| NO. | ITEM | UNIT | INDEX VALUE | ||

| 1 | Density | g/cm³ | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | ≤0.5 | ||

| 3 | Vertical bending strength | Normal | MPa | ≥340 | |

| 180±5℃ | ≥170 | ||||

| 4 | Compression strength | Vertical | MPa | ≥350 | |

| 5 | Impact strength (charpy type) | gap | KJ/m² | ≥33 | |

| 6 | Bonding strength | N | ≥5700 | ||

| 7 | Tensile strength | Lengthway | MPa | ≥300 | |

| 8 | Vertical electric strength (in oil of 90℃±2℃) | 1mm | KV/mm | ≥20.0 | |

| 2mm | ≥18.0 | ||||

| 3mm | ≥16.0 | ||||

| 9 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥30 | ||

| 10 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | ||

| 11 | Parallel Insulation Resistance | Normal | Ω | ≥1.0×1013 | |

| After soaking for 24hours | ≥1.0×1010 | ||||

| 12 | Volumn Insulation Resistance | Normal | Ω.m | ≥1.0×1011 | |

| After soaking for 24hours | ≥1.0×109 | ||||

| 180±5℃ | ≥1.0×108 | ||||

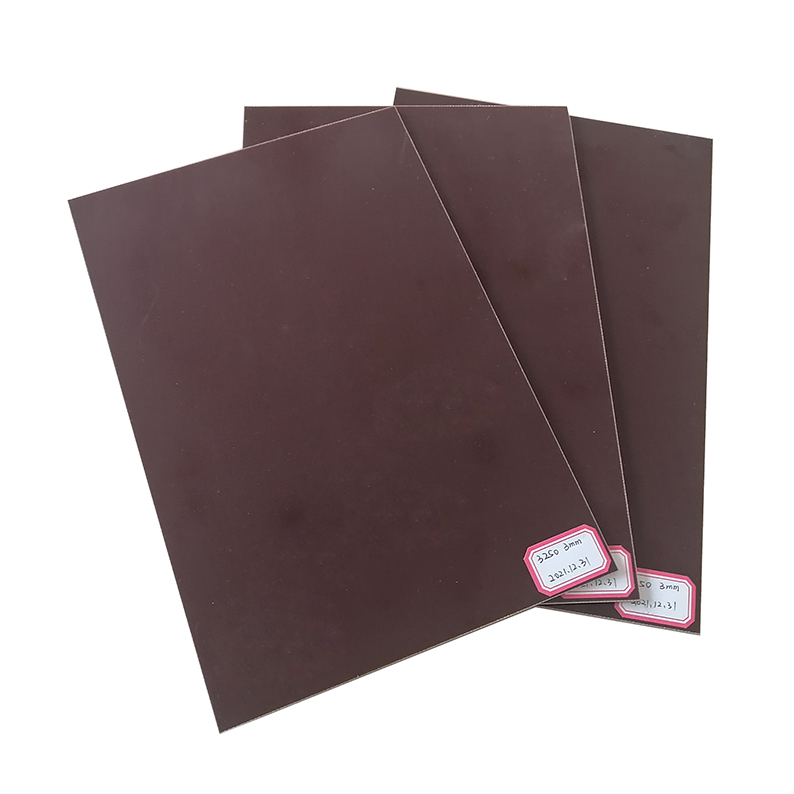

3255 Modified Diphenyl Ether Glassfiber Laminated Sheet

We, as a factory, produce top-quality 3255 Modified Diphenyl Ether Glassfiber Laminated Sheets. Our durable and adaptable product serves various industries. Order now and experience our expertise!

Request a QuotePRODUCTS DETAILS

Hot Products

3240 Epoxy phenol aldehyde Glassfiber laminated sheet

3240 Halogen-free fire retardant Epoxy phenolic glass fiber laminated sheet

3242 Epoxy Glassfiber Laminated Sheet

3233 NEMA G5 Melamine glass cloth laminate suitable for arc resistant material in switches

Glass Fiber Cloth Laminated Epoxy Board Cut Epoxy Insulating Sheet Yellow 3240

FR4 Rigid Epoxy Glassfiber Laminated Sheet

G10 Epoxy Glassfiber Laminated Sheet

Epoxy Fiberglass Laminate Sheet for Electrical Insulation EPGC201 green color sheet

G10 Halogen-free fire retardant Epoxy glass fiber laminated sheet

H Class Heat Resistant Epoxy Resin Glass Laminate Sheet Epgc308

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours