Durable and Versatile Fiberglass Composite Sheets for Various Applications

By:Admin

One company that has been leading the way in the production of fiberglass composite sheets is {Company Name}. With a history of innovation and expertise in materials science, {Company Name} has been at the forefront of developing advanced composite materials for various industries. Their fiberglass composite sheets have been used in a wide range of applications, from aerospace and automotive to marine and infrastructure.

The key to the success of {Company Name} in the fiberglass composite sheets market lies in their commitment to research and development. By continuously investing in new technologies and processes, they have been able to produce high-quality composite sheets that meet the stringent requirements of their customers. These sheets are not only lightweight and easy to install, but they also offer superior strength and resistance to corrosion, making them an ideal choice for a wide range of applications.

In addition to their technical expertise, {Company Name} also prides itself on its commitment to sustainability. The production of fiberglass composite sheets requires a careful balance of materials and energy, and {Company Name} has made it a priority to minimize their environmental impact. They have implemented eco-friendly practices in their manufacturing processes, such as recycling and reusing materials, as well as reducing waste and emissions.

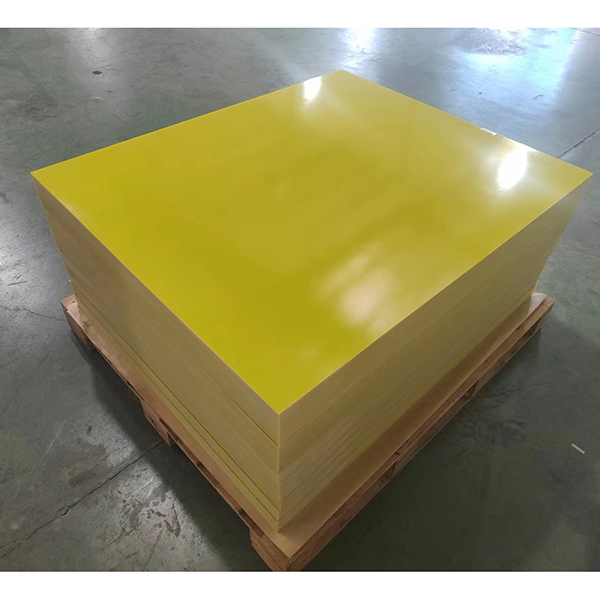

One of the key advantages of fiberglass composite sheets from {Company Name} is their ability to be customized to meet specific project requirements. Whether it's a unique color, texture, or thickness, {Company Name} can work with their customers to create a tailored solution that fits their needs. This level of flexibility has made {Company Name} a trusted partner for many architects, engineers, and builders who are looking for innovative and reliable composite materials.

Another factor that sets {Company Name} apart in the fiberglass composite sheets industry is their strict quality control measures. Every sheet that leaves their facility undergoes rigorous testing to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation for reliability and consistency, making them a preferred supplier for many leading companies and construction projects.

Looking ahead, {Company Name} is poised to continue its leadership in the fiberglass composite sheets market. With ongoing investments in research and development, as well as a focus on sustainability and customer collaboration, they are well-positioned to meet the evolving needs of the industries they serve. By staying true to their commitment to innovation, quality, and environmental responsibility, {Company Name} is set to remain a trusted provider of high-performance fiberglass composite sheets for years to come.

Company News & Blog

High-Quality G10 Phenolic Sheet: A Durable and Versatile Material for Various Applications

G10 Phenolic Sheet is a high-pressure laminate consisting of layers of resin-impregnated woven glass cloth. It is known for its exceptional strength, impact resistance, and electrical insulation properties, making it a popular material in various industries including aerospace, automotive, and electronics. The advanced properties of G10 Phenolic Sheet make it an ideal choice for applications that require superior mechanical and electrical performance.One company that has been at the forefront of providing high-quality G10 Phenolic Sheet is {}. With a strong focus on research and development, the company has been able to create innovative solutions to meet the evolving needs of its customers. The company's G10 Phenolic Sheet is manufactured using the latest technologies and highest quality materials, ensuring that it meets the stringent industry standards and performance requirements.The G10 Phenolic Sheet offered by {} is renowned for its exceptional mechanical strength and dimensional stability. This makes it an ideal material for applications where reliability and durability are paramount. In addition, the G10 Phenolic Sheet is also known for its excellent electrical insulation properties, which makes it suitable for use in electrical and electronic components.One of the key advantages of {}'s G10 Phenolic Sheet is its versatility. It can be machined to tight tolerances, allowing for complex shapes and intricate designs to be produced with ease. This versatility makes it a popular choice for a wide range of applications, from structural components in aircraft to insulating materials in high voltage equipment.{}'s commitment to quality and innovation is evident in the feedback it receives from customers. The company's G10 Phenolic Sheet has gained a reputation for its exceptional performance and reliability, making it a preferred choice for many leading industry players.In addition to its technical capabilities, {} is also known for its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions to meet their needs. This personalized approach has helped {} build long-lasting relationships with its customers, further solidifying its position as a trusted and reliable supplier of G10 Phenolic Sheet.Looking ahead, {} is continuing to invest in research and development to further enhance the performance and capabilities of its G10 Phenolic Sheet. With a strong focus on innovation, the company is well-positioned to meet the future needs of its customers and the evolving demands of the industry.In conclusion, {}'s G10 Phenolic Sheet is a high-performance material that has gained recognition for its exceptional strength, impact resistance, and electrical insulation properties. Backed by the company's commitment to quality and innovation, it has become a preferred choice for a wide range of applications across various industries. With its focus on customer satisfaction and continuous improvement, {} is well-equipped to maintain its leadership position in the market for G10 Phenolic Sheet.

Epoxy Sheet FR 5: Durable Fire-Resistant Laminates for Multiple Applications

Title: Introduction of Innovative Epoxy Sheet FR-5 in the Electrical IndustryIntroduction:In today's fast-paced world, the electrical industry continues to witness rapid advancements. One such breakthrough occurs with the introduction of a cutting-edge product – Epoxy Sheet FR-5, a game-changer that promises to revolutionize the electrical sector. This groundbreaking achievement comes from an established manufacturing company renowned for its commitment to quality and innovation. The company's dedication to research and development has resulted in the creation of a superior alternative that surpasses industry standards. In this news report, we will delve into the features, benefits, and potential applications of this exceptional epoxy sheet, while also highlighting the company's mission and commitment to excellence.Company Overview:{} is a distinguished name in the field of advanced materials, with a proven track record of providing high-quality products to various industries. With a dedication to research and development, they continue to push the boundaries of innovation. Combining cutting-edge technology with a focus on sustainability, the company strives to offer eco-friendly solutions that meet the evolving needs of their customers.Epoxy Sheet FR-5:The newly developed Epoxy Sheet FR-5 is a durable and versatile alternative offering unparalleled performance in a wide range of electrical applications. This epoxy sheet boasts exceptional mechanical and electrical properties, making it an ideal choice for high-temperature, high-voltage, and high-frequency applications.Features and Benefits:1. Superior Electrical Insulation: The FR-5 sheet provides excellent electrical insulation properties, ensuring the safety and reliability of electrical systems. It exhibits a low dielectric constant and is resistant to electric stress, effectively minimizing the risk of electrical failures and breakdowns.2. High Thermal Stability: The FR-5 sheet demonstrates exceptional thermal stability, enabling it to withstand elevated temperatures. This property is essential in applications where heat dissipation is crucial, safeguarding against possible overheating and subsequent damage.3. Flame Resistance: With its inherent flame-retardant properties, the FR-5 epoxy sheet complies with stringent safety standards. Its self-extinguishing feature significantly reduces the risk of fire propagation, making it a preferred choice in various electrical systems.4. Mechanical Strength: The robust nature of the FR-5 sheet ensures mechanical reliability even under extreme conditions. Its superior strength and resistance to impact and vibration enhance the longevity and durability of electrical products.5. Chemical Resistance: The FR-5 sheet exhibits remarkable resistance to various chemicals such as solvents, acids, and bases, making it suitable for a wide range of industrial environments.Applications:1. Printed Circuit Boards (PCBs): FR-5 sheets are widely used as substrates for PCBs due to their excellent electrical and mechanical properties. They offer enhanced performance and reliability, making them ideal for high-frequency and high-speed applications in industries such as telecommunications, automotive, and aerospace.2. Electrical Insulation: The FR-5 sheet is a preferred material for insulating busbars, transformers, switchgears, and other electrical components that require high voltage and heat resistance. Its exceptional insulation properties ensure the safe operation of electrical systems.3. Industrial Equipment: Various industrial equipment, including motors, generators, and thermal barriers, benefit from the FR-5 sheet's high thermal stability and mechanical strength, ensuring optimal performance and prolonged lifespan.Conclusion:The introduction of the FR-5 epoxy sheet marks a significant milestone in the electrical industry, offering a breakthrough solution that surpasses conventional materials. With its exceptional electrical and mechanical properties, this versatile product opens new possibilities for applications in numerous sectors. As {} continues to pioneer cutting-edge technologies, it remains committed to providing innovative, sustainable, and reliable materials that contribute to the ongoing progress of the electrical industry.

High-quality Phenolic Resin Board: A Durable and Versatile Building Material

The Phenolic Resin Board Market is expected to witness significant growth in the coming years. Phenolic resin boards are known for their durability, high-temperature resistance, and excellent mechanical properties, making them ideal for a wide range of applications in industries such as construction, transportation, and electronics.One of the leading companies in the production of Phenolic resin boards is {Company Name}, a global leader in the chemical industry. {Company Name} has established itself as a trusted provider of high-quality Phenolic resin boards, offering a wide range of products to meet the diverse needs of its customers.The company's Phenolic resin boards are manufactured using advanced technology and stringent quality control measures to ensure superior performance and reliability. With a strong focus on research and development, {Company Name} continues to innovate and improve its Phenolic resin board products to meet the evolving requirements of various industries.{Company Name} takes pride in its commitment to sustainability and environmental responsibility. The company has implemented eco-friendly production practices and actively seeks to minimize its environmental footprint. This dedication to sustainability has earned {Company Name} a strong reputation as a responsible and ethical producer of Phenolic resin boards.As the demand for durable and high-performance materials continues to grow, {Company Name} is well-positioned to capitalize on the opportunities in the Phenolic resin board market. The company's extensive experience and proven track record in the industry make it a preferred choice for customers seeking reliable and innovative Phenolic resin board solutions.In addition to its commitment to quality and sustainability, {Company Name} also places a strong emphasis on customer satisfaction. The company's dedicated team of professionals works closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. This customer-centric approach has earned {Company Name} a loyal and satisfied customer base.The global Phenolic resin board market is projected to experience robust growth in the coming years, driven by increasing demand from key industries such as construction, automotive, and electronics. {Company Name} is well-equipped to capitalize on this growth, owing to its extensive product range, technological expertise, and commitment to excellence.With a strong focus on innovation and continuous improvement, {Company Name} is poised to maintain its leadership position in the Phenolic resin board market. The company's relentless pursuit of excellence, coupled with its uncompromising commitment to quality and customer satisfaction, sets it apart as a preferred partner for businesses seeking reliable and high-performance Phenolic resin board solutions.The future looks promising for the Phenolic resin board market, and {Company Name} is poised to play a pivotal role in driving the industry forward. With its unwavering dedication to quality, innovation, and customer satisfaction, {Company Name} is set to make a significant impact on the global Phenolic resin board market in the years to come.

How to Easily Install and Maintain SMC Sheet Panels

Title: Groundbreaking Composite Technology Revolutionizing Industrial ProcessesIntroduction:In recent years, significant advancements have been made in the world of materials sciences, leading to transformative developments across various industries. One such breakthrough is the development of Sheet Molding Compound (SMC) technology, a high-performance composite material that has revolutionized industrial processes. This versatile material has gained widespread recognition for its exceptional strength, durability, and exceptional design flexibility. In this article, we will delve into the groundbreaking properties and applications of SMC, as well as explore how it is reshaping industries around the world.1. Overview of SMC:SMC, a composite material made from a combination of resins, fibers, and fillers, has emerged as a game-changer due to its superior mechanical properties. This combination creates a sheet-like material that can be molded into complex shapes, providing manufacturers with unprecedented design possibilities. Moreover, SMC exhibits excellent strength-to-weight ratio, electrical conductivity, and chemical resistance, making it an ideal choice for a wide range of applications.2. Automotive Industry Transformation:The automotive industry, known for its constant pursuit of lightweighting solutions, has embraced SMC as a viable alternative to traditional metals. By incorporating SMC components, vehicles can be substantially lighter, leading to enhanced fuel efficiency and reduced emissions. Additionally, SMC's inherent corrosion resistance contributes to longer vehicle lifespans and reduced maintenance costs. Increasingly, auto manufacturers are adopting SMC in the production of body panels, structural components, and interior parts, revolutionizing the future of mobility.3. Aerospace Applications:The aerospace industry, where lightweight materials are crucial for fuel efficiency and performance, has also been quick to recognize the potential of SMC. By replacing metal parts with SMC components, aircraft can achieve significant weight reductions without compromising integrity or safety. Its exceptional strength and durability also make SMC suitable for critical applications, including aircraft fairings, interior panels, and structural reinforcements. As a result, this technology is contributing to more sustainable and efficient air travel while reducing operating costs.4. Renewable Energy Advancements:The renewable energy sector is another area benefiting from the development of SMC technology. With its excellent resistance to weathering and ultraviolet (UV) radiation, SMC is being used in the construction of wind turbine blades, enabling higher energy production and improved reliability. By using SMC, manufacturers are optimizing blade design for increased efficiency, reducing maintenance requirements, and extending the lifespan of renewable energy infrastructure.5. Infrastructure Reinforcement:The prowess of SMC extends to infrastructure projects as well. In many countries, traditional concrete structures are being supplemented or replaced by SMC-based components. The lightweight nature of SMC makes it a particularly valuable material for retrofitting purposes, where it can reinforce structures without adding excessive weight. Applications include bridge decks, utility poles, and corrosion-resistant structures for coastal areas. This adoption of SMC in the construction sector points toward enhanced durability, efficiency, and sustainability in future infrastructure projects.Conclusion:Sheet Molding Compound (SMC) technology has revolutionized industries through its remarkable mechanical properties and design flexibility. Its applications in the automotive, aerospace, renewable energy, and construction sectors are transforming traditional approaches, prioritizing lightweighting, and enhancing sustainability. As the adoption of SMC continues to grow, we can expect a global shift towards more efficient, durable, and environmentally friendly products and infrastructure.

How Epgc308 is Impacting News Content

Epgc308, a leading manufacturer of composite materials, recently announced its latest product innovation that is set to revolutionize the industry. The company, known for its expertise in developing high-performance materials for various applications, has once again demonstrated its commitment to delivering cutting-edge solutions to its customers.Epgc308's new product, which the company has chosen to keep under wraps until its official launch, is the result of extensive research and development efforts. The company's team of engineers and materials scientists have been hard at work to create a material that offers superior performance and durability, meeting the evolving needs of the market.With a focus on enhancing the properties of their materials while maintaining a commitment to sustainability, Epgc308 has positioned itself as a key player in the composite materials industry. By leveraging their technical expertise and deep understanding of market trends, the company has consistently delivered innovative solutions to a wide range of industries, including aerospace, automotive, construction, and renewable energy.In addition to its dedication to product innovation, Epgc308 places a strong emphasis on quality assurance and environmental responsibility. The company complies with stringent industry standards and regulations to ensure that its materials meet the highest quality and safety requirements. Furthermore, Epgc308 is committed to sustainable manufacturing practices, minimizing its environmental impact throughout the production process.Epgc308's relentless pursuit of excellence has earned the company a reputation as a trusted partner for businesses seeking high-performance composite materials. Its track record of success and its ability to tailor solutions to meet the specific needs of its customers have solidified Epgc308's position as a preferred supplier in the industry.The company's new product release is expected to generate significant interest within the market, as customers eagerly anticipate the opportunity to experience the benefits of Epgc308's latest innovation. With its strong reputation for delivering reliable and high-quality materials, Epgc308 is well-positioned to capture new opportunities and expand its market presence with this new offering.In light of the upcoming launch, industry experts are optimistic about the impact that Epgc308's new product will have on the composite materials landscape. The company's commitment to pushing the boundaries of what is possible in material science, coupled with its proven track record of delivering value to customers, bodes well for the success of this latest innovation.As Epgc308 prepares for the official introduction of its new product, industry stakeholders and customers alike are eagerly awaiting further details about the material's specific features and potential applications. The anticipation surrounding this release underscores the market's recognition of Epgc308 as a driving force in shaping the future of composite materials.In conclusion, Epgc308's forthcoming product launch is a testament to the company's ongoing commitment to innovation and excellence. By continuously pushing the boundaries of material science and demonstrating a keen understanding of market needs, Epgc308 is poised to further solidify its position as a leader in the composite materials industry. As the industry eagerly awaits the official unveiling of this new product, all signs point to another significant milestone for Epgc308 and the customers who rely on its advanced materials for their operations.

Strong and Durable Glass Reinforced Laminate (G11) Explained

G11 Glass Reinforced Laminate (G11) has been making waves in the industry for its exceptional strength, durability, and versatility. This advanced material has become a popular choice for a wide range of applications, from aerospace and automotive to electronics and industrial machinery.G11 is a high-performance composite material that is known for its exceptional mechanical and electrical properties. It is made from layers of glass fabric impregnated with epoxy resin, which are then cured under high pressure and temperature. This results in a material that is incredibly strong, lightweight, and resistant to heat, chemicals, and moisture.One of the key benefits of G11 is its outstanding mechanical strength. It has a high tensile strength, excellent compressive strength, and low moisture absorption, making it an ideal choice for structural and load-bearing components. Its superior dimensional stability and resistance to creep and fatigue make it suitable for use in demanding applications where reliability and long-term performance are critical.In addition to its impressive mechanical properties, G11 also offers excellent electrical insulation properties. It has a high dielectric strength, low dissipation factor, and good arc resistance, making it a popular choice for electrical and electronic applications. Its ability to withstand high voltages and frequencies, combined with its flame-retardant properties, make it a reliable and safe choice for components in high-performance electrical systems.G11 is also highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and fuels. This makes it a popular choice for use in harsh environments where corrosion and chemical exposure are a concern. Its ability to maintain its properties over a broad temperature range further enhances its suitability for use in diverse and challenging applications.One company that is at the forefront of G11 innovation is {}. With a rich history in the development and production of advanced composite materials, {} has established itself as a leading supplier of high-performance solutions for a wide range of industries. The company's commitment to research and development, combined with its state-of-the-art manufacturing facilities, allows it to produce G11 products that meet the highest standards of quality and performance.{}'s G11 products are used in a diverse range of applications, from aerospace and defense to industrial machinery and electronics. Its expertise in customizing G11 formulations to meet specific customer requirements has earned it a reputation for delivering innovative and reliable solutions that exceed expectations. With a focus on continuous improvement and a customer-centric approach, {} remains at the forefront of G11 technology, providing its customers with the highest quality products and support.As the demand for high-performance composite materials continues to grow, {} is well-positioned to meet the needs of its customers with its advanced G11 products. With a proven track record of excellence and a commitment to innovation, the company is poised to remain a leader in the industry for years to come.In conclusion, G11 Glass Reinforced Laminate continues to gain recognition as an advanced composite material with exceptional strength, durability, and versatility. With its outstanding mechanical and electrical properties, as well as its resistance to heat, chemicals, and moisture, it has become a popular choice for a wide range of applications. Companies like {} are driving the development and production of G11 products, ensuring that customers have access to high-quality solutions that meet the highest standards of performance and reliability. As the industry continues to evolve, G11 is expected to play a key role in shaping the future of advanced composite materials.

High-quality White Laminates for Your Next Home Improvement Project

White Laminate Sheets now available for purchase from the leading manufacturer of high-quality construction materials, {company name}. Offering durability, versatility, and a sleek, modern look, these laminate sheets are the perfect solution for a wide range of applications in the residential, commercial, and industrial sectors.{Company name} has been a trusted name in the construction industry for over two decades, providing top-notch products to builders, designers, and homeowners alike. Their commitment to quality and innovation has made them a go-to source for construction materials, and the introduction of their new White Laminate Sheets is no exception.The new White Laminate Sheets from {company name} are designed to meet the needs of modern construction projects. Whether it's for kitchen countertops, bathroom vanities, office furniture, or retail displays, these laminate sheets offer a clean and contemporary aesthetic that is sure to elevate any space. The sheets are available in a variety of thicknesses and sizes, making them suitable for a wide range of applications.One of the key benefits of {company name}'s White Laminate Sheets is their durability. Made from high-quality materials, these laminate sheets are resistant to scratches, stains, and heat, making them an ideal choice for high-traffic areas. They are also easy to clean and maintain, making them a practical and long-lasting solution for any project.In addition to their durability, these laminate sheets are also highly versatile. They can be easily cut and shaped to fit any surface, allowing for endless design possibilities. Whether it's a sleek, minimalist look or a bold, statement-making design, {company name}'s White Laminate Sheets provide the flexibility to bring any vision to life.{Company name} takes pride in its commitment to sustainability, and their White Laminate Sheets are no exception. Made from environmentally friendly materials, these sheets are a responsible choice for environmentally conscious builders and designers. They are also manufactured using energy-efficient processes, further reducing their environmental impact.As with all of their products, {company name} is dedicated to providing exceptional customer service and support. Their team of experts is available to provide guidance and assistance throughout every step of the purchasing and installation process. Whether it's choosing the right size and thickness for a project or troubleshooting any challenges that may arise, customers can rely on {company name} to deliver top-notch support.With the introduction of their new White Laminate Sheets, {company name} continues to demonstrate their commitment to providing innovative, high-quality construction materials. Whether for residential, commercial, or industrial projects, these laminate sheets offer a durable, versatile, and stylish solution that is sure to exceed expectations. Builders, designers, and homeowners looking for a reliable source for construction materials need look no further than {company name} for their White Laminate Sheet needs.

Durable Epoxy Electrical Insulation Laminate Sheet for Industrial Applications

*** Company Introduction ***[Company Name] is a leading manufacturer of electrical insulation materials and laminates. With a strong focus on research and development, we have been providing high-quality products to various industries such as electronics, automotive, aerospace, and more for over two decades. Our commitment to innovation and customer satisfaction has enabled us to establish a strong presence in the global market.*** News Content ***[Company Name] has recently introduced a new product to its extensive line of electrical insulation materials – the 3240 Epoxy Electrical Insulation Laminate Sheet. This new addition is aimed at meeting the increasing demand for advanced insulation solutions in the rapidly evolving electronics and electrical engineering sectors.The 3240 Epoxy Electrical Insulation Laminate Sheet is a high-performance material that offers superior electrical insulation properties, mechanical strength, and thermal resistance. It is commonly used in applications such as electrical equipment, bus bars, switchgear, and transformers, where reliability and durability are paramount.One of the key features of the 3240 Epoxy Electrical Insulation Laminate Sheet is its exceptional dielectric strength, which ensures reliable insulation under high voltage conditions. This makes it an ideal choice for use in critical electrical components that are subjected to extreme operating conditions.In addition to its robust electrical insulation properties, the 3240 Epoxy Electrical Insulation Laminate Sheet also offers excellent mechanical strength, making it suitable for applications that require resistance to mechanical stress and impact. This ensures the longevity and reliability of electrical equipment and components in which it is used.Furthermore, the 3240 Epoxy Electrical Insulation Laminate Sheet exhibits outstanding thermal resistance, allowing it to withstand elevated temperatures without compromising its electrical and mechanical performance. This characteristic makes it suitable for use in environments where temperature variations are prevalent, ensuring sustained functionality and safety.As a leading manufacturer of electrical insulation materials, [Company Name] has developed the 3240 Epoxy Electrical Insulation Laminate Sheet with a strong focus on quality and reliability. The product undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards and specifications. This commitment to excellence is a testament to [Company Name]'s dedication to providing customers with superior products that offer exceptional performance and longevity.With the introduction of the 3240 Epoxy Electrical Insulation Laminate Sheet, [Company Name] aims to address the evolving needs of the electronics and electrical engineering industries, providing them with a reliable and high-performance insulation solution that meets their stringent requirements and standards.In conclusion, the introduction of the 3240 Epoxy Electrical Insulation Laminate Sheet further strengthens [Company Name]'s position as a frontrunner in the electrical insulation materials market. By leveraging its expertise in research and development, along with a steadfast commitment to quality and innovation, [Company Name] continues to provide customers with cutting-edge solutions that empower them to excel in their respective industries.

Insulation Epoxy Fiberglass Fr4/G10 Sheets from China: A Comprehensive Overview

China Insulation Epoxy Fiberglass Fr4/G10 Sheets are gaining popularity in the global market due to their superior insulation properties and high mechanical strength. These sheets are widely used in various industries such as electronics, aerospace, automotive, and telecommunications for applications that require high-performance insulation materials.The Fr4/G10 Sheets are manufactured using a combination of high-quality epoxy resin and fiberglass cloth. This combination results in a material that exhibits excellent electrical insulation properties, superior mechanical strength, and high heat resistance. These sheets are capable of withstanding high temperatures and have a low thermal expansion coefficient, making them ideal for use in extreme environments.In addition to their exceptional insulation properties, Fr4/G10 Sheets also offer excellent dimensional stability, chemical resistance, and good machinability. These qualities make them suitable for a wide range of applications, including printed circuit boards, electrical insulation components, and structural parts in various electronic devices.The growing demand for high-performance insulation materials has prompted several manufacturers in China to produce Fr4/G10 Sheets that meet international quality standards. These sheets are manufactured using advanced production techniques and are subjected to rigorous quality control measures to ensure that they meet the requirements of the global market.One of the leading manufacturers of China Insulation Epoxy Fiberglass Fr4/G10 Sheets is {}. With years of experience in the industry, they have established themselves as a reliable supplier of high-quality insulation materials. Their Fr4/G10 Sheets are known for their consistent performance, reliability, and durability, making them the preferred choice for many businesses around the world.The company's manufacturing facility is equipped with state-of-the-art machinery and equipment, allowing them to produce Fr4/G10 Sheets that meet the strictest quality standards. They have a team of experienced engineers and technicians who oversee the production process to ensure that all products adhere to international quality norms.In addition to their commitment to quality, the company also places a strong emphasis on research and development. They continuously invest in technology and innovation to enhance the performance of their insulation materials and develop new products that cater to the evolving needs of the market. This dedication to innovation has allowed them to stay ahead of the competition and maintain a leading position in the industry.As part of their dedication to customer satisfaction, the company offers customized solutions for businesses that require specific insulation materials for their applications. They work closely with their clients to understand their requirements and deliver tailored products that meet their unique needs. This personalized approach has earned them a loyal customer base and a strong reputation in the global market.With the increasing demand for high-performance insulation materials, the market for China Insulation Epoxy Fiberglass Fr4/G10 Sheets is expected to grow significantly in the coming years. As industries continue to seek reliable and durable insulation solutions for their applications, manufacturers like {} are well-positioned to meet this demand with their superior products and dedication to excellence.In conclusion, China Insulation Epoxy Fiberglass Fr4/G10 Sheets are becoming increasingly popular in the global market due to their exceptional insulation properties, high mechanical strength, and superior performance in extreme environments. With a strong focus on quality, innovation, and customer satisfaction, manufacturers like {} are meeting the growing demand for high-performance insulation materials and are poised to lead the industry in the years to come.