovative sheets. With such positive feedback, {} has solidified its position as a leader in the fiberglass laminate sheet industry.Overall, the latest advancements in fiberglass laminate sheets from {} are changing the game for manufacturers and builders across various industries. With their exceptional durability, versatility, and environmental credentials, these sheets are set to become the go-to choice for many applications in the coming years. As {} continues to innovate and refine its products, the future looks bright for fiberglass laminate sheets and the industries they serve.

Durable 8mm Fiberglass Sheet Ideal for Construction and DIY Projects

8mm Fiberglass Sheet: The Latest Innovation from Innovative Materials Ltd.Innovative Materials Ltd. is proud to announce the launch of their latest product, the 8mm Fiberglass Sheet. This cutting-edge material is poised to revolutionize the construction and manufacturing industries, offering a durable, versatile, and cost-effective solution for a wide range of applications.The 8mm Fiberglass Sheet is manufactured using state-of-the-art technology and premium quality materials, ensuring a product that is both reliable and long-lasting. With a thickness of 8mm, this fiberglass sheet offers exceptional strength and durability, making it suitable for use in a variety of challenging environments. Whether it's used as a roofing material, a structural component, or a protective barrier, the 8mm Fiberglass Sheet delivers unmatched performance and resilience.One of the key benefits of the 8mm Fiberglass Sheet is its versatility. This material can be easily shaped, cut, and molded to fit the specific requirements of a project, making it an ideal choice for custom applications. Its lightweight nature also makes it easy to handle and install, reducing labor costs and simplifying the construction process.In addition to its strength and flexibility, the 8mm Fiberglass Sheet offers excellent thermal and electrical insulation properties. This makes it an ideal choice for applications where temperature control and electrical safety are paramount. From industrial machinery enclosures to electrical panel housings, this fiberglass sheet provides a reliable solution for a wide range of insulation needs.Furthermore, the 8mm Fiberglass Sheet is resistant to corrosion, chemicals, and extreme weather conditions, making it suitable for outdoor and harsh environments. This level of durability ensures that the material will maintain its quality and performance over time, reducing the need for frequent repairs or replacements.Innovative Materials Ltd. is dedicated to delivering high-quality products that meet the needs of their customers, and the 8mm Fiberglass Sheet is no exception. With a commitment to innovation and excellence, the company has positioned itself as a leader in the manufacturing of fiberglass materials, serving a diverse customer base across various industries."We are thrilled to introduce the 8mm Fiberglass Sheet to the market," said the spokesperson for Innovative Materials Ltd. "This product represents the culmination of our ongoing dedication to research, development, and customer feedback. We are confident that it will deliver exceptional value and performance to our clients, and we look forward to seeing the impact it will make in the industry.”The launch of the 8mm Fiberglass Sheet underscores Innovative Materials Ltd.'s commitment to providing cutting-edge solutions that meet the evolving needs of the market. By combining premium quality materials, advanced manufacturing processes, and a dedication to customer satisfaction, the company continues to set the standard for excellence in the industry.For more information about the 8mm Fiberglass Sheet and other products offered by Innovative Materials Ltd., please visit their website at www.innovativematerials.com or contact their customer service team at [email protected]