New G11 H Class Sets the Standard for Advanced Technology

By:Admin

Leading the way in innovation and cutting-edge technology, {} has recently unveiled their latest addition to the G11 H Class series. The G11 H Class is set to revolutionize the automotive industry with its exceptional performance, advanced features, and sleek design.

The G11 H Class is a testament to {}'s commitment to pushing the boundaries of automotive engineering. With its powerful engine, precision handling, and state-of-the-art technology, this new model is poised to set a new standard for luxury vehicles. The company has invested years of research and development into perfecting the G11 H Class, and the results speak for themselves.

One of the most impressive features of the G11 H Class is its advanced safety technology. {} has integrated the latest in driver-assist and safety systems, ensuring that drivers and passengers are always protected on the road. From collision avoidance technology to advanced airbag systems, every aspect of the G11 H Class is designed to prioritize safety.

In addition to its exceptional safety features, the G11 H Class also boasts a range of cutting-edge technology and entertainment options. With a high-resolution touchscreen display, advanced navigation system, and seamless smartphone integration, every journey in the G11 H Class is a luxurious experience. The vehicle also features a premium sound system, ensuring that every drive is accompanied by crystal-clear audio.

The exterior design of the G11 H Class is nothing short of stunning. With sleek lines, a bold grille, and carefully crafted details, this vehicle commands attention on the road. Every element of the design has been meticulously planned to create a visually striking and aerodynamic vehicle. Whether parked or in motion, the G11 H Class is sure to turn heads wherever it goes.

Under the hood, the G11 H Class is powered by a high-performance engine that delivers an exhilarating driving experience. With impressive acceleration, responsive handling, and smooth power delivery, this vehicle is a thrill to drive. Whether navigating city streets or cruising on the open road, the G11 H Class offers a driving experience unlike any other.

As a leading automotive company, {} has a strong track record of delivering exceptional vehicles that combine performance, luxury, and innovation. With a commitment to excellence and a passion for pushing the boundaries of automotive design, the company has earned a reputation for producing some of the most sought-after vehicles on the market. The G11 H Class is the latest example of {}'s dedication to creating vehicles that exceed expectations and set new standards in the industry.

In conclusion, the unveiling of the G11 H Class marks an exciting new chapter for {} and the automotive industry as a whole. With its exceptional performance, advanced features, and stunning design, this vehicle is set to redefine the luxury automotive market. For drivers who demand the best in performance, technology, and design, the G11 H Class is sure to exceed expectations.

Company News & Blog

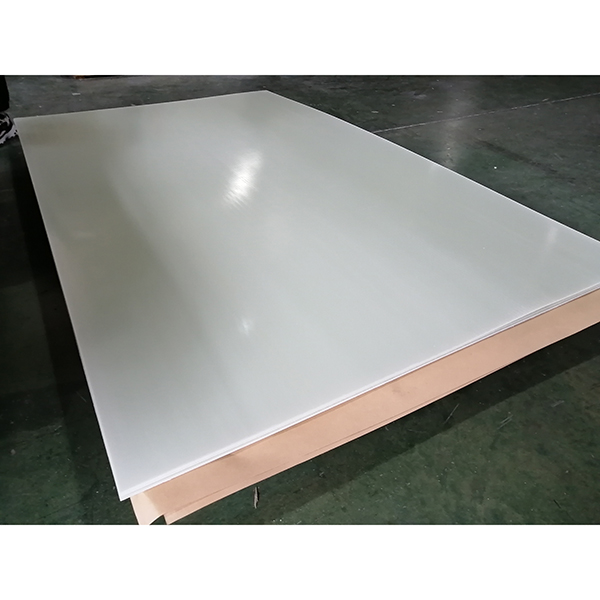

High-quality White Laminates for Your Next Home Improvement Project

White Laminate Sheets now available for purchase from the leading manufacturer of high-quality construction materials, {company name}. Offering durability, versatility, and a sleek, modern look, these laminate sheets are the perfect solution for a wide range of applications in the residential, commercial, and industrial sectors.{Company name} has been a trusted name in the construction industry for over two decades, providing top-notch products to builders, designers, and homeowners alike. Their commitment to quality and innovation has made them a go-to source for construction materials, and the introduction of their new White Laminate Sheets is no exception.The new White Laminate Sheets from {company name} are designed to meet the needs of modern construction projects. Whether it's for kitchen countertops, bathroom vanities, office furniture, or retail displays, these laminate sheets offer a clean and contemporary aesthetic that is sure to elevate any space. The sheets are available in a variety of thicknesses and sizes, making them suitable for a wide range of applications.One of the key benefits of {company name}'s White Laminate Sheets is their durability. Made from high-quality materials, these laminate sheets are resistant to scratches, stains, and heat, making them an ideal choice for high-traffic areas. They are also easy to clean and maintain, making them a practical and long-lasting solution for any project.In addition to their durability, these laminate sheets are also highly versatile. They can be easily cut and shaped to fit any surface, allowing for endless design possibilities. Whether it's a sleek, minimalist look or a bold, statement-making design, {company name}'s White Laminate Sheets provide the flexibility to bring any vision to life.{Company name} takes pride in its commitment to sustainability, and their White Laminate Sheets are no exception. Made from environmentally friendly materials, these sheets are a responsible choice for environmentally conscious builders and designers. They are also manufactured using energy-efficient processes, further reducing their environmental impact.As with all of their products, {company name} is dedicated to providing exceptional customer service and support. Their team of experts is available to provide guidance and assistance throughout every step of the purchasing and installation process. Whether it's choosing the right size and thickness for a project or troubleshooting any challenges that may arise, customers can rely on {company name} to deliver top-notch support.With the introduction of their new White Laminate Sheets, {company name} continues to demonstrate their commitment to providing innovative, high-quality construction materials. Whether for residential, commercial, or industrial projects, these laminate sheets offer a durable, versatile, and stylish solution that is sure to exceed expectations. Builders, designers, and homeowners looking for a reliable source for construction materials need look no further than {company name} for their White Laminate Sheet needs.

Discover the Versatility and Durability of Laminated Glass Sheets

Laminated Glass Sheet Improves Safety and Aesthetics in Modern ArchitectureWith the rise of innovative technologies in the construction industry, architectural design has reached new heights of both safety and aesthetics. Among the many advancements, laminated glass sheets have emerged as a popular choice for architects and designers seeking to create stunning buildings that prioritize safety. One such company that has excelled in producing high-quality laminated glass sheets is (brand name).Laminated glass is a type of safety glass that is created by sandwiching a layer of polyvinyl butyral (PVB) interlayer between two or more layers of glass. This interlayer provides strength and prevents the glass from shattering upon impact. The result is a durable and secure material that offers numerous benefits for modern buildings.First and foremost, the main advantage of laminated glass lies in its enhanced safety features. Unlike traditional glass, which shatters into sharp shards upon impact, laminated glass remains intact even when broken. The interlayer holds the glass together, minimizing the risk of injuries caused by flying glass fragments, making it an ideal choice for windows, doors, and other areas where safety is a priority.Furthermore, laminated glass sheets are highly resistant to external factors such as strong winds, burglaries, and even ballistic attacks. Due to the PVB interlayer, the glass is kept in place even when subjected to force, providing an additional layer of security to buildings. This feature has made laminated glass popular in areas prone to hurricanes, tornadoes, and other natural disasters.Apart from its exceptional safety properties, laminated glass also offers a range of aesthetic advantages. The interlayer between the glass layers can be customized to achieve various effects, including different colors, patterns, and textures. This versatility allows architects to incorporate laminated glass sheets into their designs to create stunning visual effects, adding a modern touch to buildings.Moreover, laminated glass provides excellent sound insulation properties, making it an excellent choice for noise reduction in urban environments. The interlayer dampens external noise, improving the overall comfort and livability of buildings. This benefit is particularly relevant in busy cities where noise pollution is a prevalent issue.One company that has excelled in producing high-quality laminated glass sheets is (brand name). Established in (year), (brand name) has become a trusted name in the industry, known for its commitment to safety, innovation, and exceptional product quality. Using state-of-the-art technology and high-quality materials, (brand name) produces laminated glass sheets that meet international safety standards and adhere to rigorous quality control processes. Their laminated glass sheets are available in a wide range of sizes, thicknesses, and customization options, allowing architects and designers to fulfill their creative visions while ensuring the safety of their structures.Additionally, (brand name) takes pride in its commitment to sustainability. They utilize eco-friendly manufacturing processes that minimize waste and maximize energy efficiency. Their laminated glass sheets are also capable of reducing harmful UV rays, allowing for improved energy efficiency within buildings.In conclusion, laminated glass sheets have revolutionized modern architecture by combining safety and aesthetics. Architects and designers are increasingly turning to laminated glass to create visually striking and secure buildings. With companies like (brand name) at the forefront of producing these high-quality materials, the possibilities for innovative and safe architectural design are endless. As technology continues to evolve, laminated glass will undoubtedly play a significant role in shaping the buildings of the future.

Discover the Versatile Properties and Uses of FR-4 Sheets

Fr-4 Sheet: The Next Generation of Circuit Board Substrate MaterialThe demand for high performance and lighter electronic devices has been on the rise as technology continues to evolve. Circuit board substrate materials are a key component in the design and manufacture of electronic devices. The choice of substrate materials determines the overall quality, durability, and performance of the device. Among the choices of substrate materials, Fr-4 Sheet stands out as the material of choice for manufacturers of high-performance electronic devices.What is Fr-4 Sheet?Fr-4 Sheet is a type of composite material that is widely used as a base for printed circuit boards (PCB). The material is made up of layers of glass cloth and resin, laminated together by heat and pressure. The glass cloth acts as a reinforcement and provides mechanical strength to the substrate, while the resin acts as a binder that holds the substrate together. The term FR-4 stands for "fire retardant" and refers to the material's ability to self-extinguish when exposed to fire.The material has a range of benefits, making it the material of choice for many high-performance electronic devices. First, it has excellent electrical properties, making it highly suitable for use in high-frequency applications. Fr-4 Sheet has low dielectric loss and a high dielectric constant, leading to better signal transmission. It also has excellent thermal stability and high-temperature resistance, making it a suitable material for use in harsh and demanding environmental conditions. The material's mechanical properties are also impressive, with high bendability and impact resistance, making it ideal for use in portable and handheld devices.In addition, manufacturers appreciate the cost-effectiveness of the Fr-4 Sheet. Compared to other high-performance substrate materials such as ceramic or Teflon, Fr-4 Sheet is much more affordable, yet has similar performance attributes.Leading the Way in Fr-4 Sheet ManufacturingOne of the leading manufacturers of Fr-4 Sheet is a company that has been in the business for over ten years. The company has built a reputation for producing top-quality Fr-4 Sheet that exceeds customer expectations. They have invested in state-of-the-art production facilities and equipment that enables them to produce high-performance Fr-4 Sheet with excellent consistency and uniformity. They use only the best raw materials sourced from reputable suppliers, ensuring that their Fr-4 Sheet consistently meet or exceed industry standards.The company's Fr-4 Sheet is used in a wide range of applications, including aerospace, defense, medical, and consumer electronics. They pride themselves on their ability to produce custom Fr-4 Sheet to meet the specific needs of their customers. They work closely with their customers to understand their technical requirements and develop Fr-4 Sheet that meet those requirements.The company has a team of experienced and highly skilled engineers who specialize in Fr-4 Sheet design and production. They use the latest technology and software to develop Fr-4 Sheet that are tailored to their customers' requirements. They are committed to continuous improvement and innovation, investing heavily in research and development to come up with new and improved Fr-4 Sheet products.In ConclusionFr-4 Sheet has become the substrate material of choice for manufacturers of high-performance electronic devices, thanks to its superior performance, cost-effectiveness, and versatility. With the demand for high-performance and lighter electronics continuing to grow, the demand for Fr-4 Sheet is set to increase. By investing in state-of-the-art production facilities and equipment and attracting a team of highly skilled engineers, the leading Fr-4 Sheet manufacturer is well-positioned to meet the growing demand and continue to drive innovation in the Fr-4 Sheet industry.

High-quality Epoxy Glass Insulation Board for Electrical Applications

Fr4 Epoxy Glass Insulation Board is considered to be one of the most reliable and high-quality insulation materials in the industry. It is manufactured using a combination of woven glass fabric and epoxy resin, which results in a durable and versatile material that is widely used in various electrical and electronic applications. The Fr4 Epoxy Glass Insulation Board is known for its excellent electrical insulation properties, high mechanical strength, and resistance to heat and chemicals. These characteristics make it an ideal choice for applications that require reliable insulation and protection, such as in electrical panels, circuit boards, transformers, and power distribution systems.With a proven track record of performance and reliability, the Fr4 Epoxy Glass Insulation Board has become a popular choice among engineers, designers, and manufacturers in the electrical and electronics industry. Its ability to withstand high temperatures and harsh operating conditions makes it a preferred choice for critical applications where safety and reliability are paramount.The company {} is a leading manufacturer and supplier of Fr4 Epoxy Glass Insulation Board. With years of experience and expertise in the field, the company has established itself as a trusted provider of high-quality insulation materials for a wide range of industrial applications. Their commitment to quality and innovation has made them a preferred partner for many leading companies in the electrical and electronics industry.The Fr4 Epoxy Glass Insulation Board offered by {} is manufactured to the highest standards, using the latest technology and advanced production processes. This ensures that the material meets the most demanding requirements for performance, reliability, and safety. The company's dedication to quality control and product testing also ensures that their Fr4 Epoxy Glass Insulation Board consistently meets or exceeds industry standards for electrical insulation materials.In addition to providing high-quality insulation materials, {} also offers technical support and customization services to meet the specific needs of their customers. Their team of experienced engineers and technical experts work closely with clients to develop customized solutions that address their unique requirements and challenges.The company's commitment to customer satisfaction and continuous improvement has earned them a reputation for excellence in the industry. They are known for their reliability, responsiveness, and ability to deliver quality products on time and within budget. As a result, {} has become a trusted partner for many companies seeking high-quality insulation solutions for their electrical and electronic applications.As the demand for reliable and high-performance insulation materials continues to grow, {}. The company is dedicated to maintaining its position as a leading provider of Fr4 Epoxy Glass Insulation Board and other innovative insulation solutions. By staying at the forefront of technological advancements and industry trends, the company is well-positioned to meet the evolving needs of its customers and the market.Overall, with a proven track record of performance and a commitment to excellence, {} continues to be a preferred choice for companies seeking high-quality Fr4 Epoxy Glass Insulation Board and other advanced insulation materials. The company's dedication to quality, innovation, and customer satisfaction sets them apart as a leader in the industry, and their continued success is a testament to their exceptional products and services.

Durable and Versatile Laminate Sheet for Your Home or Office

Laminate Sheet: Revolutionizing the Construction IndustryIn today's fast-paced and ever-changing world, innovation is the key to success in every industry. One such industry that has seen a substantial transformation in recent years is the construction industry. With the emergence of new technologies and materials, construction companies are constantly looking for ways to improve efficiency and durability in their projects. Enter the revolutionary product – Laminate Sheet.Laminate Sheet, a versatile and durable building material, has been making waves in the construction industry. Its unique combination of strength, flexibility, and aesthetic appeal has made it a popular choice for architects, builders, and designers worldwide. This innovative material is changing the way we think about construction, and [Company Name] is at the forefront of this revolution.[Company Name] is a leading manufacturer and distributor of high-quality construction materials. With a strong commitment to innovation and sustainability, [Company Name] has been at the forefront of developing and promoting eco-friendly and durable construction solutions. The company's dedication to providing top-notch products and exceptional customer service has earned them a solid reputation in the industry.One of [Company Name]'s flagship products is the Laminate Sheet, which has been gaining widespread attention for its outstanding performance and versatility. Made from high-grade materials, the Laminate Sheet offers a wide range of benefits, including but not limited to, durability, impact resistance, and ease of installation. Moreover, it is available in a variety of colors, patterns, and textures, allowing for endless design possibilities in construction projects.The Laminate Sheet's impact resistance makes it an ideal choice for high-traffic areas in commercial and residential buildings, where durability is paramount. Additionally, its low-maintenance nature and resistance to scratches and stains make it a practical and cost-effective solution for modern construction projects. This innovative material is also environmentally friendly, as it is made from sustainable and recyclable materials, aligning with [Company Name]'s commitment to sustainability and eco-conscious practices.Furthermore, the flexibility of Laminate Sheet allows for easy customization and installation on a wide range of surfaces, including countertops, furniture, and wall paneling. Its seamless and smooth finish adds a touch of elegance and sophistication to any space, making it a popular choice for interior designers and architects.The Laminate Sheet has also been instrumental in revolutionizing the way construction projects are executed. Its lightweight nature and ease of handling have significantly reduced installation time and labor costs, resulting in overall project efficiency and cost savings for builders and contractors. The wide range of applications and benefits offered by Laminate Sheet has positioned it as a game-changer in the construction industry.In addition to its outstanding performance, the Laminate Sheet's aesthetic appeal has been a major draw for designers and homeowners. Its ability to mimic the look of natural materials such as wood, stone, and metal, while offering superior durability and easy maintenance, has made it a sought-after choice for interior renovations and remodeling projects.As the demand for sustainable and high-performance construction materials continues to grow, [Company Name] remains committed to providing innovative and reliable solutions to meet the evolving needs of the industry. With a forward-thinking approach and a focus on research and development, [Company Name] is poised to lead the way in shaping the future of construction with its groundbreaking products like Laminate Sheet.In conclusion, the Laminate Sheet has proven to be a game-changer in the construction industry, offering a perfect combination of durability, versatility, and aesthetic appeal. As a leading manufacturer and distributor of quality construction materials, [Company Name] is proud to be at the forefront of this revolutionary shift in the industry. With its commitment to innovation and sustainability, [Company Name] is well-positioned to continue driving positive change and setting new standards for construction materials. As the construction industry continues to evolve, the Laminate Sheet is set to play a pivotal role in shaping its future.

Top Quality Epoxy Glassfiber Sheet Insulating Sheet: Titanium White/Black EPGC201/EPGC204

Our company is pleased to announce the launch of a new product, Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet insulating sheet, designed to meet the needs of the modern electrical and engineering industries. This innovative product is set to revolutionize the market with its high-quality materials and superior performance.The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a state-of-the-art insulating sheet that offers excellent electrical insulation properties, high dimensional stability, and mechanical strength. It is widely used in electrical equipment, electric motors, PCB drilling pads, and many other industrial applications. The product is available in both white and black colors, offering customers flexibility and choice to suit their specific requirements.Our company has a long-standing reputation for delivering reliable and high-quality products to our customers. With a commitment to innovation and excellence, we are constantly striving to offer the latest advancements in technology and materials. The Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a testament to our dedication to meeting the evolving needs of the industry.One of the key features of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is its exceptional thermal and chemical resistance. This makes it suitable for use in harsh and demanding environments, where it can withstand extreme temperatures and exposure to chemicals. The product is also resistant to moisture, making it an ideal choice for outdoor and marine applications.In addition, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet offers outstanding electrical insulation properties, ensuring the safety and reliability of electrical equipment. It has high dielectric strength and low water absorption, providing excellent insulation in a variety of electrical and electronic applications.The mechanical strength of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is another standout feature. It has high flexural and impact strength, as well as excellent dimensional stability, ensuring long-term performance and durability. This makes it a preferred choice for structural and mechanical applications in the engineering and construction industries.Our company is proud to offer the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet in a range of thicknesses and dimensions, catering to the diverse needs of our customers. We understand the importance of providing versatile and customizable solutions, and we are committed to delivering products that meet the specific requirements of each project.With the launch of the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet, our company is poised to further solidify its position as a leading provider of high-performance materials for the electrical and engineering industries. We are confident that this product will set a new standard for excellence in insulation and engineering materials, and we look forward to seeing the positive impact it will have on our customers' projects.In conclusion, the Titanium white/Black EPGC201/EPGC204 Epoxy Glassfiber Sheet is a cutting-edge product that offers superior electrical insulation, thermal and chemical resistance, and mechanical strength. Backed by our company's commitment to quality and innovation, this product is set to make a significant impact in the market and provide our customers with a reliable and high-performance solution for their insulation and engineering needs.

High Quality Laminate Slot Wedge for Industrial Applications

9334 Laminate Slot Wedge: Improving Efficiency and Reliability in Electrical MachinesIn the world of electrical machines, efficiency and reliability are two of the most important factors to consider. Whether it's a motor, generator, or transformer, these machines play a critical role in countless industries and applications around the globe. One key component that helps improve the efficiency and reliability of these machines is the 9334 Laminate Slot Wedge, a product that has been designed and manufactured by a leading company in the field of electrical insulation materials.The 9334 Laminate Slot Wedge is a crucial component in electrical machines, as it helps to optimize the performance and durability of the machines by providing insulation and support to the winding components. This product is made of high-quality laminate materials, and its unique design allows for easy installation and excellent thermal and mechanical properties. As a result, electrical machines equipped with the 9334 Laminate Slot Wedge are able to operate more efficiently and reliably, ultimately leading to cost savings and improved productivity for the end users.{The company} is a renowned manufacturer of electrical insulation materials, with a strong focus on innovation and quality. With decades of experience in the industry, {the company} has established itself as a trusted partner for countless OEMs and end users around the world. The company's commitment to excellence and customer satisfaction has driven them to continuously develop new and improved products, such as the 9334 Laminate Slot Wedge, in order to meet the evolving needs of the market and exceed the expectations of their customers.One of the key advantages of the 9334 Laminate Slot Wedge is its ability to enhance the thermal performance of electrical machines. With its superior thermal conductivity and heat dissipation properties, this product helps to reduce the risk of overheating and insulation degradation, which are common causes of failure in electrical machines. By using the 9334 Laminate Slot Wedge, OEMs and end users can expect their machines to operate at lower temperatures and achieve a longer service life, ultimately resulting in lower maintenance costs and higher uptime.In addition to its thermal benefits, the 9334 Laminate Slot Wedge also offers excellent mechanical strength and insulation properties. This product is designed to provide robust support and protection to the winding components of electrical machines, which are often subjected to high levels of mechanical stress and electrical voltage. By using the 9334 Laminate Slot Wedge, OEMs and end users can ensure that their machines are well-protected against potential damage and breakdowns, thus minimizing the risk of downtime and costly repairs.Furthermore, the 9334 Laminate Slot Wedge is easy to install and highly adaptable to different machine designs. Whether it's a small motor or a large generator, this product can be customized to fit various slot geometries and dimensions, allowing for seamless integration into different types of electrical machines. As a result, OEMs and end users can enjoy greater flexibility and convenience when incorporating the 9334 Laminate Slot Wedge into their products, without compromising on performance or reliability.Overall, the 9334 Laminate Slot Wedge is a key enabler for improving the efficiency and reliability of electrical machines. With its superior thermal and mechanical properties, as well as its ease of installation and adaptability, this product offers tangible benefits for OEMs and end users across a wide range of industries and applications. As {the company} continues to innovate and expand its product offerings, the 9334 Laminate Slot Wedge stands out as a prime example of their commitment to driving positive change in the field of electrical insulation materials, and ultimately, in the performance of electrical machines around the world.

High-Quality Laminated Board Sheets for Your Next Project

Laminated Board Sheets: A Sustainable Solution for Modern ConstructionIn today's rapidly growing construction industry, the demand for durable and sustainable building materials is on the rise. With a focus on reducing environmental impact and increasing efficiency, contractors and builders are constantly seeking innovative solutions to meet these evolving needs. The use of Laminated Board Sheets has emerged as a game-changing solution, offering a combination of strength, sustainability, and versatility.Manufactured by {}, these board sheets are composed of multiple layers of wood veneer that are bonded together using high-quality adhesives. This lamination process results in a robust and durable product that is well-suited for a wide range of construction applications. Whether it's for flooring, roofing, wall cladding, or furniture production, Laminated Board Sheets offer exceptional performance and aesthetic appeal.One of the key advantages of Laminated Board Sheets is their sustainability. As the construction industry places increasing importance on environmentally friendly practices, the use of sustainable materials has become a top priority. The manufacturing process of these board sheets involves using wood from responsibly managed forests, ensuring that the environmental impact is minimized. In addition, the durability and longevity of the product contribute to reducing the need for frequent replacements, further enhancing its eco-friendly credentials.Furthermore, the versatility of Laminated Board Sheets makes them an ideal choice for modern construction projects. Their ability to withstand heavy loads and resist moisture and temperature fluctuations makes them suitable for both indoor and outdoor use. The boards can also be easily cut, shaped, and customized, allowing for greater flexibility in design and construction. This adaptability has made Laminated Board Sheets a popular choice among architects and designers who are looking to push the boundaries of traditional construction methods.In addition to their structural and environmental benefits, Laminated Board Sheets also offer a high level of fire resistance. This is particularly important in the construction industry, where safety and compliance with building codes are paramount. The boards have been developed to meet stringent fire safety standards, providing peace of mind to both builders and occupants.With a commitment to quality and innovation, {} has positioned itself as a leading provider of Laminated Board Sheets. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every board sheet meets the highest standards of performance and reliability. By investing in research and development, {} continues to push the boundaries of what is possible with laminated wood products, driving the industry forward with cutting-edge solutions.As the construction industry continues to evolve, the demand for sustainable and high-performance building materials will only continue to grow. In this context, Laminated Board Sheets represent a significant advancement in meeting these needs. With their blend of strength, sustainability, and versatility, these board sheets have the potential to redefine the standard for modern construction practices. With {} leading the way in their production and development, the future looks bright for this innovative solution.

Durable Epoxy Boards of Various Thickness for Multiple Applications

Different Thickness Epoxy Board Revolutionizes the IndustryIn the world of industrial materials, innovation is the key to success. Companies are constantly looking for new ways to improve their products, increase efficiency, and reduce costs. One such company that is leading the way in this regard is {Company Name}.{Company Name} is a leading manufacturer of industrial materials, specializing in epoxy boards. These boards are widely used in a variety of industries, including electronics, aerospace, automotive, and more. They are known for their durability, strength, and versatility. However, the team at {Company Name} is constantly looking for ways to improve upon their products, and they have recently done just that with the introduction of different thickness epoxy boards.The new different thickness epoxy boards have been developed to meet the specific needs of different industries. They are available in a range of thicknesses, from thin and flexible to thick and rigid, making them suitable for a wide range of applications. This level of customization is something that has never been seen before in the industry, and it is sure to revolutionize the way epoxy boards are used.One of the key benefits of the different thickness epoxy boards is their ability to provide the same high level of performance and durability, regardless of their thickness. This means that companies can now choose the thickness of the board that best suits their needs, without having to worry about sacrificing quality. This level of flexibility is a game changer for the industry, and it is sure to be welcomed by companies across the board.In addition to their performance benefits, the different thickness epoxy boards also offer significant cost savings. By being able to choose the exact thickness of board they need, companies can avoid wasting money on unnecessarily thick or thin boards. This level of precision in materials selection can have a significant impact on the bottom line, and it is sure to be welcomed by cost-conscious companies.{Company Name} is no stranger to innovation. The company has a long history of pushing the boundaries of what is possible with industrial materials, and the introduction of the different thickness epoxy boards is just the latest example of this. The team at {Company Name} is constantly looking for ways to improve upon their products, and they are already working on the next generation of epoxy boards that will further push the boundaries of what is possible in the industry.The different thickness epoxy boards are just one of many exciting products that {Company Name} has to offer. The company also specializes in a wide range of other industrial materials, including laminates, prepregs, and more. All of their products are known for their exceptional quality, performance, and versatility, and the company has a long history of providing the highest level of customer satisfaction.In conclusion, the introduction of the different thickness epoxy boards from {Company Name} is sure to revolutionize the industrial materials industry. These boards offer a level of customization and flexibility that has never been seen before, and they are already being welcomed by companies across a wide range of industries. With their exceptional performance, cost savings, and potential for customization, these boards are sure to be a game changer for the industry as a whole. Keep an eye on {Company Name} as they continue to push the boundaries of what is possible in the world of industrial materials.