China Epoxy Sheet and Epoxy Fiberglass Laminate Sheet - Latest News Update

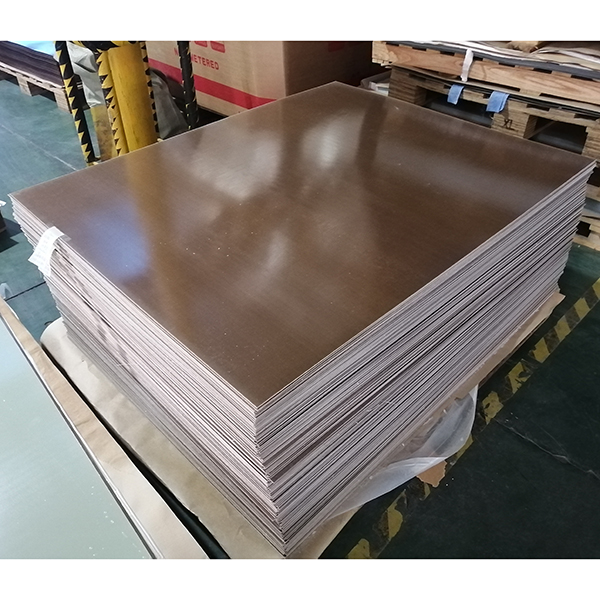

This news article aims to provide an overview of China's epoxy sheet industry and highlight the significance of 3240 Epoxy Fiberglass Laminate Sheet in this sector. It will also introduce a company involved in manufacturing and distributing epoxy sheets, showcasing their expertise and commitment to quality.China is a global leader in the production and export of various industrial materials. Among these, the epoxy sheet industry has witnessed significant growth in recent years. Epoxy sheets are widely used in electrical and electronics industries due to their excellent insulation properties, resistance to high temperatures, and mechanical strength.One prominent product in the epoxy sheet category is the 3240 Epoxy Fiberglass Laminate Sheet. Renowned for its exceptional electrical insulation performance and outstanding temperature resistance, this sheet has gained popularity both domestically and internationally. Its ability to withstand high voltage, high temperature, and high humidity environments makes it ideal for applications such as power distribution equipment, electrical insulation structures, and electronic circuit boards.China (Company Name) is a leading manufacturer and supplier of epoxy sheets, with a specialization in 3240 Epoxy Fiberglass Laminate Sheets. With a state-of-the-art production facility and a team of experienced engineers, they have carved a niche for themselves in the industry. The company's commitment to quality, reliability, and innovation has made them a preferred choice for customers from various sectors.With a production capacity of (insert production capacity), (Company Name) can efficiently cater to domestic demand as well as international orders. Their advanced manufacturing processes ensure consistent product quality and adherence to international standards, such as SGS, ISO, and RoHS. This dedication to quality control has earned them a strong reputation and a loyal customer base.In addition to producing high-quality epoxy sheets, (Company Name) also emphasizes environmental sustainability in their operations. They strictly adhere to environmental regulations and implement eco-friendly practices throughout their manufacturing process. This demonstrates their commitment to responsible production and contributes to the overall green initiative of China's industrial sector.To meet the diverse needs of their customers, (Company Name) offers a wide range of epoxy sheets, including various sizes, thicknesses, and surface finishes. The 3240 Epoxy Fiberglass Laminate Sheet, in particular, is available in different grades to suit different applications and operational requirements. Their team of experts provides personalized customer support, assisting clients in identifying the most suitable epoxy sheet solution for their specific needs.In terms of distribution, (Company Name) has established a robust network both within China and abroad. Their products are widely available through authorized distributors, ensuring efficient access for customers around the world. This extensive distribution network further strengthens their position as a leading player in the global epoxy sheet market.As China's epoxy sheet industry continues to grow, companies like (Company Name) remain at the forefront of this expansion. Through their commitment to quality, environmental sustainability, and customer satisfaction, they not only contribute to the overall industrial development of China but also reinforce the country's position as a global leader in industrial materials.In conclusion, China's epoxy sheet industry, driven by the popularity of products like 3240 Epoxy Fiberglass Laminate Sheet, has experienced significant growth. (Company Name), a leading manufacturer and supplier in this sector, has established itself as a reliable provider of high-quality epoxy sheets. Their expertise, commitment to quality, and dedication to environmental sustainability have contributed to their success in meeting the diverse needs of customers both domestically and internationally. As the demand for epoxy sheets continues to rise, companies like (Company Name) are poised to play a crucial role in shaping the industry's future.

Read More

Top Quality Laminate Sheet and Fr4/Fr5/G10 Available in China

Title: China Emerges as Prominent Producer of High-Quality Laminate Sheets and Fr4/Fr5/G10 Insulation MaterialsIntroduction: In recent years, China has witnessed a significant surge in the production of high-quality laminate sheets and insulation materials, namely Fr4/Fr5/G10. With an ever-expanding list of manufacturers dedicated to delivering top-notch products, China has solidified its position as a global leader in the industry. This article explores the growth of China's laminate sheet and insulation material market, highlighting the key players and their contributions to the industry.Market Expansion and Industry Overview: China's laminate sheet and insulation material market has experienced remarkable growth in recent years. This growth can be attributed to a multitude of factors, including advancements in manufacturing technology, increased investment in research and development, and a focus on producing innovative and high-performance products. The market has witnessed a surge in demand from various sectors, such as electronics, automotive, aerospace, and telecommunications, all of which rely heavily on laminate sheets and insulation materials for their operations.Leading Manufacturers: One prominent player in the market is [Company Name], a leading manufacturer of laminate sheets and insulation materials. Their diverse product range includes a wide variety of laminate sheets, including copper-clad laminates (CCL), aluminum-based laminates, and phenolic paper laminates. The company's emphasis on quality control and adherence to international standards has earned them a solid reputation among their global clientele.Another key player in the market is [Company Name], known for their expertise in Fr4/Fr5/G10 insulation materials. With advanced manufacturing facilities and a highly skilled workforce, they consistently deliver high-performance products to meet the diverse needs of industries such as electronics, energy, and transportation. By leveraging their deep understanding of customer requirements and market trends, they have established themselves as a reliable and trusted source for insulation materials.Innovation and Technological Advancements: China's laminate sheet and insulation material manufacturers have been at the forefront of innovation, developing new materials and manufacturing processes to meet the evolving needs of their customers. Continuous investment in research and development has led to the introduction of environmentally friendly and cost-effective materials that offer superior performance characteristics. These innovative products not only improve efficiency but also contribute to the overall sustainability goals of businesses across different industries.Quality Assurance and International Certification: To ensure the consistent quality of their products, leading Chinese manufacturers comply with international certification standards such as ISO 9001, ISO 14001, and UL. Rigorous quality control measures are implemented at every stage of the manufacturing process, from raw material inspection to final product testing. By adhering to these strict quality standards, Chinese manufacturers have garnered trust and credibility from clients worldwide.Global Market Reach:China's laminate sheet and insulation material manufacturers have successfully expanded their market reach beyond national boundaries. By tapping into the global supply chain and establishing strategic partnerships with distributors, these companies have created a robust distribution network. As a result, their high-quality products have gained recognition and acceptance in markets around the world, further solidifying China's position as a major player in the global laminate sheet and insulation material industry.Conclusion:China's emergence as a prominent producer of high-quality laminate sheets and Fr4/Fr5/G10 insulation materials has reshaped the global market. With a focus on innovation, adherence to international standards, and a commitment to delivering superior products, Chinese manufacturers have become trusted partners to industries that rely on laminate sheets and insulation materials for their operations. As the industry continues to grow, China is poised to play a pivotal role in shaping its future, meeting the evolving demands of a wide range of sectors on a global scale.

Read More

How Electrical Laminated Sheet is Revolutionizing the Industry

[News Content]Electrical Laminated Sheet Revolutionizes Power Distribution EfficiencyIn today's rapidly advancing world, technological advancements play a crucial role in shaping the landscape of various industries. Power distribution is one such sector that consistently necessitates innovation to meet growing demands and improve efficiency. Enter Electrical Laminated Sheet, a groundbreaking development designed to transform the way electricity is distributed.Electrical Laminated Sheet, developed by cutting-edge materials engineering company {}, boasts an array of features that make it an ideal choice for power distribution applications. With its superior electrical insulation properties, excellent mechanical strength, and high temperature resistance, this innovative solution ensures optimal performance in even the most demanding environments.The electrical laminated sheet category has traditionally been dominated by outdated materials, resulting in limited efficiency and effectiveness. However, with this latest offering from {}, the industry will witness a paradigm shift. The unique composition of the Electrical Laminated Sheet facilitates reduced energy losses during power transmission, thereby enhancing overall system efficiency.Furthermore, the material's remarkable mechanical strength provides exceptional protection against mechanical stress, vibration, and thermal expansion, ensuring long-term reliability. This enhanced durability translates to reduced maintenance costs and increased operational lifespan, making it an economically viable choice for power distribution systems worldwide.A significant advantage of Electrical Laminated Sheet is its ability to withstand high temperatures. Traditionally, extreme heat adversely affects the performance of electrical insulation materials, leading to compromised safety and reliability. The innovative design of this new solution equips it with the capability to operate flawlessly at elevated temperatures, thereby ensuring uninterrupted power distribution even in harsh conditions.Beyond its exceptional technical specifications, the Electrical Laminated Sheet also satisfies industry demands for sustainable solutions. The materials used in its manufacturing prioritize environmental safety and adhere to strict regulatory standards. With the growing focus on environmental consciousness, this product aligns perfectly with the shift towards sustainable practices in the power distribution sector.The advent of Electrical Laminated Sheet marks an exciting milestone in the power distribution industry. Its ability to revolutionize efficiency, reliability, and sustainability in electrical systems positions it as the trailblazer in the market. Companies around the world are eagerly embracing this groundbreaking solution to enhance the performance and longevity of their power distribution networks.Leading businesses have already recognized the benefits of Electrical Laminated Sheet and incorporated it into their operations. Testimonials from satisfied customers highlight the significant improvement in system efficiency and reduced maintenance costs achieved after implementing this innovative solution. As demand continues to rise, industry experts predict a bright future for Electrical Laminated Sheet, forecasting its rapid adoption worldwide.In conclusion, Electrical Laminated Sheet, introduced by {}, is a game-changing development in the power distribution industry. Its exceptional electrical insulation properties, mechanical strength, and high-temperature resistance contribute to enhanced efficiency, reliability, and sustainability. With its eco-friendly manufacturing process and adherence to rigorous standards, it aligns perfectly with the growing focus on sustainable practices. As more companies recognize its unparalleled performance, Electrical Laminated Sheet is set to transform power distribution systems across the globe.

Read More

Ultimate Guide to Fiberglass Insulation: Benefits, Installation Tips and Uses Revealed

Title: Driven by Innovation and Quality, Transforming the Insulation Industry: Fiberglass InsulationIntroduction:In today's rapidly evolving world, energy efficiency has become a top priority for individuals, businesses, and governments. As the demand for sustainable solutions continues to grow, companies are focusing on developing innovative products that not only reduce energy consumption but also enhance overall comfort. One such company at the forefront of this revolution is Fiberglass Insulation.Company Overview:Fiberglass Insulation, a leading provider in the insulation industry, has built a solid reputation for its commitment to quality, innovation, and sustainability. With a rich history spanning over 50 years, the company has continuously transformed the industry landscape through its cutting-edge products and techniques.A pioneer in fiberglass insulation, the company has garnered substantial recognition for its remarkable breakthroughs, ensuring that thermal efficiency and environmental consciousness go hand in hand. By leveraging advanced manufacturing processes and state-of-the-art technology, Fiberglass Insulation has successfully contributed to improving energy efficiency and reducing the carbon footprint of countless homes and commercial buildings.Key Products and Technology:Fiberglass Insulation offers a comprehensive range of insulation products, tailored to meet the specific needs of residential, commercial, and industrial sectors. With a focus on maximizing thermal performance, while minimizing environmental impact, their product line showcases a remarkable blend of innovation, sustainability, and functionality.1. Fiberglass Batts and Rolls:Engineered for optimal heat retention and acoustic control, fiberglass batts and rolls are designed to fit seamlessly between stud frames, floor joists, and ceilings. These highly flexible and easy-to-install insulation solutions provide a superior thermal barrier, reducing energy consumption and enhancing comfort.2. Blown-in Fiberglass:Blown-in fiberglass insulation offers a cost-effective solution for attics, walls, and hard-to-reach spaces. Utilizing a specially formulated adhesive, this product adheres to the substrate, ensuring uniform coverage and eliminating voids. With its remarkable heat resistance and sound absorption capabilities, blown-in fiberglass insulation guarantees long-lasting energy efficiency.3. Spray-Foam Hybrid Insulation:Fiberglass Insulation's innovative spray-foam hybrid insulation combines the benefits of traditional fiberglass insulation with the superior air sealing properties of spray foam. This revolutionary product not only provides exceptional thermal performance but also acts as a barrier against moisture, allergens, and pollutants, ensuring a healthier and more sustainable living environment.Sustainability Initiatives:Fiberglass Insulation is committed to sustainable manufacturing practices and reducing its environmental impact throughout the product life cycle. The company employs an extensive recycling program, ensuring that waste materials are transformed into usable products, significantly reducing landfill waste.With an emphasis on energy efficiency, their manufacturing processes utilize renewable energy sources, further minimizing carbon emissions. With its LEED-certified products, the company actively supports green building initiatives to create a more environmentally conscious future.Conclusion:Fiberglass Insulation's unwavering dedication to innovation, quality, and sustainability has cemented its position as an industry leader. By continuously developing cutting-edge insulation solutions, the company has successfully contributed to reducing energy consumption, providing optimal comfort, and minimizing the environmental impact of buildings.As the demand for sustainable solutions continues to rise, Fiberglass Insulation remains committed to its mission of transforming the insulation industry. With advanced technology, a focus on energy efficiency, and an unwavering commitment to quality, the company is well-positioned to shape a greener, more sustainable future.

Read More

Benefits of G10 Material for Electrical Insulation: High Strength and Dimensional Stability in Varied Conditions.

Read More

Fiberglass Sheets for Insulation: A Practical Solution for Your Home

[Date][Headline][Subheadline][Location] - [Company Name], a leading manufacturer in the insulation industry, is proud to announce the launch of their latest innovation - Insulation Fiberglass Sheet. This groundbreaking product offers unmatched efficiency and performance, revolutionizing the insulation market.Insulation is a crucial element in buildings, ensuring thermal comfort and energy efficiency. [Company Name] has always been at the forefront of developing cutting-edge insulation solutions, and their Insulation Fiberglass Sheet is another testament to their commitment to excellence.Unlike traditional insulation materials, Insulation Fiberglass Sheet boasts superior thermal insulation properties. Its unique composition effectively minimizes heat transfer, reducing energy consumption in both commercial and residential buildings. By preventing heat loss in winters and heat gain in summers, this innovative product offers significant energy savings and reduces greenhouse gas emissions.Furthermore, Insulation Fiberglass Sheet is exceptionally durable and long-lasting, ensuring insulation performance remains intact for years to come. Its robust construction safeguards against wear and tear, ensuring maximum efficiency throughout the lifespan of the building.Additionally, this insulation sheet is extremely versatile and can be easily installed in a variety of applications. Its flexible nature allows it to conform to irregular surfaces, making it an ideal choice for complex architectural designs. Whether it is insulation for walls, roofs, or floors, Insulation Fiberglass Sheet can cater to all needs efficiently.[Company Name], with their extensive experience in the insulation industry, has invested heavily in research and development to create Insulation Fiberglass Sheet. Combining the latest technology and industry expertise, this new product exceeds all expectations regarding thermal insulation."The launch of Insulation Fiberglass Sheet is a significant milestone for our company," says [Company Spokesperson]. "We firmly believe that this product will revolutionize the way insulation is perceived and utilized in the construction industry. Our goal is to provide our customers with highly efficient and durable insulation solutions, and Insulation Fiberglass Sheet epitomizes that objective."With the ever-increasing focus on energy efficiency and sustainability, Insulation Fiberglass Sheet aligns perfectly with the global movement towards greener construction practices. By reducing heat transfer and energy losses, it not only reduces energy consumption but also lowers carbon footprints, making buildings more environmentally friendly.Moreover, Insulation Fiberglass Sheet demonstrates [Company Name]'s commitment to quality and customer satisfaction. The company has always valued their relationships with clients, continuously striving to meet and exceed their expectations. With top-notch customer support and reliable product performance, [Company Name] aims to remain at the forefront of the insulation industry.In conclusion, [Company Name] has once again disrupted the insulation market with the launch of their groundbreaking product - Insulation Fiberglass Sheet. This versatile and highly efficient insulation solution offers immense benefits to both commercial and residential buildings. With its unmatched thermal insulation properties and durability, it is set to redefine the standards for insulation efficiency. As a trusted and experienced manufacturer, [Company Name] continues its legacy of innovation and customer satisfaction, leading the way towards sustainable and energy-efficient construction practices.For more information about Insulation Fiberglass Sheet and other products offered by [Company Name], please visit their website [Website Link].[Company Name][Company Address][Contact Information]

Read More

How to Easily Install and Maintain SMC Sheet Panels

Title: Groundbreaking Composite Technology Revolutionizing Industrial ProcessesIntroduction:In recent years, significant advancements have been made in the world of materials sciences, leading to transformative developments across various industries. One such breakthrough is the development of Sheet Molding Compound (SMC) technology, a high-performance composite material that has revolutionized industrial processes. This versatile material has gained widespread recognition for its exceptional strength, durability, and exceptional design flexibility. In this article, we will delve into the groundbreaking properties and applications of SMC, as well as explore how it is reshaping industries around the world.1. Overview of SMC:SMC, a composite material made from a combination of resins, fibers, and fillers, has emerged as a game-changer due to its superior mechanical properties. This combination creates a sheet-like material that can be molded into complex shapes, providing manufacturers with unprecedented design possibilities. Moreover, SMC exhibits excellent strength-to-weight ratio, electrical conductivity, and chemical resistance, making it an ideal choice for a wide range of applications.2. Automotive Industry Transformation:The automotive industry, known for its constant pursuit of lightweighting solutions, has embraced SMC as a viable alternative to traditional metals. By incorporating SMC components, vehicles can be substantially lighter, leading to enhanced fuel efficiency and reduced emissions. Additionally, SMC's inherent corrosion resistance contributes to longer vehicle lifespans and reduced maintenance costs. Increasingly, auto manufacturers are adopting SMC in the production of body panels, structural components, and interior parts, revolutionizing the future of mobility.3. Aerospace Applications:The aerospace industry, where lightweight materials are crucial for fuel efficiency and performance, has also been quick to recognize the potential of SMC. By replacing metal parts with SMC components, aircraft can achieve significant weight reductions without compromising integrity or safety. Its exceptional strength and durability also make SMC suitable for critical applications, including aircraft fairings, interior panels, and structural reinforcements. As a result, this technology is contributing to more sustainable and efficient air travel while reducing operating costs.4. Renewable Energy Advancements:The renewable energy sector is another area benefiting from the development of SMC technology. With its excellent resistance to weathering and ultraviolet (UV) radiation, SMC is being used in the construction of wind turbine blades, enabling higher energy production and improved reliability. By using SMC, manufacturers are optimizing blade design for increased efficiency, reducing maintenance requirements, and extending the lifespan of renewable energy infrastructure.5. Infrastructure Reinforcement:The prowess of SMC extends to infrastructure projects as well. In many countries, traditional concrete structures are being supplemented or replaced by SMC-based components. The lightweight nature of SMC makes it a particularly valuable material for retrofitting purposes, where it can reinforce structures without adding excessive weight. Applications include bridge decks, utility poles, and corrosion-resistant structures for coastal areas. This adoption of SMC in the construction sector points toward enhanced durability, efficiency, and sustainability in future infrastructure projects.Conclusion:Sheet Molding Compound (SMC) technology has revolutionized industries through its remarkable mechanical properties and design flexibility. Its applications in the automotive, aerospace, renewable energy, and construction sectors are transforming traditional approaches, prioritizing lightweighting, and enhancing sustainability. As the adoption of SMC continues to grow, we can expect a global shift towards more efficient, durable, and environmentally friendly products and infrastructure.

Read More

Introducing Versatile and Durable Polyimide Sheets for Various Industries

Resistant Polyimide Sheet Revolutionizes Industrial Design: A Breakthrough in Material InnovationIn today's rapidly evolving world of industrial design, manufacturers and engineers are constantly searching for state-of-the-art materials that can meet the demanding requirements of modern applications. Recently, a pioneering company has introduced a groundbreaking product called the Resistant Polyimide Sheet, which is set to redefine the possibilities of material innovation within various industries.The Resistant Polyimide Sheet, developed by the leading materials manufacturer {}, is a game-changer in multiple fields including aerospace, automotive, electronics, and more. This cutting-edge product exhibits exceptional performance characteristics that make it highly sought-after, revolutionizing the way engineers and designers approach their projects.The Resistant Polyimide Sheet sets itself apart from traditional materials with its extraordinary thermal resistance and electrical insulation properties. Its ability to withstand extreme temperatures ranging from -200°C to +400°C makes it particularly suitable for applications where heat dissipation and thermal management are critical, such as electronic devices and automotive components. Additionally, its high electrical insulation capabilities ensure a safe and reliable operation even in highly sensitive electronic systems.Another remarkable feature of the Resistant Polyimide Sheet is its mechanical strength and durability. With its combination of high tensile strength, superior impact resistance, and excellent tensile elongation, this innovative material provides manufacturers and engineers with a versatile solution for structurally demanding applications. It not only ensures the integrity of designs but also extends the lifespan of components, reducing maintenance and replacement costs.Furthermore, the Resistant Polyimide Sheet's exceptional chemical resistance makes it ideal for applications in corrosive environments. It exhibits an impressive resistance to chemicals, solvents, and oils, ensuring the longevity and integrity of components in industries such as chemical processing, oil and gas, and marine engineering.The material's lightweight nature is also a significant advantage, enabling manufacturers to reduce the overall weight of their products without compromising performance or structural integrity. This characteristic is particularly important in the aerospace industry, where every gram saved translates into better fuel efficiency and lower operational costs.Being highly customizable, the Resistant Polyimide Sheet offers great flexibility in terms of design and manufacturing. It can be easily fabricated, thermoformed, and machined into various shapes and sizes, making it an ideal choice for complex and intricate designs. Its ability to adhere to a wide range of other materials further expands its possibilities and potential applications.The introduction of the Resistant Polyimide Sheet has sparked excitement and enthusiasm among engineers, designers, and manufacturers worldwide. Its remarkable properties, along with its ease of use and versatility, have opened up new avenues for innovation and creativity within the industrial sector.The company behind this groundbreaking product has been a pioneer in material science for several decades. With a focus on continuous research and development, they have established themselves as a trusted and reliable provider of cutting-edge solutions. Their commitment to quality and their customer-centric approach have earned them a stellar reputation in the industry.In conclusion, the introduction of the Resistant Polyimide Sheet represents a significant breakthrough in material innovation, setting new standards for performance and versatility. Its exceptional thermal resistance, electrical insulation properties, mechanical strength, and durability make it a game-changer in various industries, from aerospace to electronics and beyond. With its unmatched capabilities, this pioneering product is poised to transform the way we approach industrial design and manufacturing, enabling engineers and designers to push the boundaries of what is possible.

Read More

Cost-Effective Thin Insulation Sheets: A Key Solution for Efficient Thermal Control

[Company Name] Develops Innovative Thin Insulation Sheets for Various Applications[City, Date] - [Company Name], a renowned leader in the field of insulation solutions, has recently unveiled its latest product innovation - Thin Insulation Sheets. These sheets, designed to provide effective thermal insulation, offer significant benefits over traditional insulation materials. With this groundbreaking development, [Company Name] aims to revolutionize the insulation industry and meet the growing demands for energy-efficient solutions.Utilizing state-of-the-art technology, [Company Name] has successfully produced insulation sheets that are incredibly thin yet highly efficient. These sheets have unique properties that allow them to effectively reduce heat transfer, providing optimal insulation for both residential and commercial applications. The innovative design of the Thin Insulation Sheets makes them versatile and adaptable to various environments, making them an ideal choice for a wide range of projects.One of the key advantages of the Thin Insulation Sheets is their superior thermal performance. By effectively minimizing heat loss or gain, these sheets help maintain a comfortable indoor temperature while significantly reducing energy consumption. This thermal efficiency contributes to cost savings for homeowners and businesses alike, as it reduces the need for excessive heating or cooling usage.In addition to their exceptional insulating capabilities, the Thin Insulation Sheets are also incredibly lightweight and easy to handle. This makes them an ideal choice for retrofitting existing structures, allowing for hassle-free installation without the need for extensive modifications. Moreover, their thin profile provides more space for additional insulation or accomodates architectural designs that require minimal thickness.[Company Name] takes pride in offering environmentally friendly solutions, and the Thin Insulation Sheets are no exception. Made from sustainable materials, these sheets are non-toxic and do not emit harmful substances, ensuring a healthy living environment. By incorporating these insulation sheets into their projects, individuals and businesses can contribute to a greener future while enjoying the benefits of reduced energy consumption.To cater to diverse insulation needs, [Company Name] manufactures Thin Insulation Sheets in various sizes and thicknesses. Customers can choose the most suitable option based on the specific requirements of their project. The sheets can be easily customized to fit different shapes and sizes, ensuring a perfect fit and maximum thermal performance.The versatility of the Thin Insulation Sheets opens up a world of potential applications. From residential buildings and commercial spaces to industrial facilities and transportation, these sheets can be used in a wide range of environments. Whether it is for new construction projects, renovations, or insulation upgrades, [Company Name]'s Thin Insulation Sheets are a cost-effective and efficient solution.As a frontrunner in the insulation industry, [Company Name] has established a solid reputation for delivering high-quality products and innovative solutions. With the introduction of the Thin Insulation Sheets, the company reaffirms its commitment to meeting the evolving needs of its customers and driving sustainability in the industry.[Company Name]'s Thin Insulation Sheets are now available to customers worldwide. By choosing these revolutionary insulation sheets, individuals, architects, and construction professionals can enjoy the benefits of superior thermal performance, ease of installation, and environmental sustainability. With [Company Name] leading the way, the future of insulation is thin, efficient, and eco-friendly.About [Company Name]:[Company Name] is a renowned company specializing in insulation solutions. With years of experience and a dedication to quality and innovation, [Company Name] has become a trusted name in the industry. The company takes pride in its commitment to delivering energy-efficient products that meet international standards while minimizing the environmental impact. From residential to commercial projects, [Company Name] provides reliable insulation solutions for a sustainable future. For more information, visit [Company Website].Contact:[Company Name][Company Address][Phone Number][Email Address][Website]

Read More