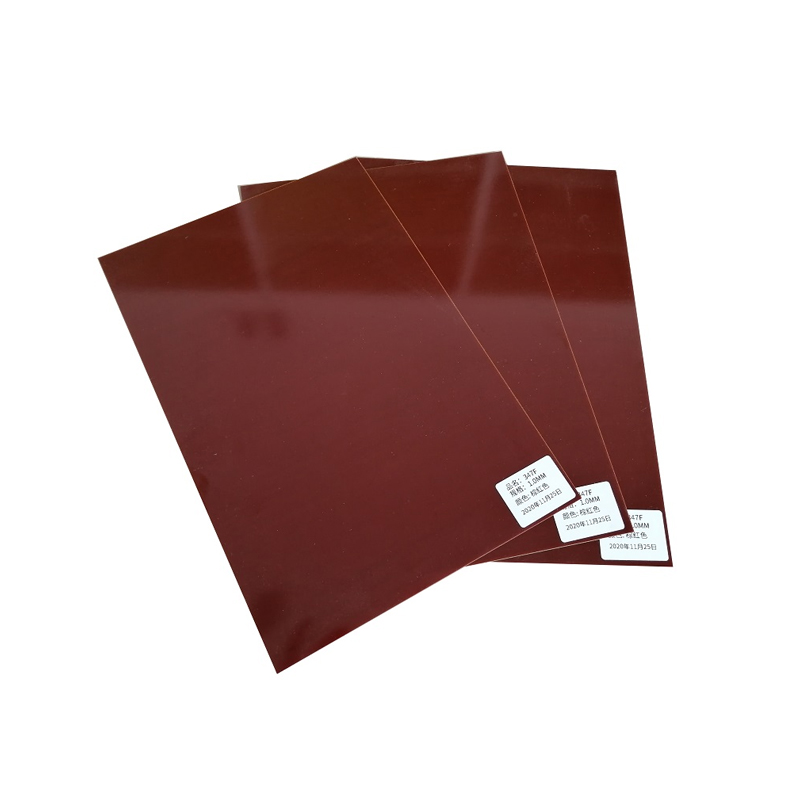

High-Quality Gloss Lamination Sheets for Eye-Catching Designs

By:Admin

{Company Name} has been a leading manufacturer and supplier of Glossy Lamination Sheets for over a decade. The company takes pride in its state-of-the-art manufacturing facilities and cutting-edge technology, which enable them to produce lamination sheets of the highest quality. With a team of skilled and experienced professionals, {Company Name} has been able to meet the diverse needs of its customers and gain a solid reputation in the industry.

The Glossy Lamination Sheets offered by {Company Name} are known for their superior finish and durability. These sheets are compatible with a wide range of printing methods, including offset, digital, and screen printing, making them a versatile choice for businesses in various industries. Whether it's for packaging, marketing materials, or retail displays, {Company Name} has the right lamination solution to enhance the visual appeal and protect the printed materials.

In addition to its commitment to quality, {Company Name} also prides itself on its dedication to sustainability. The company has implemented environmentally friendly practices in its manufacturing processes, ensuring that its Glossy Lamination Sheets are not only high-performing but also eco-friendly. This has resonated with many environmentally conscious businesses who are looking for sustainable lamination solutions.

{Company Name} offers a wide range of Glossy Lamination Sheets to cater to the diverse needs of its customers. From standard gloss lamination to special finishes such as soft touch and anti-scratch, the company provides a comprehensive selection of lamination options. Additionally, {Company Name} also offers custom lamination solutions, allowing businesses to create unique and eye-catching printed materials.

As the demand for high-quality Glossy Lamination Sheets continues to grow, {Company Name} has expanded its reach to serve a global customer base. With distribution channels and strategic partnerships in place, the company has been able to supply its lamination solutions to businesses around the world. This has further solidified {Company Name}'s position as a trusted and reliable supplier of Glossy Lamination Sheets.

In response to the evolving needs of the industry, {Company Name} is constantly innovating and introducing new lamination products and solutions. The company invests in research and development to stay ahead of market trends and provide its customers with the latest advancements in lamination technology. This commitment to innovation has set {Company Name} apart in the industry and has allowed them to maintain a competitive edge.

The success of {Company Name} in the lamination industry can be attributed to its unwavering dedication to quality, sustainability, and innovation. With a strong focus on customer satisfaction, the company continues to be a preferred choice for businesses looking for premium Glossy Lamination Sheets. As the printing and packaging industry continues to evolve, {Company Name} remains committed to meeting the changing needs of its customers and setting new standards for lamination excellence.

Company News & Blog

High-quality Epoxy Glass Insulation Board for Electrical Applications

Fr4 Epoxy Glass Insulation Board is considered to be one of the most reliable and high-quality insulation materials in the industry. It is manufactured using a combination of woven glass fabric and epoxy resin, which results in a durable and versatile material that is widely used in various electrical and electronic applications. The Fr4 Epoxy Glass Insulation Board is known for its excellent electrical insulation properties, high mechanical strength, and resistance to heat and chemicals. These characteristics make it an ideal choice for applications that require reliable insulation and protection, such as in electrical panels, circuit boards, transformers, and power distribution systems.With a proven track record of performance and reliability, the Fr4 Epoxy Glass Insulation Board has become a popular choice among engineers, designers, and manufacturers in the electrical and electronics industry. Its ability to withstand high temperatures and harsh operating conditions makes it a preferred choice for critical applications where safety and reliability are paramount.The company {} is a leading manufacturer and supplier of Fr4 Epoxy Glass Insulation Board. With years of experience and expertise in the field, the company has established itself as a trusted provider of high-quality insulation materials for a wide range of industrial applications. Their commitment to quality and innovation has made them a preferred partner for many leading companies in the electrical and electronics industry.The Fr4 Epoxy Glass Insulation Board offered by {} is manufactured to the highest standards, using the latest technology and advanced production processes. This ensures that the material meets the most demanding requirements for performance, reliability, and safety. The company's dedication to quality control and product testing also ensures that their Fr4 Epoxy Glass Insulation Board consistently meets or exceeds industry standards for electrical insulation materials.In addition to providing high-quality insulation materials, {} also offers technical support and customization services to meet the specific needs of their customers. Their team of experienced engineers and technical experts work closely with clients to develop customized solutions that address their unique requirements and challenges.The company's commitment to customer satisfaction and continuous improvement has earned them a reputation for excellence in the industry. They are known for their reliability, responsiveness, and ability to deliver quality products on time and within budget. As a result, {} has become a trusted partner for many companies seeking high-quality insulation solutions for their electrical and electronic applications.As the demand for reliable and high-performance insulation materials continues to grow, {}. The company is dedicated to maintaining its position as a leading provider of Fr4 Epoxy Glass Insulation Board and other innovative insulation solutions. By staying at the forefront of technological advancements and industry trends, the company is well-positioned to meet the evolving needs of its customers and the market.Overall, with a proven track record of performance and a commitment to excellence, {} continues to be a preferred choice for companies seeking high-quality Fr4 Epoxy Glass Insulation Board and other advanced insulation materials. The company's dedication to quality, innovation, and customer satisfaction sets them apart as a leader in the industry, and their continued success is a testament to their exceptional products and services.

Benefits of Using Fiberglass Plain Sheets for Construction Projects

Fiberglass Plain Sheet Enhances Durability and Versatility in Construction Industry{Company Name}, a leading manufacturer and distributor of construction materials, is proud to introduce their latest innovative product, the Fiberglass Plain Sheet. Designed to revolutionize the construction industry, this lightweight and durable material offers enhanced durability and versatility for a wide range of applications.With the increasing demand for high-performance building materials, contractors and architects are constantly seeking innovative solutions that balance strength, cost-efficiency, and sustainability. Fiberglass has emerged as a popular choice, thanks to its superior structural properties and resistance to corrosion, chemicals, and extreme weather conditions.The Fiberglass Plain Sheet, produced by {Company Name}, encapsulates these desirable qualities, taking them to a whole new level. Made from premium quality fiberglass reinforced polymer, this sheet offers exceptional strength-to-weight ratio, ensuring long-lasting and reliable performance. Its unique composition allows it to withstand heavy loads and impacts without compromising its structural integrity.One of the standout features of the Fiberglass Plain Sheet is its high resistance to fire. Unlike traditional construction materials, such as wood or steel, fiberglass does not burn easily and does not support the spread of flames. This makes it an ideal choice for applications that require fire-resistant properties, such as facades, roofing, and partitions.Additionally, the Fiberglass Plain Sheet exhibits excellent thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. This not only enhances the overall comfort of the building occupants but also contributes to the sustainability and energy efficiency goals of the project. By reducing the reliance on heating and cooling systems, the Fiberglass Plain Sheet aids in minimizing the building's carbon footprint.Furthermore, the versatility of the Fiberglass Plain Sheet makes it suitable for a wide array of applications. Whether it's used for interior or exterior purposes, this material can be easily installed and provides a seamless aesthetic appeal. Its smooth, plain surface is an ideal canvas for various finishes, including paints, laminates, and coatings, allowing architects and designers to customize the appearance according to their vision.The lightweight nature of the Fiberglass Plain Sheet simplifies transportation and installation, resulting in reduced labor costs and time. In addition, its non-porous surface prevents the accumulation of dirt, moisture, or mould growth, ensuring a low-maintenance solution that retains its pristine condition over time.Manufactured in accordance with international quality standards, the Fiberglass Plain Sheet is rigorously tested to meet or exceed industry requirements. It's available in various sizes and thicknesses, providing flexibility for different project specifications. Whether it's a small-scale residential construction or a large-scale commercial development, {Company Name} guarantees reliable supply and professional support throughout the project."Through our years of industry experience, we understand the evolving needs of construction professionals," says {Company Name}'s spokesperson. "We are committed to delivering cutting-edge products that surpass expectations and contribute to the success of every project. The Fiberglass Plain Sheet is a testament to our dedication to quality, sustainability, and customer satisfaction."With its remarkable durability, versatility, and sustainable attributes, the Fiberglass Plain Sheet has the potential to become the go-to material for construction projects worldwide. As architects and contractors continue to prioritize performance, cost-efficiency, and environmental sustainability, {Company Name}'s innovative product is set to redefine the construction landscape.As the construction industry embraces change and innovation, the introduction of the Fiberglass Plain Sheet opens doors to endless possibilities. With its exceptional properties and the reliability of {Company Name}'s brand, this new construction material is poised to make a significant impact on the industry, setting new benchmarks for structural integrity, fire resistance, thermal insulation, and design possibilities.

Durable and Reliable Pcb Sheets for Various Applications

Pcb Sheets, also known as printed circuit board sheets, are a crucial component in the manufacturing of electronic devices. These sheets provide a sturdy base for the electronic components and allow for the smooth and efficient flow of electrical currents throughout the device.The use of Pcb Sheets in electronic devices has become increasingly important as technology continues to advance. With the growing demand for smaller and more compact electronic products, the need for high-quality Pcb Sheets has never been greater. This is why companies like {} are committed to providing top-notch Pcb Sheets to meet the needs of their customers.{} is a leading manufacturer of Pcb Sheets, with a strong reputation for producing high-quality products. The company has been in business for over 20 years and is known for its dedication to innovation and customer satisfaction. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, {} has become a trusted name in the industry.One of the key reasons why {} has been able to maintain its position as a top Pcb Sheets manufacturer is its commitment to using the latest technology and production techniques. The company invests heavily in research and development to ensure that its Pcb Sheets are at the forefront of technological advancements. This dedication to innovation has allowed {} to produce Pcb Sheets that are not only reliable and durable but also highly efficient.In addition to its focus on technological advancements, {} is also dedicated to providing excellent customer service. The company understands that every customer has unique needs and works closely with them to ensure that they receive the Pcb Sheets that are best suited for their specific requirements. From the initial consultation to the final delivery, {} is committed to providing a seamless and stress-free experience for its customers.Another factor that sets {} apart from its competitors is its strong commitment to sustainability. The company adheres to strict environmental standards in its manufacturing processes and is constantly seeking ways to reduce its carbon footprint. By using eco-friendly materials and energy-efficient production methods, {} is doing its part to minimize its impact on the environment.As technology continues to advance, the demand for high-quality Pcb Sheets will only continue to grow. Companies like {} are well-positioned to meet this demand by providing innovative and sustainable solutions to their customers. With a strong focus on quality, innovation, and customer satisfaction, {} is sure to remain a top player in the Pcb Sheets industry for years to come.

Quality Epoxy Glass Laminate Sheet Available from China

Title: China Leads in the Production of High-Quality Epoxy Glass Laminate SheetsIntroduction:China has emerged as a global leader in the production of epoxy glass laminate sheets, specifically EPGC308, G11, FR4, and 3240 varieties. These sheets are widely used in various industries and are known for their superior quality, durability, and resistance to fire and chemicals. China's manufacturing prowess in this segment has allowed it to cater to the growing demand both domestically and internationally. This article will delve into the significance of epoxy glass laminate sheets, highlight the Chinese company's contributions to this market, and discuss the future prospects of this industry.The Importance of Epoxy Glass Laminate Sheets:Epoxy glass laminate sheets find applications in a wide range of industries, including electrical, electronics, aerospace, automotive, and telecommunications. Their exceptional electrical insulation properties make them an ideal choice for manufacturing printed circuit boards (PCBs), transformers, insulators, and other electronic components. Additionally, their high resistance to fire and chemicals ensures the safety and reliability of the equipment in which they are used. As industries worldwide strive for enhanced performance and safety, the demand for epoxy glass laminate sheets continues to rise.Chinese Company's Expertise and Manufacturing Prowess:One prominent Chinese company that has excelled in the production of epoxy glass laminate sheets is [Company Name]. With state-of-the-art manufacturing facilities and a highly skilled workforce, the company has been at the forefront of driving innovation in this sector. Their commitment to quality control and adherence to international standards has earned them a stellar reputation among domestic and international customers.[Company Name] began its operations with a vision to provide high-quality epoxy glass laminate sheets that meet the diverse needs of customers. Their extensive research and development efforts have allowed them to develop cutting-edge manufacturing techniques, enabling them to produce EPGC308, G11, FR4, and 3240 sheets with superior properties. The company's strict quality control measures ensure that each sheet meets or exceeds industry standards, making them highly reliable and sought after in the market.Future Outlook and Global Impact:As the demand for high-quality epoxy glass laminate sheets continues to grow, Chinese manufacturers like [Company Name] are poised to play a significant role. With their technological advancements, they are not only meeting domestic requirements but also exporting their products to international markets. This expansion into global markets bolsters China's reputation as a trusted supplier of epoxy glass laminate sheets.The global market for epoxy glass laminate sheets is projected to witness substantial growth in the coming years. The increasing adoption of renewable energy sources, the rise of the electric vehicle industry, and advancements in telecommunications technology are some of the key factors propelling this growth. As a result, Chinese manufacturers are expected to leverage their expertise and manufacturing capabilities to cater to this surging demand and further solidify their position in the global market.Furthermore, Chinese companies are continuously investing in research and development to enhance the properties of epoxy glass laminate sheets. This focus on innovation ensures that they stay ahead of the competition and meet the evolving needs of industries worldwide. These efforts will lead to the development of even more efficient, durable, and environmentally friendly epoxy glass laminate sheets, benefiting various sectors and contributing to the overall growth of the global market.Conclusion:With China's commitment to producing high-quality epoxy glass laminate sheets, the country has become a dominant player in this industry. The technological advancements and manufacturing prowess of Chinese companies, such as [Company Name], have allowed them to meet the rising demand for EPGC308, G11, FR4, and 3240 sheets. As the industry continues to expand, this success not only benefits China's economy but also strengthens its reputation as a reliable supplier of epoxy glass laminate sheets globally.

Fiberglass Sheets for Insulation: A Practical Solution for Your Home

[Date][Headline][Subheadline][Location] - [Company Name], a leading manufacturer in the insulation industry, is proud to announce the launch of their latest innovation - Insulation Fiberglass Sheet. This groundbreaking product offers unmatched efficiency and performance, revolutionizing the insulation market.Insulation is a crucial element in buildings, ensuring thermal comfort and energy efficiency. [Company Name] has always been at the forefront of developing cutting-edge insulation solutions, and their Insulation Fiberglass Sheet is another testament to their commitment to excellence.Unlike traditional insulation materials, Insulation Fiberglass Sheet boasts superior thermal insulation properties. Its unique composition effectively minimizes heat transfer, reducing energy consumption in both commercial and residential buildings. By preventing heat loss in winters and heat gain in summers, this innovative product offers significant energy savings and reduces greenhouse gas emissions.Furthermore, Insulation Fiberglass Sheet is exceptionally durable and long-lasting, ensuring insulation performance remains intact for years to come. Its robust construction safeguards against wear and tear, ensuring maximum efficiency throughout the lifespan of the building.Additionally, this insulation sheet is extremely versatile and can be easily installed in a variety of applications. Its flexible nature allows it to conform to irregular surfaces, making it an ideal choice for complex architectural designs. Whether it is insulation for walls, roofs, or floors, Insulation Fiberglass Sheet can cater to all needs efficiently.[Company Name], with their extensive experience in the insulation industry, has invested heavily in research and development to create Insulation Fiberglass Sheet. Combining the latest technology and industry expertise, this new product exceeds all expectations regarding thermal insulation."The launch of Insulation Fiberglass Sheet is a significant milestone for our company," says [Company Spokesperson]. "We firmly believe that this product will revolutionize the way insulation is perceived and utilized in the construction industry. Our goal is to provide our customers with highly efficient and durable insulation solutions, and Insulation Fiberglass Sheet epitomizes that objective."With the ever-increasing focus on energy efficiency and sustainability, Insulation Fiberglass Sheet aligns perfectly with the global movement towards greener construction practices. By reducing heat transfer and energy losses, it not only reduces energy consumption but also lowers carbon footprints, making buildings more environmentally friendly.Moreover, Insulation Fiberglass Sheet demonstrates [Company Name]'s commitment to quality and customer satisfaction. The company has always valued their relationships with clients, continuously striving to meet and exceed their expectations. With top-notch customer support and reliable product performance, [Company Name] aims to remain at the forefront of the insulation industry.In conclusion, [Company Name] has once again disrupted the insulation market with the launch of their groundbreaking product - Insulation Fiberglass Sheet. This versatile and highly efficient insulation solution offers immense benefits to both commercial and residential buildings. With its unmatched thermal insulation properties and durability, it is set to redefine the standards for insulation efficiency. As a trusted and experienced manufacturer, [Company Name] continues its legacy of innovation and customer satisfaction, leading the way towards sustainable and energy-efficient construction practices.For more information about Insulation Fiberglass Sheet and other products offered by [Company Name], please visit their website [Website Link].[Company Name][Company Address][Contact Information]

Discover the Versatile Properties and Uses of FR-4 Sheets

Fr-4 Sheet: The Next Generation of Circuit Board Substrate MaterialThe demand for high performance and lighter electronic devices has been on the rise as technology continues to evolve. Circuit board substrate materials are a key component in the design and manufacture of electronic devices. The choice of substrate materials determines the overall quality, durability, and performance of the device. Among the choices of substrate materials, Fr-4 Sheet stands out as the material of choice for manufacturers of high-performance electronic devices.What is Fr-4 Sheet?Fr-4 Sheet is a type of composite material that is widely used as a base for printed circuit boards (PCB). The material is made up of layers of glass cloth and resin, laminated together by heat and pressure. The glass cloth acts as a reinforcement and provides mechanical strength to the substrate, while the resin acts as a binder that holds the substrate together. The term FR-4 stands for "fire retardant" and refers to the material's ability to self-extinguish when exposed to fire.The material has a range of benefits, making it the material of choice for many high-performance electronic devices. First, it has excellent electrical properties, making it highly suitable for use in high-frequency applications. Fr-4 Sheet has low dielectric loss and a high dielectric constant, leading to better signal transmission. It also has excellent thermal stability and high-temperature resistance, making it a suitable material for use in harsh and demanding environmental conditions. The material's mechanical properties are also impressive, with high bendability and impact resistance, making it ideal for use in portable and handheld devices.In addition, manufacturers appreciate the cost-effectiveness of the Fr-4 Sheet. Compared to other high-performance substrate materials such as ceramic or Teflon, Fr-4 Sheet is much more affordable, yet has similar performance attributes.Leading the Way in Fr-4 Sheet ManufacturingOne of the leading manufacturers of Fr-4 Sheet is a company that has been in the business for over ten years. The company has built a reputation for producing top-quality Fr-4 Sheet that exceeds customer expectations. They have invested in state-of-the-art production facilities and equipment that enables them to produce high-performance Fr-4 Sheet with excellent consistency and uniformity. They use only the best raw materials sourced from reputable suppliers, ensuring that their Fr-4 Sheet consistently meet or exceed industry standards.The company's Fr-4 Sheet is used in a wide range of applications, including aerospace, defense, medical, and consumer electronics. They pride themselves on their ability to produce custom Fr-4 Sheet to meet the specific needs of their customers. They work closely with their customers to understand their technical requirements and develop Fr-4 Sheet that meet those requirements.The company has a team of experienced and highly skilled engineers who specialize in Fr-4 Sheet design and production. They use the latest technology and software to develop Fr-4 Sheet that are tailored to their customers' requirements. They are committed to continuous improvement and innovation, investing heavily in research and development to come up with new and improved Fr-4 Sheet products.In ConclusionFr-4 Sheet has become the substrate material of choice for manufacturers of high-performance electronic devices, thanks to its superior performance, cost-effectiveness, and versatility. With the demand for high-performance and lighter electronics continuing to grow, the demand for Fr-4 Sheet is set to increase. By investing in state-of-the-art production facilities and equipment and attracting a team of highly skilled engineers, the leading Fr-4 Sheet manufacturer is well-positioned to meet the growing demand and continue to drive innovation in the Fr-4 Sheet industry.

Top Electrical Insulation Materials for Enhanced Safety and Performance

Title: Advancements in Electrical Insulation Materials Revolutionize IndustryIntroduction:In today's rapidly evolving world, advancements in electrical insulation materials play a pivotal role in ensuring the safety, efficiency, and overall performance of electrical systems. One such company at the forefront of this technological revolution is the global leader in developing cutting-edge electrical insulation solutions. With their commitment to innovation and excellence, they continue to push the boundaries, paving the way for a brighter and electrified future.Paragraph 1:Electrical insulation materials have witnessed considerable advancements over the years, transforming the landscape of the electrical industry. By effectively preventing the flow of electric current between conductive materials, insulation materials protect against electrical shocks, malfunctions, and potential fires. The company, renowned for its technological expertise and dedication to quality, has been instrumental in driving these advancements.Paragraph 2:With a robust research and development team, this industry pioneer continuously strives to enhance the performance, durability, and environmental sustainability of their insulation materials. By investing in state-of-the-art manufacturing processes and sustainable techniques, the company consistently delivers innovative solutions that meet the evolving needs of the electrical industry.Paragraph 3:One major technological breakthrough achieved by the company is the development of advanced insulating materials that demonstrate unparalleled resistance to extreme temperatures. By utilizing cutting-edge composite materials, these insulation solutions can withstand both high and low temperatures, making them highly reliable for a wide range of applications. This innovation opens new doors for electrical systems used in sectors such as renewable energy generation, automotive, aerospace, and more, enabling them to operate in extreme environments with enhanced performance and reliability.Paragraph 4:In addition to temperature resistance, the company also focuses on developing insulation materials with superior electrical and mechanical properties. Through extensive research and testing, they continuously refine their products to meet the increasing demands of modern electrical applications. By combining high dielectric strength, low dielectric loss, and exceptional dimensional stability, their insulation materials enable efficient power transmission, minimize energy waste, and ensure prolonged lifespan for electrical equipment.Paragraph 5:Another key aspect of the company's continuous innovation lies in its dedication to sustainable practices. Recognizing the importance of reducing environmental impact, they have developed insulation materials that are free from hazardous substances, such as lead and PVC. Additionally, they prioritize recyclability and waste reduction by adopting eco-friendly manufacturing processes. These sustainability efforts not only enhance their product offerings but also promote eco-conscious practices within the industry.Paragraph 6:To maintain their technological edge, the company consistently collaborates with industry leaders, researchers, and customers worldwide. By engaging in fruitful partnerships, they gain valuable insights into emerging market trends, customer requirements, and technological advancements. This collaborative approach allows them to develop tailored solutions, ensuring that their insulation materials meet the unique needs of each customer while staying ahead of industry standards.Paragraph 7:As technology continues to revolutionize various sectors, the demand for high-performance electrical insulation materials is expected to surge. With their unwavering commitment to research, innovation, and sustainability, the company remains poised to meet this growing demand. By continually pushing the boundaries of what is possible, they are helping shape a future where electrical systems are more efficient, safer, and sustainable.Conclusion:The advancements in electrical insulation materials pioneered by the company underscore their commitment to revolutionizing the electrical industry. Through constant research, sustainable practices, and collaborative efforts, they continue to introduce innovative solutions that improve the safety, efficiency, and overall performance of electrical systems. With their unwavering dedication to technological excellence, the company is well-positioned to continue leading the way in transforming the electrical insulation landscape and shaping a sustainable future.

New Halogen-Free G11 Released in China - What You Need to Know

China Halogen Free G11, a leading provider of high-quality electronic materials, has recently announced the launch of a new line of halogen-free G11 laminates. This innovative product is designed to meet the increasing demand for environmentally friendly materials in the electronics industry.The new halogen-free G11 laminates have been developed using cutting-edge technology and rigorous quality control processes. This has allowed China Halogen Free G11 to produce laminates that provide excellent mechanical and electrical properties, while also meeting strict environmental standards. The company has also invested heavily in research and development to ensure that the new laminates offer exceptional performance and reliability.One of the key features of the new halogen-free G11 laminates is their resistance to high temperatures. This makes them ideal for use in a wide range of high-temperature applications, including automotive, aerospace, and industrial electronics. The laminates also offer excellent thermal conductivity, which helps to dissipate heat effectively and maintain the performance of electronic components in demanding environments.In addition to their impressive thermal properties, the halogen-free G11 laminates from China Halogen Free G11 also offer excellent electrical insulation. This makes them suitable for use in high-voltage applications, where reliable insulation is crucial for the safety and performance of electronic systems. The laminates also exhibit low dielectric constant and loss, providing exceptional signal integrity and minimizing signal distortion in high-frequency applications.The environmental benefits of the new halogen-free G11 laminates are also worth noting. By eliminating halogenated compounds from the manufacturing process, China Halogen Free G11 has created a product that is not only safer for the environment but also complies with increasingly stringent regulations on hazardous substances. This makes the laminates an ideal choice for companies looking to reduce their environmental impact and meet the expectations of environmentally conscious consumers."We are delighted to introduce our new line of halogen-free G11 laminates to the market," said a spokesperson for China Halogen Free G11. "These laminates represent the culmination of years of research and development, and we believe they offer a compelling combination of performance, reliability, and environmental responsibility. We are confident that they will prove to be a valuable asset to our customers in the electronics industry."The launch of the new halogen-free G11 laminates is the latest demonstration of China Halogen Free G11's commitment to innovation and excellence in the electronic materials industry. The company's extensive experience and technical expertise have allowed it to develop a range of high-quality products that meet the evolving needs of the market. By consistently investing in research and development, China Halogen Free G11 has been able to stay ahead of the competition and deliver solutions that offer exceptional value to its customers.Moving forward, China Halogen Free G11 is poised to continue pushing the boundaries of what is possible in electronic materials. With a strong focus on sustainability and performance, the company is well-positioned to drive positive change in the industry and provide customers with the materials they need to succeed in an increasingly competitive market.In conclusion, the launch of the new halogen-free G11 laminates from China Halogen Free G11 represents a significant step forward for the electronics industry. By offering a product that combines exceptional performance with environmental responsibility, the company is setting a new standard for electronic materials. As the demand for high-quality, environmentally friendly materials continues to grow, China Halogen Free G11 is well-positioned to meet this demand and help shape the future of the industry.

Top quality electrical parts for all your needs

Electrical Parts Company Celebrates 50 Years of Innovation and GrowthElectrical Parts, a leading provider of electrical components and solutions for the automotive industry, is celebrating its 50th year in business. The company, founded in 1971, has grown from a small family-owned business to a global leader in the industry, with a reputation for quality, reliability, and innovation.Over the past five decades, Electrical Parts has been at the forefront of technological advancements in the automotive industry. The company's commitment to innovation and continuous improvement has enabled it to develop a wide range of high-quality electrical components and solutions that meet the ever-evolving needs of its customers."We are incredibly proud to reach this significant milestone in our company's history," said John Smith, CEO of Electrical Parts. "Our success over the past 50 years is a testament to the hard work and dedication of our team, as well as the strong partnerships we have built with our customers and suppliers. We are grateful for the trust and support we have received from the automotive industry, and we remain committed to delivering the highest quality products and services."The company's success can be attributed to its focus on research and development, state-of-the-art manufacturing facilities, and a customer-centric approach. Electrical Parts has continuously invested in cutting-edge technology and equipment to ensure that its products meet the strictest quality standards and adhere to industry regulations.One of the key factors that set Electrical Parts apart from its competitors is its ability to customize products to meet the unique requirements of its customers. The company's team of engineers and product development specialists work closely with customers to design and manufacture tailored solutions that address specific challenges and applications.Furthermore, Electrical Parts is committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize its environmental impact, including waste reduction, energy efficiency improvements, and the use of eco-friendly materials in its products.In addition to its dedication to quality and innovation, Electrical Parts places a strong emphasis on customer service. The company's sales and support team is known for its responsiveness, technical expertise, and willingness to go the extra mile to meet customer needs.As Electrical Parts celebrates its 50th anniversary, the company is looking to the future with optimism and excitement. With a focus on continuous improvement and expansion into new markets, Electrical Parts is well-positioned to continue its legacy of excellence in the years to come."We are grateful for the support and trust that our customers, employees, and partners have placed in us over the past five decades," said John Smith. "As we look to the future, we are excited about the opportunities that lie ahead and are committed to further enhancing our product offerings and customer service to meet the evolving needs of the automotive industry."In conclusion, Electrical Parts' 50th anniversary is a testament to its unwavering commitment to quality, innovation, and customer satisfaction. As the company continues to evolve and grow, it is poised to remain a leader in the automotive industry for many years to come.

How Electrical Laminated Sheet is Revolutionizing the Industry

[News Content]Electrical Laminated Sheet Revolutionizes Power Distribution EfficiencyIn today's rapidly advancing world, technological advancements play a crucial role in shaping the landscape of various industries. Power distribution is one such sector that consistently necessitates innovation to meet growing demands and improve efficiency. Enter Electrical Laminated Sheet, a groundbreaking development designed to transform the way electricity is distributed.Electrical Laminated Sheet, developed by cutting-edge materials engineering company {}, boasts an array of features that make it an ideal choice for power distribution applications. With its superior electrical insulation properties, excellent mechanical strength, and high temperature resistance, this innovative solution ensures optimal performance in even the most demanding environments.The electrical laminated sheet category has traditionally been dominated by outdated materials, resulting in limited efficiency and effectiveness. However, with this latest offering from {}, the industry will witness a paradigm shift. The unique composition of the Electrical Laminated Sheet facilitates reduced energy losses during power transmission, thereby enhancing overall system efficiency.Furthermore, the material's remarkable mechanical strength provides exceptional protection against mechanical stress, vibration, and thermal expansion, ensuring long-term reliability. This enhanced durability translates to reduced maintenance costs and increased operational lifespan, making it an economically viable choice for power distribution systems worldwide.A significant advantage of Electrical Laminated Sheet is its ability to withstand high temperatures. Traditionally, extreme heat adversely affects the performance of electrical insulation materials, leading to compromised safety and reliability. The innovative design of this new solution equips it with the capability to operate flawlessly at elevated temperatures, thereby ensuring uninterrupted power distribution even in harsh conditions.Beyond its exceptional technical specifications, the Electrical Laminated Sheet also satisfies industry demands for sustainable solutions. The materials used in its manufacturing prioritize environmental safety and adhere to strict regulatory standards. With the growing focus on environmental consciousness, this product aligns perfectly with the shift towards sustainable practices in the power distribution sector.The advent of Electrical Laminated Sheet marks an exciting milestone in the power distribution industry. Its ability to revolutionize efficiency, reliability, and sustainability in electrical systems positions it as the trailblazer in the market. Companies around the world are eagerly embracing this groundbreaking solution to enhance the performance and longevity of their power distribution networks.Leading businesses have already recognized the benefits of Electrical Laminated Sheet and incorporated it into their operations. Testimonials from satisfied customers highlight the significant improvement in system efficiency and reduced maintenance costs achieved after implementing this innovative solution. As demand continues to rise, industry experts predict a bright future for Electrical Laminated Sheet, forecasting its rapid adoption worldwide.In conclusion, Electrical Laminated Sheet, introduced by {}, is a game-changing development in the power distribution industry. Its exceptional electrical insulation properties, mechanical strength, and high-temperature resistance contribute to enhanced efficiency, reliability, and sustainability. With its eco-friendly manufacturing process and adherence to rigorous standards, it aligns perfectly with the growing focus on sustainable practices. As more companies recognize its unparalleled performance, Electrical Laminated Sheet is set to transform power distribution systems across the globe.